Flexographic Printing Ink Mileage Test American Inks and Coatings Form

What is the Flexographic Printing Ink Mileage Test American Inks and Coatings

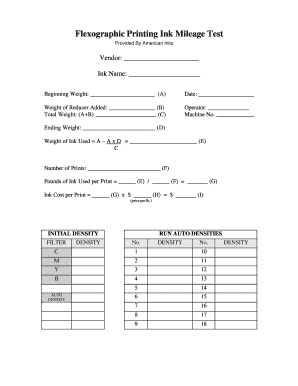

The Flexographic Printing Ink Mileage Test American Inks and Coatings is a standardized procedure designed to evaluate the performance and efficiency of flexographic inks. This test measures the mileage of inks used in printing processes, ensuring that businesses can assess the quality and durability of their products. Understanding this test is crucial for companies involved in the production and application of inks and coatings, as it helps in maintaining quality control and meeting industry standards.

How to use the Flexographic Printing Ink Mileage Test American Inks and Coatings

To effectively utilize the Flexographic Printing Ink Mileage Test American Inks and Coatings, businesses should first gather the necessary materials, including the specific inks to be tested and the appropriate substrates. The process involves applying the ink to the substrate and then measuring the mileage achieved before the ink begins to degrade or lose its properties. Documenting the results meticulously is essential, as this data contributes to quality assurance and helps in making informed decisions about ink formulations and applications.

Steps to complete the Flexographic Printing Ink Mileage Test American Inks and Coatings

Completing the Flexographic Printing Ink Mileage Test involves several key steps:

- Prepare the testing environment by ensuring all equipment is clean and calibrated.

- Apply the ink to the substrate using a consistent method, such as a specific printing technique.

- Allow the ink to dry according to manufacturer specifications.

- Measure the mileage achieved by the ink before any visible degradation occurs.

- Record all findings, including conditions of the test and any variables that may affect results.

Legal use of the Flexographic Printing Ink Mileage Test American Inks and Coatings

The legal use of the Flexographic Printing Ink Mileage Test American Inks and Coatings is governed by standards set forth by industry regulations. Companies must ensure compliance with these regulations to validate their testing processes and results. Proper documentation and adherence to testing protocols not only protect businesses legally but also enhance credibility in the marketplace, ensuring that products meet the necessary safety and quality standards.

Key elements of the Flexographic Printing Ink Mileage Test American Inks and Coatings

Several key elements are crucial for the Flexographic Printing Ink Mileage Test American Inks and Coatings:

- Ink formulation: The specific composition of the ink can significantly impact its performance.

- Substrate type: Different substrates may react differently to inks, affecting mileage.

- Environmental conditions: Temperature and humidity can influence drying times and ink behavior.

- Application method: The technique used to apply the ink can alter the results of the mileage test.

Examples of using the Flexographic Printing Ink Mileage Test American Inks and Coatings

Examples of using the Flexographic Printing Ink Mileage Test American Inks and Coatings can be found across various industries. For instance, packaging companies often conduct this test to ensure that inks used on food packaging maintain integrity and safety during the product's shelf life. Additionally, manufacturers of labels and tags may use the test to evaluate how inks perform under different environmental conditions, ensuring that their products remain vibrant and legible throughout their intended use.

Quick guide on how to complete flexographic printing ink mileage test american inks and coatings

Effortlessly Complete Flexographic Printing Ink Mileage Test American Inks And Coatings on Any Device

The management of digital documents has gained popularity among businesses and individuals. It serves as an ideal environmentally friendly alternative to conventional printed and signed documents, allowing you to easily find the necessary form and securely store it online. airSlate SignNow provides all the tools you require to create, modify, and eSign your documents quickly without delays. Manage Flexographic Printing Ink Mileage Test American Inks And Coatings using the airSlate SignNow applications for Android or iOS, and streamline any document-related process today.

The easiest way to modify and eSign Flexographic Printing Ink Mileage Test American Inks And Coatings effortlessly

- Find Flexographic Printing Ink Mileage Test American Inks And Coatings and click on Get Form to begin.

- Use the tools we provide to complete your form.

- Emphasize pertinent sections of your documents or redact sensitive information using tools that airSlate SignNow offers specifically for that purpose.

- Generate your signature with the Sign feature, which takes mere seconds and has the same legal validity as a traditional ink signature.

- Review the information and click on the Done button to save your changes.

