Wps for Fillet Weld Form

What is the WPS for Fillet Weld?

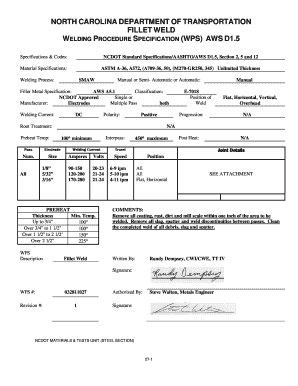

The WPS for fillet weld, or Welding Procedure Specification, is a crucial document that outlines the specific welding processes and parameters necessary for executing a fillet weld. This document serves as a guideline for welders, detailing the types of materials, welding techniques, and equipment to be used. Understanding the WPS is essential for ensuring quality and compliance with industry standards, as it helps maintain consistency and safety in welding operations.

Key Elements of the WPS for Fillet Weld

A comprehensive WPS for fillet weld includes several key elements that define the welding process. These elements typically encompass:

- Base Materials: Specifications for the types and grades of materials being welded.

- Welding Process: The specific welding method to be employed, such as MIG, TIG, or stick welding.

- Filler Materials: Information on the type and classification of filler materials used in the weld.

- Welding Parameters: Details on voltage, amperage, travel speed, and heat input.

- Preheat and Interpass Temperature: Guidelines for temperature control before and during the welding process.

- Post-Weld Heat Treatment: Recommendations for any heat treatment required after welding.

How to Use the WPS for Fillet Weld

Using the WPS for fillet weld involves several steps to ensure compliance with the specified procedures. First, the welder should thoroughly review the WPS document to understand the requirements. Next, gather all necessary materials and equipment as outlined in the WPS. During the welding process, adhere strictly to the parameters specified, including amperage and voltage settings. Finally, document the welding process, including any deviations from the WPS, to maintain a record for quality assurance and compliance verification.

Legal Use of the WPS for Fillet Weld

The legal use of the WPS for fillet weld is governed by industry standards and regulations. To be considered legally binding, the WPS must comply with relevant codes, such as those set by the American Welding Society (AWS) or the American Society of Mechanical Engineers (ASME). Proper documentation and adherence to the WPS not only ensure quality workmanship but also protect against liability in the event of a failure or accident. It is essential for businesses to maintain accurate records of WPS documents and any modifications made during the welding process.

Steps to Complete the WPS for Fillet Weld

Completing the WPS for fillet weld involves a systematic approach to ensure all necessary information is included. The steps typically include:

- Identify the project requirements and applicable codes.

- Gather material specifications and welding process details.

- Draft the WPS, incorporating all key elements and parameters.

- Review the WPS for accuracy and compliance with standards.

- Obtain approval from a qualified individual or organization.

- Distribute the finalized WPS to all relevant personnel.

Examples of Using the WPS for Fillet Weld

Examples of using the WPS for fillet weld can be found across various industries, including construction, manufacturing, and shipbuilding. For instance, in a construction project, the WPS may specify the use of a particular welding method for joining steel beams. In manufacturing, it could dictate the parameters for welding components in machinery. Each example highlights the importance of following the WPS to achieve consistent quality and ensure compliance with safety regulations.

Quick guide on how to complete wps for fillet weld

Effortlessly Prepare Wps For Fillet Weld on Any Device

Digital document management has gained popularity among organizations and individuals. It offers an ideal environmentally friendly substitute for traditional printed and signed paperwork, allowing you to obtain the correct form and securely save it online. airSlate SignNow provides all the tools necessary to create, modify, and eSign your documents swiftly without delays. Handle Wps For Fillet Weld on any platform using airSlate SignNow's Android or iOS applications and enhance any document-focused procedure today.

How to Modify and eSign Wps For Fillet Weld with Ease

- Obtain Wps For Fillet Weld and click Get Form to begin.

- Utilize the tools we offer to complete your document.

- Emphasize important sections of your documents or obscure sensitive data with tools that airSlate SignNow specifically provides for that purpose.

- Create your signature using the Sign tool, which takes seconds and carries the same legal validity as a conventional wet ink signature.

- Review all the details and click the Done button to save your modifications.

- Select how you would like to send your form: via email, text message (SMS), invitation link, or download it to your computer.

