Wps Welding Procedure Forms 2013

What is the WPS Welding Procedure Specification?

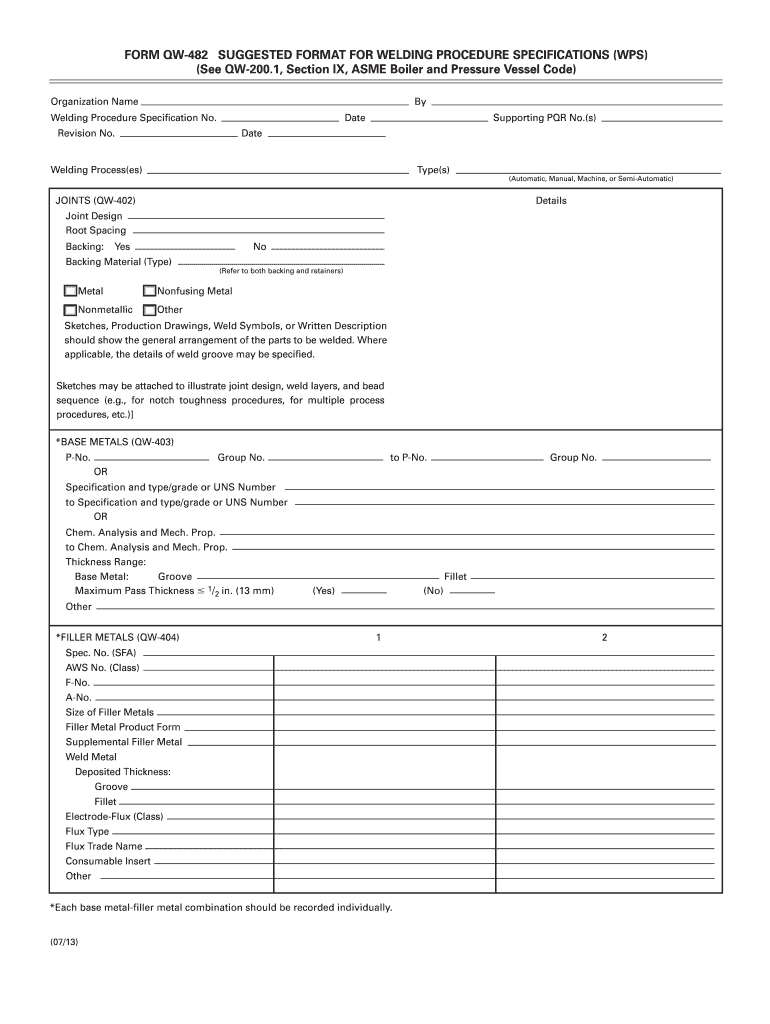

The WPS welding procedure specification is a formal document that outlines the necessary parameters and guidelines for welding operations. It serves as a critical reference for welders, ensuring that all welding activities comply with industry standards and safety regulations. The WPS includes details such as the type of materials to be welded, the welding process to be used, and the specific techniques and settings required for successful welds. This document is essential for maintaining quality control and ensuring that welds meet the necessary structural integrity and performance requirements.

How to Use the WPS Welding Procedure Specification

Using the WPS welding procedure specification involves several key steps. First, ensure that you have the correct WPS for the specific project and materials involved. Next, review the document thoroughly to understand the welding parameters, including preheat and interpass temperatures, filler materials, and welding techniques. During the welding process, refer back to the WPS to confirm compliance with the specified procedures. This practice not only enhances the quality of the welds but also ensures adherence to safety standards and regulatory requirements.

Steps to Complete the WPS Welding Procedure Specification

Completing the WPS welding procedure specification requires a systematic approach. Begin by gathering all necessary information regarding the welding project, including material types and thicknesses. Next, select the appropriate welding process and parameters based on industry standards and project requirements. Document each parameter clearly in the WPS template, ensuring that all details are accurate and comprehensive. After filling out the template, review it for completeness and compliance with relevant codes, such as ASME or AWS standards. Finally, obtain the necessary approvals from qualified personnel before proceeding with the welding operations.

Key Elements of the WPS Welding Procedure Specification

Several key elements are crucial to the WPS welding procedure specification. These include:

- Base Materials: Specifications of the materials being welded, including type and thickness.

- Welding Process: The method to be used, such as MIG, TIG, or stick welding.

