Catering Bill Format for Supervision Made Easy

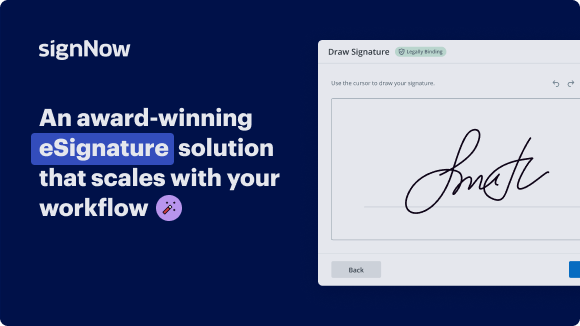

See airSlate SignNow eSignatures in action

Choose a better solution

Move your business forward with the airSlate SignNow eSignature solution

Add your legally binding signature

Integrate via API

Send conditional documents

Share documents via an invite link

Save time with reusable templates

Improve team collaboration

Our user reviews speak for themselves

airSlate SignNow solutions for better efficiency

Why choose airSlate SignNow

-

Free 7-day trial. Choose the plan you need and try it risk-free.

-

Honest pricing for full-featured plans. airSlate SignNow offers subscription plans with no overages or hidden fees at renewal.

-

Enterprise-grade security. airSlate SignNow helps you comply with global security standards.

Catering bill format for supervision

Creating an effective catering bill format for supervision is essential for maintaining clear financial records and ensuring transparency in your catering services. This guide will walk you through using airSlate SignNow, an innovative platform that simplifies document signing and management, which is crucial for any catering business looking to enhance its operational efficiency.

Catering bill format for supervision steps

- Open the airSlate SignNow website in your preferred browser.

- Register for a complimentary trial or access your existing account.

- Upload the document you wish to sign or request signatures for.

- If you anticipate using your document frequently, create a customizable template.

- Select your file to make necessary adjustments: incorporate fillable fields or personalize content.

- Affix your signature and designate fields for other required signatures.

- Proceed to configure and dispatch your eSignature invitation.

In conclusion, airSlate SignNow not only streamlines your document management process but also offers signNow advantages such as high return on investment due to its extensive features and affordable pricing. Its user-friendly design allows for effortless scaling, making it suitable for small and mid-sized businesses.

Take advantage of airSlate SignNow today and revolutionize the way you handle your catering bills!

How it works

Get legally-binding signatures now!

FAQs

-

What is the catering bill format for supervision?

The catering bill format for supervision is a structured document that outlines all financial transactions related to catering services. It ensures detailed tracking of costs and services provided, making it easier for supervisors to manage budgets. Using a clear format helps in quick review and ensures all aspects of catering services are transparent. -

How can airSlate SignNow help with the catering bill format for supervision?

airSlate SignNow allows you to create, edit, and eSign your catering bill format for supervision effortlessly. With its user-friendly interface, you can customize templates to fit your specific needs. This streamlines the billing process and improves efficiency, ensuring that every catering event is accounted for properly. -

Is airSlate SignNow cost-effective for managing catering bills?

Yes, airSlate SignNow offers a cost-effective solution for managing your catering bills. With flexible pricing plans, businesses can choose an option that suits their budget and needs. By utilizing this platform, you can reduce administrative costs and enhance document management efficiency. -

What features are included in airSlate SignNow for catering bill formats?

AirSlate SignNow provides features like customizable templates, electronic signatures, and secure cloud storage for your catering bill format for supervision. You can easily integrate forms and documents, ensuring a streamlined workflow. These features enhance productivity and reduce paperwork associated with catering operations. -

Can I integrate airSlate SignNow with other software for managing catering services?

Absolutely! airSlate SignNow offers seamless integrations with various software solutions, enabling you to manage your catering bill format for supervision efficiently. Whether you're using CRM tools or accounting software, these integrations facilitate better data flow and connectivity, simplifying your administrative tasks. -

What benefits does using airSlate SignNow provide for catering supervision?

Using airSlate SignNow for your catering bill format for supervision delivers numerous benefits, including enhanced accuracy, streamlined communication, and improved tracking of expenses. This software minimizes errors and ensures that all billing is handled systematically. Furthermore, it enables quick approvals, helping caterers focus more on service delivery. -

Is it easy to use airSlate SignNow for creating a catering bill format?

Yes, airSlate SignNow is designed to be user-friendly, making it easy to create a catering bill format for supervision. The drag-and-drop interface allows users to customize their documents without any prior technical skills. This ease of use leads to faster document preparation and enhances overall efficiency.

What active users are saying — catering bill format for supervision

Get more for catering bill format for supervision

- Invoice editor online free for Pharmaceutical

- Invoice Editor Online Free for Human Resources

- Invoice editor online free for HR

- Invoice Editor Online Free for Entertainment

- Invoice editor online free for Education

- Automated Invoice in Google Sheets for Accounting and Tax

- Automated invoice in google sheets for Communications & Media

- Automated Invoice in Google Sheets for Construction Industry

Find out other catering bill format for supervision

- Boost Your Business with eSignature Legitimateness in ...

- Unlock Electronic Signature Legitimateness for ...

- Electronic signature licitness for small businesses in ...

- Unlock the Power of Electronic Signature Licitness for ...

- Unlock the Power of Online Signature Legality for ...

- Unlock the Power of eSignature Legality for Independent ...

- Unlock the Power of eSignature Legitimacy for Interview ...

- Boost eSignature legitimacy for Military Leave Policy

- Ensure eSignature Legality for Your Affidavit of ...

- Boost Your Memorandum of Understanding with airSlate ...

- Electronic Signature Legality for Storage Rental ...

- Ensure Electronic Signature Lawfulness for Profit ...

- Boost your Manufacturing and Supply Agreement ...

- ESignature Legality for General Power of Attorney in ...

- Unlock eSignature legality for Distributor Agreement in ...

- ESignature Legality for Property Inspection Report in ...

- The Legal Power of eSigning General Power of Attorney ...

- Unlock eSignature Legitimateness for Business Associate ...

- Unlock eSignature Legitimateness for Payroll Deduction ...

- ESignature Legality for Non-Compete Agreement in UAE