TP-201-02

March 3, 1989

U.S. DEPARTMENT OF TRANSPORTATION

NATIONAL HIGHWAY TRAFFIC SAFETY ADMINISTRATION

LABORATORY TEST PROCEDURE

FOR

FMVSS 201

Occupant Protection in Interior Impact

SAFETY ASSURANCE

Office of Vehicle Safety Compliance

Room 6115, NSA-30

400 Seventh Street, SW

Washington, DC 20590

�OVSC LABORATORY TEST PROCEDURE NO. 201

TABLE OF CONTENTS

PAGE

1.

PURPOSE AND APPLICATION.............................................................................

1

2.

GENERAL REQUIREMENTS.................................................................................

2

3.

SECURITY .............................................................................................................

3

4.

GOOD HOUSEKEEPING .......................................................................................

3

5.

TEST SCHEDULING AND MONITORING .............................................................

3

6.

TEST DATA DISPOSITION....................................................................................

4

7.

GOVERNMENT FURNISHED PROPERTY (GFP).................................................

4

8.

CALIBRATION OF TEST INSTRUMENTATION ....................................................

5

9.

PHOTOGRAPHIC DOCUMENTATION..................................................................

6

10.

DEFINITIONS.........................................................................................................

7

11.

PRETEST REQUIREMENTS .................................................................................

10

12.

COMPLIANCE TEST EXECUTION........................................................................

11

13.

POST TEST REQUIREMENTS..............................................................................

27

14.

REPORTS ..............................................................................................................

28

14.1

MONTHLY STATUS REPORTS.................................................................

28

14.2

APPARENT NONCOMPLIANCE................................................................

28

14.3

FINAL TEST REPORTS .............................................................................

28

14.3.1 COPIES .........................................................................................

28

14.3.2 REQUIREMENTS..........................................................................

29

14.3.3 FIRST THREE PAGES OF FINAL REPORT.................................

29

14.3.4 TABLE OF CONTENTS ................................................................

35

15.

DATA SHEETS.......................................................................................................

36

16.

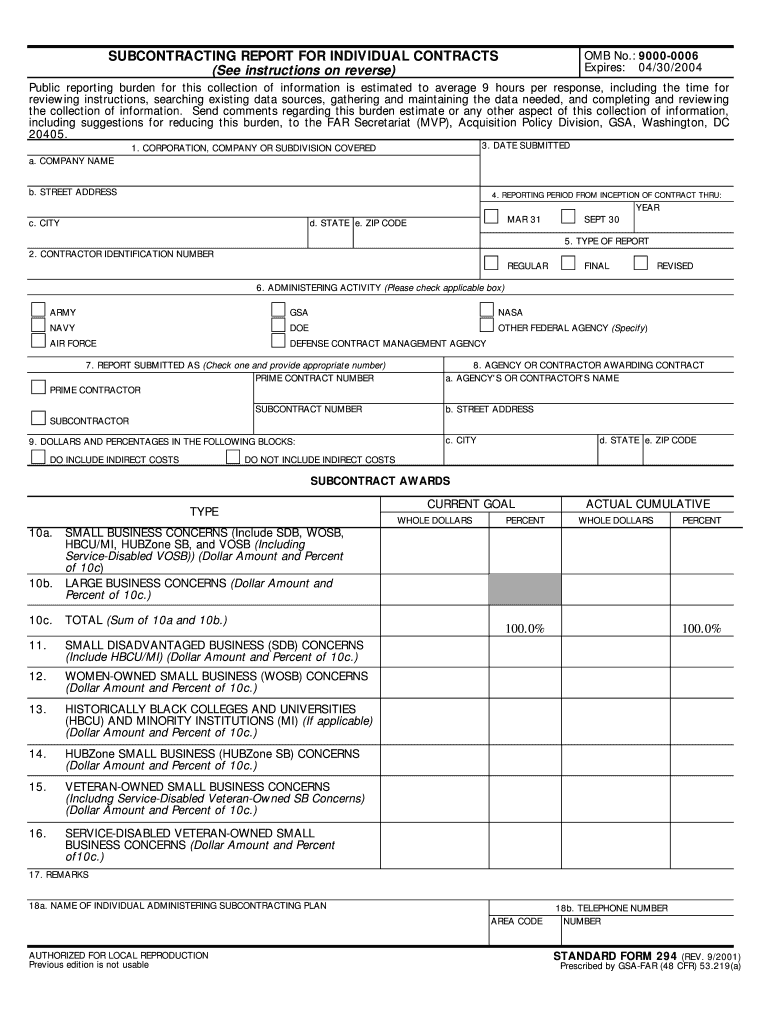

FORMS ..................................................................................................................

44

�2

APPENDIX A

FMVSS 201 ............................................................................

47

APPENDIX B

SAE J921 ...............................................................................

51

APPENDIX C

SAE J839 ...............................................................................

67

APPENDIX D

SAE J984 ...............................................................................

76

APPENDIX E

SAE J211 ...............................................................................

