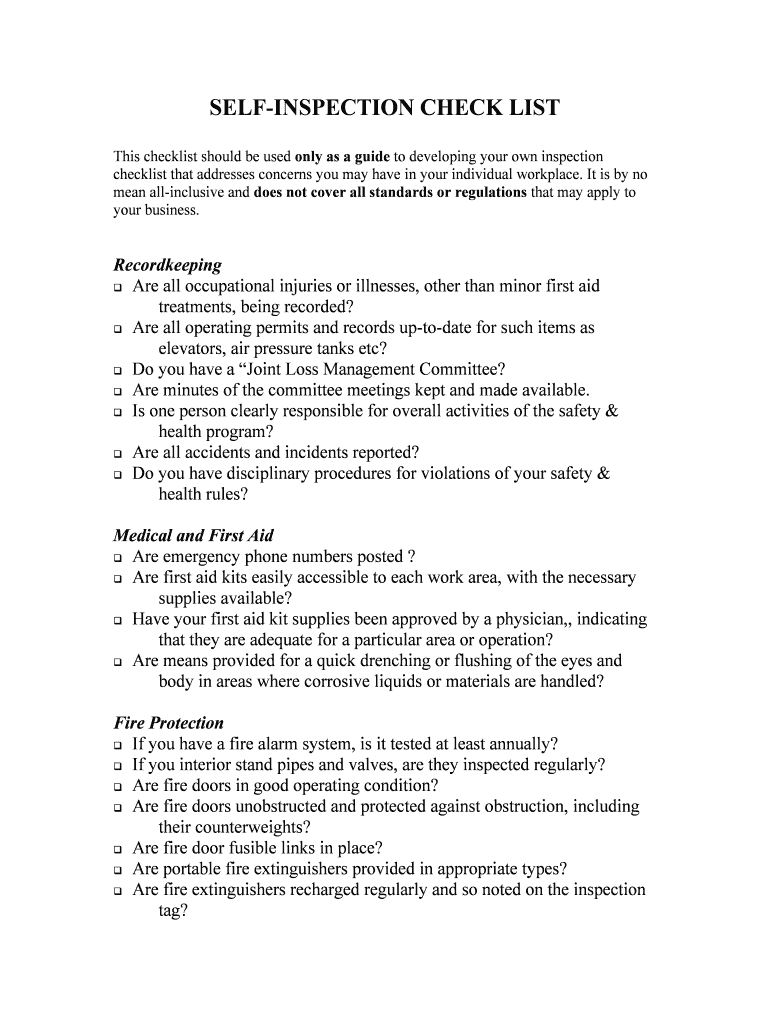

SELF-INSPECTION CHECK LIST This checklist should be used only as a guide to developing your own inspectionchecklist that addresses concerns you may have in your individual workplace. It is by nomean all-inclusive and does not cover all standards or regulations that may apply toyour business.Recordkeeping��Are all occupational injuries or illnesses, other than minor first aidtreatments, being recorded?��Are all operating permits and records up-to-date for such items aselevators, air pressure tanks etc?��Do you have a “Joint Loss Management Committee?��Are minutes of the committee meetings kept and made available.��Is one person clearly responsible for overall activities of the safety &health program?��Are all accidents and incidents reported?��Do you have disciplinary procedures for violations of your safety &health rules?Medical and First Aid��Are emergency phone numbers posted ?��Are first aid kits easily accessible to each work area, with the necessarysupplies available?��Have your first aid kit supplies been approved by a physician,, indicatingthat they are adequate for a particular area or operation?��Are means provided for a quick drenching or flushing of the eyes andbody in areas where corrosive liquids or materials are handled?Fire Protection��If you have a fire alarm system, is it tested at least annually?��If you interior stand pipes and valves, are they inspected regularly?��Are fire doors in good operating condition?��Are fire doors unobstructed and protected against obstruction, includingtheir counterweights?��Are fire door fusible links in place?��Are portable fire extinguishers provided in appropriate types?��Are fire extinguishers recharged regularly and so noted on the inspectiontag?

