Hot Dip Galvanized Form

What is the Hot Dip Galvanized

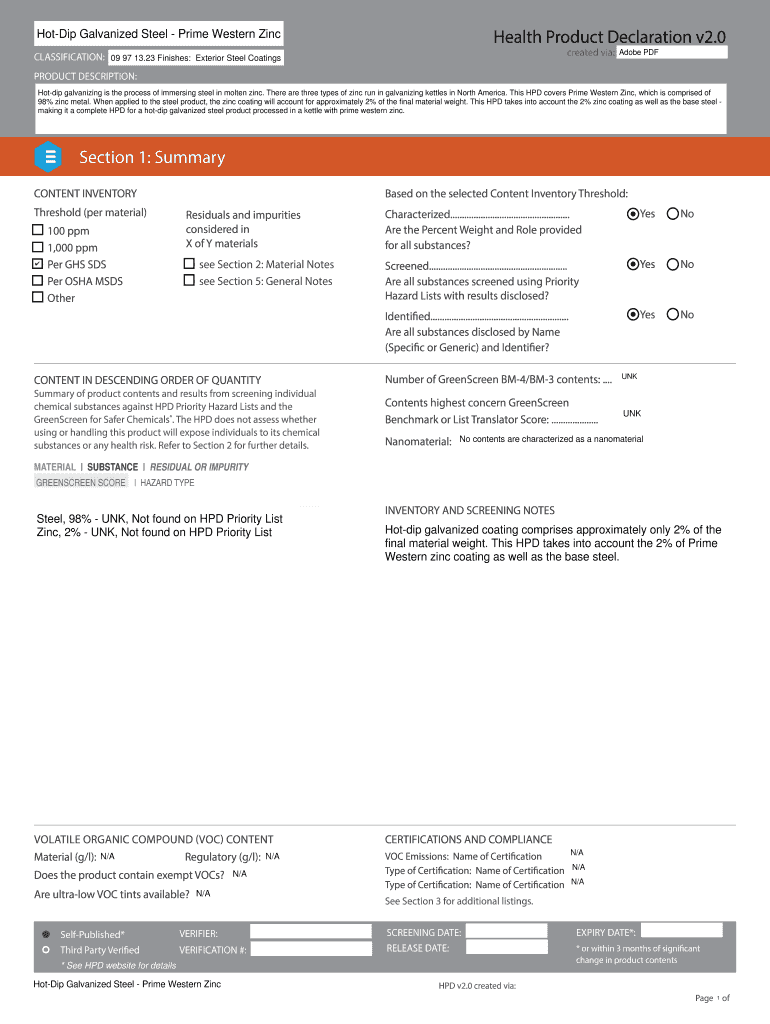

The hot dip galvanized form refers to a process where steel or iron is coated with a layer of zinc to prevent corrosion. This method involves immersing the metal in molten zinc, creating a durable and protective barrier. The hot dip galvanized technique is widely used in various industries, including construction and manufacturing, due to its effectiveness in extending the lifespan of metal structures.

How to use the Hot Dip Galvanized

Using the hot dip galvanized form typically involves several steps. First, ensure that the metal surface is clean and free from contaminants. Next, immerse the prepared metal in the molten zinc bath. After the coating process, allow the metal to cool and solidify. This procedure can be performed by professionals in specialized facilities to ensure optimal results. It is essential to follow safety guidelines during this process to protect workers and the environment.

Key elements of the Hot Dip Galvanized

Several key elements contribute to the effectiveness of the hot dip galvanized process. These include:

- Surface Preparation: Proper cleaning of the metal surface is crucial to ensure good adhesion of the zinc coating.

- Temperature Control: Maintaining the correct temperature of the molten zinc is vital for achieving a uniform coating.

- Coating Thickness: The thickness of the zinc layer can vary, impacting the corrosion resistance and overall durability.

- Post-Treatment: Additional treatments, such as passivation, can enhance the corrosion resistance of the galvanized coating.

Steps to complete the Hot Dip Galvanized

Completing the hot dip galvanized process involves several systematic steps:

- Prepare the metal surface by removing rust, oil, and other contaminants.

- Heat the zinc to the appropriate temperature, typically around 450 degrees Celsius.

- Immerse the cleaned metal in the molten zinc for a specified duration.

- Remove the metal from the bath and allow it to cool, forming a protective zinc layer.

- Inspect the coated metal for uniformity and adherence of the zinc layer.

Legal use of the Hot Dip Galvanized

The legal use of hot dip galvanized materials is governed by various industry standards and regulations. In the United States, compliance with standards set by organizations such as the American Society for Testing and Materials (ASTM) is essential. These standards ensure that hot dip galvanized products meet safety and quality requirements, making them suitable for construction and manufacturing applications.

Examples of using the Hot Dip Galvanized

Hot dip galvanized materials are commonly used in various applications, including:

- Construction of bridges and buildings, where corrosion resistance is critical.

- Manufacturing of outdoor furniture and fixtures, ensuring longevity in harsh weather conditions.

- Production of fencing and gates, providing durability and aesthetic appeal.

- Automotive components, where resistance to rust and wear is essential for performance.