80

�1

1.

PURPOSE AND APPLICATION

The Office of Vehicle Safety Compliance (OVSC) provides contracted

laboratories with Laboratory Test Procedures (TPs) which serve as guidelines for

obtaining compliance test data. The data are used to determine if a specific

vehicle meets the minimum performance requirements of the subject Federal

Motor Vehicle Safety Standard (FMVSS). The purpose of the OVSC Laboratory

Test Procedures is to present a uniform testing and data recording format, and

provide suggestions for the use of specific equipment and procedures. Any

contractor interpreting any part of an OVSC Laboratory Test Procedure to be in

conflict with a Federal Motor Vehicle Safety Standard or observing any

deficiencies in a Laboratory Test Procedure is required to advise the Contracting

Officer's Technical Representative (COTR) and resolve the discrepancy prior to

the start of compliance testing.

Contractors are required to submit a detailed test procedure to the COTR before

initiating the compliance test program. The procedure must include a step-by-step

description of the methodology to be used.

The OVSC Laboratory Test Procedures are not intended to limit or restrain a contractor

from developing or utilizing any testing techniques or equipment which will assist in

procuring the required compliance test data.

NOTE: The OVSC Laboratory Test Procedures, prepared for use by independent

laboratories under contract to conduct compliance tests for the OVSC, are not intended

to limit the requirements of the applicable FMVSS(s). In some cases, the OVSC

Laboratory Test Procedures do not include all of the various FMVSS minimum

performance requirements. Sometimes, recognizing applicable test tolerances, the Test

Procedures specify test conditions which are less severe than the minimum

requirements of the standards themselves. Therefore, compliance of a vehicle or item

of motor vehicle equipment is not necessarily guaranteed if the manufacturer limits

certification tests to those described in the OVSC Laboratory Test Procedures.

�2

2.

GENERAL REQUIREMENTS

Within the provisions of the National Traffic and Motor Vehicle Safety Act of 1966 and

the Highway Safety Act of 1966, the Department of Transportation is charged with the

responsibility of setting Motor Vehicle Safety Standards and ensuring that they are met.

Within the charter, the Department of Transportation has specified various minimum

performance requirements for motor vehicles and motor vehicle equipment.

FMVSS 201 sets forth minimum requirements for instrument panels, seat backs,

interior compartment doors, sun visors and armrests. The purpose of this

standard is to afford impact protection for occupants.

FMVSS 201 applies to passenger cars and to multipurpose passenger vehicles,

trucks and buses with a GVWR of 10,000 pounds of less.

IMPACT PROTECTION REQUIREMENTS

Instrument Panel and Seat Backs

A point within the "head impact area" is impacted by a 15 pound, 6.5 inch

diameter head form at a velocity of 15 miles per hour. The deceleration of the

head form shall not exceed 80g continuously for more than 3 milliseconds (ms).

Interior Compartment Doors

The interior compartment doors are subjected to the inertia load requirements of

SAE J839b, Passenger Car Side Door Latch Systems, May 1965, or approved

equivalent.

Sun Visors

Constructed of or covered with energy absorbing material and have no rigid

material edge radius of less than 0.125 inch.

Armrests

The armrest shall meet the requirements under S3.5 of FMVSS 201.

�3

3.

SECURITY

The contractor shall provide appropriate security measures to protect the OVSC test

vehicles and Government Furnished Property (GFP) from unauthorized personnel

during the entire compliance testing program. The contractor is financially responsible

for any acts of theft and/or vandalism which occur during the storage of test vehicles

and GFP. Any security problems which arise shall be reported by telephone to the

Industrial Property Manager (IPM), Office of Contracts and Procurement, within two

working days after the incident. A letter containing specific details of the security

problem will be sent to the IPM (with copy to the COTR) within 48 hours.

The contractor shall protect and segregate the data that evolves from compliance

testing and test dummy calibration (if applicable) before and after each vehicle test. No

information concerning the vehicle safety compliance testing program shall be released

to anyone except the COTR, unless specifically authorized by the COTR or the COTR's

Group Supervisor or Division Chief.

NOTE: NO INDIVIDUALS, OTHER THAN CONTRACTOR PERSONNEL DIRECTLY

INVOLVED IN THE COMPLIANCE TESTING PROGRAM OR OVSC PERSONNEL,

SHALL BE ALLOWED TO WITNESS ANY VEHICLE OR EQUIPMENT ITEM

COMPLIANCE TEST OR TEST DUMMY CALIBRATION UNLESS SPECIFICALLY

AUTHORIZED BY THE COTR.

4.

GOOD HOUSEKEEPING

Contractors shall maintain the entire vehicle compliance testing area, test fixtures and

instrumentation in a neat, clean and painted condition with test instruments arranged in

an orderly manner consistent with good test laboratory housekeeping practices.

5.

TEST SCHEDULING AND MONITORING

The contractor shall submit a vehicle test schedule to the COTR prior to conducting the

first compliance test. Tests shall be completed as required in the contract.

