Stud Welding Wps 2008

What is the stud welding WPS?

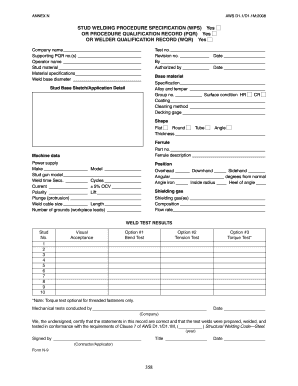

The stud welding procedure specification (WPS) is a critical document that outlines the specific parameters and guidelines for performing stud welding. This document is essential for ensuring consistency and quality in the welding process. It includes details such as the type of materials to be welded, the welding technique to be used, and the qualifications required for the welders. The WPS serves as a reference for both the welding personnel and inspectors, ensuring that all procedures adhere to industry standards and regulations.

Key elements of the stud welding WPS

A comprehensive stud welding WPS includes several key elements that ensure effective and safe welding practices. These elements typically encompass:

- Base materials: Specifications of the materials being welded, including their grades and thicknesses.

- Welding process: The specific stud welding technique to be employed, such as drawn arc or short cycle.

- Welding parameters: Details on voltage, current, and travel speed that must be maintained during the welding process.

- Preheat and interpass temperatures: Requirements for temperature control to prevent material distortion or cracking.

- Welder qualifications: Documentation of the necessary certifications and skills required for welders to perform the task.

Steps to complete the stud welding WPS

Completing a stud welding WPS involves several important steps to ensure compliance with industry standards. The process typically includes:

- Gathering information: Collect data on the materials, welding techniques, and equipment to be used.

- Drafting the WPS: Create a detailed document that outlines all necessary parameters and guidelines.

- Review and approval: Submit the WPS for review by qualified personnel or inspectors to ensure it meets all regulatory requirements.

- Implementation: Train welders on the specifics of the WPS and ensure they understand the procedures outlined.

- Monitoring and revision: Continuously monitor the welding process and make necessary adjustments to the WPS as needed.

Legal use of the stud welding WPS

Utilizing a stud welding WPS is not only a best practice but also a legal requirement in many jurisdictions. Compliance with industry standards, such as those set by the American Welding Society (AWS) and the American National Standards Institute (ANSI), is crucial. The WPS must be adhered to during the welding process to ensure that the work meets safety and quality regulations. Failure to comply with these legal standards can result in penalties and increased liability for the contractor or company involved.

How to obtain the stud welding WPS

Obtaining a stud welding WPS can be accomplished through several avenues. Companies may develop their own WPS tailored to their specific processes and materials, or they can purchase pre-existing templates from reputable welding organizations. Additionally, consulting with welding engineers or certified welding inspectors can provide valuable insights and assistance in creating a compliant WPS. It is essential to ensure that the WPS aligns with current industry standards and regulations.

Examples of using the stud welding WPS

Stud welding WPSs are widely used in various industries, including construction, automotive, and manufacturing. For instance, in the construction industry, a WPS may be utilized for attaching studs to steel beams in a building framework. In automotive manufacturing, it can be applied to weld components of vehicle frames. Each application requires adherence to the specific parameters outlined in the WPS to ensure structural integrity and safety.

Quick guide on how to complete stud welding wps 79647173

Complete Stud Welding Wps effortlessly on any device

Online document management has gained popularity among businesses and individuals. It offers an excellent eco-friendly substitute for traditional printed and signed documents, as you can easily find the correct form and securely store it online. airSlate SignNow provides all the tools necessary for you to create, modify, and eSign your documents quickly without delays. Manage Stud Welding Wps on any platform using the airSlate SignNow Android or iOS applications and enhance any document-centric operation today.

The simplest way to modify and eSign Stud Welding Wps without hassle

- Find Stud Welding Wps and click Get Form to begin.

- Utilize the tools we provide to complete your form.

- Highlight important sections of the documents or redact sensitive information with tools specifically designed for that purpose by airSlate SignNow.

- Create your eSignature using the Sign tool, which takes mere seconds and holds the same legal validity as a traditional wet ink signature.

- Verify the details and click on the Done button to save your modifications.

- Select your preferred delivery method for your form, via email, text message (SMS), or invitation link, or download it to your computer.

