Hydraulic

Design

f Stilling

Basin

Channel

Outlets

�Research

Report

No. 24

l

A WATER RESOURCES

TECHNICAL

PUBLICATION

Hydraulic

Designof

StillingBasinfor Pipe

or Channel

Outlets

Basin VI in the

Bureauof Reclamation

designation

By G. L. Beichley

Division of Research

Denver, Colorado

UNITED

STATES

DEPARTMENT

BUREAU

OF THE

OF RECLAMATION

INTERIOR

�As the Nation’s

principal

conservation

agency, the Department

of the Interior

has

responsibility

for most of our nationally

owned public lands and natural

resources.

This includes fostering

the wisest use of our land and water resources, protecting

our fish and wildlife,

preserving

the environmental

and cultural

values of our

national

parks and historical

places, and providing for the enjoyment

of life through

outdoor recreation.

The Department

assesses our energy and mineral resources and

works to assure that their development

is in the best interests

of all our people.

The Department

also has a major responsibility

for American

Indian

reservation

communities

and for people who live in Island

Territories

under

U.S. administration.

First Printing: 1971

Revised Reprint: 1976

Revised Reprint: 1978

UNITED

STATES

GOVERNMENT

DENVER:

PRINTING

1978

OFFICE

�PREFACE

High-energy

forces in flowing or falling water must

be contained

or dissipated

to prevent

damaging

scour

or erosion of downstream

channels.

Various

means for energy dissipation

are employed

at hydraulic

installations.

Stilling

basins are among

the most common.

Ten types, I through

X, are used

by the Bureau of Reclamation.

(The Roman numeral

classifications

are internal

Bureau designations.)

The

variety of operating

conditions

necessitates

this wide

range of stilling

basin designs.

Criteria

for design of the 10 stilling basin types were

first summarized

in Engineering

Monograph

No. 25,

published

in 1958

and revised

in 1963.

The

monograph

was based on a series of earlier papers and

laboratory

reports.

This study of the type VI stilling basin, which is used

for pipe or open channel

outlets,

was made to

standardize

and modify

existing and previously

used

procedures

in the design of this impact stilling basin.

Development

of the type VI short impact-type

basin

originated

with a need for some 50 or more stilling

structures

on a single irrigation

project.

Relatively

small basins providing

of a tailwater

curve

required.

The information

resource centers,

industrial

irrigation

Included

energy dissipation

independent

or tailwater

of any kind were

in this report is intended

for water

government

agencies, municipal

and

water

systems

in this

operators,

designers.

publication

and

hydraulics

and

is an informative

abstract

with a list of descriptors,

or keywords,

and

identifiers.

The abstract

was prepared

as part of the

Bureau

of Reclamation’s

program

of indexing

and

retrieving

the literature

of water

resources

development.

The descriptors

were selected from the

Thesaurus

of Descriptors,

which

is the Bureau’s

standard

for listing of keywords.

��CONTENTS

Page

...

Preface

.....................................................

Introduction

.................................................

..................................................

The Models

..............................................

The Investigation

111

1

3

5

Standardization

of the basin dimensions

in terms of basin width

...........................

Standardization

of the basin flow entrance

Standardization

of the basin size ..................................

.....................

Standardization

of the entrance

velocity

limitation

.......................

Standardization

of the discharge channel riprap

.....................................

Tailwater

recommendations

Performance

evaluation

........................................

Alternate

end sill design ........................................

....................................

Debris barrier and trashrack

..........................................

Self-cleaning

feature

............

.............................

Design Conclusions

and Recommendations

...................................................

References

. ..... ..... .... ...... .... ..... .... ...... ... ...... ...

Abstract

5

5

7

8

19

19

19

24

24

24

27

29

31

TABLE

Page

Table

1

Design specifications

for the outlet

Picacho North and South Dams

works structure

at

. . . . . . . . . . . . . . . . . . . . . . . . . . .

25

FIGURES

Page

Figure

1

2

3

4

5

6

7

8

9

10

General design of the type VI impact stilling basin

. . .

Test flows with uncontrolled

tailwater

. . . . . . . . . . . .

Test flows with controlled

tailwater

. . . . . . . . . . . . . .

Entrance

pipe flowing full with uncontrolled

tailwater

in

2.4-foot

(730 -mm) wide basin . . . . . . . . . . . . . . . . .

Erosion for uncontrolled

tailwater

with entrance

pipe

flowing

full in 2.4-foot

(730-mm)

wide basin . . . . . . .

Entrance

pipe flowing half full with uncontrolled

tailwater

in 2.4-foot

(730-mm)

wide basin

. . . . . . . . . . . . . . .

Erosion for uncontrolled

tailwater

with entrance

pipe

flowing half full in 2.4.foot

(730.mm)

wide basin . . . .

Design width of basin

. . . . . . . . . . . . . . . . . . . . . . .