��Are employees periodically instructed in the proper use of portable fireextinguishers and fire protection procedures?Personal Protective Clothing and Equipment��Are protective goggles or face shields provided and worn where there is adanger of flying particles or corrosive materials?��Are approved safety glasses required to be worn at all times in areaswhere there is a risk of eye injuries?��Are protective gloves, aprons, shields or other means provided and required where employees could be cut or where there is a reasonablyanticipated exposure to corrosive liquids, chemicals, blood, or otherpotentially infectious materials?��Are hard hats provided and worn when there is a danger of fallingobjects?��Is appropriate foot protection required where there is a risk of footinjuries from hot or corrosive materials, falling objects, or crushing orpenetrating injuries?��Are approved respirators provided for regular or emergency use asrequired?��Is all personal protective equipment maintained in a sanitary conditionand ready for use?��Do you have an eye wash station for quick drenching of the eyes in areaswhere employees are exposed to corrosive materials?��Is protection against occupational noise exposure provided when thesound levels exceed limits?General Work Environment��Are all work areas clean, sanitary and orderly?��Are work surfaces kept dry or appropriate means taken to assure thesurfaces are slip-resistant?��Is combustible scrap, debris and waste stored safely and removed fromthe worksite promptly?��Are accumulations of combustible dust routinely removed from the workareas?��Are covered metal waste cans used for oily and paint-soaked rags?��Are paint spray booths, dip tanks and spray areas cleaned regularly?��Are all toilets and washing facilities clean and sanitary?��Are all work areas adequately illuminated?��Are pits and floor openings covered or otherwise guarded?

Walkways��Are aisles and passageways kept clear?��Are aisles and walkways marked as appropriate?��Are wet surfaces covered with a non-slip material?��Is there safe clearance for walking in aisles where motorized ormechanical handling equipment is operating?��Are spilled materials cleaned up immediately?��Are standard guardrails provided wherever aisle or walkway surfaces areelevated above any floor or ground��Are bridges provided over conveyors and similar hazards?Floor and Wall Openings��Are floor openings guarded by a cover, guardrail?��Are toeboards installed around the edge of permanent floor openings(where persons may pass below the opening)?��Are unused portions of service pits or pits not in use covered or protectedby guardrails or equivalent?��Are floor or wall openings in fire resistive construction provided withdoors or covers compatible with the fire rating of the structure and

also provided with self-closing devices?Stairs and Stairways��Are standards stair rails or handrails provided on all stairways having 4or more risers?��Do stairway handrails have at least 3” of clearance between the rail andthe wall or surface they are mounted on?��Are stairways at least 22” wide?��Are step risers on stairs uniform from top to bottom?��Are stairway handrails capable of withstanding a load of 200 pounds,applied within 2” of the top edge, in any downward or outward direction?Elevated Surfaces��Are signs posted, when appropriate, showing the elevated surface loadcapacity?��Are all surfaces elevated more than 30” above the ground provided with astandard guard?��Is material on elevated surfaces piled, stacked or racked in a manner toprevent it from tipping, falling, collapsing or rolling?��Are dockboards or bridge plates used when transferring materialsbetween a loading dock and truck or rail car?

Exiting or Egress��Are all exits marked with an exit sign and illuminated by a reliable lightsource?��Is the direction to exits, when not immediately apparent, marked withvisible signs?��Are doors, passageways or stairways, that are neither exits not access toexits and which could be mistaken for exits, marked “Not An Exit”?��Are all exits kept free from obstructions?��Are there sufficient exits to permit prompt escape in the event of anemergency?��Are special precautions taken to protect employees during construction orrepair operations?Exit Doors��Are doors which are required to serve as exits designed and constructedsuch that the way of exit is obvious/��Are exit doors operable from the direction of exit travel without the useof a key or any special knowledge or effort?��Are doors on cold storage rooms provided with an inside releasemechanism, which will release the latch and open the door even when

it is padlocked or otherwise locked on the outside?��Where exit doors open directly to any street, alley or other area wherevehicles may be operated, are adequate barriers and warnings

provided to prevent employees from stepping into the path of traffic?��Are doors that swing in both directions and are located between roomswhere there is frequent traffic, provided with viewing ports in each

door?Portable Ladders��Are all ladders maintained in good condition?��Are non-slip safety feet provided on each ladder?��Are ladder rungs and steps free from grease or oil?��Is it prohibited to place a ladder in front of doors opening toward theladder except when the door is blocked, locked or guarded?��Is it prohibited to place ladders on boxes, barrels, or other unstable basesto gain additional height?��Are employees instructed to face the ladder while ascending ordescending?��Are employees prohibited from using ladders that are broken, missingsteps, rungs or cleats, or otherwise defective?

��Are employees instructed not to use the top step of the stepladder as astep?��When portable ladders are used to gain access to elevated platforms,roofs, etc., does the ladder always extend at least 3’ above the

elevated surface?��Are all ladders inspected periodically for damage?��Are the rungs of ladders uniformly spaced at 12” center to center?Hand Tools and Equipment��Are all tools, used by the employees at the workplace, in good condition?��Are hand tools such as chisels, & punches, which may developmushroomed heads during use, reconditioned or replaced as

