Welding Procedure Specification Form 2009-2026

What is the Welding Procedure Specification Form

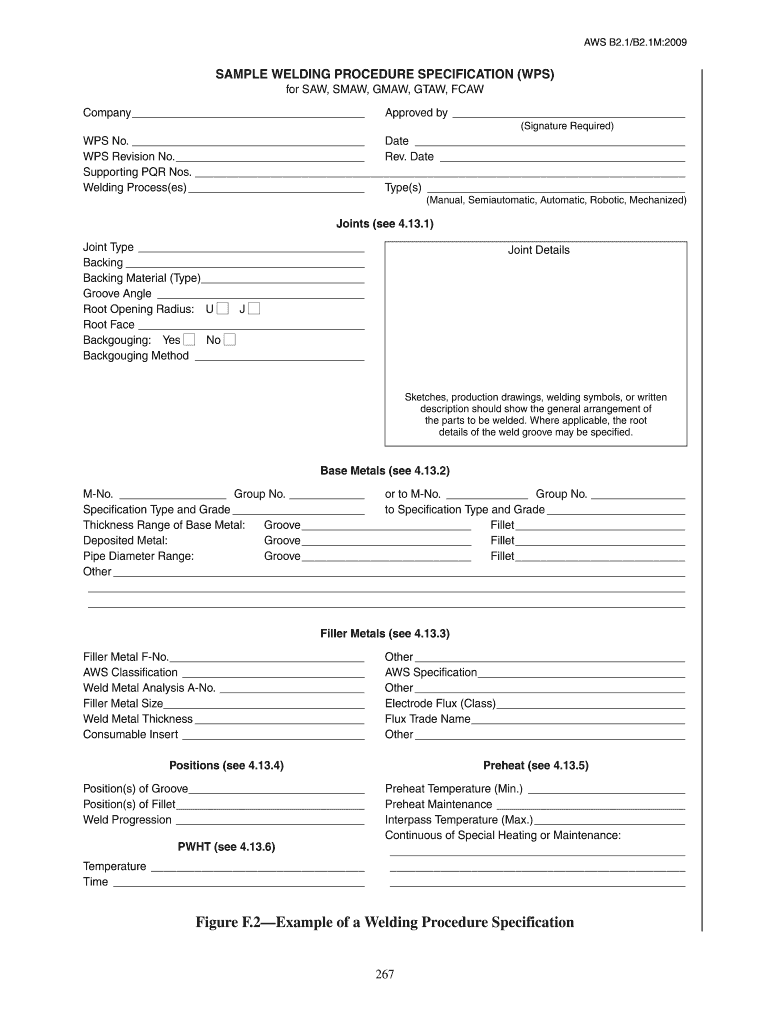

The Welding Procedure Specification (WPS) form is a critical document that outlines the specific parameters and procedures necessary for welding operations. It serves as a guideline to ensure that welds are performed consistently and meet the required standards for quality and safety. The WPS includes details such as the type of materials being welded, the welding process to be used, preheat and interpass temperatures, and the filler materials. Understanding the WPS is essential for welders and engineers to maintain compliance with industry standards and ensure the integrity of welded structures.

How to use the Welding Procedure Specification Form

Using the Welding Procedure Specification form involves several key steps. First, identify the specific welding process and materials relevant to your project. Next, fill out the form with accurate details, including joint design, welding parameters, and any necessary pre-weld treatments. It is important to ensure that the information aligns with applicable codes and standards, such as those set by the American Welding Society (AWS). Once completed, the WPS should be reviewed and approved by a qualified individual to verify its compliance and effectiveness before proceeding with the welding work.

Key elements of the Welding Procedure Specification Form

Several key elements must be included in a Welding Procedure Specification form to ensure its effectiveness. These elements typically encompass:

- Welding Process: Specify the method used, such as MIG, TIG, or stick welding.

- Base Materials: Identify the materials being welded, including their specifications.

- Filler Material: Detail the type and specifications of the filler metal used.

- Welding Parameters: Include essential parameters such as voltage, amperage, and travel speed.

- Preheat and Interpass Temperatures: Indicate any temperature requirements necessary for the welding process.

Incorporating these elements ensures that the WPS is comprehensive and meets industry standards.

Steps to complete the Welding Procedure Specification Form

Completing the Welding Procedure Specification form involves a systematic approach. Follow these steps to ensure accuracy:

- Gather Information: Collect all relevant data about the welding project, including materials and processes.

- Select the Correct WPS Template: Choose a welding procedure specification template that aligns with your project requirements.