Entrance

pipe flowing one-fourth

full with uncontrolled

tailwater

in 2.4-foot

(730-mm)

wide basin . . . . . . . . .

Entrance

pipe flowing three-fourths

full with uncontrolled

tailwater

in 1.6-foot

(490-mm)

wide basin . . . . . . . . .

V

. . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . .

4

6

7

. . . . . . . . . . . .

9

. . . . . . . . . . . .

10

. . . . . . . . . . . .

11

. . . . . . . . . . . .

. . . . . . . . . . . .

12

13

. . . . . . . . . . . .

14

. . . . . . . . . . . .

15

�CONTENTS-Continued

Page

Figure

11

12

13

14

15

16

17

Entrance

pipe flowing half full with uncontrolled

tailwater

in 1.6-foot

(490-mm)

wide basin

. . . . . . . . . , . . . . .

Entrance

pipe flowing one-fourth

full with uncontrolled

tailwater

in 1.6-foot

(490-mm)

wide basin . . . . . . . . .

Prototype

operation

. . . . . . . . . . . . . . . . . . . . . . . .

End sill velocity,

water surface drop from end sill, and

energy loss through

basin . . . . . . . . . . . . . . . . . . . .

Recommended

riprap stone size . . . . . . . . . . . . . . . . .

Entrance

pipe flowing full with controlled

tailwater

in

2.4-foot

(730-mm)

wide basin . . . . . . . . . . . . . . . . .

Entrance

pipe flowing half full with controlled

tailwater

in 2.4-foot

(730-mm)

wide basin

. . . . . . . . . . . . . . .

vi

_.-.

__...

. . . . . . . . . . . .

16

. . . . . . . . . . . .

. . . . . . . . . . . .

17

18

. . . . . . . . . . . .

. . . . . . . . . . . .

20

21

. . . . . . . . . . . .

22

. . . . . . . . . . . .

23

�INTRODUCTION

revision

of these design

standards.

Unforeseen

operating

conditions

in the field

and the

over-generalization

of the present

design rules have

This study was conducted

to standardize

and modify

existing procedures

used in the design of the impact,

type VI stilling basin.

Stilling Basin VI, as referred to in section 6 of report

and in Engineering

Monograph

No. Hyd-399

[ I]’

No.

25 [Z],

is an impact-type

energy

caused operating

structures.

Four

principal

dissipator,

refer

operating

at some of the prototype

problems

that

have

occurred

at various

installations

are: (1) the basin

tends to clog with debris upstream

of the hanging

baffle. Russian thistles and similar weeds are the main

contained

in a relatively

small boxlike structure

which

requires

no tailwater

for successful

performance.

Although

the emphasis in this discussion

is placed on

use with pipe outlets, the structure

may be used with

an open channel

chute.

It was originally

developed

for use as an energy

dissipator

at several locations

on the Franklin

Canal.

Many

of these basins are in use on other

Bureau

projects

and generally

have been designed

in

accordance

with the procedures

outlined

in these two

publications.

However,

operation

of the various

prototype

structures

has revealed

the need for

* Italicized

numbers

in brackets

cited at the end of this report.

problems

source of the debris, which is not generally

a problem

in cultivated

areas. (2) Excessive splash overtopping

the compartment

walls upstream

of the baffle, usually

resulting

from too small a basin for the quantity

and

velocity

of flow involved,

has eroded the fill outside

the basin walls. (3) The discharge

from the entrance

pipe passes under the baffle, resulting

in very little

energy dissipation

in the basin and excessive erosion

of the downstream

channel.

This has occurred

with

a sloping

entrance

pipe or with an oversized

basin

having a horizontal

entrance

pipe discharging

at less

than the design flow. (4) Channel

erosion at the end

of the basin where the size of riprap was not adequate.

to references

1

�-___-

__

�THE MODELS

Two model

millimeters)

basins,

wide,

1.6 and 2.4 feet

were constructed.

(490 and 730

The other

tests,

as well as flow from

an 8-inch

(200-mm)

rectangular

open channel.

Each of the two basins discharged

into a canal

section lined with 1.5~inch (38-mm)

gravel. Tailwater

dimensions

were related to the width of the basin, as

shown in figure 1.

An 8-inch (200-mm)

inside-diameter

pipe was used

at the entrance

to each of the basins. Deflectors

of

various sizes were installed

on the crown of this pipe

upstream

of the portal to vary the velocity

of flow

entering

the basins.

One-fourth,

one-half,

three-fourths,

and full pipe flows were used in the

elevations

were controlled

by stoplogs at the end of

the canal section. The bottoms

of the canal sections

were at the same elevation

of the basin end sill and

were as wide and as long as the basin width. The side

slopes were 1.5 to 1 for the 2.4-foot

(730-mm)

wide

basin and vertical

for the smaller basin.