Scheduling of vehicle tests shall be adjusted to permit vehicles to be tested to other

FMVSSs as may be required by the OVSC. All vehicle compliance testing shall be

coordinated with the COTR in order to allow monitoring by the COTR and/or other

OVSC personnel if desired.

6.

TEST DATA DISPOSITION

The contractor shall make all vehicle preliminary compliance test data available to the

COTR immediately. Final test data, including digital printouts and computer generated

plots (if applicable), shall be furnished to the COTR within five working days.

Additionally, the contractor shall analyze the preliminary test results as directed by the

COTR.

�4

6.

TEST DATA DISPOSITION....Continued

All backup data sheets, strip charts, recordings, plots, technician's notes, etc., shall be

either sent to the COTR or destroyed at the conclusion of each delivery order, purchase

order, etc.

7.

GOVERNMENT FURNISHED PROPERTY (GFP)

GFP shall consist of test vehicles.

ACCEPTANCE OF VEHICLE

The Contractor has the responsibility of accepting the test vehicle from either a new car

dealer or a vehicle transporter. In both instances, the contractor acts in the OVSC's

behalf when signing an acceptance of the test vehicle. If the vehicle is delivered by a

dealer, the contractor must check to verify the following:

A.

All options listed on the "window sticker" are present on the test vehicle.

B.

Tires and wheel rims are new and the same as listed.

C.

There are no dents or other interior or exterior flaws.

D.

The vehicle has been properly prepared and is in running condition.

E.

The glove box contains an owner's manual, warranty document, consumer

information, and extra set of keys.

F.

Proper fuel filler cap is supplied on the test vehicle.

If the test vehicle is delivered by a government contracted transporter, the contractor

should check for damage which may have occurred during transit.

A "Vehicle Condition" form will be supplied to the contractor by the COTR when the test

vehicle is transferred from the new car dealer or between test contracts. The upper half

of the form describes the vehicle in detail, and the lower half provides space for a

detailed description of the post test condition. Vehicle Condition forms must be returned

to the COTR with the copies of the Final Test Report or the reports will NOT be

accepted.

NOTIFICATION OF COTR

The COTR must be notified within 24 hours after a vehicle has been delivered.

�5

8.

CALIBRATION OF TEST INSTRUMENTS

Before the contractor initiates the safety compliance test program, a test instrumentation

calibration system will be implemented and maintained in accordance with established

calibration practices. The calibration system shall be set up and maintained as follows:

A.

Standards for calibrating the measuring and test equipment will be stored and

used under appropriate environmental conditions to assure their accuracy and

stability.

B.

All measuring instruments and standards shall be calibrated by the contractor, or

a commercial facility, against a higher order standard at periodic intervals NOT

TO EXCEED TWELVE (12) MONTHS! Records, showing the calibration

traceability to the National Institute of Standards and Technology (NIST), shall be

maintained for all measuring and test equipment.

C.

All measuring and test equipment and measuring standards will be labeled with

the following information:

(1)

(2)

(3)

D.

A written calibration procedure shall be provided by the contractor which includes

as a minimum the following information for all measurement and test equipment:

(1)

(2)

(3)

(4)

(5)

E.

Date of calibration

Date of next scheduled calibration

Name of the technician who calibrated the equipment

Type of equipment, manufacturer, model number, etc.

Measurement range

Accuracy

Calibration interval

Type of standard used to calibrate the equipment (calibration traceability

of the standard must be evident)

Records of calibration for all test instrumentation shall be kept by the contractor

in a manner which assures the maintenance of established calibration schedules.

All such records shall be readily available for inspection when requested by the

COTR. The calibration procedure must be approved by the COTR before the

test program commences.

�6

9.

PHOTOGRAPHIC DOCUMENTATION

Photographs, if required, shall be glossy black and white, 8½ x 11 inches, and properly

focused for clear images. A tag, label or placard identifying the test vehicle model,

NHTSA number and date shall appear in each photograph and must be legible. Each

photograph shall be labeled as to the subject matter. As a minimum the following

photographs shall be included in each final test report:

A.

B.

C.

D.

E.

F.

G.

H.

I.

J.

K.

L.

M.

N.

O.

P.

Q.

R.

S.

Left side view of vehicle

Right side view of vehicle

3/4 frontal view from left side of vehicle

3/4 rear view from right side of vehicle

Vehicle's certification label

Vehicle's tire information label

Head impact location fixture

Instrument panel and seat backs marked to indicate areas to be

investigated

Instrument panel, seat backs and sun visors marked to show areas of possible

head impact

Instrument panel and seat backs with impact locations marked and identified

Areas on the instrument panel creating local stiffness.

Impactor fixture

Instrument panel and seat backs before and after impact

Sun visor marked to indicate which edges could suffer head impact

Interior compartment doors that will have their latch analyzed

Armrests marked to indicate areas of possible pelvic impact

Armrests before and after evaluation

Instrumentation setup

Any areas of potential failure or hazard not clearly evident in the above list of

photographs

�7

10.

