Collaborate on Money Receipt Design for Quality Assurance with Ease Using airSlate SignNow

See how it works!Click here to sign a sample doc

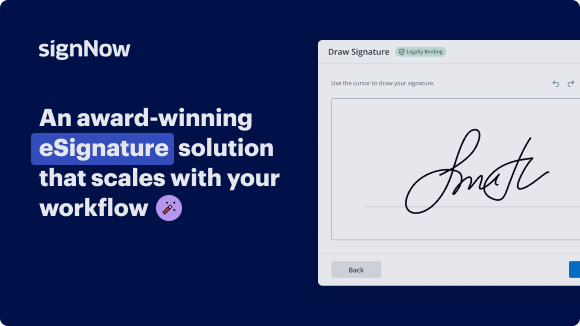

See airSlate SignNow eSignatures in action

be ready to get more

Choose a better solution

Move your business forward with the airSlate SignNow eSignature solution

Add your legally binding signature

Create your signature in seconds on any desktop computer or mobile device, even while offline. Type, draw, or upload an image of your signature.

Integrate via API

Deliver a seamless eSignature experience from any website, CRM, or custom app — anywhere and anytime.

Send conditional documents

Organize multiple documents in groups and automatically route them for recipients in a role-based order.

Share documents via an invite link

Collect signatures faster by sharing your documents with multiple recipients via a link — no need to add recipient email addresses.

Save time with reusable templates

Create unlimited templates of your most-used documents. Make your templates easy to complete by adding customizable fillable fields.

Improve team collaboration

Create teams within airSlate SignNow to securely collaborate on documents and templates. Send the approved version to every signer.

Our user reviews speak for themselves

Collect signatures

24x

faster

Reduce costs by

$30

per document

Save up to

40h

per employee / month

airSlate SignNow solutions for better efficiency

Keep contracts protected

Enhance your document security and keep contracts safe from unauthorized access with dual-factor authentication options. Ask your recipients to prove their identity before opening a contract to money receipt design for quality assurance.

Stay mobile while eSigning

Install the airSlate SignNow app on your iOS or Android device and close deals from anywhere, 24/7. Work with forms and contracts even offline and money receipt design for quality assurance later when your internet connection is restored.

Integrate eSignatures into your business apps

Incorporate airSlate SignNow into your business applications to quickly money receipt design for quality assurance without switching between windows and tabs. Benefit from airSlate SignNow integrations to save time and effort while eSigning forms in just a few clicks.

Generate fillable forms with smart fields

Update any document with fillable fields, make them required or optional, or add conditions for them to appear. Make sure signers complete your form correctly by assigning roles to fields.

Close deals and get paid promptly

Collect documents from clients and partners in minutes instead of weeks. Ask your signers to money receipt design for quality assurance and include a charge request field to your sample to automatically collect payments during the contract signing.

be ready to get more

Why choose airSlate SignNow

-

Free 7-day trial. Choose the plan you need and try it risk-free.

-

Honest pricing for full-featured plans. airSlate SignNow offers subscription plans with no overages or hidden fees at renewal.

-

Enterprise-grade security. airSlate SignNow helps you comply with global security standards.

Explore how to ease your process on the money receipt design for Quality Assurance with airSlate SignNow.

Searching for a way to optimize your invoicing process? Look no further, and follow these simple steps to easily collaborate on the money receipt design for Quality Assurance or ask for signatures on it with our intuitive platform:

- Set up an account starting a free trial and log in with your email credentials.

- Upload a document up to 10MB you need to sign electronically from your device or the cloud.

- Proceed by opening your uploaded invoice in the editor.

- Execute all the required actions with the document using the tools from the toolbar.

- Click on Save and Close to keep all the changes performed.

- Send or share your document for signing with all the needed recipients.

Looks like the money receipt design for Quality Assurance process has just become more straightforward! With airSlate SignNow’s intuitive platform, you can easily upload and send invoices for eSignatures. No more generating a printout, signing by hand, and scanning. Start our platform’s free trial and it optimizes the whole process for you.