necessary/��Are broken or fractured handles on hammers, axes and similar toolsreplaced immediately?��Are worn or bent wrenches replaced as necessary?��Are appropriate safety glasses, face shields, etc., used while using handtools or equipment which might be subject to breakage or could result in flying parts such as metal from chisels?��Are tools stored in dry, secure locations where they won’t be tamperedwith?��Are grinders, saws and similar equipment provided with appropriatesafety guards?��Are power tools used with the correct shield, guard or other attachmentas recommended by the manufacturer?��Are portable circular saws equipped with guards above and below theblade?��Are portable circular saws checked to assure that the guard is not wedgedin the up position?��Are rotating or moving parts of equipment guarded to prevent physicalcontact?��Are all cord-connected, electrically operated tools and equipmenteffectively grounded or of the approved double insulted type.��Are effective guards in place over belts, pulleys, chains, sprockets, andgears?��Are portable fans provided with full guards or screens with openings notlarger than ½”?��Is hoisting equipment available and used for lifting heavy objects, and areratings and characteristics appropriate for that task?��Are ground fault circuit interrupters provided on all temporary electrical

15 & 20-ampere circuits used during periods of construction?Abrasive Wheel Equipment- Grinders��Is the work rest adjusted to within 1/8” of the face of the abrasive wheel?��Is the adjustable tongue guard on the top side of the grinder used and keptadjusted to within ¼” of the wheel?��Do side guards cover the spindle end, nut and flange and 75% of thewheel diameter?��Are bench and pedestal grinders permanently mounted?��Are goggles and or face shields worn while grinding?��Is the maximum RPM rating of each abrasive wheel compatible with theRPM rating of the grinder motor?��Are fixed or permanently mounted grinders connected to their supplysystem with metal conduit or other permanent wiring?��Does each grinder have it’s own on-off control?��Before new abrasive wheels are mounted, are they visually inspected andring tested/Machine Guarding��Is there a training program to instruct employees on the safe methods ofmachine operation?��Is there a regular program of inspection to assure the safe operation ofmachinery and equipment?��Is sufficient clearance provided around and between machines to allowfor safe operations, set up and servicing?��Is there a power shut-off switch within reach of the operator’s station?��Can all power sources to each machine be locked out for safemaintenance or set-up?��Are all non-current carrying metal parts of electrically operatedequipment properly grounded/��Are foot-operated switches guarded or arranged to prevent accidentaloperation from personnel or falling objects?��Are all emergency stop buttons colored red?��Are all pulleys and belts within 7’ of the floor properly guarded?��Are all moving chains and gears guarded?��Are methods provided to protect the operator and other employees in themachine area from hazards created at the point of operation?��Are machine guards secure and so arranged so that they do not pose ahazard by their use?��Are provisions made to prevent machines from automatically re-starting

following a restoration of power after a power outage?��Are saws used for ripping equipped with an anti-kick back device andspreader bar?��Are radial arm saws so arranged so that the cutting head will gentlyreturn to the back of the table when released?Lockout/Tagout Procedures��Is there a program that describes the procedures for safely locking outmachinery and equipment prior to repairs, routine maintenance and

setup?��Are employees properly trained in the correct lockout techniques?��Does the lockout program include all energy sources such as electrical,pneumatic, hydraulic, and all other stored energy?Welding, Cutting and Brazing��Are only authorized and trained personnel permitted to use welding,cutting and brazing equipment?��Are compressed gas cylinders regularly examined for obvious signs ofdefects, rusting or leakage?��Are cylinders kept away from heat sources?��Are all hoses, regulators and valves checked periodically for wear ordefects?��Are electrodes removed from the holder when not in use?��Are firewatchers assigned when welding or cutting is performed inlocations where there is a danger of fires starting?��Is eye protection worn whenever welding or cutting operations areperformed?Compressed Gas Cylinders��Are compressed gas cylinders stored in the upright position and securedto prevent them from being knocked over?��Are fuel cylinders and oxygen cylinders stored at least 20 feet apart orseparated by a non-combustible petition at least 5’ high and with a firerating of at least ½ hour?��Are valve protection caps in place when cylinders are transported, movedor stored?Industrial Trucks – Forklifts��Are only trained employees allowed to operate powered industrial trucks/��Are forklifts trucks with extended lifts equipped with an overhead guard?

