Bandsaw Inspection Checklist Form

What is the bandsaw inspection checklist?

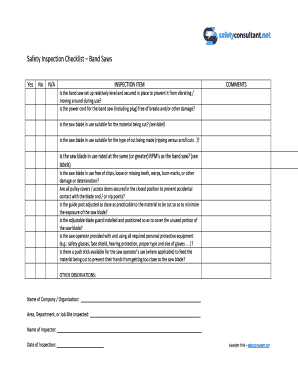

The bandsaw inspection checklist is a comprehensive tool designed to ensure that bandsaws operate safely and efficiently. It includes a series of items that operators should examine regularly to maintain optimal performance. This checklist typically covers aspects such as blade condition, alignment, tension, and the overall mechanical integrity of the bandsaw. Regular use of this checklist helps prevent accidents, prolongs the life of the equipment, and ensures compliance with safety standards.

How to use the bandsaw inspection checklist

Using the bandsaw inspection checklist involves several straightforward steps. First, gather all necessary tools and safety equipment before beginning the inspection. Next, systematically go through each item on the checklist, marking off completed tasks as you verify their condition. Pay close attention to critical components such as the blade, guides, and motor. After completing the inspection, document any findings or necessary repairs. This record can be vital for maintenance schedules and safety audits.

Key elements of the bandsaw inspection checklist

Essential elements of the bandsaw inspection checklist include various safety and operational checks. Key areas to examine are:

- Blade tension and alignment

- Blade sharpness and wear

- Guide bearings and blocks

- Motor function and electrical connections

- Safety guards and emergency stop functionality

- Lubrication of moving parts

These elements ensure that the bandsaw operates efficiently and safely, reducing the risk of malfunctions or accidents.

Steps to complete the bandsaw inspection checklist

Completing the bandsaw inspection checklist involves a methodical approach. Follow these steps:

- Prepare the workspace by clearing any obstructions and ensuring proper lighting.

- Turn off the bandsaw and disconnect it from the power source for safety.

- Inspect the blade for damage, ensuring it is sharp and properly tensioned.

- Check the alignment of the blade and adjust if necessary.

- Examine the guides and bearings for wear and replace them if needed.

- Test the motor and electrical components for proper function.

- Document any issues found during the inspection and schedule repairs as required.

Following these steps helps maintain the bandsaw's performance and safety standards.

Legal use of the bandsaw inspection checklist

The legal use of the bandsaw inspection checklist is crucial for compliance with workplace safety regulations. In the United States, organizations must adhere to standards set by the Occupational Safety and Health Administration (OSHA). Proper documentation of inspections can serve as evidence of compliance during audits. It is essential to retain records of completed checklists, as they demonstrate due diligence in maintaining equipment safety and can protect businesses from liability in case of accidents.

How to obtain the bandsaw inspection checklist

The bandsaw inspection checklist can typically be obtained through various channels. Many manufacturers provide their own version of the checklist with equipment purchases. Additionally, industry associations and safety organizations often offer templates that can be customized for specific needs. Online resources may also feature downloadable checklists, ensuring easy access for operators and maintenance personnel. It is advisable to choose a checklist that aligns with the specific bandsaw model and operational requirements.

Quick guide on how to complete bandsaw inspection checklist

Effortlessly Prepare Bandsaw Inspection Checklist on Any Device

Digital document management has gained traction among businesses and individuals alike. It offers an ideal environmentally friendly alternative to conventional printed and signed documents, allowing you to locate the appropriate form and securely store it online. airSlate SignNow equips you with all the necessary tools to create, edit, and eSign your documents quickly and without hassle. Manage Bandsaw Inspection Checklist on any device using the airSlate SignNow apps for Android or iOS and enhance any document-related process today.

Editing and eSigning Bandsaw Inspection Checklist with Ease

- Locate Bandsaw Inspection Checklist and click Get Form to initiate the process.

- Utilize the tools we provide to complete your form.

- Emphasize pertinent sections of your documents or obscure sensitive information using tools specifically offered by airSlate SignNow.

- Generate your signature with the Sign tool, which takes just seconds and holds the same legal validity as a traditional wet ink signature.

- Review all the details and click on the Done button to save your changes.

- Select how you wish to send your form, whether by email, text message (SMS), invitation link, or download it to your computer.