- Filler Material: Details about the filler rods or wires, including specifications.

- Welding Parameters: Information on voltage, amperage, travel speed, and preheat temperatures.

- Welding Position: The position in which the welding will be performed, such as flat, horizontal, or vertical.

Legal Use of the WPS Welding Procedure Specification

The legal use of the WPS welding procedure specification is essential to ensure compliance with industry regulations and standards. In the United States, various codes and standards govern welding practices, including those set by the American Welding Society (AWS) and the American Society of Mechanical Engineers (ASME). Adhering to these standards not only helps in achieving quality welds but also protects businesses from liability issues. It is important to keep the WPS updated and ensure that all personnel involved in welding operations are trained to understand and implement the specifications outlined in the document.

How to Obtain the WPS Welding Procedure Specification

Obtaining a WPS welding procedure specification can be done through several avenues. Many organizations develop their own WPS based on specific projects and requirements. Additionally, industry standards organizations, such as AWS and ASME, provide templates and guidelines that can be used to create compliant WPS documents. For businesses looking to streamline the process, utilizing a welding procedure specification template in Excel can simplify the documentation process, allowing for easy customization and compliance with regulatory standards.

Quick guide on how to complete form welding procedure

Discover how to effortlessly navigate the Wps Welding Procedure Forms implementation with this simple guide

Submitting and signNowing documents online is gaining popularity and has become the preferred option for many users. It provides several benefits over traditional printed materials, including ease, time savings, enhanced precision, and security.

With platforms like airSlate SignNow, you can find, modify, sign, enhance, and send your Wps Welding Procedure Forms without the hassle of constant printing and scanning. Follow this concise tutorial to initiate and complete your document.

Follow these steps to obtain and complete Wps Welding Procedure Forms

- Begin by clicking the Get Form button to access your document in our editor.

- Pay attention to the green marker on the left that indicates required fields to ensure none are missed.

- Utilize our advanced tools to comment, modify, sign, secure, and enhance your form.

- Safeguard your document or transform it into a fillable format using the appropriate tab functions.

- Review the document and verify it for any errors or inconsistencies.

- Click DONE to conclude your editing.

- Rename your file or leave it unchanged.

- Choose the storage option you wish to use for keeping your form, send it via USPS, or click the Download Now button to save your document.

If Wps Welding Procedure Forms isn't what you need, feel free to explore our vast selection of pre-uploaded forms that require minimal input to complete. Take a look at our solution today!

Create this form in 5 minutes or less

Find and fill out the correct form welding procedure

FAQs

-

Does it pay off to get welding certifications?

Certification is one way to advance in the field after you complete your welding training. The type of certification a welder seeks usually depends on the industry he or she works in. Most welding certifications must be renewed after a certain length of time. Find out how long some of the most common certifications are good for in this article.When Do Welding Certifications Expire?Welding certifications are usually good for anywhere from six months to three years.Employer Certifications6 MonthsEmployers often test job applicants on the specific welding process they’ll be using in that line of work. Once a welder has proven his or her ability in a certain welding process, metal, position, and thickness range, he or she is considered qualified for the job. If the welder’s test results were documented, then he or she is certified to work in that welding process for six months.American Welding Society – industry standard6 monthsLearn More About Attending TWSIt’s easy – just fill out the form below and we will signNow out with more info!Full NameEmail AddressPhone NumberZip CodeGET STARTEDThe American Welding Society (AWS) offers eight certifications for welders. One of the tests is for the Certified Welder. This certification could prove helpful to welders working in the chemical refinery, structural steel, sheet metal, and petroleum pipeline welding industries.Every six months after you receive this certification you must submit a maintenance form to AWS verifying that you’re still performing the same welding you were initially tested on. Welders who do not submit their maintenance forms within this timeframe must be tested on the procedures again to reinstate their certification in them.

-

What is the procedure to fill out the DU admission form? How many colleges and courses can I fill in?

It's as simple as filling any school admission form but you need to be quite careful while filling for courses ,don't mind you are from which stream in class 12 choose all the courses you feel like choosing,there is no limitations in choosing course and yes you must fill all the courses related to your stream ,additionally there is no choice for filling of college names in the application form .

-

What is the procedure to fill out a 15G form?

Form 15G is the form which you give to Bank requesting them not to deduct tax as the liability is on you to state the interest as your income in returns, now a days banks are deducting TDS directly and hence Form 15G may be void now a days.