3

�r

4

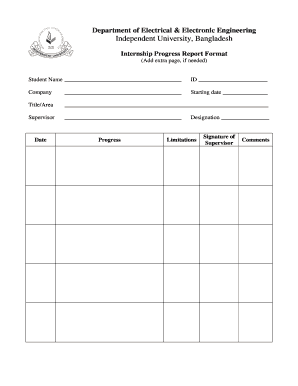

SEC. A-A

4 :I

.-

I--

a

-L

PLAN

I

PLAN

-0 :.‘.‘.-6:

:..

..‘.

‘.i?‘.

:

:

‘p,’

La

Bedding/

SECTION

H= 3W/4

L=4W/3

a-W/2

b- 3w/0

ALTERNATE

END SILL AND

WING WALL

c= w/2

d-W/6

e- w/l2

t-w/@

suggested minimum

Riprap stone size diameter = W/Z!0

Figore L-General

SECTION

design of the type VI impact stilling basin.

4

�THE INVESTIGATION

intermittently

The investigation

was primarily

concerned

with

relating

the basin size to the discharge

and velocity

and in relating

the downstream

channel

and riprap

requirements

to the basin size. It was also concerned

with special situations

involving

debris, silt, tailwater,

sloping entrance

pipe, and rectangular

open channel

entrances

not usually

encountered

design of the type VI basin.

Standardization

Terms

of Basin

of the

Width

Basin

and splashed

high

on the basin

moved a short distance away from the sidewalls.

Also,

the slope of the top of the basin sidewalls was reduced

to increase the height of the wall at the downstream

end of the basin. The modification

to the notches

reduced

the splashing

and the height

of the water

surface rise on the sidewalls.

Increasing

the height of

the sidewalls

provided

additional

freeboard

at the

downstream

end of the basin. These modifications

are

incorporated

into the standard

design dimensions

shown in figure 1.

in the standard

Dimeneions

surged

walls immediately

downstream

from the hanging

baffle

and overtopped

the sidewalls

at the

downstream

end of the basin (figs. 2 and 3). To

improve

these flow conditions,

the width

of the

notches

in the baffle was reduced

and the notches

in

A test basin was constructed

having

dimensions

related to the basin width in accordance

with those

developed

for the basin in the earlier study [Z].

To test the adequacy

of this 2.4,foot

(730~mm)

wide

model basin, tests were conducted

over a range of

flows that had been determined

in the earlier tests [Z]

to be the limits of exceptionally

mild operation

and

of safe maximum

operation

for a given basin width,

provided

the entrance

flow velocity

did not exceed 30

feet per second (9.1 m/s) (prototype).

These test discharges were related to the basin width

in accordance

with the equation:

Q = (W/C)=

where “Q” is the discharge

in cubic feet per second,

“W” is the inside width of basin in feet, and “C” is

a coefficient

that varies for the maximum,

minimum,

and intermediate

flows. The coefficient

in English

units is 1.46 for the maximum

permissible

flow, 1.80

for the minimum

mild

flow,

and 1.60 for the

intermediate

flow.’ Each test discharge

was run at

approximately

half full and full pipe to obtain highand low-entrance

velocity

conditions

and with

controlled

and uncontrolled

tailwater

depths (figs. 2

and 3).

The larger

flows

with

the higher

velocities

Standardization

of the

Basin

Flow

Entrance

The flow will usually enter the basin from a circular

pipe but may enter from a rectangular

open channel.

The pipe may flow full or partially

full. If it flows

partially

full and the upstream

entrance

to the pipe

is submerged,

the pipe should

be vented

to the

atmosphere.

The vent should

be located

near the

upstream

end of the pipe and have a diameter

of

about one-sixth

the pipe diameter.

Although

the entrance

pipe or channel

is usually

horizontal

or on a very slight downward

grade, some

installations

may require

an entrance

pipe on a

relatively

steep slope. The hydraulic

performance

of

the 2.4-foot

(730-mm)

wide

model

basin

was

determined

with the entrance

pipe sloped downward

about

12’.

Both high- and low-velocity

test flows

partially

impinged

on the hanging

baffle

and the

bottom

of the baffle was only partially

submerged,

resulting

in incomplete

energy dissipation.

The model tests showed that a horizontal

fillet on

the invert

of the pipe for a distance

of one pipe

diameter

upstream

from the portal caused greater jet

impingement

on the baffle,deeper

submergence

of the

bottom

of the baffle, and consequently

better energy

dissipation.

The same improvement

could be obtained

by placing

the entrance

pipe horizontally

for a

distance of one or more pipe diameters

upstream

from

the basin entrance.

