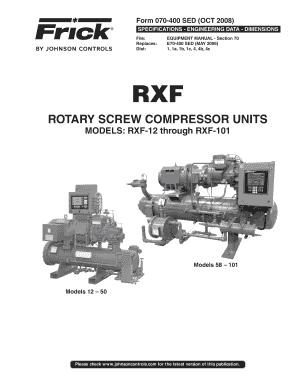

ROTARY SCREW COMPRESSOR UNITS Johnson Controls Inc Form

Understanding Rotary Screw Compressor Units

Rotary screw compressors are essential machines used in various industrial applications. These units operate by using two interlocking screws to compress air or gas, making them efficient and reliable. Johnson Controls Inc. manufactures rotary screw compressor units that are designed for durability and performance, catering to diverse operational needs. Their design minimizes energy consumption while maximizing output, making them a preferred choice for businesses seeking cost-effective solutions.

How to Utilize Rotary Screw Compressor Units

Using rotary screw compressor units effectively involves several steps. First, ensure that the unit is properly installed according to the manufacturer's guidelines. Regular maintenance is crucial for optimal performance; this includes checking oil levels, replacing filters, and inspecting belts. Operators should also monitor the pressure settings to align with specific operational requirements. Familiarizing oneself with the control panel is essential for efficient operation, allowing users to make adjustments as needed.

Acquiring Rotary Screw Compressor Units

To obtain rotary screw compressor units from Johnson Controls Inc., businesses should contact authorized suppliers or distributors in their region. It's advisable to request detailed product specifications and pricing information. Additionally, potential buyers can inquire about warranty options and after-sales support to ensure long-term satisfaction with their purchase. Researching customer reviews and case studies can also provide insights into the performance of these units in real-world applications.

Key Components of Rotary Screw Compressor Units

Understanding the key elements of rotary screw compressor units is vital for effective operation. Major components include the compressor element, motor, oil separator, and control panel. The compressor element is responsible for the air compression process, while the motor powers the unit. The oil separator removes oil from the compressed air, ensuring clean output. The control panel allows users to monitor and adjust settings for optimal performance. Regular inspection of these components can prevent operational issues and extend the unit's lifespan.

Legal Considerations for Rotary Screw Compressor Units

When operating rotary screw compressor units, businesses must comply with relevant regulations and standards. This includes adhering to safety guidelines set by organizations such as OSHA. Additionally, environmental regulations may apply, particularly concerning emissions and noise levels. It is important for businesses to stay informed about local laws and industry standards to avoid penalties and ensure safe operation.

Examples of Rotary Screw Compressor Applications

Rotary screw compressors are used in a variety of applications across different industries. For instance, they are commonly employed in manufacturing facilities for powering pneumatic tools and equipment. In the food and beverage industry, these compressors are used for packaging and processing. Additionally, they play a crucial role in the automotive sector for paint spraying and assembly line operations. Understanding these applications can help businesses identify how rotary screw compressors can enhance their operational efficiency.

Create this form in 5 minutes or less

Create this form in 5 minutes!

How to create an eSignature for the rotary screw compressor units johnson controls inc

How to create an electronic signature for a PDF online

How to create an electronic signature for a PDF in Google Chrome

How to create an e-signature for signing PDFs in Gmail

How to create an e-signature right from your smartphone

How to create an e-signature for a PDF on iOS

How to create an e-signature for a PDF on Android

People also ask

-

What are the key features of screw compressors available from suppliers in Melbourne?

Screw compressors from suppliers in Melbourne typically offer high efficiency, durability, and low maintenance requirements. They are designed to provide a continuous supply of compressed air, making them ideal for various industrial applications. Additionally, many models come with advanced control systems for optimal performance.

-

How much do screw compressors 240 volt cost from suppliers in Melbourne?

The pricing for screw compressors 240 volt from suppliers in Melbourne can vary signNowly based on the brand, model, and features. Generally, you can expect to pay anywhere from a few thousand to tens of thousands of dollars. It's advisable to compare prices from multiple suppliers to find the best deal.

-

What are the benefits of using a screw compressor over other types?

Screw compressors are known for their efficiency and reliability compared to other types, such as piston compressors. They provide a steady flow of compressed air, which is essential for many industrial processes. Additionally, they tend to operate more quietly and have a longer lifespan, making them a cost-effective choice for businesses.

-

Can screw compressors be integrated with existing systems?

Yes, screw compressors from suppliers in Melbourne can often be integrated with existing air systems. Many models come with compatibility features that allow for easy integration with other equipment. This flexibility helps businesses enhance their operations without the need for a complete overhaul of their systems.

-

What maintenance is required for screw compressors?

Regular maintenance for screw compressors includes checking oil levels, replacing filters, and inspecting belts and hoses. It's essential to follow the manufacturer's guidelines to ensure optimal performance and longevity. Many suppliers in Melbourne offer maintenance services to help keep your compressor running smoothly.

-

Are there energy-efficient options available for screw compressors in Melbourne?

Yes, many suppliers in Melbourne offer energy-efficient screw compressors designed to reduce energy consumption and operational costs. These models often feature advanced technology that optimizes performance while minimizing energy use. Investing in an energy-efficient compressor can lead to signNow savings over time.

-

What industries commonly use screw compressors?

Screw compressors are widely used across various industries, including manufacturing, automotive, and food processing. Their ability to provide a consistent supply of compressed air makes them suitable for applications such as pneumatic tools, packaging, and assembly lines. Suppliers in Melbourne cater to these diverse industry needs.

Get more for ROTARY SCREW COMPRESSOR UNITS Johnson Controls Inc

Find out other ROTARY SCREW COMPRESSOR UNITS Johnson Controls Inc

- eSign Minnesota Real Estate Living Will Free

- eSign Massachusetts Real Estate Quitclaim Deed Myself

- eSign Missouri Real Estate Affidavit Of Heirship Simple

- eSign New Jersey Real Estate Limited Power Of Attorney Later

- eSign Alabama Police LLC Operating Agreement Fast

- eSign North Dakota Real Estate Business Letter Template Computer

- eSign North Dakota Real Estate Quitclaim Deed Myself

- eSign Maine Sports Quitclaim Deed Easy

- eSign Ohio Real Estate LLC Operating Agreement Now

- eSign Ohio Real Estate Promissory Note Template Online

- How To eSign Ohio Real Estate Residential Lease Agreement

- Help Me With eSign Arkansas Police Cease And Desist Letter

- How Can I eSign Rhode Island Real Estate Rental Lease Agreement

- How Do I eSign California Police Living Will

- Can I eSign South Dakota Real Estate Quitclaim Deed

- How To eSign Tennessee Real Estate Business Associate Agreement

- eSign Michigan Sports Cease And Desist Letter Free

- How To eSign Wisconsin Real Estate Contract

- How To eSign West Virginia Real Estate Quitclaim Deed

- eSign Hawaii Police Permission Slip Online