-

What is the procedure to fill out the form for re-viva in CSJM University?

It is not difficult. Every year CSJM university organises left over viva examination in university campus. For this contact Registrar University. Fill a form. Submit the fees. Usually such viva takes.place in summer months. You can get contact information from csjm website

-

What is the procedure to fill out the GRE exam application form?

Visit this site The GRE Tests . Register yourself. Fill the form, choose a date and make the payment.You are done.If you need any specific help, you can contact me anytime.Thanks

Create this form in 5 minutes!

How to create an eSignature for the form welding procedure

How to make an electronic signature for your Form Welding Procedure in the online mode

How to make an electronic signature for your Form Welding Procedure in Google Chrome

How to make an electronic signature for signing the Form Welding Procedure in Gmail

How to make an eSignature for the Form Welding Procedure right from your smartphone

How to generate an electronic signature for the Form Welding Procedure on iOS devices

How to create an eSignature for the Form Welding Procedure on Android devices

People also ask

-

What is a welding procedure specification template excel?

A welding procedure specification template excel is a structured document designed to guide welders in the welding process, ensuring quality and consistency. It includes essential information like welding processes, filler materials, and joint design. Utilizing this template helps streamline the welding procedure and maintain industry standards.

-

How can I benefit from using a welding procedure specification template excel?

Using a welding procedure specification template excel offers numerous benefits, including increased efficiency, improved safety, and consistent quality. It provides a clear framework for welders to follow, minimizing errors and enhancing productivity. Overall, it results in higher-quality welds and better compliance with industry standards.

-

Is the welding procedure specification template excel customizable?

Yes, the welding procedure specification template excel is fully customizable to meet your specific project requirements. You can modify sections to include unique specifications or additional instructions pertinent to your welding processes. This flexibility ensures that the template best suits your operational needs.

-

Are there any integration options available for the welding procedure specification template excel?

Our airSlate SignNow platform supports seamless integrations with various software and tools, allowing you to incorporate your welding procedure specification template excel effortlessly. This connectivity ensures that your workflows are efficient and that all documents are easily accessible within your preferred applications.

-

What features should I look for in a welding procedure specification template excel?

When selecting a welding procedure specification template excel, look for features such as detailed procedural guidelines, compliance checklists, and easy-to-read formatting. Additionally, ensure that the template allows for version control and easy updates, enabling you to keep all information relevant and accurate as standards evolve.

-

How do I create a welding procedure specification template excel?

Creating a welding procedure specification template excel can be done by gathering essential details about your welding process and inputting them into an organized spreadsheet format. Begin by defining the welding processes, materials, and parameters, and then structure the document for clarity and ease of use. Alternatively, you can utilize pre-built templates available through airSlate SignNow for even quicker setup.

-

Can I access my welding procedure specification template excel on mobile devices?

Absolutely! With airSlate SignNow, your welding procedure specification template excel is fully accessible on mobile devices. This feature allows team members to review, edit, and sign documents on the go, providing flexibility and convenience for busy professionals in the field.

Get more for Wps Welding Procedure Forms

Find out other Wps Welding Procedure Forms

- Sign Washington Sports Last Will And Testament Free

- How Can I Sign Ohio Real Estate LLC Operating Agreement

- Sign Ohio Real Estate Quitclaim Deed Later

- How Do I Sign Wisconsin Sports Forbearance Agreement

- How To Sign Oregon Real Estate Resignation Letter

- Can I Sign Oregon Real Estate Forbearance Agreement

- Sign Pennsylvania Real Estate Quitclaim Deed Computer

- How Do I Sign Pennsylvania Real Estate Quitclaim Deed

- How Can I Sign South Dakota Orthodontists Agreement

- Sign Police PPT Alaska Online

- How To Sign Rhode Island Real Estate LLC Operating Agreement

- How Do I Sign Arizona Police Resignation Letter

- Sign Texas Orthodontists Business Plan Template Later

- How Do I Sign Tennessee Real Estate Warranty Deed

- Sign Tennessee Real Estate Last Will And Testament Free

- Sign Colorado Police Memorandum Of Understanding Online

- How To Sign Connecticut Police Arbitration Agreement

- Sign Utah Real Estate Quitclaim Deed Safe

- Sign Utah Real Estate Notice To Quit Now

- Sign Hawaii Police LLC Operating Agreement Online