Either of these two methods

may

’ 1 ft3/s = 28.3 L/s = 28.3 x 10-s m3/s. To obtain

the discharge

in cubic meters per second (ms/s),

the

width must be in meters and the discharge coefficient

must be multiplied

by 1.27. To obtain the discharge

in liters per second (L/s),

either multiply

the cubic

meters per second value by 1000, or calculate

with

the width in millimeters

and the discharge coefficient

multiplied

by 80.

5

�be used for entrance pipe slopes up to 15 0. Entrance

pipes having a downward grade exceeding 15 ° should

performance of the basin. However, flow from the

basin backed up into the open channel, making it

necessary to raise the channel waIls to the same height

as the basin waIls. To further contain the flow, the

invert of the channel should be horizontal for a

distance equivalent to at least two channel widths

upstream from the basin entrance.

be horizontal for at least two diameters upstream

from the basin entrance.

Replacing the sloping entrance pipe in the model

with an 8.inch {200-mm) wide rectangular channel on

a similar slope did not change the hydraulic

v

=

9.9 ft/s

(3.0 m/s)

v

c

Q

v

=

7.89 ft/s

=

=

5.84 ft/s

3.47

ft31s

c

1.60

(98

21.58

(6.6

m/s)

=

17.15

ft/s

(5.2

m/s)

2.76 ft31s (78 Lis)

(1.8 m/s)

v = 12.69 ft/s (3.9 m/s)

C = 1.80

Q = 2.04 ft3/s (58 Lis)

Q = (W IC)2.S where W =basin width of 2.4 feet (730 mm)

V = velocity of flow at entrance

Tailwater

ft/s

Lis)

v

=

=

1.46

(2.4 m/s)

Q =

v

=

elevation in tailbox is below basin end sill

Figure 2.-Test flows with uncontrolled

6

tailwater.

�v

=

9.9

v

=

7.89

ft/8

(3.0

ft/s

m/8)

(2.4

v

m/s)

c

Q =

v

=

5.84

Ct/s

(1.8

v

c = 1.46

Q = 3.47(131s(98 Lis)

2.76

=

=

=

21.58

17.15

ft/s

ft/s

(6.6

(5.2

m/s}

m/s)

1.60

fl31s (78 Lis)

v

m/s)

=

12.69

ft/s

(3.9

m/s)

c = 1.80

Q = 2.04 ft31s (58 Lis)

Q = (WIC)2oSwhere W = basin width of 2.4 feet (730 mm)

V = velocity of flow at entrance

Tailwater elevation in the tailbox is at d + bl2 (see fig. 1)

Figure 3.-Test flows with controlled tailwater.

Standardization

of the Basin

Size

by the basin width,

the quantity

and velocity

of flow

After standardizing

the basin dimensions in relation

to the basin width, the next step was to standardize

by the Froude number of the incoming jet.

It was believed that the shape of the incoming jet

was relatively

unimportant

in evaluating

the

the size in relation

adequacy

flow entering

to the quantity

and velocity

of the

the basin. The basin size is represented

standardize

of a type

the method

VI

basin.

Therefore,

of computing

to

the Froude

�number

of the incoming

flow,

it was assumed

that

than

the

number

cross sectional

area of the jet in the circular

pipe or

rectangular

channel had the shape of a square; thus,

the depth of the incoming

flow “D”

was considered

to he the square root of its cross sectional

area.

a riprapped

channel

simulated

end of the basin.

Water

at the

surface

In figure 8, the straight

points with the highest

roughness and erosion, together

with the ability of the

basin to contain

the flow, were used as guidelines

in

evaluating

the hydraulic

performance

test flows

corresponds

to a flow

having

a Froude

of 1.1.

Additional

tests were run in this smaller model (figs.

11 and 12) to confirm

the findings found in the larger

model basin. The results of these tests are plotted

in

figure 8 at W/D ratios of 3.8 and 6.1. The two models

showed very good agreement

in what was considered

satisfactory

and unsatisfactory

performance,

as seen

by comparing

figures 4 and 6 with 11 and 12.

The test flows (figs. 2 and 3) used in verifying

the

standard

dimensions

of the basin in reference

II were

repeated

in the 2.4.foot

(730-mm)

wide model basin,

but with

downstream

3, which

line drawn through

the data

Froude

numbers

for which

satisfactory

operation

existed indicates

the minimum

width of basin that can be used for a given Froude

number.

Data points above the line indicate

that it

should be permissible

to increase the size of the basin

approximately

25 percent;

however,

this should not

be done as these points represent

the condition

when

the basin

is operating

at less than

the design

discharge.

If the basin is too large, the incoming

jet

will pass under the baffle as has occurred

at some

installations

and effective

energy dissipation

will not

occur. For best results, the basin should be designed

for the minimum

width indicated

in figure 8.

(figs.

4 through

7). Each of the test flows was judged to be

satisfactory

or unsatisfactory

and plotted

in

dimensionless

terms (Froude number

of the incoming

flow “F”

versus

the ratio of basin width

to the

incoming

depth of the flow ‘*W/D”)

in figure 8.

