Welder Continuity Reports UA Local 21 Ualocal136 Form

What is the Welder Continuity Reports UA Local 21 Ualocal136

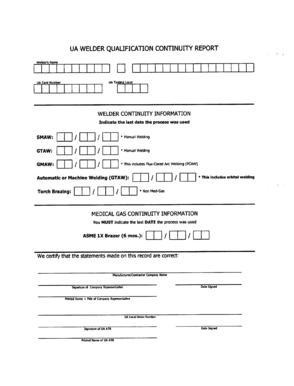

The Welder Continuity Reports UA Local 21 Ualocal136 is a crucial document used by welders to maintain a record of their welding qualifications and certifications. This report helps ensure that welders meet the necessary standards set by the UA Local 21 and Ualocal136 unions. It serves as a verification tool for employers, allowing them to confirm a welder's skills and compliance with industry regulations. The report typically includes information such as the welder's name, certification levels, and the specific types of welding processes they are qualified to perform.

How to use the Welder Continuity Reports UA Local 21 Ualocal136

Using the Welder Continuity Reports UA Local 21 Ualocal136 involves several straightforward steps. First, ensure that you have the most recent version of the report, as updates may occur periodically. Next, fill out the required fields accurately, providing details about your welding experience, certifications, and any relevant training. Once completed, the report should be submitted to your local union representative for validation. This process helps maintain accurate records and ensures compliance with union standards.

Steps to complete the Welder Continuity Reports UA Local 21 Ualocal136

Completing the Welder Continuity Reports UA Local 21 Ualocal136 involves a series of steps:

- Gather necessary documentation, including previous certifications and training records.

- Access the report form, ensuring it is the latest version.

- Fill in your personal information, including name, contact details, and union membership number.

- Detail your welding qualifications, specifying the types of welding you are certified in.

- Review the form for accuracy and completeness.

- Submit the completed report to your union representative for approval.

Key elements of the Welder Continuity Reports UA Local 21 Ualocal136

The key elements of the Welder Continuity Reports UA Local 21 Ualocal136 include:

- Welder Identification: Personal details such as name and contact information.

- Certification Levels: Specific welding certifications held by the welder.

- Welding Processes: Types of welding techniques the welder is qualified to perform.

- Training Records: Documentation of any additional training or workshops attended.

- Union Affiliation: Confirmation of membership in UA Local 21 or Ualocal136.

Legal use of the Welder Continuity Reports UA Local 21 Ualocal136

The legal use of the Welder Continuity Reports UA Local 21 Ualocal136 is essential for ensuring compliance with labor laws and industry standards. This report acts as a formal record of a welder's qualifications, which can be critical in disputes or audits. By maintaining accurate and up-to-date continuity reports, welders can protect their rights and demonstrate their competencies to employers, ensuring they meet the necessary legal requirements for their trade.

How to obtain the Welder Continuity Reports UA Local 21 Ualocal136

To obtain the Welder Continuity Reports UA Local 21 Ualocal136, you can contact your local union office directly. They will provide you with the necessary forms and any additional information you may need. Additionally, some unions may offer downloadable versions of the report on their official websites. Ensure that you have the correct and most current form to avoid any issues during the submission process.

Quick guide on how to complete welder continuity reports ua local 21 ualocal136

Complete Welder Continuity Reports UA Local 21 Ualocal136 effortlessly on any device

Web-based document management has gained traction among companies and individuals alike. It offers an ideal eco-friendly substitute for conventional printed and signed documentation, since you can obtain the necessary form and securely store it online. airSlate SignNow equips you with all the essentials to create, alter, and electronically sign your documents swiftly without delays. Handle Welder Continuity Reports UA Local 21 Ualocal136 on any platform using airSlate SignNow's Android or iOS applications and streamline any document-related task today.

How to modify and electronically sign Welder Continuity Reports UA Local 21 Ualocal136 without hassle

- Locate Welder Continuity Reports UA Local 21 Ualocal136 and click on Get Form to begin.

- Use the tools we offer to fill out your form.

- Emphasize pertinent sections of your documents or obscure sensitive information with tools specifically designed for that purpose by airSlate SignNow.

- Create your signature using the Sign feature, which takes mere seconds and holds the same legal validity as a conventional handwritten signature.

- Review the details and click on the Done button to save your alterations.

- Select your preferred method for sharing your form, whether by email, SMS, invite link, or download it to your computer.

Put an end to lost or misplaced forms, frustrating document searches, or mistakes that necessitate the printing of new copies. airSlate SignNow fulfills all your document management requirements in just a few clicks from any device you prefer. Modify and eSign Welder Continuity Reports UA Local 21 Ualocal136 and ensure excellent communication at every phase of your form preparation journey with airSlate SignNow.

