FF 10/96©

STP7010-1

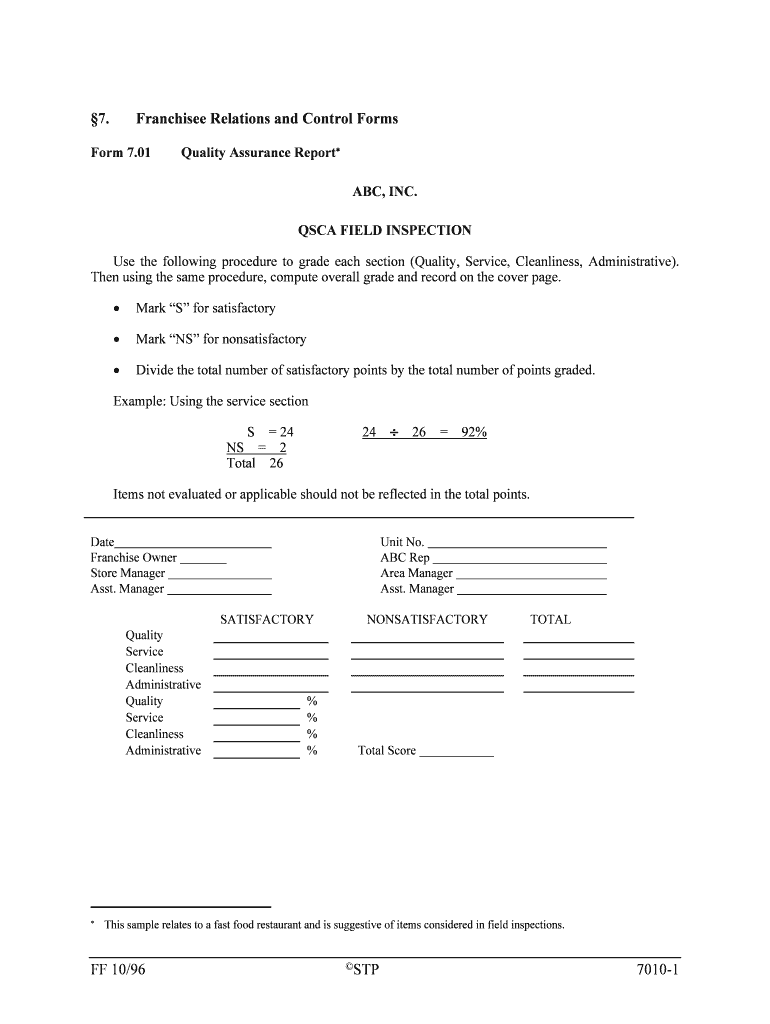

§7.Franchisee Relations and Control FormsForm 7.01Quality Assurance Report� ABC, INC. QSCA FIELD INSPECTION Use the following procedure to grade each section (Quality, Service, Cleanliness, Administrative).

Then using the same procedure, compute overall grade and record on the cover page.�Mark “S” for satisfactory�Mark “NS” for nonsatisfactory�Divide the total number of satisfactory points by the total number of points graded.Example: Using the service section

S = 24 24 � 26 = 92%NS = 2Total 26 Items not evaluated or applicable should not be reflected in the total points.DateUnit No. Franchise Owner ABC Rep Store Manager Area Manager Asst. Manager Asst. Manager SATISFACTORYNONSATISFACTORYTOTALQualityServiceCleanlinessAdministrativeQuality%Service%Cleanliness%Administrative%Total Score �

This sample relates to a fast food restaurant and is suggestive of items considered in field inspections.

Form 7.017010-2©

STPFF 10/96Grill SNS1.Grill thermostat working properly at correct settings . . . . . . . . 2.Meat stored, rotated properly . . . . . . . . . . . . . . . . . . . . . . . . . .3.Meat placed on grill properly using accurate projections . . . . . 4.Salt and pepper mixed, stored, and used properly . . . . . . . . . . .5.Timers used and working properly . . . . . . . . . . . . . . . . . . . . . .6.Meat turned and cooked properly with holding times recorded

and observed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.Meat check properly with holding times recorded and observed 8.Correct amount of cheese out and melted on patties properly . . 9.Grill area kept clean for customer view . . . . . . . . . . . . . . . . . . Total Sandwiches SNS 10.Buns properly stored and rotated . . . . . . . . . . . . . . . . . . . . . . . 11.Condiment pans full, rotated, and clean . . . . . . . . . . . . . . . . . .12.Condiments placed on buns correctly, evenly, and in proper amounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.Bun toaster working with correct temperature and height . . . . . 14.Sandwich placed on toaster properly using toaster strap with 10-

second timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15.Sandwich wrapped and marked properly . . . . . . . . . . . . . . . . . 16.Toaster and board area kept clean for customer view . . . . . . . . Total French Fries SNS 17.Fryer, timer and heating elements working properly . . . . . . . . . 18.Correct amount of fries properly stored . . . . . . . . . . . . . . . . . . 19.Shortening level correct, properly skimmed and clean . . . . . . . 20.Fry baskets filled, fries cooked properly using accurate

projections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21.Fries drained, placed in bin and salted correctly . . . . . . . . . . . . 22.Fries rotated and boxed properly with correct 3-oz portion . . . . 23.Holding times recorded and observed. Discarded after 7

minutes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Total Prepped Products SNS 24.Accurate tomato projection; prepped and stored properly . . . . . 25.Accurate onion projection; prepped and stored properly . . . . . . 26.Accurate bacon projection; cooked and stored properly . . . . . . 27.Mayonnaise stored properly . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.Lettuce crisp, green and covered . . . . . . . . . . . . . . . . . . . . . . . 29.Cheese wrapped and stored properly . . . . . . . . . . . . . . . . . . . . 30.Back-up stock adequate for projected sales. . . . . . . . . . . . . . . . Total

Form 7.01 FF 10/96©

STP7010-3Soft Drinks SNS 31.Drink brix accurate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.Portion controls accurate . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33.Drawn Cola 40��or less . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34.Line CO2 pressure 90-100 PSI . . . . . . . . . . . . . . . . . . . . . . . . .35.CO2 tank 400 PSI or more . . . . . . . . . . . . . . . . . . . . . . . . . . . .36.CO2 valve open all the way . . . . . . . . . . . . . . . . . . . . . . . . . . .37.CO2 tanks tied securely . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38.Dispenser head and out cone clean . . . . . . . . . . . . . . . . . . . . . .39.Cold plate covered with ice . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.Correct ice portion in cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41.Cup dispenser working properly . . . . . . . . . . . . . . . . . . . . . . . .42.Drink lid flavor tabs used . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.Bag in the box stored properly . . . . . . . . . . . . . . . . . . . . . . . . .44.Multiple bag-in-box connected used . . . . . . . . . . . . . . . . . . . . Total Comments ____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Form 7.017010-4©

STPFF 10/96

SERVICE SECTION

Cashier/Window SNS1.Respond to customer immediately with proper greeting (Hi, may

I take your order please?) . . . . . . . . . . . . . . . . . . . . . . . . . . 2.Order taking procedures correct (ask Tomato?) . . . . . . . . . . . . . 3.Suggestive selling (fries, soft drinks) . . . . . . . . . . . . . . . . . . . . . 4.Order repeated to customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.Order called to crew . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.Order ticket and receipt posted properly . . . . . . . . . . . . . . . . . . 7.Money handled properly, change counted back . . . . . . . . . . . . . 8.Double check order, customer thanked and asked to come back . 9.Order completed within service guidelines (1 minute) .. . . . . . . . 10.Window area clean and neat . . . . . . . . . . . . . . . . . . . . . . . . . . . .11.Opens and closes window smoothly . . . . . . . . . . . . . . . . . . . . . . 12.Courtesy; uses ma’am, sir, please . . . . . . . . . . . . . . . . . . . . . . . .13.Enthusiastic and smiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Total Bagging Procedures SNS 14.Soft drinks bagged with proper amount of straws . . . . . . . . . . . . 15.Burgers and fries properly bagged . . . . . . . . . . . . . . . . . . . . . . . 16.Accurate number of napkins and condiments . . . . . . . . . . . . . . . 17.Order ticket and receipt bagged . . . . . . . . . . . . . . . . . . . . . . . . . 18.Proper size bag used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19.Bags clean, crisp, and properly folded . . . . . . . . . . . . . . . . . . . . Total Store Personnel SNS 20.Employees properly groomed . . . . . . . . . . . . . . . . . . . . . . . . . . . 21.Employees in correct uniform . . . . . . . . . . . . . . . . . . . . . . . . . . 22.Employees in proper position; teamwork apparent . . . . . . . . . . . 23.Employees demonstrates courtesy, hustling and enthusiastic . . . 24.Employees are well trained, professional and businesslike . . . . . 25.Adequate number of employees for the amount of business . . . . 26.Ample employees on schedule for overall storage coverage . . . . Total Comments ____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Form 7.01 FF 10/96©