To increase

the range of data to be evaluated

for

figure 8, the cross sectional

area of the incoming

flow

was reduced

to one-fourth

the area of the 8-inch

(200-mm)

pipe , and the velocity

of the flow entering

the 2.4-foot

(730-mm)

wide model basin was increased

(fig. 9). Thus,

both the Froude

number

and the

width/depth

ratio increased.

The width/depth

ratio

for these tests was 8.15, at which the Froude number

of a theoretical

square jet at the entrance

was 6.70

for the minimum

satisfactory

operation.

Because the

size of the jet was becoming

very small in relation

to

Standardization

Limitation

of the

Entrance

Velocity

In previous

studies [Z], the design criteria

for this

type of structure

were based on discharge

alone. The

maximum

incoming

velocity

was arbitrarily

limited to

30 feet per second

(9.1 m/s).

However,

some

prototype

structures

have been designed

and

operated

at velocities

exceeding

this limit. The type

VI stilling

basins for the outlet

works of Picacho

South and North

Dams were designed

for velocities

up to 39 and 48 feet per second (11.9 and 14.6 m/s),

respectively,

for flows of 165 and 275 cubic feet per

second (4.7 and 7.8 m3/s), respectively.

They have

operated

satisfactorily

at 80 percent

capacity

at

velocities

of 32 and 37 feet per second (9.8 and 11.3

m/s) (fig. 13).

To prevent

the possibility

of cavitation

or impact

damage to the basin, the maximum

entrance

velocity

should be limited

to about

50 feet per second (15

m/s). At this velocity

the maximum

Froude number,

9.00, for which the basin is recommended

will occur

at a design flow of 46 cubic feet per second (1.3 m3/s).

For Froude

numbers

less than about

4, this basin

would not be feasible at this velocity

because of the

enormous

size of the structure

involved.

the width of the basin, the design curve in figure 8

was not extended

beyond

a width to depth ratio of

10, which

corresponded

to flow having

a Froude

number

of about 9.

To increase the range of data in the other direction,

the cross sectional

area of the incoming

flow was

increased

in relation

to the basin width by switching

to the 1.6-foot

(490-mm)

wide

model

while

maintaining

the 8-inch (200-mm)

entrance

pipe (fig.

10). The tests were evaluated

and plotted

in figure 8

at a W/D

ratio

of 3.08.

The side slopes

of the

downstream

discharge

channel

were vertical

and the

same distance

apart as the basin sidewalls.

Although

this was not typical of the usual prototype

installation

and is not recommended,

it was not considered

to be

critical

in evaluating

the performance

of the basin.

For these tests, the Froude number was in the vicinity

of 1.0 and the height of the incoming

flow was near

the top of the baffle.

Therefore,

it did not appear

practical

to design this basin for W/D ratios smaller

8

�F = 1.34

WID = 4.06

Satisfactory

F = 1.81

WID = 4.06

Satisfactory

F = 2.27

WID = ~.O6

Unsatisfactory

Note: For erosion results, see figure .5; for plot of these operating conditions, see figure 8.

Figure

4.-Entrance

pipe

flowing

full

with

uncontrolled

9

tailwater

in 2.4-foot

(730-mm)

wide

basin.

�F

=

1.34

WID

No

=

4.06

erosion

Satisfactory

F

=

WID

1.81

=

4.06

Erosion

Satisfactory

F

=

WID

2.27

=

Excessive

4.06

erosion

Unsatisfactory

Note: For plot of these operating conditions, see fig lIre 8.

Figure

5.-Erosion

for uncontrolled

tail water

with

entrance

10

pipe

nowing

full

in 2.4.foot

(730.mm)

wide

basin

�F = 3.53

WID = 5.98

Satisfactory

F = 4.77

WID = 5.98

Unsatisfactory

F = 6.01

WID = 5.98

Unsatisfactory

Note: For erosion results, see figure 7; for plot of these operating conditions, see figure 8.

Figure

6.-Entrance

pipe flowing

half

full

with

uncontrolled

"ailwater

in 2.4-foot

(730-mm)

wide

basin.

�F

=

WID

3.53

=

Minor

5.98

erosion

Satisfactory

F

=

WID

4.77

=

5.98

Excessive

erosion

U nsatisfactory

F

=

WID

6.01

=

5.98

Excessive

erosion

U nsatisfactory

Note: For plot of these operating conditions. see figure 8.

Figure 7.-Erosion for uncontrolled tailwater with entrance pipe nowing half full in 2.4.foot (730-mm) wide basin.