DEFINITIONS

INSTRUMENT PANEL AREA TO BE INVESTIGATED

Area of the instrument panel NOT excluded by the following (see Figure 1):

Console assemblies

Areas less than 5 inches inboard from the juncture of the instrument panel

attachment to the body side inner structure

Areas closer to the windshield juncture than those statically contactable by the

head form with the windshield in place

Areas outboard of any point of tangency on the instrument panel of a 6.5 inch

diameter head form tangent to and inboard of a vertical longitudinal plane

tangent to the inboard edge of the steering wheel

Areas below any point at which a vertical line is tangent to the rearmost surface

of the panel

EXCLUDED AREA

INSTRUMENT PANEL

5"

HEADFORM

VERTICAL PLANE

STEERING WHEEL

TOP VIEW

WINDSHIELD

HEADFORM

VERTICAL PLANE

EXCLUDED AREA

INSTRUMENT PANEL

FIGURE 1

LEFT SIDE VIEW

�8

10.

DEFINITIONS....Continued

HEAD IMPACT LOCATION FIXTURE

Fixture that is placed in each Designated Seating Position (DSP) to determine areas of

possible head impact for each position. Fixture has a pivoted arm with a head form

attached to determine points of contact as the arm is swung forward.

HEAD IMPACT AREA

All nonglazed surfaces of the interior of a vehicle that are statically contactable by 6.5

inch diameter head form of a measuring device having a pivot point to "top-of-head"

dimension infinitely adjustable from 29 to 33 inches in accordance with the following

procedure, or its graphic equivalent:

A.

At each Designated Seating Position (DSP), place the pivot point of the

measuring device —(1)

For seats that are adjustable fore and aft, at —(A)

(B)

(2)

the Seating Reference Point (SRP).

a point 5 inches horizontally forward of the Seating Reference Point

(SRP) and vertically above the SRP an amount equal to the rise

which results from a 5 inch forward adjustment of the seat or 0.75

inch.

For seats that are not adjustable fore and aft, at the SRP.

B.

With the pivot point to "top-of-head" dimension at each value allowed by the

device and the interior dimensions of the vehicle, determine all contact points

above the lower windshield glass line and forward of the SRP.

C.

With the head form at each contact point, and with the device in a vertical

position if no contact points exists for a particular adjusted length, pivot the

measuring device forward and downward through all arcs in vertical planes to 90

degrees each side of the vertical longitudinal plane through the SRP, until the

head form contacts an interior surface or until it is tangent to a horizontal plane 1

inch above the SRP, whichever occurs first.

INTERIOR COMPARTMENT DOOR

Any door in the interior of the vehicle installed by the manufacturer as a cover for

storage space normally used for personal effects.

�9

10.

DEFINITIONS....Continued

PELVIC IMPACT AREA

Any area of the door or body side panel adjacent to any outboard Designated Seating

Position (DSP) which is bounded by horizontal planes 7 inches above and 4 inches

below the SRP and vertical transverse planes 8 inches forward and 2 inches rearward

of the SRP.

SEATING REFERENCE POINT (SRP)

Manufacturer's Design Reference Point which does the following:

A.

Establishes the rearmost normal design driving or riding position of each DSP in

a vehicle

B.

Has coordinates established relative to the designed vehicle structure

C.

Simulates the position of the pivot center of the human torso and thigh

D.

Is the reference point employed to position the two dimensional templates

described in SAE J826, Manikins for Use in Defining Vehicle Seating

Accommodations, Nov62

�10

11.

PRETEST REQUIREMENTS

Prior to conducting any compliance tests, contractors are required to submit a detailed

in-house compliance test procedure to the COTR which includes a step-by-step

description of the methodology to be used. Written approval must be obtained from the

COTR before initiating the compliance test program so that all parties are in agreement.

The contractor's test procedure shall contain a complete listing of test equipment and a

detailed check-off list. There shall be no contradiction between the OVSC Laboratory

Test Procedure and the contractor's in-house test procedure. The list of test equipment

shall include instrument accuracy and calibration dates.

TEST DATA LOSS

A compliance test is not to be conducted unless all of the various test conditions

specified in the applicable OVSC Laboratory Test Procedure have been met. Failure of

a contractor to obtain the required test data and to maintain acceptable limits on test

parameters (such as impact velocity) in the manner outlined in the applicable OVSC

Laboratory Test Procedure may require a retest at the expense of the contractor. The

retest costs will include the cost of the replacement vehicle (with the same equipment

as the original vehicle) or item of motor vehicle equipment and all costs associated with

conducting the retest. The original test specimen (vehicle or equipment item) used for

the invalid test shall remain the property of OVSC, and the retest specimen shall remain

the property of the contractor. If there is a test failure, the contractor shall retain the

retest specimen for a period not exceeding 180 days. If there is no test failure, the

Contractor may dispose of the test specimen upon notification from the COTR that the

final test report has been accepted.