- Fill in the Details: Accurately input the necessary information into the form, ensuring all sections are addressed.

- Review for Compliance: Have the completed form reviewed by a qualified professional to ensure compliance with applicable standards.

- Obtain Approval: Secure the necessary approvals before using the WPS for actual welding work.

Legal use of the Welding Procedure Specification Form

The legal use of the Welding Procedure Specification form is essential for ensuring compliance with industry regulations and standards. It is important to adhere to guidelines set forth by organizations such as the American Welding Society (AWS) and the American National Standards Institute (ANSI). Utilizing a properly completed and approved WPS can protect businesses from liability and ensure that welding operations meet safety and quality requirements. Additionally, maintaining accurate records of the WPS can be crucial in the event of inspections or audits.

Examples of using the Welding Procedure Specification Form

There are various scenarios in which the Welding Procedure Specification form is utilized. For instance:

- Construction Projects: In large-scale construction, the WPS is used to ensure that structural welds meet safety standards.

- Manufacturing: In manufacturing environments, the WPS helps maintain consistency in production processes involving welding.

- Repair Work: When performing repairs on existing structures, the WPS ensures that the repair welds are executed correctly and safely.

These examples illustrate the versatility and importance of the WPS in various welding applications.

Quick guide on how to complete welding procedure specification form

The optimal method to locate and endorse Welding Procedure Specification Form

At the extent of an entire organization, ineffective workflows surrounding document approval can consume a considerable amount of work hours. Endorsing documents such as Welding Procedure Specification Form is an inherent aspect of operations in any enterprise, which is why the productivity of every agreement’s lifecycle signNowly impacts the organization's overall performance. With airSlate SignNow, authorizing your Welding Procedure Specification Form is as straightforward and quick as possible. You will discover on this platform the latest version of nearly any document. Even better, you can authorize it instantly without the necessity of downloading external software on your computer or producing any hard copies.

How to acquire and endorse your Welding Procedure Specification Form

- Browse our repository by category or use the search function to locate the document you require.

- View the document preview by clicking on Learn more to ensure it’s the correct one.

- Click Get form to start editing immediately.

- Fill out your document and insert any necessary information using the toolbar.

- Once completed, click the Sign tool to endorse your Welding Procedure Specification Form.

- Choose the signature method that is most comfortable for you: Draw, Create initials, or upload an image of your handwritten signature.

- Click Done to conclude editing and move on to document-sharing options as required.

With airSlate SignNow, you possess everything you need to manage your documents efficiently. You can find, complete, edit, and even dispatch your Welding Procedure Specification Form in a single tab without any complications. Enhance your processes with a single, intelligent eSignature solution.

Create this form in 5 minutes or less

FAQs

-

Does it pay off to get welding certifications?

Certification is one way to advance in the field after you complete your welding training. The type of certification a welder seeks usually depends on the industry he or she works in. Most welding certifications must be renewed after a certain length of time. Find out how long some of the most common certifications are good for in this article.When Do Welding Certifications Expire?Welding certifications are usually good for anywhere from six months to three years.Employer Certifications6 MonthsEmployers often test job applicants on the specific welding process they’ll be using in that line of work. Once a welder has proven his or her ability in a certain welding process, metal, position, and thickness range, he or she is considered qualified for the job. If the welder’s test results were documented, then he or she is certified to work in that welding process for six months.American Welding Society – industry standard6 monthsLearn More About Attending TWSIt’s easy – just fill out the form below and we will signNow out with more info!Full NameEmail AddressPhone NumberZip CodeGET STARTEDThe American Welding Society (AWS) offers eight certifications for welders. One of the tests is for the Certified Welder. This certification could prove helpful to welders working in the chemical refinery, structural steel, sheet metal, and petroleum pipeline welding industries.Every six months after you receive this certification you must submit a maintenance form to AWS verifying that you’re still performing the same welding you were initially tested on. Welders who do not submit their maintenance forms within this timeframe must be tested on the procedures again to reinstate their certification in them.

-

What is the procedure to fill out the DU admission form? How many colleges and courses can I fill in?

It's as simple as filling any school admission form but you need to be quite careful while filling for courses ,don't mind you are from which stream in class 12 choose all the courses you feel like choosing,there is no limitations in choosing course and yes you must fill all the courses related to your stream ,additionally there is no choice for filling of college names in the application form .

-

What is the procedure to fill out a 15G form?

Form 15G is the form which you give to Bank requesting them not to deduct tax as the liability is on you to state the interest as your income in returns, now a days banks are deducting TDS directly and hence Form 15G may be void now a days.