Create this form in 5 minutes or less

Create this form in 5 minutes!

How to create an eSignature for the welder continuity reports ua local 21 ualocal136

How to create an electronic signature for a PDF online

How to create an electronic signature for a PDF in Google Chrome

How to create an e-signature for signing PDFs in Gmail

How to create an e-signature right from your smartphone

How to create an e-signature for a PDF on iOS

How to create an e-signature for a PDF on Android

People also ask

-

What are Welder Continuity Reports UA Local 21 Ualocal136?

Welder Continuity Reports UA Local 21 Ualocal136 are essential documents that track the qualifications and certifications of welders. These reports ensure that welders maintain their skills and meet industry standards, especially required by unions like UA Local 21 and Ualocal136. They are crucial for compliance and maintaining safety in welding projects.

-

How can I obtain Welder Continuity Reports UA Local 21 Ualocal136?

To obtain Welder Continuity Reports UA Local 21 Ualocal136, you can request them through your training program or union representative. Additionally, platforms like airSlate SignNow provide a reliable option to create and manage these reports digitally, streamlining the process for all involved. Ensuring timely access to these reports is important for your ongoing welding credentials.

-

What features does airSlate SignNow offer for managing Welder Continuity Reports UA Local 21 Ualocal136?

airSlate SignNow offers robust features for managing Welder Continuity Reports UA Local 21 Ualocal136, including easy document creation, electronic signatures, and secure storage. The platform is designed to enhance collaboration and ensure documents are easily accessible. It also provides templates tailored for welding reports, making the process more efficient.

-

Are there any costs associated with using airSlate SignNow for Welder Continuity Reports UA Local 21 Ualocal136?

Yes, there are costs associated with using airSlate SignNow, but it is considered a cost-effective solution for managing Welder Continuity Reports UA Local 21 Ualocal136. The pricing plans are designed to fit various business needs, providing flexibility and scalability. It's best to review the pricing page to choose a plan that works for you.

-

What are the benefits of using airSlate SignNow for Welder Continuity Reports UA Local 21 Ualocal136?

Using airSlate SignNow for Welder Continuity Reports UA Local 21 Ualocal136 offers numerous benefits, including improved efficiency through automation and ease of access through cloud storage. Additionally, the platform enhances compliance by providing audit trails and secure signature options. Overall, it simplifies the management of essential documentation for welders.

-

Can airSlate SignNow integrate with other tools I use for Welder Continuity Reports UA Local 21 Ualocal136?

Absolutely! airSlate SignNow integrates with various business tools and applications, allowing for seamless management of Welder Continuity Reports UA Local 21 Ualocal136. This integration can enhance workflows by connecting different platforms for a more cohesive operational experience. Check the integration options on the SignNow website for compatibility details.

-

How do I ensure compliance with Welder Continuity Reports UA Local 21 Ualocal136?

Ensuring compliance with Welder Continuity Reports UA Local 21 Ualocal136 involves maintaining accurate and up-to-date records of all welding certifications. Using airSlate SignNow can assist in this process by providing secure storage, automated reminders, and the ability to easily update reports. Staying diligent about documentation will help prevent compliance issues.

Get more for Welder Continuity Reports UA Local 21 Ualocal136

Find out other Welder Continuity Reports UA Local 21 Ualocal136

- eSign Nevada Software Development Proposal Template Mobile

- Can I eSign Colorado Mobile App Design Proposal Template

- How Can I eSignature California Cohabitation Agreement

- How Do I eSignature Colorado Cohabitation Agreement

- How Do I eSignature New Jersey Cohabitation Agreement

- Can I eSign Utah Mobile App Design Proposal Template

- eSign Arkansas IT Project Proposal Template Online

- eSign North Dakota IT Project Proposal Template Online

- eSignature New Jersey Last Will and Testament Online

- eSignature Pennsylvania Last Will and Testament Now

- eSign Arkansas Software Development Agreement Template Easy

- eSign Michigan Operating Agreement Free

- Help Me With eSign Nevada Software Development Agreement Template

- eSign Arkansas IT Consulting Agreement Computer

- How To eSignature Connecticut Living Will

- eSign Alaska Web Hosting Agreement Computer

- eSign Alaska Web Hosting Agreement Now

- eSign Colorado Web Hosting Agreement Simple

- How Do I eSign Colorado Joint Venture Agreement Template

- How To eSign Louisiana Joint Venture Agreement Template