The Contracting Officer of NHTSA is the only NHTSA official authorized to notify the

contractor that a retest is required. The retest shall be completed within two (2) weeks

after receipt of notification by the Contracting Officer that a retest is required. If a retest

is conducted, no test report is required for the original test.

�11

12.

COMPLIANCE TEST EXECUTION

12.1

PREPARATION OF VEHICLE

A.

Place vehicle on rigid supports such that side sills are parallel to the ground. Set

parking brake and provide ground supports so that vehicle will not move.

B.

Place front seats in rearmost position.

C.

Place adjustable seat backs in their Nominal Design Driving Position, as

furnished by the manufacturer, through the COTR.

D.

Close and latch all interior compartment doors. If any doors have locking

devices, set locks to the unlocked position.

NOTE: In an instance where the desired direction of impact is not possible to attain

because of space constraints or otherwise, the COTR shall be notified. A decision can

be made in using a suitable laboratory fixture or the COTR may authorize cutting up of

the intruding vehicle parts to permit the impact test sequence.

12.2

PREPARATION OF THE AREAS TO BE INVESTIGATED

INSTRUMENT PANEL

As shown in Figure 1, outline the area on the instrument panel that is to be investigated

with a marker or tape. The instrument panel area to be evaluated for head impact is

specified in S201 S3.1.1.

Photograph the panel with the outlined area.

SEAT BACKS

As shown on Figures 2 and 2A, outline the area on the seat backs that are to be

investigated. The seat back area to be evaluated for head impact is specified in S201

S3.2.2

Photograph the seat backs with the outlined areas.

�12

12.

COMPLIANCE TEST EXECUTION....Continued

INSTRUMENT PANEL

EXCLUDED AREA

5"

HEADFORM

VERTICAL PLANE

STEERING WHEEL

TOP VIEW

WINDSHIELD

HEADFORM

VERTICAL PLANE

EXCLUDED AREA

LEFT SIDE VIEW

INSTRUMENT PANEL

FIGURE 1

SEATS WITHOUT HEAD RESTRAINTS

BUCKET SEAT

DSP

CENTERLINE

FRONT OF

BENCH SEAT

RIGHT

FRONT

4"

RIGHT

REAR

4"

4"

LEFT

FRONT

4"

DSP

CENTERLINE

4"

LEFT

REAR

BACK

4"

BUCKET SEAT

TOP VIEW

FIGURE 2

VEHICLE

CENTERLINE

�13

12.

COMPLIANCE TEST EXECUTION....Continued

SEATS WITH HEAD RESTRAINTS

BUCKET SEAT

DSP

CENTERLINE

BENCH SEAT

RIGHT

FRONT

BACK

RIGHT

REAR

LEFT

FRONT

BACK

LEFT

REAR

BACK

FRONT OF VEHICLE

DSP

CENTERLINE

BUCKET SEAT

TOP VIEW

VEHICLE

CENTERLINE

FIGURE 2A

12.3

DETERMINATION OF THE AREA OF POSSIBLE HEAD IMPACT

12.3.1 INSTRUMENT PANEL AND SUN VISORS

A.

Using information provided by the COTR, locate the SRP for the right front

seating position.

B.

Place the base of the Head Impact Location Fixture in the right front seating

position as described in Sec. 12.10.1. A representative head impact location

fixture is shown in Figure 3.

C.

Adjust the base and the pivot until the pivot is located at the SRP.

D.

Assemble the arm to the base of the fixture.

E.

Adjust the head form to the 33 inch radius position.

F.

Adjust the arm to a position where it will swing in a plane parallel to the vehicle

centerline.

G.

Swing the arm forward until it contacts the instrument panel.

�14

12.

COMPLIANCE TEST EXECUTION....Continued

WINDSHIELD

STEERING WHEEL

IMPACT

FIXTURE

HEADFORM

INSTRUMENT

PANEL

RIGHT SIDE VIEW

FIGURE 3

H.

Keeping the head form in contact with the instrument panel, rotate the arm about

the vertical axis through the pivot. Rotating to the left and right, find the locus of

points for head impacts. Only the points that fall within the "Area to investigated"

are permissible, as shown in Figure 1.

I.

With the fixture arm again in the plane parallel to the vehicle centerline, swing the

arm forward and the sun visor down to find a contact with the edge of the visor.

J.

Move the arm forward to left and right to find all possible contacts along the edge

of the visor.

Adjust head form to each value allowed by the device including the 29 inch

radius position and repeat steps F to J.

For seats that are ADJUSTABLE FORE AND AFT, move the pivot of the

measuring device to a point 5 inches horizontally forward and 0.75 inches

vertically above the SRP.

Repeat all above steps for the center and/or driver's DSP. Outline the

extremities of the loci found above on the instrument panel and sunvisor.

Photograph these areas of possible impact.

�15

12.