Quick guide on how to complete hot dip galvanized

Effortlessly prepare Hot Dip Galvanized on any device

Online document management has gained signNow traction among businesses and individuals. It offers an ideal eco-conscious alternative to conventional printed and signed documents, allowing you to obtain the correct form and securely store it online. airSlate SignNow equips you with all the necessary features to create, modify, and electronically sign your documents swiftly without any delays. Manage Hot Dip Galvanized on any device with the airSlate SignNow applications for Android or iOS and enhance any document-related process today.

The easiest way to modify and eSign Hot Dip Galvanized seamlessly

- Find Hot Dip Galvanized and click on Get Form to begin.

- Utilize the tools we provide to complete your document.

- Emphasize relevant sections of your documents or obscure sensitive information using tools that airSlate SignNow offers specifically for that purpose.

- Generate your signature with the Sign tool, which takes mere seconds and carries the same legal validity as an original wet ink signature.

- Review the details and click on the Done button to save your changes.

- Choose how you wish to send your form, via email, SMS, or an invitation link, or download it to your computer.

Say goodbye to lost or misplaced paperwork, tedious form searching, or mistakes that necessitate printing new document copies. airSlate SignNow fulfills your document management needs within a few clicks from any device you prefer. Modify and eSign Hot Dip Galvanized and ensure outstanding communication throughout the document preparation process with airSlate SignNow.

Create this form in 5 minutes or less

Create this form in 5 minutes!

How to create an eSignature for the hot dip galvanized

The best way to generate an electronic signature for your PDF file online

The best way to generate an electronic signature for your PDF file in Google Chrome

The way to make an eSignature for signing PDFs in Gmail

How to make an electronic signature from your mobile device

The way to make an electronic signature for a PDF file on iOS

How to make an electronic signature for a PDF file on Android devices

People also ask

-

What is Hot Dip Galvanized and how is it applied?

Hot Dip Galvanized refers to the process of coating steel or iron with a layer of zinc to prevent corrosion. This method involves dipping the metal into molten zinc, which provides a durable, long-lasting finish. It is widely used in construction and manufacturing where rust resistance is crucial.

-

What are the benefits of using Hot Dip Galvanized products?

The main benefits of Hot Dip Galvanized products include enhanced corrosion resistance, extended lifespan, and reduced maintenance costs. This makes them an ideal choice for outdoor and industrial applications. Additionally, Hot Dip Galvanized materials can handle extreme weather conditions without deteriorating.

-

How does Hot Dip Galvanized compare to other galvanizing methods?

Hot Dip Galvanized offers superior coverage and protection compared to other methods like mechanical galvanizing or electroplating. The thicker zinc coating provides better resistance to wear and corrosion. Overall, it is considered more effective for heavy-duty applications.

-

Are Hot Dip Galvanized products cost-effective?

Yes, Hot Dip Galvanized products are considered cost-effective due to their durability and low maintenance requirements. While the initial investment may be higher than uncoated alternatives, the long-term savings from reduced repairs and replacements make them an economical choice. Manufacturers find that Hot Dip Galvanized items often have lower life-cycle costs.

-

Can Hot Dip Galvanized materials be painted or coated?

Yes, Hot Dip Galvanized materials can be painted, but proper surface preparation is essential for adhesion. It is often recommended to use specific primers designed for galvanized surfaces. This allows for aesthetic customization while retaining the corrosion resistance of the Hot Dip Galvanized finish.

-

What industries benefit from Hot Dip Galvanized products?

Multiple industries, including construction, manufacturing, and transportation, benefit from Hot Dip Galvanized products. Structures like bridges, railings, and outdoor fixtures often utilize this method for its strength and longevity. Moreover, agricultural equipment and fencing also gain from Hot Dip Galvanizing.

-

Are there any environmental concerns with Hot Dip Galvanized processes?

While Hot Dip Galvanized processes have been scrutinized for environmental impact, modern practices have signNowly minimized harmful emissions. The zinc used is recyclable and does not leach harmful substances. Efforts are continuously made to enhance the sustainability of Hot Dip Galvanized processes.

Get more for Hot Dip Galvanized

- Teacher interview evaluation form

- Icb business literacy past exam papers pdf form

- Annex 1b form

- Petition for a court order of protection adult missouri courts form

- Ab 540 form mt san antonio college mtsac

- Agency partnership agreement template form

- Aircraft partnership agreement template form

- Accounting firm partnership agreement template form

Find out other Hot Dip Galvanized

- Sign Nevada Home Repair Contract Easy

- Sign Oregon Construction Contract Template Online

- Sign Wisconsin Construction Contract Template Simple

- Sign Arkansas Business Insurance Quotation Form Now

- Sign Arkansas Car Insurance Quotation Form Online

- Can I Sign California Car Insurance Quotation Form

- Sign Illinois Car Insurance Quotation Form Fast

- Can I Sign Maryland Car Insurance Quotation Form

- Sign Missouri Business Insurance Quotation Form Mobile

- Sign Tennessee Car Insurance Quotation Form Online

- How Can I Sign Tennessee Car Insurance Quotation Form

- Sign North Dakota Business Insurance Quotation Form Online

- Sign West Virginia Car Insurance Quotation Form Online

- Sign Wisconsin Car Insurance Quotation Form Online

- Sign Alabama Life-Insurance Quote Form Free

- Sign California Apply for Lead Pastor Easy

- Sign Rhode Island Certeficate of Insurance Request Free

- Sign Hawaii Life-Insurance Quote Form Fast

- Sign Indiana Life-Insurance Quote Form Free

- Sign Maryland Church Donation Giving Form Later