Job Safety Analysis for Welding and Cutting PDF Form

Understanding the Job Safety Analysis for Welding and Cutting

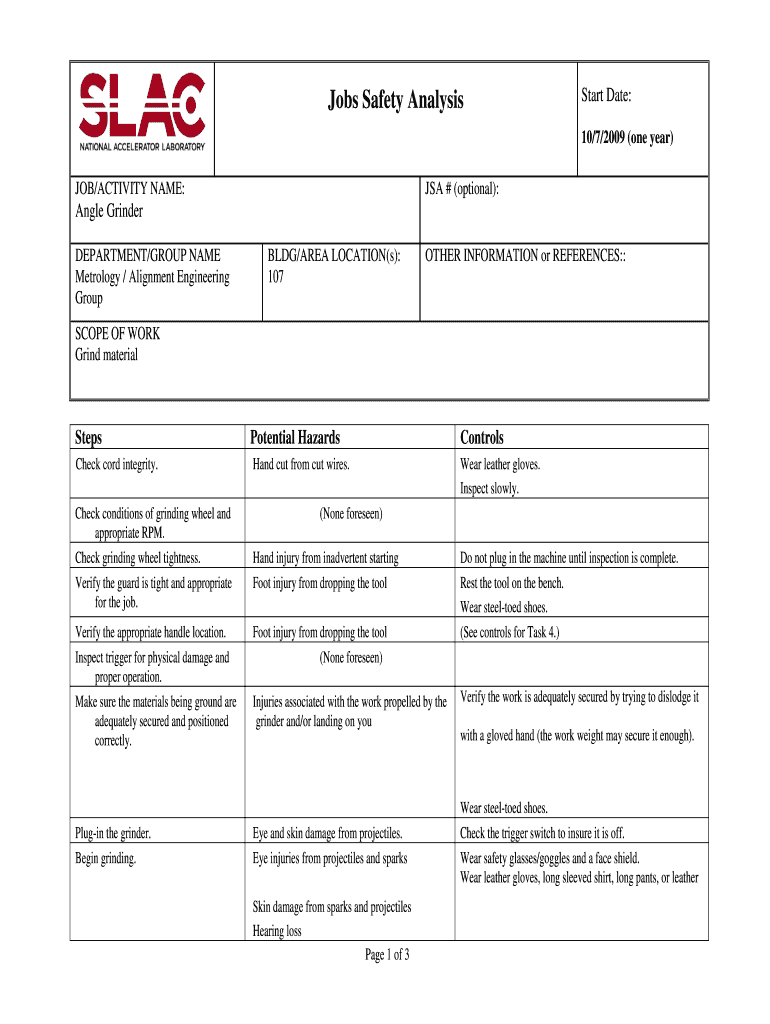

The Job Safety Analysis (JSA) for welding and cutting is a critical document that identifies potential hazards associated with these processes. It serves as a systematic approach to ensure the safety of workers by assessing risks and implementing control measures. The JSA outlines specific tasks involved in welding and cutting, evaluates the risks associated with each task, and provides guidance on how to mitigate those risks effectively. This document is essential for compliance with safety regulations and for promoting a culture of safety in the workplace.

Steps to Complete the Job Safety Analysis for Welding and Cutting

Completing a Job Safety Analysis for welding and cutting involves several key steps:

- Identify the Job: Select the specific welding or cutting task to analyze.

- Break Down the Job: Divide the job into individual steps or tasks to facilitate a thorough analysis.

- Identify Hazards: For each step, identify potential hazards that could cause injury or damage.

- Assess Risks: Evaluate the severity and likelihood of each hazard occurring.

- Implement Controls: Determine and document control measures to mitigate identified risks.

- Review and Revise: Regularly review the JSA to ensure it remains relevant and effective.

Legal Use of the Job Safety Analysis for Welding and Cutting

The legal validity of a Job Safety Analysis for welding and cutting is grounded in compliance with federal and state occupational safety regulations. The JSA must be completed accurately and maintained as part of the workplace safety documentation. Ensuring that the JSA is accessible to all employees involved in welding and cutting tasks is crucial. This transparency not only promotes safety but also fulfills legal obligations under the Occupational Safety and Health Administration (OSHA) standards.

Key Elements of the Job Safety Analysis for Welding and Cutting

A comprehensive Job Safety Analysis for welding and cutting should include the following key elements:

- Job Description: A clear outline of the welding or cutting task.

- Hazard Identification: A detailed list of potential hazards associated with each step.

- Risk Assessment: An evaluation of the risks associated with identified hazards.

- Control Measures: Specific actions or equipment needed to mitigate risks.

- Responsibilities: Designation of individuals responsible for implementing safety measures.

- Review Process: A procedure for regularly updating the JSA as needed.

How to Obtain the Job Safety Analysis for Welding and Cutting

The Job Safety Analysis for welding and cutting can typically be obtained through workplace safety programs, industry associations, or safety training organizations. Many companies develop their own JSAs tailored to specific tasks and environments. Additionally, templates and resources are often available online to assist in creating a JSA. It is important to ensure that any JSA used is relevant to the specific welding or cutting tasks performed and complies with applicable safety regulations.

Examples of Using the Job Safety Analysis for Welding and Cutting

Practical examples of using the Job Safety Analysis for welding and cutting include:

- Conducting a JSA before starting a new welding project to ensure all hazards are identified and addressed.

- Utilizing the JSA during safety training sessions to educate employees about potential risks and safety measures.

- Reviewing and updating the JSA after an incident to prevent similar occurrences in the future.