COMPLIANCE TEST EXECUTION....Continued

INSTRUMENT PANEL

EXCLUDED AREA

5"

HEADFORM

VERTICAL PLANE

STEERING WHEEL

TOP VIEW

WINDSHIELD

HEADFORM

VERTICAL PLANE

EXCLUDED AREA

LEFT SIDE VIEW

INSTRUMENT PANEL

FIGURE 1

12.3.2

SEAT BACKS

12.3.2.1 SEATS WITHOUT HEAD RESTRAINTS

Repeat the above procedure by placing the head impact location fixture in the rear

DSPs and locating the areas of possible impact on the seat backs.

12.3.2.2 SEATS WITH HEAD RESTRAINTS

Place head restraint in its lowest adjustable position. Only points along the centerline of

the head restraint that are parallel to the vehicle longitudinal centerline, may be

considered.

In an instance where the impact on the seat back is not possible within the vehicle

interior because of space constraints, or otherwise, the COTR shall be notified. A

decision can be made in using a suitable laboratory fixture or the COTR may authorize

cutting up of the intruding vehicle structure or removal of vehicle parts to permit impact

test sequence.

�16

12.

COMPLIANCE TEST EXECUTION....Continued

12.4

SELECTION OF THE POINTS OF IMPACT

12.4.1 INSTRUMENT PANEL

The points of impact shall be located on a line (maximum length of 33 inches) tangent to

the instrument panel surface. The origin of the line tangent to the instrument panel

surface shall be a point on a transverse horizontal line through the FORWARD SRP.

Construct a perpendicular at the point of tangency. The intersection is the location of

the point of impact.

NOTE: POINTS OF IMPACT MUST BE WITHIN THE IMPACT AREA.

12.4.2 SEAT BACKS

The points of impact shall be located on a line (maximum length of 33 inches) tangent to

the seat back frame. The origin of the line tangent to the seat back frame shall be on a

point on a transverse horizontal line through the SRP of the right rear DSP.

Construct a perpendicular at the point of tangency. The intersection is the location of

the point of impact.

Adjustable front seats shall be in their rearmost Design Driving Position.

Adjustable front seat backs shall be in their Nominal Design Driving Position

(information will be obtained from vehicle manufacturer and supplied by the COTR).

NOTE: POINTS OF IMPACT MUST BE WITHIN THE IMPACT AREA

12.5

DIRECTION OF IMPACT

Direction of impact shall be one of the following:

A.

In a vertical plane parallel to the vehicle longitudinal axis

B.

In a plane normal to the surface at the point of contact

Mark selected points for impact and number each point.

Photograph the impact points.

�17

12.

COMPLIANCE TEST EXECUTION....Continued

12.6

IMPACT TEST FOR SEAT BACKS AND INSTRUMENT PANELS

12.6.1 GENERAL REQUIREMENTS

Maintain test samples and the head form at 72ºF ± 5ºF for 12 hours prior to test.

Statement of measurement requirements is in Section 12.10.3 and representative

components are shown below.

MANUFACTURE

R/

MODEL

SERIAL

NUMBER

Computer

486DX2/66Mz

Endevco 2735PQ

GP14

Accelerometer

Endevco 2272

PA49

Time Interval Meter

CMC915

09150116

Time Trap No. 1

MS 1"/01

1

Time Trap No. 2

MS 1"/02

2

Integrator Processor

Fine Engineering

Weather

Instrument

CALIBRATIO

N

DUE

486DX2-2203

Charge Amplifier

CALIBRATI

ON

DATE

BOOKD

ITEM

Temperature

FIGURE 4

Use a 6.5 inch diameter head form (cross-section shown in Figure 5) which weighs 14.7

pounds ± 0.2 pounds.

Impact velocity shall be 14.7 mph ± 0.2 mph. Deceleration shall not exceed 80g

continuously for more than 3 milliseconds (ms) to pass the test.

12.6.2 IMPACT TEST STEPS

The following steps will be followed in accomplishing the impact tests on seat backs and

the instrument panel:

A.

Install the head form actuator mount in the area of the test vehicle aft of the

impact area selected for the test.

�18

12.

COMPLIANCE TEST EXECUTION....Continued

MOUNTING LIP

6.5" DIA. HEADFORM

CENTERLINE

ACCELEROMETER

MOUNTING HOLES

WEIGHT = 14.9 LBS. MAXIMUM

SIDE VIEW

FIGURE 5

B.

The test engineer will select approximately five "worse case" impact locations

within the head impact zone where the local area is hard or stiff. The COTR will

be consulted before finalizing the selection.

C.

Record X and Y coordinates of each impact location and angle of impact with

reference to a common reference axis system that will be selected by the test

engineer.

D.

Ensure that the accelerometer is properly mounted at the designated location on

the head form (SAE J984 Jun80) and that the accelerometer output is properly

connected to the recorder.

E.

Set the actuator pressure to previously calibrated level to achieve 14.7 mph ± 0.2

mph impact velocity. Activate the velocity timing trap. Fire the actuator and

verify that the specified velocity is achieved.

F.