STP7010-5

CLEANLINESS

Outside SNS1.Lot free of litter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.Lot striping easy to see . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.Lot surface good . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.Surrounding area free of litter . . . . . . . . . . . . . . . . . . . . . . . . . . 5.Directional signs clean, in good repair . . . . . . . . . . . . . . . . . . . .6.Banners clean, hung properly, in good repair . . . . . . . . . . . . . . . 7.Outside lights working properly . . . . . . . . . . . . . . . . . . . . . . . . . 8.Menu boards clean with proper insert, in good repair . . . . . . . . . 9.Dumpster area clean and neat, no trash visible, doors closed . . . 10.Corral clean and neat, no trash visible . . . . . . . . . . . . . . . . . . . . 11.Grease tank lid closed, clean . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.Concrete areas reflect a good maintenance program, drive-thru

pad clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.Outside of building in good repair, paint clean, fresh looking . . . 14.Exterior structures (fencing, guardrails, etc.) clean and in good

repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15.All windows clean, tracks clean and in good repair - no clutter

visible to customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16.Awnings in good repair, clean . . . . . . . . . . . . . . . . . . . . . . . . . . 17.Steps clean, in good repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18.Ice maker clean, working properly . . . . . . . . . . . . . . . . . . . . . . .19.Fry area clean-walls, bins, pans and utensils . . . . . . . . . . . . . . . . 20.Filtering unit clean, correct bulb, in good repair . . . . . . . . . . . . . 21.Heat lamps clean, correct bulb, in good repair . . . . . . . . . . . . . . 22.Grills, clean top and bottom, in good repair, no missing parts -

area clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23.Sinks have drain covers clean, hot water 140 mins., faucets work,

hand soap and towels available . . . . . . . . . . . . . . . . . . . . . 24.Hoods and filters clean, exhaust working properly, drip pan in

place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.Fire extinguishing equipment manual level labeled, inspection

tags current. Hand extinguishers properly stored and charged . . 26.Tomato slicer clean, works . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27.Utensils clean, stored properly . . . . . . . . . . . . . . . . . . . . . . . . . .28.Ketchup vol-pack clean, working . . . . . . . . . . . . . . . . . . . . . . . . 29.Stock racks clean, organized, stock off of floor . . . . . . . . . . . . . 30.Chemicals not stored over food prep. areas . . . . . . . . . . . . . . . . 31.First aid kit clean, properly stocked . . . . . . . . . . . . . . . . . . . . . .32.Desk area neat, not full of clutter . . . . . . . . . . . . . . . . . . . . . . . . 33.Walls, baseboards, corners clean . . . . . . . . . . . . . . . . . . . . . . . . 34.Air vents clean and in good repair . . . . . . . . . . . . . . . . . . . . . . . 35.Ceilings clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36.Light work-covers clean and in place . . . . . . . . . . . . . . . . . . . . .37.Coolers clean, inside doors, hinges, and gaskets clean. Temp.

32� - 38� - lights work, thermometers in place, stock rotated . . .38.Freezers clean inside. Doors, hinges, and gaskets clean,

Temp. 10� to -10�. Lights work, thermometers in place, stock

Form 7.017010-6©

STPFF 10/96rotated .

Form 7.01 FF 10/96©

STP7010-739.Ice maker, cooler, freezer, condensers clean, filters checked

regularly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.Electric panels labeled for emergency . . . . . . . . . . . . . . . . . . . . 41.Mop, broom, and buckets clean and stored properly . . . . . . . . . . 42.Licenses and permits posted properly . . . . . . . . . . . . . . . . . . . . . Total Comments ____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Form 7.017010-8©