12

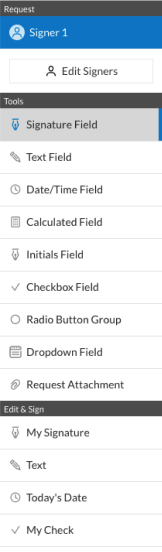

�IC

9

-

8

-

7

-

6

-

5

-

4

-

n

2

-

3

-

‘(0

at W/D = 3.08,

F = 0.91)

-

2

-

0 - Satisfactory

Hydraulic Performance

X - Unsatisfactory

2

Hydraulic Performance

3

4

FROUDE NUMBER

5

6

7

8

V/AjI7

is the inside width of the basin.

represents the depth of flow entering the basin and is the

square root of the flaw area.

“v” is the velocity of the incoming flow.

The tailwater depth is uncontrolled.

“w”

I’D”

Figure E.-Design width of basin.

9

IO

�F

=

WID

No

5.87

=

8.15

erosion

Satisfactory

F

=

WID

No

6.67

=

8.15

erosion

Satisfactory

F

=

WID

Minor

7.59

=

8.15

erosion

Unsatisfactory

Note: For plot of these operating conditions, see figure 8.

Figure

9.-Entrance

pipe

nowing

one-fourth

full

with

14

uncontrolled

tailwater

in 2.4.foot

(730-mm)

wide

basin.

�F

=

WID

No

0.91

=

3.08

erosion

Satisfactory

F

=

WID

No

1.07

=

3.08

erosion

Satisfactory

F

=

WID

Minor

1.27

=

3.08

erosion

Unsatisfactory

Note: For plot of these operating conditions, see figure 8.

Figure

IO.-I':ntrance

pipe flowing

three.fourths

full with

uncontrolled

15

tailwater

in 1.6.foot

(490-mm)

wide basin.

�F

=

1.01

WID

No

=

3.81

erosion

Satisfactory

F

=

1.56

W/D=3.81

No

erosion

Satisfactory

F

=

WID

1.83

=

Minor

3.81

erosion

Unsatisfactory

F

=

WID

2.17

=

3.81

Excessive

erosion

Unsatisfactory

Note: For plot of these operating conditions, see figure 8.

Figure

11.-i'~ntrance

pipe nowing

half

full

with

uncontn,lIl'd

16

tailwatl'r

in 1.6-foot

(190-mm)

wide

basin.

�F = 3.72

W/D=6.14

No erosion

Satisfactory

F

=

5.11

WID

=

6.14

Excessive

erosion

Unsatisfactory

F

=

WID

6.28

=

6.14

Excessive

erosion

Unsatisfactory

Note: For plot of these operating conditions, see figure 8.

Figure

12.-Entrance

pipe

nowing

one.fourth

full

with

uncontrolled

17

tailwater

in 1.6.foot

(490.mm)

wide

basin.

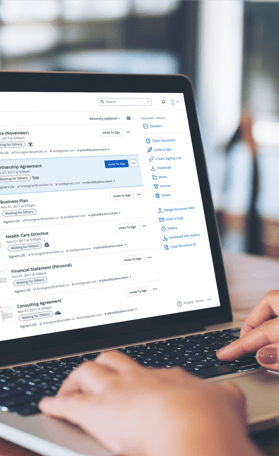

�Picacho South Dam outlet works

structure discharging 130 ft3/s

(3.7 m3/ s) (80 percent of maximum capacity).

Picacho North Dam outlet works

structure discharging 210 ft3/s

(5.9 m3/s) (80 percent of maximum capacity).

Scour below Picacho North Dam

outlet works following flood of

August 20, 1954. Evidence points

to undersized riprap.

Note: At full capacity the basins are approximately

13 percent IIndersized, based on present design standards.

Figure 13.-Prototype

18

operation.

�Standardization

of the

Discharge

Channel

plotted

in figure

Riprap

flow

Channel

bed erosion tests were not conducted

to

prove

the required

size of stones

in the riprap.

Instead, a reasonable

riprap size was chosen to fit the

size of the basin. Having predetermined

the basin size

and relative size of stones in the riprap, the discharge

Tailwater

capacity

and entrance

velocity

limitations

determined

as already described.

A model riprap

was chosen that approximated

basin width-to-stone

diameter

size appeared

to be reasonable

from

14 is not

the center

as high

as the velocity

of

of the sill.

Recommendations

The effect of tailwater

on the basin efficiency

was

determined

by repeating

the above tests using a

maximum

tailwater

controlled

to a depth of d+ b/2

above the basin floor. [Z] (See fig. 1 for definitions.)

A comparison

of these flow conditions

(figs. 16 and

were

a

ratio of 20 to 1. This

and satisfactory,

as was

confirmed

by the tests described

in the preceding

section on standardization

of basin size. These tests

showed

that slight erosion

of the riprap

began at

about

the same time as excessive

water

surface

roughness

appeared

within

and downstream

of the

basin. The model

stones were rounded,

although

angular ones would be preferred

in the prototype.