Eliminate the stress of lost or misplaced documents, tedious form searching, or errors that necessitate printing new document copies. airSlate SignNow meets all your document management needs in just a few clicks from any device of your preference. Alter and eSign Wps For Fillet Weld and guarantee effective communication at any phase of your form preparation process with airSlate SignNow.

Create this form in 5 minutes or less

Create this form in 5 minutes!

How to create an eSignature for the wps for fillet weld

How to create an electronic signature for a PDF online

How to create an electronic signature for a PDF in Google Chrome

How to create an e-signature for signing PDFs in Gmail

How to create an e-signature right from your smartphone

How to create an e-signature for a PDF on iOS

How to create an e-signature for a PDF on Android

People also ask

-

What is the WPS full form in welding?

The WPS full form in welding is 'Welding Procedure Specification.' It is a crucial document that dictates how welding should be performed, including the materials and techniques to be used. Understanding the WPS full form in welding is vital for ensuring quality and consistency in welding projects.

-

How does airSlate SignNow support WPS documentation?

airSlate SignNow allows users to easily create and manage Welding Procedure Specifications (WPS) through its user-friendly platform. With electronic signatures and customizable templates, streamlining the WPS documentation process has never been easier. This saves time and enhances workflow efficiency in welding projects.

-

Is there a cost associated with using airSlate SignNow for WPS documentation?

Yes, airSlate SignNow offers various pricing plans to suit different business needs, including options for those specifically requiring WPS documentation capabilities. The cost is competitive and designed to provide an easy-to-use, cost-effective solution for managing all types of documents. This ensures that businesses can efficiently handle their welding documentation.

-

Can I integrate airSlate SignNow with other software for WPS management?

Absolutely! airSlate SignNow provides integration capabilities with a variety of software solutions, which can be beneficial for managing WPS documentation seamlessly. This ensures that all your welding procedure specifications are easily accessible across your organization's tools and platforms.

-

What are the benefits of using airSlate SignNow for WPS management?

Using airSlate SignNow for WPS management enhances efficiency, reduces paperwork, and increases compliance in welding projects. The platform’s electronic signature feature allows for quick approvals, making it easier to adhere to deadlines. Additionally, it simplifies the verification process of the WPS full form in welding.

-

How can I ensure compliance with the WPS full form in welding while using airSlate SignNow?

To ensure compliance with the WPS full form in welding while using airSlate SignNow, you can leverage the platform’s customizable templates and compliance tracking features. This allows you to create WPS documents that meet industry standards and regulations. Regular audits of the documentation will also help maintain adherence to compliance requirements.

-

Is it easy to create a WPS document with airSlate SignNow?

Yes, creating a WPS document with airSlate SignNow is straightforward and user-friendly. Users can customize welding procedure specifications using pre-designed templates, making it efficient to gather the necessary information. The intuitive interface ensures that even those new to WPS documentation can navigate it easily.

Get more for Wps For Fillet Weld

- Nc do 2a form

- Nc do 3 form

- Nc do 3a form

- Steps and guidelines to dissolve a form

- State by state guide to court mediator qualification standards form

- Certificate of observation mediated settlement conference form

- How do do i become a mediator florida courts form

- Gs 7a 381 page 17a 381 mediated settlement form

Find out other Wps For Fillet Weld

- Sign Banking Presentation Oregon Fast

- Sign Banking Document Pennsylvania Fast

- How To Sign Oregon Banking Last Will And Testament

- How To Sign Oregon Banking Profit And Loss Statement

- Sign Pennsylvania Banking Contract Easy

- Sign Pennsylvania Banking RFP Fast

- How Do I Sign Oklahoma Banking Warranty Deed

- Sign Oregon Banking Limited Power Of Attorney Easy

- Sign South Dakota Banking Limited Power Of Attorney Mobile

- How Do I Sign Texas Banking Memorandum Of Understanding

- Sign Virginia Banking Profit And Loss Statement Mobile

- Sign Alabama Business Operations LLC Operating Agreement Now

- Sign Colorado Business Operations LLC Operating Agreement Online

- Sign Colorado Business Operations LLC Operating Agreement Myself

- Sign Hawaii Business Operations Warranty Deed Easy

- Sign Idaho Business Operations Resignation Letter Online

- Sign Illinois Business Operations Affidavit Of Heirship Later

- How Do I Sign Kansas Business Operations LLC Operating Agreement

- Sign Kansas Business Operations Emergency Contact Form Easy

- How To Sign Montana Business Operations Warranty Deed