Boosting Digital Signature Legitimateness for Manufacturing in Mexico

- Quick to start

- Easy-to-use

- 24/7 support

Simplified document journeys for small teams and individuals

We spread the word about digital transformation

Why choose airSlate SignNow

-

Free 7-day trial. Choose the plan you need and try it risk-free.

-

Honest pricing for full-featured plans. airSlate SignNow offers subscription plans with no overages or hidden fees at renewal.

-

Enterprise-grade security. airSlate SignNow helps you comply with global security standards.

Your complete how-to guide - digital signature legitimateness for manufacturing in mexico

Digital Signature Legitimateness for Manufacturing in Mexico

In today's digital age, the use of digital signatures is becoming increasingly common, especially in industries like manufacturing. Ensuring the legitimateness of digital signatures is crucial, particularly for businesses operating in Mexico. By utilizing airSlate SignNow, companies can streamline their document signing processes and ensure compliance with Mexican regulations regarding digital signatures.

How to Use airSlate SignNow for Digital Signature Legitimateness in Manufacturing in Mexico

- Launch the airSlate SignNow web page in your browser.

- Sign up for a free trial or log in.

- Upload a document you want to sign or send for signing.

- If you're going to reuse your document later, turn it into a template.

- Open your file and make edits: add fillable fields or insert information.

- Sign your document and add signature fields for the recipients.

- Click Continue to set up and send an eSignature invite.

airSlate SignNow empowers businesses to send and eSign documents with an easy-to-use, cost-effective solution. Its rich feature set provides a great ROI for businesses, particularly for SMBs and Mid-Market companies. Additionally, the platform offers transparent pricing with no hidden support fees or add-on costs, along with superior 24/7 support for all paid plans.

Experience the benefits of airSlate SignNow today and elevate your document signing processes!

How it works

Rate your experience

What is the digital signature legitimateness for manufacturing in Mexico

The digital signature legitimateness for manufacturing in Mexico refers to the legal recognition and acceptance of electronic signatures within the manufacturing sector. This framework ensures that digital signatures have the same legal standing as traditional handwritten signatures, allowing businesses to streamline their operations while maintaining compliance with local laws. In Mexico, the use of digital signatures is governed by the Federal Law on Electronic Signatures, which outlines the requirements for validity and security.

How to use the digital signature legitimateness for manufacturing in Mexico

To utilize the digital signature legitimateness for manufacturing in Mexico, businesses can follow a straightforward process. First, they must ensure they have a valid digital certificate issued by an accredited certification authority. Once the certificate is obtained, users can fill out necessary documents electronically using airSlate SignNow. After completing the document, they can apply their digital signature, which is then securely stored and can be easily shared with relevant parties. This process enhances efficiency and reduces the time spent on document management.

Steps to complete the digital signature legitimateness for manufacturing in Mexico

Completing the digital signature legitimateness for manufacturing in Mexico involves several key steps:

- Obtain a digital certificate from an accredited provider.

- Access the document that requires signing through airSlate SignNow.

- Fill out the required fields within the document.

- Apply your digital signature by selecting the appropriate option in airSlate SignNow.

- Review the signed document for accuracy.

- Save and securely share the completed document with stakeholders.

These steps ensure that the document is legally binding and compliant with Mexican regulations.

Legal use of the digital signature legitimateness for manufacturing in Mexico

The legal use of digital signatures in the manufacturing sector in Mexico is firmly established under the Federal Law on Electronic Signatures. This law stipulates that electronic signatures must meet specific criteria to be deemed valid. These criteria include the use of secure methods for signature creation and verification, as well as ensuring the signer's identity is authenticated. By adhering to these legal guidelines, businesses can confidently use digital signatures in contracts, agreements, and other critical documents.

Security & Compliance Guidelines

Security and compliance are paramount when using digital signatures in manufacturing. Organizations should implement the following guidelines:

- Ensure the digital signature solution complies with local regulations and standards.

- Utilize encryption to protect sensitive information during transmission.

- Regularly update software to safeguard against vulnerabilities.

- Train employees on best practices for digital signature usage and security.

By following these guidelines, businesses can enhance the security of their electronic documents and maintain compliance with legal requirements.

