7 Families of Additive Manufacturing Form

What is the 7 families of additive manufacturing?

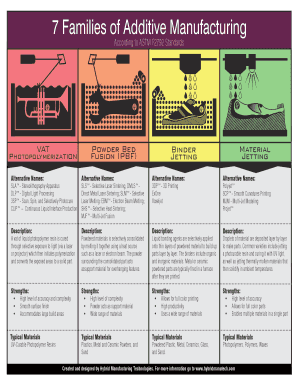

The seven families of additive manufacturing encompass a range of technologies that create objects layer by layer from digital models. These processes include:

- Material Extrusion: This method involves extruding thermoplastic materials through a nozzle to build parts.

- Vat Photopolymerization: In this process, liquid resin is cured layer by layer using ultraviolet light.

- Powder Bed Fusion: This technique uses a laser or electron beam to fuse powdered material into solid parts.

- Binder Jetting: A binding agent is selectively deposited onto a powder bed to create a solid part.

- Material Jetting: This process involves depositing droplets of material to create layers of an object.

- Sheet Lamination: Layers of material sheets are bonded together through adhesive or ultrasonic welding.

- Directed Energy Deposition: This method uses focused thermal energy to fuse materials as they are deposited.

How to use the 7 families of additive manufacturing

Utilizing the seven families of additive manufacturing requires understanding the specific applications and materials suited for each process. Here are some steps to consider:

- Identify the desired properties of the final product, such as strength, flexibility, or heat resistance.

- Choose the appropriate additive manufacturing process based on the material and design requirements.

- Create a digital model using computer-aided design (CAD) software that meets the specifications for the chosen process.

- Prepare the printer settings, including layer thickness, print speed, and material feed rate.

- Monitor the printing process to ensure quality and accuracy throughout the build.

Legal use of the 7 families of additive manufacturing

When engaging in additive manufacturing, it is essential to comply with legal standards and regulations. Key considerations include:

- Intellectual property rights: Ensure that the designs used do not infringe on existing patents or copyrights.

- Safety regulations: Follow guidelines to ensure that the materials used are safe and suitable for the intended application.

- Environmental compliance: Be aware of regulations regarding waste disposal and emissions related to the manufacturing process.

Examples of using the 7 families of additive manufacturing

Real-world applications of the seven families of additive manufacturing demonstrate their versatility across industries:

- In aerospace, powder bed fusion is used to create lightweight components that enhance fuel efficiency.

- In healthcare, material extrusion is employed to produce customized prosthetics and implants.

- Automotive manufacturers utilize binder jetting for rapid prototyping of complex parts.

- Consumer products often leverage material jetting to create intricate designs with multiple materials.

Steps to complete the 7 families of additive manufacturing

Completing a project using the seven families of additive manufacturing involves several critical steps:

- Design the part using CAD software, ensuring compatibility with the selected manufacturing process.

- Convert the design file into a format suitable for the additive manufacturing machine.

- Set up the machine, including material loading and calibration.

- Initiate the printing process and monitor for any issues during production.

- Post-process the printed part as necessary, which may include cleaning, curing, or finishing.

Key elements of the 7 families of additive manufacturing

Understanding the key elements that define each family of additive manufacturing is vital for effective application:

- Material type: Different processes require specific materials, such as plastics, metals, or ceramics.

- Layering technique: Each family employs a unique method for building layers, influencing the final product's characteristics.

- Application suitability: Certain processes are better suited for specific applications, affecting design choices.

Quick guide on how to complete 7 families of additive manufacturing

Complete 7 Families Of Additive Manufacturing effortlessly on any device

Digital document management has gained popularity among companies and individuals alike. It serves as an ideal environmentally friendly substitute to conventional printed and signed papers, allowing you to access the necessary form and securely save it online. airSlate SignNow equips you with all the tools required to create, modify, and eSign your documents swiftly without delays. Manage 7 Families Of Additive Manufacturing on any device using airSlate SignNow Android or iOS applications and enhance any document-related procedure today.

How to modify and eSign 7 Families Of Additive Manufacturing with ease

- Obtain 7 Families Of Additive Manufacturing and then click Get Form to begin.

- Utilize the tools we provide to fill out your document.

- Emphasize important sections of the documents or obscure sensitive information with tools specifically offered by airSlate SignNow for that purpose.

- Create your signature using the Sign tool, which takes only seconds and carries the same legal validity as a traditional handwritten signature.