Position the head form actuator as required and impact the selected impact point

at the locations/angles selected in step B and C, with the head form traveling at

14.7 mph ± 0.2 mph. Record the actual velocity from the speed trap.

G.

The same procedure will be repeated at each selected impact zone.

�19

12.

COMPLIANCE TEST EXECUTION....Continued

H.

The test engineer will process the acceleration versus time data recorded from

the head form accelerometer by using "3 ms clip" computer routine to establish

the maximum (3 ms clip) value of head form acceleration data using SAE J211

recommended filter class 1000.

I.

The test engineer will process the accelerometer versus time head form

acceleration data to obtain the dynamic head form displacement. This will be

accomplished by double integrating the head form accelerometer data from time

zero to find the maximum value.

J.

Document each impact location photographically with pretest and post test still

black and white photographs.

K.

Note any unusual events, occurrence or anomalies in test log and the data sheet.

L.

Record all parameters and the results.

The details of the instrumentation required are provided in Section 11.10, Test

Equipment. A representative list of measurement system components is shown in

Figure 4.

MANUFACTURE

R/

MODEL

SERIAL

NUMBER

Computer

486DX2/66Mz

486DX2-2203

Charge Amplifier

Endevco 2735PQ

GP14

Accelerometer

Endevco 2272

PA49

Time Interval Meter

CMC915

09150116

Time Trap No. 1

MS 1"/01

1

Time Trap No. 2

MS 1"/02

2

Integrator Processor

Fine Engineering

Weather

Instrument

CALIBRATI

ON

DATE

BOOKD

ITEM

Temperature

FIGURE 4

A representative recording setup is shown in Figure 6 on the next page.

CALIBRATIO

N

DUE

�20

12.

COMPLIANCE TEST EXECUTION....Continued

ACCELEROMETER

TIME TRAP NO. 1

TIME TRAP NO. 2

TIME

INTERVAL

METER

NO. 2

DATA FROM

ACCELEROMETER

AMPLIF./

SIGNAL

CONDIT.

DATA

COLLECTTION

TIME

INTERVAL

METER

NO. 1

DATA

PROCESSING

DATA

PLOTS

COMPUTER SYSTEM

FIGURE 6

12.7

SUN VISOR EVALUATION

A.

B.

Determine areas of sun visor mounting that are contactable by a spherical 6.5

inch diameter head form.

C.

Measure the edge radii that were found to be contact areas with the head form.

Radius must equal or exceed 0.125 inch to be acceptable. Mark edges that are

not acceptable and photograph.

D.

12.8

Check that the sun visor is covered with energy absorbing material.

Disassemble the sun visor and identify the construction material.

ARMREST EVALUATION

This evaluation includes attached armrests, such as on door panels, and folding

armrests that fold into the seat back.

12.8.1 REQUIREMENTS

The armrest shall conform to at least one of the following:

�21

12.

COMPLIANCE TEST EXECUTION....Continued

A.

It shall be constructed with energy absorbing material and shall deflect or

collapse laterally at least 2 inches without permitting contact with any underlying

rigid material.

B.

It shall be constructed with energy absorbing material that deflects or collapses

to within 1.25 inches of a rigid test panel surface without permitting contact with

any rigid material. Any rigid material between 0.5 and 1.25 inches from the panel

surface shall have a minimum vertical height of not less than 1 inch.

C.

Along not less than 2 continuous inches of its length, the armrest shall, when

measured vertically in side elevation, provide at least 2 inches of coverage within

the pelvic impact area.

If the armrest folds into the seat back or in between the two seat backs it shall conform

to at least one of the following requirements:

A.

One of the three requirements identified in items A, B, C as they apply to fixed

armrests

B.

Be constructed of or covered with energy absorbing material

12.8.2 ARMREST EVALUATION PROCEDURE

A.

Test engineer will inspect each armrest to establish if its of a fixed configuration

or a folding configuration.

B.

Each armrest will be further evaluated to record if it is constructed or covered

with energy absorbing material, such as foam, padding, soft fabric or other

material designed to absorb impact energy.

C.

Mark the pelvic impact area as defined in Section 10. A cardboard or sheet

metal cutout may be required to identify the pelvic impact area. A representative

cutout is shown in Figure 7.

D.

Place the pelvic area cutout in proper orientation in a vertical plane next to the

armrest under evaluation.

E.

Mark the outline of the armrest on the cutout (representative sample shown on

previous page).

F.

Examine the armrest outline on the cutout to record if at least 2 inches of vertical

coverage has been provided by the armrest along at least 2 inches of its

continuous length.

G.

Use a scale graduated in 1/32 inch to make the measurements.

�22

12.

COMPLIANCE TEST EXECUTION....Continued

7"

2"

SRP

4"

8"

FIGURE 7

H.

Record the results.

I.

Document the measurement using black and white photographs.

J.

Position a portapower or equivalent device with which to load the armrest along a

lateral axis at the center point of the armrest. A representative device is shown

in Figure 8.

K.

Load the armrest laterally until a deflection of the 1-1/4 inches is observed.