STPFF 10/96

ADMINISTRATIVE SECTION

Cash Handling SNS1.Adequate change for store . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.Weekend change handled properly . . . . . . . . . . . . . . . . . . . . . . . . 3.Change fund secured in locked safe . . . . . . . . . . . . . . . . . . . . . . . .4.Hourly cash drops made properly . . . . . . . . . . . . . . . . . . . . . . . . . 5.Deposits correct, legible, proper validation date . . . . . . . . . . . . . . 6.Banking procedures followed . . . . . . . . . . . . . . . . . . . . . . . . . . . . Total Record Keeping SNS7.Registers working properly, readings legible and correct . . . . . . . . 8.Proper procedures for voids/overrings followed . . . . . . . . . . . . . . . 9.Sales reports complete, legible . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.Weekly inventories correct, invoices logged properly . . . . . . . . . . 11.Weekly paperwork complete, legible . . . . . . . . . . . . . . . . . . . . . . .12.Filing system complete, organized . . . . . . . . . . . . . . . . . . . . . . . . .13.Personnel files complete, extra forms in stock . . . . . . . . . . . . . . . . 14.Payroll procedures handled properly . . . . . . . . . . . . . . . . . . . . . . . 15.Sales and labor forecast complete and tracked . . . . . . . . . . . . . . . . 16.Weekly action plan, Monthly Operations Focus posted . . . . . . . . . Total Comments ____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

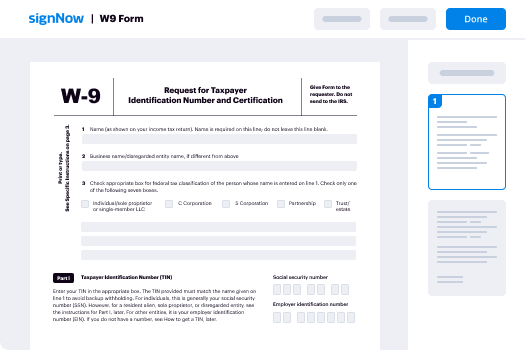

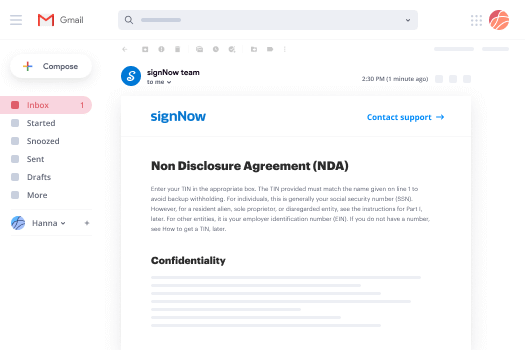

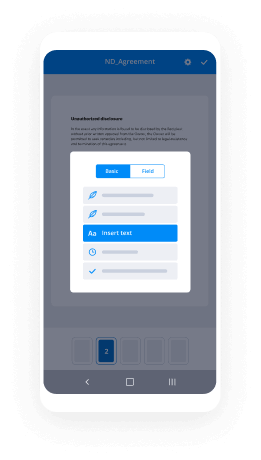

Valuable suggestions for preparing your ‘7franchisee Relations And Control Forms’ online

Are you fed up with the inconvenience of managing paperwork? Look no further than airSlate SignNow, the premier eSignature platform for individuals and small-to-medium businesses. Wave farewell to the monotonous routine of printing and scanning documents. With airSlate SignNow, you can easily finalize and sign documents online. Take advantage of the extensive features integrated into this user-friendly and cost-effective platform and transform your document management approach. Whether you need to sign forms or gather eSignatures, airSlate SignNow takes care of everything smoothly, with just a few clicks.

Follow this comprehensive guide:

- Sign in to your account or initiate a free trial with our service.

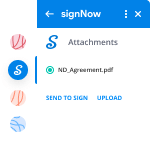

- Click +Create to upload a file from your device, cloud storage, or our form library.

- Open your ‘7franchisee Relations And Control Forms’ in the editor.

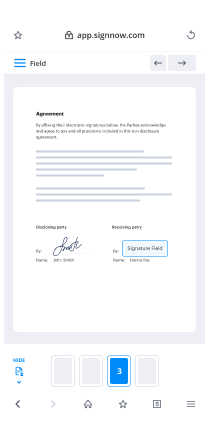

- Click Me (Fill Out Now) to set up the document on your end.

- Add and allocate fillable fields for others (if required).

- Proceed with the Send Invite options to solicit eSignatures from others.

- Download, print your copy, or convert it into a reusable template.

No need to worry if you require collaboration with colleagues on your 7franchisee Relations And Control Forms or need to send it for notarization—our solution provides all the tools necessary to accomplish such tasks. Sign up with airSlate SignNow today and elevate your document management to a new level!