- Review the information and then click on the Done button to save your modifications.

- Select your preferred method to deliver your form, whether by email, SMS, invite link, or download it to your computer.

Eliminate the worries of lost or misplaced documents, tedious form searching, or mistakes that require printing new document copies. airSlate SignNow fulfills all your document management needs in just a few clicks from any device you prefer. Alter and eSign 7 Families Of Additive Manufacturing to ensure effective communication at every stage of your form preparation process with airSlate SignNow.

Create this form in 5 minutes or less

Create this form in 5 minutes!

How to create an eSignature for the 7 families of additive manufacturing

How to create an electronic signature for a PDF online

How to create an electronic signature for a PDF in Google Chrome

How to create an e-signature for signing PDFs in Gmail

How to create an e-signature right from your smartphone

How to create an e-signature for a PDF on iOS

How to create an e-signature for a PDF on Android

People also ask

-

What are the 7 additive manufacturing processes?

The 7 additive manufacturing processes include Material Extrusion, Powder Bed Fusion, Vat Polymerization, Material Jetting, Binder Jetting, Sheet Lamination, and Directed Energy Deposition. Each process has unique advantages and applications, making them suitable for various industries. Understanding these processes helps businesses choose the best method for their specific needs.

-

How can the 7 additive manufacturing processes benefit my business?

Utilizing the 7 additive manufacturing processes can signNowly enhance your production efficiency and reduce material waste. These processes allow for complex geometries that traditional manufacturing cannot achieve, streamlining product development. Furthermore, they contribute to lower costs and faster time-to-market for your products.

-

Are the 7 additive manufacturing processes cost-effective?

Yes, the 7 additive manufacturing processes can be cost-effective depending on your production scale and complexity. By using only the necessary materials and minimizing waste, businesses can lower their overall costs. Additionally, faster prototyping and production can lead to signNow savings in time and resources.

-

What features should I look for in a solution that utilizes the 7 additive manufacturing processes?

When evaluating solutions that leverage the 7 additive manufacturing processes, ensure they offer advanced design tools, compatibility with various materials, and robust support for post-processing. Additionally, look for features that facilitate quick iteration and adaptation to new designs, enhancing productivity and innovation.

-

Which industries benefit the most from the 7 additive manufacturing processes?

The 7 additive manufacturing processes benefit a wide range of industries, including aerospace, automotive, healthcare, and consumer products. Each industry utilizes these processes to create lightweight structures, custom implants, and innovative designs. This versatility allows companies to stay competitive and meet evolving market demands.

-

Can I integrate the 7 additive manufacturing processes with other software tools?

Yes, many solutions that enable the 7 additive manufacturing processes offer integration capabilities with popular engineering and design software. This seamless integration allows for efficient collaboration across teams and enhances workflow efficiency. Look for solutions that support common file formats and APIs for the best compatibility.

-

What are the key challenges in implementing the 7 additive manufacturing processes?

Some key challenges in implementing the 7 additive manufacturing processes include ensuring quality control, material selection, and workforce training. Businesses need to invest in proper training to maximize the potential of these processes. Additionally, understanding the characteristics of different materials is crucial for achieving desired outcomes.

Get more for 7 Families Of Additive Manufacturing

- Uniform single party or multiple party account form

- Uniform anatomical gift act donation generic poa 203

- Transfer under the alaska uniform custodial trust act

- Declaration of trust under the massachusetts uniform custodial trust act

- 642 903 form and effect of receipt and acceptance by

- A registered in the name of the transferor an adult other than the transferor or a trust company followed in substance b form

- Notice of lien for medial services by hospital form

- Statutory and common law repairmens liens in illinois form

Find out other 7 Families Of Additive Manufacturing

- How To Integrate Sign in Banking

- How To Use Sign in Banking

- Help Me With Use Sign in Banking

- Can I Use Sign in Banking

- How Do I Install Sign in Banking

- How To Add Sign in Banking

- How Do I Add Sign in Banking

- How Can I Add Sign in Banking

- Can I Add Sign in Banking

- Help Me With Set Up Sign in Government

- How To Integrate eSign in Banking

- How To Use eSign in Banking

- How To Install eSign in Banking

- How To Add eSign in Banking

- How To Set Up eSign in Banking

- How To Save eSign in Banking

- How To Implement eSign in Banking

- How To Set Up eSign in Construction

- How To Integrate eSign in Doctors

- How To Use eSign in Doctors