Documents You Can Sign

In the manufacturing sector, various documents can be signed electronically using digital signatures. These include:

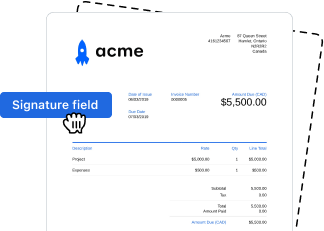

- Contracts and agreements with suppliers and clients.

- Purchase orders and invoices.

- Quality assurance and compliance documents.

- Employee onboarding and HR-related forms.

Using digital signatures for these documents not only speeds up the signing process but also ensures that all parties have access to a secure and verifiable record.

-

Best ROI. Our customers achieve an average 7x ROI within the first six months.

-

Scales with your use cases. From SMBs to mid-market, airSlate SignNow delivers results for businesses of all sizes.

-

Intuitive UI and API. Sign and send documents from your apps in minutes.

FAQs

-

What is the digital signature legitimateness for manufacturing in Mexico?

In Mexico, digital signatures are legally recognized under the Federal Law on Electronic Signatures. This means that digital signatures have the same legal standing as traditional handwritten signatures, ensuring that your documents are valid and enforceable. This legitimateness is crucial for manufacturing businesses that rely on secure and efficient document management.

-

How does airSlate SignNow ensure compliance with digital signature legitimateness for manufacturing in Mexico?

airSlate SignNow complies with Mexican regulations regarding digital signatures, ensuring that all signed documents meet legal standards. Our platform uses advanced encryption and authentication methods to guarantee the integrity and authenticity of your documents. This compliance is essential for manufacturing companies that need to maintain regulatory standards.

-

What are the benefits of using digital signatures for manufacturing businesses in Mexico?

Using digital signatures streamlines the signing process, reduces paperwork, and enhances security for manufacturing businesses in Mexico. It allows for faster turnaround times on contracts and agreements, which is vital in a competitive industry. Additionally, the digital signature legitimateness for manufacturing in Mexico helps in maintaining compliance with legal requirements.

-

Are there any costs associated with implementing digital signatures in manufacturing?

While there may be initial costs for setting up a digital signature solution like airSlate SignNow, the long-term savings on paper, printing, and storage can be signNow. Our pricing plans are designed to be cost-effective for businesses of all sizes, making it easier for manufacturing companies to adopt digital signature legitimateness for manufacturing in Mexico without breaking the bank.

-

What features does airSlate SignNow offer to support digital signature legitimateness for manufacturing in Mexico?

airSlate SignNow offers a range of features including customizable templates, audit trails, and secure storage to support digital signature legitimateness for manufacturing in Mexico. These features ensure that your documents are not only signed but also tracked and stored securely. This enhances accountability and compliance in your manufacturing processes.

-

Can airSlate SignNow integrate with other software used in manufacturing?

Yes, airSlate SignNow offers integrations with various software solutions commonly used in the manufacturing sector, such as ERP and CRM systems. This seamless integration allows for a more efficient workflow, enabling businesses to manage documents and signatures without disrupting existing processes. This is essential for maintaining digital signature legitimateness for manufacturing in Mexico.

-

How secure is the digital signature process with airSlate SignNow?

The digital signature process with airSlate SignNow is highly secure, utilizing advanced encryption and multi-factor authentication to protect your documents. This security is vital for manufacturing businesses that handle sensitive information and need to ensure the integrity of their signed documents. Our commitment to security supports the digital signature legitimateness for manufacturing in Mexico.

Related searches to digital signature legitimateness for manufacturing in mexico

Join over 28 million airSlate SignNow users

Get more for digital signature legitimateness for manufacturing in mexico

- Electronic Signature Legality for Planning in Australia

- Electronic Signature Legality for Planning in United ...

- Electronic Signature Legality for Planning in European ...

- Electronic Signature Legality for Planning in Canada: ...

- Maximize Efficiency with Electronic Signature Legality ...

- Electronic Signature Legality for Planning in UAE - ...

- Understanding the Electronic Signature Legality for ...

- Electronic Signature Legality for Purchasing in Mexico