L.

Examine if any underlying rigid material has been contacted. If the answer is no

go to step M. If the answer is yes go to step N.

M.

Continue loading until a deflection of 2 inches is reached. At each 1/4 inch

deflection repeat step L.

N.

At any stage, in step L or M, if underlying rigid material is contacted, stop the

loading test, examine the armrest construction to establish if the underlying rigid

material between 0.5 inches to 1.25 inches from the end has a minimum height

of 1 inch. Record the actual height. The examination may require tearing down

of the armrest.

�23

12.

COMPLIANCE TEST EXECUTION....Continued

FLAT STOCK

ROUND

TUBE

STOCK

3/8" DIA. ROD STOCK

1" SQ. TUBE STOCK

SIDE VIEW

FIGURE 8

O.

12.9

Use collected data in steps A to N to evaluate PASS/FAIL performance of the

tested armrest.

INTERIOR COMPARTMENT DOORS

Doors located in the instrument panel, console assembly, seat back or side panel area

adjacent to a designated seating position shall be evaluated for unlatching due to

inertial loads developed during an accident

12.9.1 LOADING CONDITIONS

A.

Inertial load of 10 g in a horizontal transverse direction.

B.

Inertial load of 10 g in a vertical direction.

C.

Inertial load of 30 g in a horizontal longitudinal direction.

12.9.2 EVALUATION

Each latch assembly evaluation shall be conducted mathematically by using the

algebraic method described in SAE Recommended Practice J839b Section 5 and

shown in the Appendix C or equivalent. The latch assembly evaluation method must be

approved by the COTR.

�24

12.

COMPLIANCE TEST EXECUTION....Continued

INTERIOR COMPARTMENT DOOR LATCH DATA:

COTR will provide manufacturer's data that will be used as input to the analysis. Such

data will include:

A.

Geometric details of the latch/lock configuration.

B.

Mass data for each element in the linkage.

C.

Spring rates for each spring element in the configuration.

D.

Any additional details unique to the design yet necessary for the calculations.

12.10 TEST EQUIPMENT REQUIREMENTS

The test equipment requirements for S201 testing in terms of overall performance

guidelines are outlined in this section. Two designs are described: one for the Head

Impact Location Fixture and the other for the impact fixture. Measurement equipment is

also identified.

12.10.1 HEAD IMPACT LOCATION FIXTURE

The fixture consists of a head form rigidly attached to an arm that pivots about the SRP

with both horizontal and vertical axes of rotation.

The length of the arm must be infinitely adjustable between 29 and 33 inches,

measured from the pivot to the top of the head.

Provision must be made for placing the pivot at the SRP and also at a position five

inches in front of and 0.75 inch above the SRP.

The lower end of the pivot has a threaded shaft that serves two purposes. It permits

height adjustment of the pivot to align it with the SRP. Rotation of the shaft also

provides the vertical axis of rotation.

12.10.2 IMPACTOR FIXTURE

The impactor fixture can be installed by removing the side doors of the vehicle and by

setting up the base of the impactor test setup frame going across the test vehicle at

right angles to vehicle longitudinal centerline. The fully adjustable impactor setup then

can be mounted and operated from this base. The type of impact fixture shown in

Figure 11 on the next page can be utilized. The head form, rod and actuator would be

mounted on a ball-joint attached to a frame member extending through the vehicle. The

accumulator and controls would be mounted outside the vehicle.

�25

12.

COMPLIANCE TEST EXECUTION....Continued

HEADFORM

IMPACTOR ASSEMBLY

FRONT BUCKET

SEAT

LEFT SIDE VIEW

FIGURE 11

The impactor shown above is not suitable for an impact on almost horizontal surfaces of

the instrument panel. A swinging type impactor end as shown in Figure 10 on the next

page or equivalent could be used to accomplish the impact sequence.

12.10.3 MEASUREMENT SENSORS

VELOCITY SENSORS

Two noncontacting optical velocity sensors are required to obtain a redundant

measurement of the impact speed. The sensors should be capable of measuring

velocity of 14.70 mph to an accuracy of plus or minus 0.05 mph. The sensors should be

operated from independent power supplies such that no single failure results in a loss of

both speed measurements.

ACCELEROMETER

An accelerometer suitable for impact testing with full scale range of at least 200g's will

be required. The frequency response of the accelerometer shall be consistent with the

requirements of SAE J211.

�26

12.

COMPLIANCE TEST EXECUTION....Continued

HEAD IMPACT LOCATION FIXTURE

ADJUSTABLE

29" to 33"

HEADFORM DIA. = 6.5"

WT. = 14.7 lbs ± 0.2 lbs

BALL JOINT

SIDE VIEW

5"

FIGURE 10

ZERO TIME MARKER

A trigger switch capable of accurately signaling the first contact of the impactor with the

impacted part will be used.

TEMPERATURE

The temperature will be continuously recorded on a "Hyrothermograph" by Weather

Measurement Corp. or a similar device.

