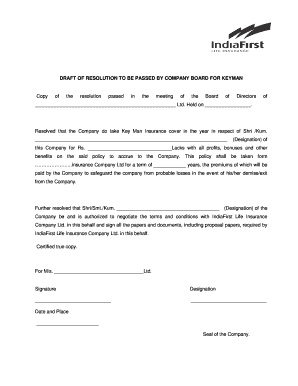

Fill and Sign the Board Resolution for Insurance Policy Form

Useful suggestions for finishing your ‘Board Resolution For Insurance Policy’ online

Are you weary of the burden of handling paperwork? Look no further than airSlate SignNow, the premier electronic signature solution for both individuals and organizations. Bid farewell to the lengthy routine of printing and scanning documents. With airSlate SignNow, you can smoothly finalize and sign papers online. Utilize the powerful tools integrated into this user-friendly and affordable platform and transform your document management approach. Whether you need to approve forms or collect eSignatures, airSlate SignNow manages everything seamlessly, requiring only a few clicks.

Adhere to this comprehensive guide:

- Sign in to your account or sign up for a complimentary trial of our service.

- Tap +Create to upload a file from your device, cloud storage, or our template library.

- Open your ‘Board Resolution For Insurance Policy’ in the editor.

- Click Me (Fill Out Now) to finalize the document on your end.

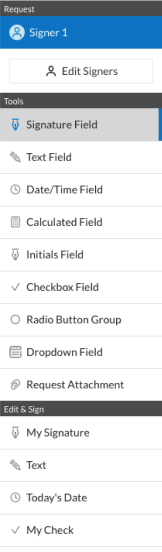

- Add and designate fillable fields for others (if needed).

- Proceed with the Send Invite settings to solicit eSignatures from others.

- Save, print your copy, or convert it into a reusable template.

Don’t fret if you need to collaborate with others on your Board Resolution For Insurance Policy or send it for notarization—our solution provides everything you require to achieve such goals. Register with airSlate SignNow today and take your document management to a new height!

FAQs

-

What is a Board Resolution For Insurance Policy?

A Board Resolution For Insurance Policy is a formal document created by a company's board of directors, authorizing specific individuals to manage and execute insurance policies on behalf of the company. This resolution ensures that the insurance policy decisions align with the company's goals and are legally binding.

-

How can airSlate SignNow help with creating a Board Resolution For Insurance Policy?

airSlate SignNow provides an intuitive platform for drafting, signing, and managing your Board Resolution For Insurance Policy. With our easy-to-use tools, you can create, customize, and securely send your resolutions for electronic signatures, streamlining the approval process.

-

Is there a cost associated with using airSlate SignNow for Board Resolutions?

Yes, airSlate SignNow offers various pricing plans tailored to fit different business needs. You can choose a plan based on the number of users and the features required for managing your Board Resolution For Insurance Policy efficiently.

-

What features does airSlate SignNow offer for managing Board Resolutions?

airSlate SignNow includes features such as customizable templates, electronic signatures, document tracking, and secure storage. These tools simplify the process of creating and managing Board Resolution For Insurance Policy, ensuring your documents are always organized and accessible.

-

Can I integrate airSlate SignNow with other tools for my Board Resolution For Insurance Policy?

Absolutely! airSlate SignNow offers seamless integrations with popular business tools like Google Drive, Salesforce, and more. This allows you to easily incorporate your Board Resolution For Insurance Policy into your existing workflow, enhancing productivity.

-

What are the benefits of using airSlate SignNow for Board Resolutions?

Using airSlate SignNow for your Board Resolution For Insurance Policy enhances efficiency and compliance. With electronic signatures and easy document management, you can reduce turnaround times and ensure that your resolutions are legally binding and easily accessible.

-

Is airSlate SignNow secure for handling Board Resolutions?

Yes, airSlate SignNow prioritizes security and compliance. Our platform uses encryption and robust security measures to protect your documents, including Board Resolution For Insurance Policy, ensuring that sensitive information remains confidential.

Related searches to board resolution for insurance policy form

Find out other board resolution for insurance policy form

- Close deals faster

- Improve productivity

- Delight customers

- Increase revenue

- Save time & money

- Reduce payment cycles