No more worries about lost or misplaced documents, tedious form searching, or errors requiring the printing of new document copies. airSlate SignNow fulfills all your document management needs in just a few clicks from any device of your choice. Edit and eSign Stud Welding Wps and ensure outstanding communication at every stage of the form preparation process with airSlate SignNow.

Create this form in 5 minutes or less

Find and fill out the correct stud welding wps 79647173

Create this form in 5 minutes!

How to create an eSignature for the stud welding wps 79647173

How to create an electronic signature for a PDF online

How to create an electronic signature for a PDF in Google Chrome

How to create an e-signature for signing PDFs in Gmail

How to create an e-signature right from your smartphone

How to create an e-signature for a PDF on iOS

How to create an e-signature for a PDF on Android

People also ask

-

What is the importance of the stud welding procedure qualification?

The stud welding procedure qualification is crucial for ensuring that all welding processes comply with industry standards and safety regulations. It guarantees that the welded joints are strong and reliable, which is essential for structural integrity in various applications. Without proper qualification, companies risk incurring additional costs and safety hazards.

-

How can airSlate SignNow help with stud welding procedure qualification documentation?

airSlate SignNow simplifies the management of documents related to stud welding procedure qualification. Our eSignature solution allows you to securely sign and store all necessary forms and certifications electronically. This not only saves time but also ensures easy access and compliance with all documentation requirements.

-

What are the benefits of using airSlate SignNow for stud welding procedure qualification processes?

Using airSlate SignNow for your stud welding procedure qualification processes enhances efficiency and reduces paperwork. You can streamline the qualification process by easily sending documents for approval and tracking the status of signatures in real-time. This leads to faster project completion and increased productivity.

-

Is airSlate SignNow compatible with stud welding procedure qualification software?

Yes, airSlate SignNow integrates seamlessly with various welding procedure qualification software solutions. This compatibility allows you to manage all your documents in one place, ensuring that you can quickly access and update your qualification records. Integration helps maintain an organized workflow while adhering to industry standards.

-

What pricing plans does airSlate SignNow offer for businesses focusing on stud welding procedure qualification?

airSlate SignNow offers flexible pricing plans tailored for businesses needing to manage stud welding procedure qualification documentation. Our plans are designed to provide cost-effective solutions for teams of all sizes, ensuring that you only pay for what you need. You can easily choose a plan that fits your business requirements without sacrificing functionality.

-

Can airSlate SignNow enhance team collaboration during the stud welding procedure qualification?

Absolutely! airSlate SignNow fosters effective team collaboration by enabling multiple users to review and sign stud welding procedure qualification documents simultaneously. With options for assigning tasks, leaving comments, and tracking changes, your team can work together seamlessly to ensure compliance and expedite the qualification process.

-

What security features does airSlate SignNow provide for stud welding procedure qualification documents?

airSlate SignNow prioritizes the security of your stud welding procedure qualification documents with advanced encryption and authentication measures. All files are securely stored and accessible only to authorized users, ensuring the confidentiality and integrity of your critical documents. This protection is vital for maintaining compliance with industry regulations.

Get more for Stud Welding Wps

Find out other Stud Welding Wps

- How To Electronic signature Florida Car Dealer Word

- How Do I Electronic signature Florida Car Dealer Document

- Help Me With Electronic signature Florida Car Dealer Presentation

- Can I Electronic signature Georgia Car Dealer PDF

- How Do I Electronic signature Georgia Car Dealer Document

- Can I Electronic signature Georgia Car Dealer Form

- Can I Electronic signature Idaho Car Dealer Document

- How Can I Electronic signature Illinois Car Dealer Document

- How Can I Electronic signature North Carolina Banking PPT

- Can I Electronic signature Kentucky Car Dealer Document

- Can I Electronic signature Louisiana Car Dealer Form

- How Do I Electronic signature Oklahoma Banking Document

- How To Electronic signature Oklahoma Banking Word

- How Can I Electronic signature Massachusetts Car Dealer PDF

- How Can I Electronic signature Michigan Car Dealer Document

- How Do I Electronic signature Minnesota Car Dealer Form

- Can I Electronic signature Missouri Car Dealer Document

- How Do I Electronic signature Nevada Car Dealer PDF

- How To Electronic signature South Carolina Banking Document

- Can I Electronic signature New York Car Dealer Document