��Are forklift trucks maintained in good operating condition and are repairsperformed in a timely manner?Spraying Operations��Is adequate ventilation assured before spray operations begin?��Is mechanical ventilation provided when spraying operations areconducted in confined areas?��Is the spray area at least 20’ feet from any flames, sparks, operatingelectric motors or other ignition sources?��Are “No Smoking” signs posted in any spray area or booth?��Is approved respiratory equipment provided and used when sprayingoperations are undertaken?��Are spray booth filters checked on a regular schedule and replaced whennecessary?Confined Space Entry��Is there a plan for assuring the safety and health of employees when theyare required to enter into any confined workspace?��Are all the provisions of the Confined Space Entry program strictlyadhered to by all employees?��Are employees trained in the hazards of working in confined spaces?��Is documentation kept to assure that the correct procedures have beenfollowed whenever anyone has had to enter into a confined space?Flammable & Combustible Materials��Are proper containers used for storage and handling of flammable andcombustible materials?��Are drums of flammable liquids grounded and bonded to containers whendispensing?��Do storage rooms for flammable and combustible liquids have explosion

proof wiring and lights?��Is there a portable fire extinguisher, rated at least 6# BC, located within75’ of any refueling area?Hazardous and Toxic Substances��Are all employees who might be exposed to hazardous materials duringthe course of their work, properly trained as required by the Worker’sRight To Know Law”?��Are Materials Safety Data Sheets (MSDS’), available for all hazardousmaterials used in the facility?

��Is proper personnel protective equipment available and utilized to protectemployees working with hazardous or toxic materials?��Do employees understand the reasons for use and limitations of thepersonnel protective equipment?��Are all containers of such materials properly labeled to indicate theircontent?Electrical Requirements��Are live parts of all electrical equipment operating at 50 volts or moreadequately guarded to prevent accidental contact?��Are all metal non-current carrying parts of fixed equipment grounded?��Are exposed non-current carrying metals parts of cord & plug connectedequipment grounded?��Is flexible cord being used in place of required fixed wiring?��Are disconnects in electrical service panels legibly marked to indicatetheir purpose?��Are flexible cords used free from splices, cracks in insulation andfraying?��Are ground fault circuit interrupters used on all 15-20 ampere circuits forconstruction sites that are not a part of the permanent wiring of thebuilding or structure?��Are flexible cords connected to devices and fittings so that strain relief isprovided which will prevent pull from being directly transmitted to

the joints or terminal screws?�

Valuable advice on preparing your ‘Laboratory Self Inspection Using A Checklist For Safety And ’ online

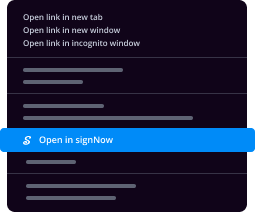

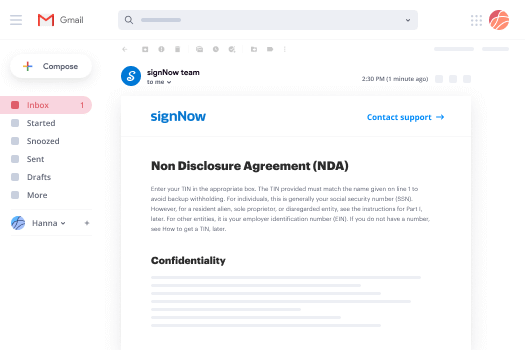

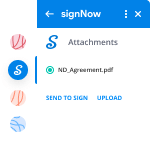

Are you fed up with the inconvenience of handling paperwork? Look no further than airSlate SignNow, the top electronic signature solution for individuals and businesses. Bid farewell to the lengthy procedure of printing and scanning documents. With airSlate SignNow, you can effortlessly complete and sign forms online. Utilize the powerful features embedded in this user-friendly and affordable platform and transform your method of document administration. Whether you need to authorize forms or gather electronic signatures, airSlate SignNow manages it all effortlessly, with just a few clicks.

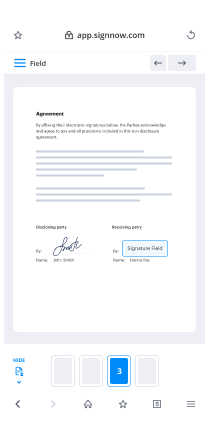

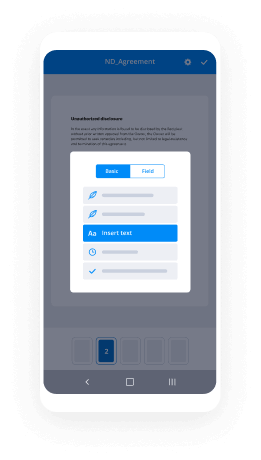

Follow this step-by-step guide:

- Access your account or sign up for a complimentary trial with our service.

- Click +Create to upload a file from your device, cloud storage, or our template library.

- Open your ‘Laboratory Self Inspection Using A Checklist For Safety And ’ in the editor.

- Click Me (Fill Out Now) to prepare the document on your behalf.

- Add and assign fillable fields for others (if needed).

- Proceed with the Send Invite settings to solicit eSignatures from others.

- Save, print your version, or convert it into a reusable template.

No need to worry if you need to collaborate with others on your Laboratory Self Inspection Using A Checklist For Safety And or send it for notarization—our platform provides everything you require to achieve such tasks. Register with airSlate SignNow today and enhance your document management to a higher level!