Ensuring Digital Signature Licitness for Toll Manufacturing Agreement in United States

- Quick to start

- Easy-to-use

- 24/7 support

Simplified document journeys for small teams and individuals

We spread the word about digital transformation

Why choose airSlate SignNow

-

Free 7-day trial. Choose the plan you need and try it risk-free.

-

Honest pricing for full-featured plans. airSlate SignNow offers subscription plans with no overages or hidden fees at renewal.

-

Enterprise-grade security. airSlate SignNow helps you comply with global security standards.

Your complete how-to guide - digital signature licitness for toll manufacturing agreement in united states

Digital Signature Licitness for Toll Manufacturing Agreement in United States

In the United States, ensuring the digital signature licitness for a Toll Manufacturing Agreement is crucial. By utilizing airSlate SignNow, businesses can streamline this process efficiently.

Steps to Utilize airSlate SignNow:

- Launch the airSlate SignNow web page in your browser.

- Sign up for a free trial or log in.

- Upload a document you want to sign or send for signing.

- If you're going to reuse your document later, turn it into a template.

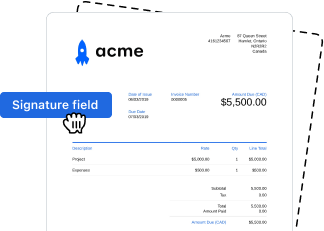

- Open your file and make edits: add fillable fields or insert information.

- Sign your document and add signature fields for the recipients.

- Click Continue to set up and send an eSignature invite.

airSlate SignNow empowers businesses to send and eSign documents with an easy-to-use, cost-effective solution. It offers great ROI, easy scalability for SMBs and Mid-Market, transparent pricing with no hidden fees, and superior 24/7 support for all paid plans.

Experience the benefits of airSlate SignNow for efficient document management and eSigning processes today!

How it works

Rate your experience

What is the toll manufacturing definition

Toll manufacturing refers to a process where one company (the client) contracts another company (the toll manufacturer) to produce products on its behalf. The client provides the raw materials, while the toll manufacturer handles the production process. This arrangement allows businesses to leverage the expertise and facilities of the toll manufacturer without the need for significant capital investment in production infrastructure. It is commonly used in industries such as pharmaceuticals, chemicals, and food processing.

How to use the toll manufacturing definition

Understanding the toll manufacturing definition is essential for businesses looking to outsource production. Companies should first assess their production needs and identify potential toll manufacturers that align with their industry requirements. Once a suitable partner is found, businesses can negotiate terms, including pricing, production timelines, and quality standards. This definition serves as a foundational understanding for establishing a contract that outlines the responsibilities of both parties involved in the manufacturing process.

Steps to complete the toll manufacturing definition

To effectively utilize the toll manufacturing definition, businesses should follow these steps:

- Identify production requirements, including volume and specifications.

- Research and select potential toll manufacturers based on their capabilities and reputation.

- Engage in discussions to clarify expectations, including timelines and costs.

- Draft a contract that clearly outlines the terms of the toll manufacturing agreement.

- Monitor the production process to ensure compliance with agreed standards.

Key elements of the toll manufacturing definition

Several key elements define the toll manufacturing process:

- Raw Materials: The client provides all necessary materials for production.

- Production Process: The toll manufacturer is responsible for the actual manufacturing.

- Quality Control: Both parties must agree on quality standards and inspection processes.

- Intellectual Property: Contracts should address ownership of proprietary information and processes.

- Pricing Structure: Clear terms regarding costs and payment schedules are essential.

Legal use of the toll manufacturing definition

When engaging in toll manufacturing, it is crucial to ensure that all agreements comply with applicable laws and regulations. This includes understanding intellectual property rights, product liability, and any industry-specific regulations. A well-drafted contract should outline the legal responsibilities of each party, including liability for defects and compliance with safety standards. Consulting with legal professionals can help businesses navigate these complexities effectively.

Security & Compliance Guidelines

Security and compliance are vital in toll manufacturing agreements. Businesses should ensure that toll manufacturers adhere to industry standards and regulations, particularly regarding data protection and product safety. Implementing secure electronic workflows, such as using airSlate SignNow for contract management and eSigning, can enhance security by providing a clear audit trail and ensuring that sensitive information is handled appropriately. Regular audits and compliance checks can further mitigate risks associated with outsourcing production.

-

Best ROI. Our customers achieve an average 7x ROI within the first six months.

-

Scales with your use cases. From SMBs to mid-market, airSlate SignNow delivers results for businesses of all sizes.

-

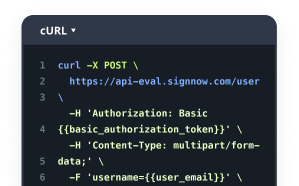

Intuitive UI and API. Sign and send documents from your apps in minutes.

FAQs

-

What is the toll manufacturing definition?

The toll manufacturing definition refers to a business arrangement where one company (the toll manufacturer) produces goods for another company (the client) using the client's raw materials. This allows businesses to leverage specialized manufacturing capabilities without investing in their own facilities.

-

What are the benefits of using toll manufacturing?

Using toll manufacturing can signNowly reduce production costs and time. It allows companies to focus on their core competencies while outsourcing manufacturing to experts, ensuring high-quality production without the overhead of maintaining a manufacturing facility.

-

How does toll manufacturing impact pricing?

The pricing in toll manufacturing is typically based on the volume of production and the specific services provided. Understanding the toll manufacturing definition helps businesses negotiate better terms and ensure they are getting value for their investment in outsourced production.

-

What industries commonly use toll manufacturing?

Toll manufacturing is prevalent in various industries, including pharmaceuticals, chemicals, and food production. Companies in these sectors often seek specialized manufacturing processes that align with the toll manufacturing definition to enhance efficiency and product quality.

-

Can toll manufacturing be integrated with other business processes?

Yes, toll manufacturing can be seamlessly integrated with other business processes such as supply chain management and logistics. Understanding the toll manufacturing definition allows businesses to create a cohesive strategy that enhances overall operational efficiency.

-

What features should I look for in a toll manufacturing partner?

When selecting a toll manufacturing partner, look for features such as quality control measures, flexibility in production volumes, and expertise in your specific industry. A clear understanding of the toll manufacturing definition will help you assess potential partners effectively.

-

How can I ensure quality in toll manufacturing?

To ensure quality in toll manufacturing, establish clear quality standards and maintain open communication with your manufacturing partner. Regular audits and performance reviews can help uphold the standards outlined in the toll manufacturing definition.

Join over 28 million airSlate SignNow users

Get more for digital signature licitness for toll manufacturing agreement in united states

- Unlock the Secret to Changing Your Signature in Office ...

- Streamline Your Workflow: Learn How to Edit Email ...

- How to Change Your Digital Signature in Adobe with ...

- How to Change Your Email Signature in Outlook Online ...

- Discover How to Change Your Name in Email Signature ...

- Unlock the Secret to Changing Your Signature in Outlook ...

- Discover How to Change the Signature on Outlook 365 ...

- Discover How to Change the Signature in PDF ...