- Choose your preferred method for delivering your form, whether by email, SMS, or invite link, or download it to your computer.

Say goodbye to lost or misplaced documents, tedious form searches, or errors that necessitate printing new copies. airSlate SignNow addresses your document management needs in just a few clicks from any device of your choosing. Modify and eSign Flexographic Printing Ink Mileage Test American Inks And Coatings to ensure excellent communication at every stage of the document preparation process with airSlate SignNow.

Create this form in 5 minutes or less

Create this form in 5 minutes!

How to create an eSignature for the flexographic printing ink mileage test american inks and coatings

How to create an electronic signature for a PDF online

How to create an electronic signature for a PDF in Google Chrome

How to create an e-signature for signing PDFs in Gmail

How to create an e-signature right from your smartphone

How to create an e-signature for a PDF on iOS

How to create an e-signature for a PDF on Android

People also ask

-

What are American inks and coatings used for?

American inks and coatings are essential for a variety of applications including printing, packaging, and industrial uses. They provide excellent adhesion, durability, and color vibrancy, making them suitable for both indoor and outdoor use. Understanding their applications can help you choose the right product for your specific needs.

-

How do American inks and coatings compare to international brands?

American inks and coatings often meet stringent regulatory standards, which ensures quality and safety in their formulation. Additionally, they are formulated to work in various environments and can provide superior performance in terms of coverage and drying times. This makes them a reliable choice for businesses looking for high-quality solutions.

-

What factors influence the pricing of American inks and coatings?

Pricing for American inks and coatings can vary based on formulation, quality, and quantity purchased. Additionally, specialized inks that offer unique properties or environmental benefits may be priced higher. Exploring different suppliers and understanding your requirements can help in finding the best deals.

-

Are there eco-friendly options available for American inks and coatings?

Yes, there are eco-friendly options available for American inks and coatings. Many manufacturers are now producing water-based inks and coatings that minimize environmental impact while still providing exceptional performance. This makes it easier for businesses to align their operations with sustainability goals.

-

What benefits do American inks and coatings offer for packaging?

American inks and coatings provide excellent print quality and adhesion on a variety of packaging materials. Their durability ensures designs withstand the rigors of shipping and handling, while vibrant colors enhance shelf appeal. This contributes to better branding and customer engagement, which are crucial in competitive markets.

-

Can American inks and coatings be customized for specific needs?

Absolutely, many manufacturers offer customization options for American inks and coatings to meet specific industry requirements. Custom formulations can address factors such as color matching, special effects, or unique application methods. Collaborating with suppliers can help you achieve the desired results tailored to your business.

-

How long does it take for American inks and coatings to dry?

The drying time for American inks and coatings varies depending on the type and formulation used. Generally, water-based inks dry quicker than solvent-based inks, with some sessions taking just a few minutes. It's important to consult product specifications for precise drying timelines to avoid production delays.

Get more for Flexographic Printing Ink Mileage Test American Inks And Coatings

- Kessel v leavitt et al 1998 supreme court of justia law form

- Resources texas center for legal ethics opinions form

- Board on attorney certification official website of the new form

- Township of blank form

- Designation of trial counsel form

- Ecd ny inc v britt realty llc new york law journal form

- Appellate division first department october 3 lawcom form

- 123 distribution inc form

Find out other Flexographic Printing Ink Mileage Test American Inks And Coatings

- eSign Delaware Termination of Employment Worksheet Safe

- Can I eSign New Jersey Job Description Form

- Can I eSign Hawaii Reference Checking Form

- Help Me With eSign Hawaii Acknowledgement Letter

- eSign Rhode Island Deed of Indemnity Template Secure

- eSign Illinois Car Lease Agreement Template Fast

- eSign Delaware Retainer Agreement Template Later

- eSign Arkansas Attorney Approval Simple

- eSign Maine Car Lease Agreement Template Later

- eSign Oregon Limited Power of Attorney Secure

- How Can I eSign Arizona Assignment of Shares

- How To eSign Hawaii Unlimited Power of Attorney

- How To eSign Louisiana Unlimited Power of Attorney

- eSign Oklahoma Unlimited Power of Attorney Now

- How To eSign Oregon Unlimited Power of Attorney

- eSign Hawaii Retainer for Attorney Easy

- How To eSign Texas Retainer for Attorney

- eSign Hawaii Standstill Agreement Computer

- How Can I eSign Texas Standstill Agreement

- How To eSign Hawaii Lease Renewal