How it works

Upload a document

Edit & sign it from anywhere

Save your changes and share

be ready to get more

Get legally-binding signatures now!

FAQs

-

What is a money receipt design for quality assurance?

A money receipt design for quality assurance is a professional template that ensures accurate documentation of financial transactions. This design is created to meet quality standards, making it easy for businesses to keep track of payments and receipts. It is essential for maintaining transparency and trust in financial dealings. -

How can airSlate SignNow help with money receipt design for quality assurance?

airSlate SignNow provides customizable templates for money receipt design for quality assurance, allowing businesses to create receipts that align with their branding. This platform simplifies the process of generating professional documents that meet compliance requirements. Users can easily edit and save templates for future use. -

What features are included in the money receipt design for quality assurance?

The money receipt design for quality assurance includes customizable fields for transaction details, company branding options, and options for electronic signatures. Additionally, it allows for automated calculations and offers storage solutions for easy retrieval of past receipts. These features ensure accurate and efficient handling of financial documents. -

What are the benefits of using a money receipt design for quality assurance?

Using a money receipt design for quality assurance streamlines financial documentation processes and enhances accuracy in record-keeping. It improves professionalism and customer trust while also ensuring regulatory compliance. Overall, it improves operational efficiency and supports effective financial management. -

Is airSlate SignNow affordable for small businesses needing money receipt design for quality assurance?

Yes, airSlate SignNow offers cost-effective solutions for small businesses looking for money receipt design for quality assurance. With various pricing plans available, businesses can choose the plan that best fits their needs and budget. This makes it accessible for companies of all sizes to maintain quality in their financial documentation. -

Can I integrate airSlate SignNow with other tools for money receipt design for quality assurance?

Absolutely! airSlate SignNow supports integrations with several popular business tools, enhancing the money receipt design for quality assurance process. You can easily connect it with platforms like CRM systems, accounting software, and others for seamless workflow management. This integration ensures that your financial processes are efficient and consistent. -

How user-friendly is the money receipt design for quality assurance feature in airSlate SignNow?

The money receipt design for quality assurance feature in airSlate SignNow is highly user-friendly. Its intuitive interface allows users to create and send receipts without any technical expertise. This makes it easy for businesses to adopt and start using the service quickly, enhancing their financial documentation capabilities.

What active users are saying — money receipt design for quality assurance

Get more for money receipt design for quality assurance

- Work receipt template for Hospitality

- Work Receipt Template for Travel Industry

- Work receipt template for HighTech

- Work Receipt Template for Manufacturing

- Work receipt template for Building services

- Work Receipt Template for Sport Organisations

- Work receipt template for Pharmaceutical

- Work Receipt Template for Human Resources

Find out other money receipt design for quality assurance

- Unlock the Power of eSignature Legitimateness for ...

- Unlocking the Power of eSignature Legality for Support ...

- Boost Your Procurement with Legitimate eSignatures in ...

- Unlock eSignature Legitimateness for Logistics in ...

- Ensuring Digital Signature Legality for Support in ...

- The Definitive Guide to Digital Signature Legality for ...

- Ensuring the Legality of Digital Signatures for ...

- Unlock the Power of Digital Signature Legality for ...

- Digital Signature Legality for Quality Assurance in ...

- Digital Signature Legitimacy for Procurement in United ...

- Unlock Digital Signature Legitimateness for Procurement ...

- Electronic Signature Legality for IT in Canada - ...

- Unlocking the Power of Electronic Signature Legality ...

- Electronic Signature Legality for Sales in United ...

- Electronic Signature Legality for Quality Assurance in ...

- Unlock the Power of Electronic Signature Lawfulness for ...

- Unlock Electronic Signature Legitimacy for Accounting ...

- Boost Sales with Electronic Signature Legitimateness in ...

- Electronic Signature Legitimateness for Logistics in ...

- Unlock Electronic Signature Legitimateness for ...