-

What is the procedure to fill out the form for re-viva in CSJM University?

It is not difficult. Every year CSJM university organises left over viva examination in university campus. For this contact Registrar University. Fill a form. Submit the fees. Usually such viva takes.place in summer months. You can get contact information from csjm website

-

What is the procedure to fill out the GRE exam application form?

Visit this site The GRE Tests . Register yourself. Fill the form, choose a date and make the payment.You are done.If you need any specific help, you can contact me anytime.Thanks

Create this form in 5 minutes!

How to create an eSignature for the welding procedure specification form

How to make an electronic signature for your Welding Procedure Specification Form in the online mode

How to create an eSignature for your Welding Procedure Specification Form in Google Chrome

How to make an eSignature for signing the Welding Procedure Specification Form in Gmail

How to make an electronic signature for the Welding Procedure Specification Form from your smart phone

How to create an eSignature for the Welding Procedure Specification Form on iOS devices

How to make an electronic signature for the Welding Procedure Specification Form on Android devices

People also ask

-

What is a Welding Procedure Specification Form?

The Welding Procedure Specification Form is a crucial document that outlines the necessary guidelines and procedures for welding operations. It ensures that all welding activities meet industry standards and safety requirements. By using this form, businesses can maintain consistency and quality in their welding processes.

-

How can airSlate SignNow help with Welding Procedure Specification Forms?

airSlate SignNow simplifies the process of creating and managing Welding Procedure Specification Forms by providing a user-friendly platform for document creation and electronic signatures. With our solution, users can easily generate, send, and eSign these forms, ensuring quick approval and compliance with regulatory standards.

-

What features does airSlate SignNow offer for Welding Procedure Specification Forms?

Our platform offers various features tailored for Welding Procedure Specification Forms, including customizable templates, real-time collaboration, and secure cloud storage. Additionally, users can track the status of their documents, set reminders for renewals, and integrate with other business tools for seamless workflow management.

-

Is airSlate SignNow cost-effective for managing Welding Procedure Specification Forms?

Yes, airSlate SignNow provides a cost-effective solution for managing Welding Procedure Specification Forms, with flexible pricing plans that cater to businesses of all sizes. Our plans are designed to save you time and money by streamlining the document signing process and reducing paper waste.

-

Can I integrate airSlate SignNow with other software for Welding Procedure Specification Forms?

Absolutely! airSlate SignNow offers integration capabilities with various software solutions commonly used in the industry, such as project management and ERP systems. This allows you to link your Welding Procedure Specification Forms with existing workflows, enhancing efficiency and data accuracy.

-

What are the benefits of using airSlate SignNow for Welding Procedure Specification Forms?

Using airSlate SignNow for your Welding Procedure Specification Forms offers numerous benefits, including improved compliance, faster turnaround times, and enhanced collaboration among team members. Our platform also ensures that your documents are secure and easily accessible, streamlining the entire process from creation to approval.

-

How does airSlate SignNow ensure the security of Welding Procedure Specification Forms?

airSlate SignNow employs robust security measures to protect your Welding Procedure Specification Forms. We utilize encryption, secure cloud storage, and access controls to safeguard sensitive information, ensuring that your documents remain confidential and compliant with industry regulations.

Get more for Welding Procedure Specification Form

Find out other Welding Procedure Specification Form

- Sign Delaware Insurance Claim Online

- Sign Delaware Insurance Contract Later

- Sign Hawaii Insurance NDA Safe

- Sign Georgia Insurance POA Later

- How Can I Sign Alabama Lawers Lease Agreement

- How Can I Sign California Lawers Lease Agreement

- Sign Colorado Lawers Operating Agreement Later

- Sign Connecticut Lawers Limited Power Of Attorney Online

- Sign Hawaii Lawers Cease And Desist Letter Easy

- Sign Kansas Insurance Rental Lease Agreement Mobile

- Sign Kansas Insurance Rental Lease Agreement Free

- Sign Kansas Insurance Rental Lease Agreement Fast

- Sign Kansas Insurance Rental Lease Agreement Safe

- How To Sign Kansas Insurance Rental Lease Agreement

- How Can I Sign Kansas Lawers Promissory Note Template

- Sign Kentucky Lawers Living Will Free

- Sign Kentucky Lawers LLC Operating Agreement Mobile

- Sign Louisiana Lawers Quitclaim Deed Now

- Sign Massachusetts Lawers Quitclaim Deed Later

- Sign Michigan Lawers Rental Application Easy