Quick guide on how to complete job safety analysis for welding and cutting pdf

Complete Job Safety Analysis For Welding And Cutting Pdf effortlessly on any device

Online document management has become increasingly popular among businesses and individuals. It offers an excellent eco-friendly alternative to traditional printed and signed documents, as you can access the required form and securely store it online. airSlate SignNow equips you with all the tools necessary to create, modify, and electronically sign your documents quickly and without interruptions. Manage Job Safety Analysis For Welding And Cutting Pdf on any device using airSlate SignNow's Android or iOS applications and streamline any document-related process today.

How to modify and eSign Job Safety Analysis For Welding And Cutting Pdf with ease

- Find Job Safety Analysis For Welding And Cutting Pdf and click Get Form to initiate the process.

- Utilize the tools we provide to complete your document.

- Emphasize important sections of the documents or redact sensitive information using tools that airSlate SignNow specially provides for that purpose.

- Generate your signature with the Sign tool, which takes seconds and holds the same legal validity as a conventional wet ink signature.

- Review the information and click on the Done button to save your changes.

- Choose how you wish to send your form, whether via email, SMS, or invitation link, or download it to your computer.

Eliminate the hassle of lost or misplaced files, tedious form searches, or mistakes that necessitate printing new document copies. airSlate SignNow meets your document management needs in several clicks from any device of your choice. Edit and eSign Job Safety Analysis For Welding And Cutting Pdf and ensure excellent communication at any stage of your form preparation process with airSlate SignNow.

Create this form in 5 minutes or less

Create this form in 5 minutes!

How to create an eSignature for the job safety analysis for welding and cutting pdf

How to create an electronic signature for a PDF online

How to create an electronic signature for a PDF in Google Chrome

How to create an e-signature for signing PDFs in Gmail

How to create an e-signature right from your smartphone

How to create an e-signature for a PDF on iOS

How to create an e-signature for a PDF on Android

People also ask

-

What is a JSA for welding and why is it important?

A Job Safety Analysis (JSA) for welding is a systematic process to identify and evaluate hazards associated with welding tasks. Implementing a JSA ensures that workers are aware of potential risks and the safety measures required to mitigate them. It is essential for maintaining a safe work environment and adhering to regulatory requirements.

-

How can airSlate SignNow assist with creating a JSA for welding?

airSlate SignNow provides an efficient platform to create, edit, and facilitate the signing of JSAs for welding. With its easy-to-use interface, you can quickly draft a JSA, gather necessary approvals, and ensure all stakeholders have access to the finalized document. This streamlines the process and improves compliance and safety records.

-

Is there a cost associated with using airSlate SignNow for JSAs for welding?

Yes, airSlate SignNow offers various pricing plans that cater to different business needs, including options for creating JSAs for welding. Pricing is competitive and reflects the number of users, features, and document signing capabilities you require. You can start with a free trial to understand how it benefits your welding safety protocols.

-

What features does airSlate SignNow provide for managing a JSA for welding?

airSlate SignNow includes features such as customizable templates for JSAs for welding, easy document sharing, and secure electronic signatures. It also enables real-time collaboration and tracking, ensuring that every team member is updated and compliant with safety procedures. These tools make managing JSAs more efficient and organized.

-

Can airSlate SignNow integrate with other tools for managing JSAs for welding?

Absolutely! airSlate SignNow can seamlessly integrate with a variety of popular business applications to manage JSAs for welding effectively. This includes project management tools and compliance software, allowing you to centralize your workflow and enhance productivity. Integration helps in automating processes and ensuring documents are linked to related tasks.

-

What are the benefits of using airSlate SignNow for JSAs for welding?

Utilizing airSlate SignNow for JSAs for welding enhances efficiency and promotes workplace safety. With easy document management and electronic signing, you reduce paper usage and ensure faster turnaround times for approvals. This not only saves time but also strengthens compliance with health and safety regulations.

-

How secure is airSlate SignNow when handling JSAs for welding?

Security is a top priority for airSlate SignNow, especially when handling sensitive documents like JSAs for welding. The platform uses advanced encryption methods to protect your data, along with robust authentication processes to ensure that only authorized users can access and sign documents. This provides peace of mind when managing critical safety documentation.

Get more for Job Safety Analysis For Welding And Cutting Pdf

Find out other Job Safety Analysis For Welding And Cutting Pdf

- How To Sign Wyoming Legal Quitclaim Deed

- Sign Wisconsin Insurance Living Will Now

- Sign Wyoming Insurance LLC Operating Agreement Simple

- Sign Kentucky Life Sciences Profit And Loss Statement Now

- How To Sign Arizona Non-Profit Cease And Desist Letter

- Can I Sign Arkansas Non-Profit LLC Operating Agreement

- Sign Arkansas Non-Profit LLC Operating Agreement Free

- Sign California Non-Profit Living Will Easy

- Sign California Non-Profit IOU Myself

- Sign California Non-Profit Lease Agreement Template Free

- Sign Maryland Life Sciences Residential Lease Agreement Later

- Sign Delaware Non-Profit Warranty Deed Fast

- Sign Florida Non-Profit LLC Operating Agreement Free

- Sign Florida Non-Profit Cease And Desist Letter Simple

- Sign Florida Non-Profit Affidavit Of Heirship Online

- Sign Hawaii Non-Profit Limited Power Of Attorney Myself

- Sign Hawaii Non-Profit Limited Power Of Attorney Free

- Sign Idaho Non-Profit Lease Agreement Template Safe

- Help Me With Sign Illinois Non-Profit Business Plan Template

- Sign Maryland Non-Profit Business Plan Template Fast