The gravel was placed on the channel bottom

at end

still elevation

and on the l-1/2

to 1 side slopes to a

normal depth equal to the height of the end sill (fig. 1)

and for a distance

downstream

equal to the basin

width.

This arrangement

was satisfactory

in the

model

tests and is, therefore,

recommended

for

prototype

construction.

In some instances,

the discharge

channel

bed may

be several

inches or a few feet below the end sill

elevation.

This will considerably

increase the riprap

stone size requirement.

To determine

the increased

riprap

stone size requirement,

the average

flow

velocity

at the end sill was determined.

It was then

related to the average entrance

velocity

and plotted

versus Froude number in figure 14, and plotted

versus

the stone size requirement

in figure 15.

The additional

head as provided

by the lower

channel bed should be added to the velocity

head at

the sill to determine

the velocity

of flow entering

the

channel.

Having

determined

the increased

velocity,

figure 15 can be entered to determine

the riprap stone

size requirement.

The stone size requirement

for end sill velocities

is

compared

in figure 15 with the stone size requirement

for bottom

velocities

in channels

downstream

of

stilling basin [Z]. Th e comparison

indicates

that the

stone size recommendation

here is conservative;

however,

the flow from the sill is in a downward

direction

as there is a drop in water surface from end

sill to channel

(fig. 14). Also, the average

velocity

19

17) with the uncontrolled

(figs. 4 and 6) shows that

tailwater

flow conditions

the water surface roughness

and bed erosion are reduced

by the higher tailwater

but not sufficiently

to allow a reduction

in the basin

size. The riprap stone size could be reduced

slightly

as determined

by,the reduced velocity

using figure 15.

Performance

Evaluation

Energy

dissipation

is initiated

by flow striking

the

vertical

hanging baffle and being turned upstream

by

the horizontal

portion

of the baffle and by the floor,

in vertical

eddies. Its effectiveness

is best illustrated

by plotting

the percent

of energy loss between

the

entrance

portal

and the end sill for a range

of

operating

conditions

as represented

by the Froude

number

(fig. 14). Comparing

the energy loss with the

losses in a hydraulic

jump shows the impact basin to

be more efficient.

Prototype

structures

[Z] that meet these design

standards

have operated

successfully.

The outlet

basins at Picacho South and North

Dams, discharing

at 80-percent

capacity,

are examples

(fig. 13). The

design requirements

for the 80-percent

capacity

and

for the loo-percent

design capacity

are given in

table 1.

For operation

of these structures

at 80-percent

capacity,

the table shows the width

of basin and,

therefore,

the size of basins to be adequate

to meet

design requirements.

However,

for loo-percent

design

capacity,

the table shows the basins to be about 13

percent

undersized

based on the design standards

presented

herein

(fig. 8). The actual

performance

proved this to be true (fig. 13).

The prototype

structures

at Picacho

South

and

North

Dams

can also be used

to verify

the

recommended

size of riprap.

According

to

construction

specifications

for both dams, the riprap

below the outlets was to “* * * consist of durable rock

�velocity

velocity

at

to 1,he basin.

entrance

\

over

the

\

i i i I

I i i i i i i i i 7--H4J

elevation

.06

from

end sill

nnel with

the

to

the

.05

.03

.--ns!

7

L” is the energy

loss in the

flow from

basin

entrance

to the end sill.

is the flow

energy

at the

.6

.5

/I

I

0

I

2

I

FROUOE

(Where

area

Figure

IL-End

“D”

of

sill velocity,

I

3

I

I

4

surface

I

5

NUMBER

is the sqllare

the entrance

water

I

root

flow

drop

front

6

I

7

I

I

8

I

I

9

= v/m

of the cross-sectional

area.)

end sill, aud energy

20

___

loss through

basin.

�VELOCITY

0

I

IN

METERS

2

PER

3

SECOND

4

5

IO00

900

CnJO

W

I

:

500

f5

+

I”

4

400

0

WN

300 uY

:

200

100

0

0

0

2

4

VELOCITY

6

6

IO

IN

FEET

I2

14

PER

16

I6

SECOND

Note: The riprap

should

he composed

of a well-graded

-mixture but most of the stones should bc of the size indicated

by the curve.

End sill velocity

in riprap.

in type

VI Basin

.___ Bottom

velocity

in a channel

riprap. (See figure 165 in reference

Fire

15.-Recommended

21

vs stone size required

vs stone

2)

riprap

size required

stone

size.

in

E

u)

�F

=

1.34

WID

=

No

4.06

erosion

Satisfactory

F

=

1.81

WID

No

=

4.06

erosion

Satisfactory

F

=

WID

2.27

=

4.06

Excessive

erosion

Unsatisfactory

Note: Tailwater

Figure

16.-Entrance

pipe

flowing

full

with

= d + b/2; see figure 1 for definitions.

controlled

22

tailwater

in 2.4-foot

(730-mm)

wide

basin.