Say goodbye to lost or misfiled documents, tedious form searching, or errors necessitating printing new document copies. airSlate SignNow addresses all your document management needs in just a few clicks from any device of choice. Edit and eSign Bandsaw Inspection Checklist and ensure outstanding communication throughout the form preparation process with airSlate SignNow.

Create this form in 5 minutes or less

Create this form in 5 minutes!

How to create an eSignature for the bandsaw inspection checklist

How to create an electronic signature for a PDF online

How to create an electronic signature for a PDF in Google Chrome

How to create an e-signature for signing PDFs in Gmail

How to create an e-signature right from your smartphone

How to create an e-signature for a PDF on iOS

How to create an e-signature for a PDF on Android

People also ask

-

What is a bandsaw inspection checklist?

A bandsaw inspection checklist is a comprehensive document designed to ensure that bandsaws are properly maintained and operated safely. It includes critical points to check, such as blade condition, safety features, and operational settings. This checklist helps prevent accidents and prolongs the lifespan of the bandsaw.

-

Why is a bandsaw inspection checklist important?

Implementing a bandsaw inspection checklist is essential for promoting workplace safety and equipment reliability. Regular inspections can identify potential issues before they become serious problems, reducing downtime and repair costs. Additionally, it ensures compliance with safety standards and regulations.

-

How can I create a bandsaw inspection checklist?

Creating a bandsaw inspection checklist involves identifying key inspection points and documenting them in a clear format. You can customize your checklist based on your specific bandsaw model and its manufacturer recommendations. Utilizing tools like airSlate SignNow can streamline the checklist creation process.

-

What features should I include in my bandsaw inspection checklist?

A well-rounded bandsaw inspection checklist should include features like blade tension, alignment, maintenance of safety guards, and lubrication of moving parts. You may also want to include sections for operator training and machine-specific settings. This ensures thorough inspections that cater to all aspects of the bandsaw's operation.

-

Does airSlate SignNow provide templates for a bandsaw inspection checklist?

Yes, airSlate SignNow offers customizable templates that you can use for your bandsaw inspection checklist. These templates can be easily tailored to your business's specific needs, allowing for efficient documentation and eSigning. This simplifies the inspection process and ensures compliance with safety standards.

-

How does a bandsaw inspection checklist improve efficiency?

Using a bandsaw inspection checklist contributes to improved efficiency by systematically identifying issues before they disrupt operations. Regular inspections help maintain optimal performance and avoid unplanned downtime. Consequently, this leads to enhanced productivity and cost savings in the long run.

-

What are the costs associated with implementing a bandsaw inspection checklist?

Implementing a bandsaw inspection checklist can be cost-effective, especially when using digital solutions like airSlate SignNow. There may be initial setup costs for creating the checklist and training staff, but the long-term savings from preventing equipment failure and enhancing safety far outweigh these costs.

Get more for Bandsaw Inspection Checklist

- Mtsa facility compliance guide 201636440 form

- Sentara employee handbook form

- Hipaa quiz form

- Farm and ranch purchase agreement form

- Please use this renewal application if your certificate expires after august 31 form

- Special renewal application pdf form

- Atfs law firm application revised september atfs law firm application revised september form

- Co parenting parenting plan agreement template form

Find out other Bandsaw Inspection Checklist

- Can I eSign South Dakota Real Estate Quitclaim Deed

- How To eSign Tennessee Real Estate Business Associate Agreement

- eSign Michigan Sports Cease And Desist Letter Free

- How To eSign Wisconsin Real Estate Contract

- How To eSign West Virginia Real Estate Quitclaim Deed

- eSign Hawaii Police Permission Slip Online

- eSign New Hampshire Sports IOU Safe

- eSign Delaware Courts Operating Agreement Easy

- eSign Georgia Courts Bill Of Lading Online

- eSign Hawaii Courts Contract Mobile

- eSign Hawaii Courts RFP Online

- How To eSign Hawaii Courts RFP

- eSign Hawaii Courts Letter Of Intent Later

- eSign Hawaii Courts IOU Myself

- eSign Hawaii Courts IOU Safe

- Help Me With eSign Hawaii Courts Cease And Desist Letter

- How To eSign Massachusetts Police Letter Of Intent

- eSign Police Document Michigan Secure

- eSign Iowa Courts Emergency Contact Form Online

- eSign Kentucky Courts Quitclaim Deed Easy