Create Your Advance Bill Format for Facilities Effortlessly

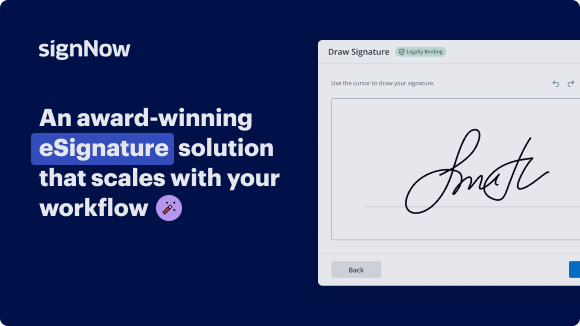

See airSlate SignNow eSignatures in action

Choose a better solution

Move your business forward with the airSlate SignNow eSignature solution

Add your legally binding signature

Integrate via API

Send conditional documents

Share documents via an invite link

Save time with reusable templates

Improve team collaboration

Our user reviews speak for themselves

airSlate SignNow solutions for better efficiency

Why choose airSlate SignNow

-

Free 7-day trial. Choose the plan you need and try it risk-free.

-

Honest pricing for full-featured plans. airSlate SignNow offers subscription plans with no overages or hidden fees at renewal.

-

Enterprise-grade security. airSlate SignNow helps you comply with global security standards.

Advance bill format for facilities

Creating an advance bill format for facilities has never been easier, thanks to the efficiency of airSlate SignNow. This powerful tool streamlines the process of eSigning documents, allowing businesses to manage their billing and agreements seamlessly. With its user-friendly platform, you'll not only save time but also reduce paperwork signNowly while ensuring compliance.

Advance bill format for facilities steps

- Navigate to the airSlate SignNow website using your preferred browser.

- Register for a complimentary trial or access your existing account.

- Select a document intended for signature or to send out for signing.

- If you plan to use this document on future occasions, transform it into a reusable template.

- Open the document to modify it by adding fields for input or other essential information.

- Complete your document by adding your own signature, and designate areas for additional signatories.

- Press 'Continue' to finalize the setup and forward an eSignature invitation.

airSlate SignNow provides numerous advantages for businesses, making document management efficient and cost-effective. Expect a strong return on investment with a comprehensive feature set tailored to fit your budget. Its design caters specifically to small to mid-sized businesses, providing straightforward scalability without any hidden costs.

With dedicated 24/7 support available for all subscription plans, help is just a click away. Start optimizing your document signing processes today!

How it works

Get legally-binding signatures now!

FAQs

-

What is an advance bill format for facilities?

An advance bill format for facilities is a structured document that outlines expected charges for services or products provided by a facility, sent to the customer before the actual billing occurs. This format is essential for transparency and allows customers to understand the costs associated with their services upfront. -

How can airSlate SignNow help in creating an advance bill format for facilities?

airSlate SignNow simplifies the process of creating an advance bill format for facilities by providing customizable templates that can be easily filled and eSigned. This ensures a quick turnaround and aids in maintaining consistent billing communication with customers. -

What are the pricing options for using airSlate SignNow for advance billing?

airSlate SignNow offers various pricing plans designed to accommodate businesses of all sizes. Whether you're a small facility or a large organization, you can select a plan that suits your needs while easily managing advance bill format for facilities. -

Can I integrate airSlate SignNow with other software for handling advance billing?

Yes, airSlate SignNow offers seamless integrations with various ERPs and accounting software, making it easier to manage your advance bill format for facilities. This reduces manual work and ensures your billing processes are efficient and accurate. -

What are the main benefits of using airSlate SignNow for advance billing?

Using airSlate SignNow for advance billing enhances efficiency and accuracy while reducing the time spent on administrative tasks. Additionally, eSigning features expedite the billing process, ensuring that facilities receive timely approvals and payments. -

Is it easy to customize advance bill formats within airSlate SignNow?

Absolutely! airSlate SignNow offers a user-friendly interface that allows you to easily customize your advance bill format for facilities to match your branding and specific service details, ensuring that every bill accurately reflects your business. -

How does airSlate SignNow ensure the security of my advance billing documents?

airSlate SignNow prioritizes security with advanced encryption and compliance with industry standards. All advance bill formats for facilities are securely stored, ensuring that sensitive business and customer information is protected throughout the transaction process.

What active users are saying — advance bill format for facilities

Get more for advance bill format for facilities

- Top Form Creation Software for Technology Industry

- Form Creation Software for Animal Science

- Form Creation Software for Banking

- Form Creation Software for Hospitality

- Form Creation Software for Travel Industry

- Form Creation Software for Hightech

- Form Creation Software for Manufacturing

- Form Creation Software for Building Services

Find out other advance bill format for facilities

- Explore Your Digital Signature – Questions Answered: ...

- Unlock the Power of eSignature: how do I do a signature ...

- Start Your eSignature Journey: how do I do my signature ...

- Try Seamless eSignatures: how do I eSign a Word ...

- Start Your eSignature Journey: how do I get my ...

- Explore Your Digital Signature – Questions Answered: ...

- Explore Your Digital Signature – Questions Answered: ...

- Explore Your Digital Signature – Questions Answered: ...

- Find All You Need to Know: how do I sign a PDF form ...

- Find All You Need to Know: how do I sign a PDF online?

- Start Your eSignature Journey: how do I sign my ...

- Enjoy Flexible eSignature Workflows: how do I sign ...

- Explore Your Digital Signature – Questions Answered: ...

- Explore Your Digital Signature – Questions Answered: ...

- Start Your eSignature Journey: how do you do a ...

- Start Your eSignature Journey: how do you do an online ...

- Explore Your Digital Signature – Questions Answered: ...

- Find All You Need to Know: how do you sign a PDF form ...

- Explore Your Digital Signature – Questions Answered: ...

- Explore Your Digital Signature – Questions Answered: ...