�F

=

3.53

WID

No

=

5.98

erosion

Satisfactory

F

=

4.77

WID

=

Minor

5.98

erosion

Unsatisfactory

F

=

WID

6.01

=

Excessive

5.98

erosion

Unsatisfactory

Note: Tailwater

Figure 17.-Entrance

= d + b/2; see figure 1 for definitions.

pipe flowing half full with controlled

23

tailwater in 2.4.foot (730.mm) wide basin.

�fragments

reasonably

graded

in size * * *” from

3.4

channel

wave

cubic feet (95 dms) to 0.1 cubic foot (3 dm3). The

individual

rocks would

range from about

18- to

5.5.inch

(460- to 140-mm)

cubes and have a mass of

500 to 15 pounds

(225 to 7 kg). Although

it is

impossible

Dam (fig.

Debris

from the photograph

of the outlet at North

13) to determine

the size of stones in the

Sill

reduce

erosion

tendencies

and

heights.

Barrier

At some

and

prototype

Traehrack

installations,

have

portal

weeds

and debris

been trapped

in the

and the baffle.

This

debris has compacted

to the extent of blocking

the

portal,

thus reducing

the capacity

of the structure.

The compacted

weeds will not wash out and are very

difficult

to remove.

The only satisfactory

field

method

of removing

the debris has been to destroy

at the beginning

of the run; but, here again, the bank

riprap

and the waterfall

effect of the flow over the

end sill in figure 13 indicate

that there is a drop from

the end sill to the channel,

as shown in the table.

Therefore,

the majority

of the stones in the riprap

should

be 28 inches

(710 mm) in diameter

as

recommended

here. Since the specified

stones were

smaller than this size, the riprap

would be expected

to fail and did.

At South

Dam,

the photographs

of the outlet

discharging

do not show a waterfall

effect from the

end sill. Therefore,

the riprap was probably

nearer to

end sill elevation

than specified

in the table. This

would

reduce

the required

stone

diameter

to

something

less than 18 inches (460 mm), but greater

than 8 inches (200 mm). Since this range is within that

specified,

the riprap would be expected

to remain in

place and did.

End

thereby,

such as Russian

thistles

basin between

the pipe

channel riprap at the start of the run, the bank riprap

indicates

that there were very few pieces of the

500-pound

(225-kg)

size. The few remaining

pieces

hear the man at the right seem to be in the upper

range of sizes and are not washed

out.

It is also

difficult

to determine

the elevation

of the channel bed

Alternate

and,

portions

of the baffle.

This condition

was tested in the two models using

Russian

thistle

branches.

The model demonstrated

that

the thistles

would

not wash out and no

satisfactory

method

of making the basin self-cleaning

of weeds and debris was developed.

At structures

where thistles or other debris are likely

to be a problem,

it is suggested that screening be used

to cover the upstream

portion

of the basin and that

a screen or trashrack

device be used where the flow

enters the pipe to the basin.

Self-Cleaning

Feature

Sediment

may accumulate

in the basin below the

hanging baffle during periods of nonuse. The notches

were installed

in the baffles

to provide

an opening

through

which a jet would discharge to begin erosion

and removal

of the sediment

from the basin.

The 2.4-foot

(730-mm)

wide basin was operated

with the portion of the basin below the hanging baffle

blocked

to simulate

a sediment-filled

basin. It was

determined

from this test that the design discharges

could be passed over the top of the baffle with very

little splashing

outside the basin and, in general, only

minor

erosion

in the riprapped

area. This type of

operation

could be tolerated

for a limited

time while

sediment

is being washed

from the basin.

If it is

anticipated

that the basin beneath

the baffle

will

remain relatively

free of sediment,

the notches

may

Design

The alternate

end sill design (fig. 1) having

45’

wingwalls

was not tested in this study. Examination

of the data and photographic

results of the earlier

studies [ 21, however,

indicated

that height of boil and

drop in water

surface

elevation

to the channel

(fig. 14) will be reduced by using the 45’ wingwalls

and a longer end sill. The use of this sill would allow

the flow to spread

more uniformly

over a wider

be omitted.

24

�Table 1.-Design specifications for the outlet works structure

at Picacho North and South Dams

Estimated maximum

flood ( record

North Dam

South Dam

Discharge (Q)

130 ft3/s (3.7 m3/s)

Estimated entrance

velocity (V)

3 1.8 ft/s (9.7 m/s)

Cross-sectional

area of flow (A)

4.09 ft2 (0.38 m2)

Depth (D)

2.02 ft (0.616 m)

Froude number (F)

3.94

Width to depth ratio

(W/D), figure 8

6.21

Width recommended (W) 12.54 ft (3.82 m)

Width actually used

12.50 ft (3.81 m)

Percent undersized