Ensuring eSignature Legality for Logistics in Mexico

- Quick to start

- Easy-to-use

- 24/7 support

Simplified document journeys for small teams and individuals

We spread the word about digital transformation

Why choose airSlate SignNow

-

Free 7-day trial. Choose the plan you need and try it risk-free.

-

Honest pricing for full-featured plans. airSlate SignNow offers subscription plans with no overages or hidden fees at renewal.

-

Enterprise-grade security. airSlate SignNow helps you comply with global security standards.

Your complete how-to guide - e signature legality for logistics in mexico

eSignature Legality for Logistics in Mexico

In the logistics industry in Mexico, ensuring the legality of eSignatures is crucial for streamlining operations. By utilizing airSlate SignNow, businesses can confidently send and sign important documents electronically while complying with local regulations.

How to Use airSlate SignNow for eSignatures in Logistics:

- Launch the airSlate SignNow web page in your browser.

- Sign up for a free trial or log in.

- Upload a document you want to sign or send for signing.

- If you're going to reuse your document later, turn it into a template.

- Open your file and make edits: add fillable fields or insert information.

- Sign your document and add signature fields for the recipients.

- Click Continue to set up and send an eSignature invite.

airSlate SignNow empowers logistics businesses in Mexico to securely handle document workflows by providing a user-friendly platform for eSignatures. It offers a reliable and efficient solution to ensure the legality of electronic signatures in the logistics sector.

Experience the benefits of airSlate SignNow today and revolutionize your document signing process for better efficiency and compliance in the logistics industry.

How it works

Rate your experience

What is the e signature legality for logistics in Mexico

The e signature legality for logistics in Mexico refers to the legal framework that allows electronic signatures to be used in logistics-related documents. This framework is established under the Mexican Electronic Signature Law, which recognizes the validity of eSignatures in various transactions, including contracts, agreements, and shipping documents. The law ensures that electronic signatures carry the same legal weight as traditional handwritten signatures, provided they meet specific criteria for authenticity and integrity.

How to use the e signature legality for logistics in Mexico

To utilize the e signature legality for logistics in Mexico, businesses must ensure that their electronic signatures comply with the requirements set forth by the law. This includes using secure methods to create and store eSignatures, such as digital certificates issued by accredited providers. When preparing logistics documents, users can fill out the necessary fields electronically, apply their eSignature, and send the document for review or approval. This process streamlines operations, reduces paperwork, and enhances efficiency in logistics management.

Steps to complete the e signature legality for logistics in Mexico

Completing the e signature process for logistics documents involves several key steps:

- Prepare the document: Ensure that all necessary fields are included and that the document is ready for signing.

- Access an eSignature platform: Use a reliable platform like airSlate SignNow to upload the document.

- Fill and sign: Complete any required fields and apply your eSignature securely.

- Send for signature: If additional signatures are needed, send the document to the relevant parties for their eSignatures.

- Store securely: Once all signatures are collected, save the completed document in a secure location for future reference.

Legal use of the e signature legality for logistics in Mexico

The legal use of e signatures in logistics in Mexico is governed by specific regulations that ensure their acceptance in various transactions. To be considered legally binding, eSignatures must be created using secure methods that authenticate the signer's identity. Additionally, the documents must maintain integrity throughout the signing process. Businesses should familiarize themselves with these legal requirements to ensure compliance and avoid disputes related to the validity of their electronic signatures.

Security & Compliance Guidelines

When using e signatures in logistics, it is essential to adhere to security and compliance guidelines to protect sensitive information. Key practices include:

- Utilizing encryption technologies to safeguard documents during transmission.

- Implementing strong authentication measures for users accessing the eSignature platform.

- Regularly auditing eSignature processes to ensure compliance with legal standards.

- Maintaining detailed logs of all eSignature activities for accountability.

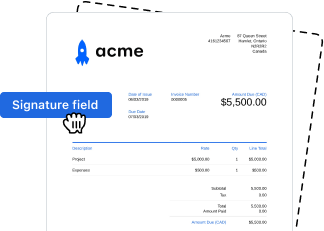

Documents You Can Sign

In the logistics sector, various documents can be signed electronically, including:

- Shipping agreements

- Delivery receipts

- Customs declarations

- Purchase orders

- Contracts with suppliers and partners

These documents benefit from the efficiency and security provided by eSignatures, facilitating smoother operations in logistics management.

-

Best ROI. Our customers achieve an average 7x ROI within the first six months.

-

Scales with your use cases. From SMBs to mid-market, airSlate SignNow delivers results for businesses of all sizes.

-

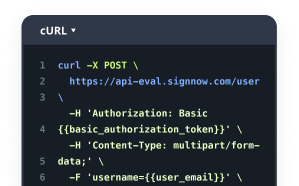

Intuitive UI and API. Sign and send documents from your apps in minutes.

FAQs

-

What is the e signature legality for logistics in Mexico?

In Mexico, e signatures are legally recognized under the Federal Civil Code and the Electronic Signature Law. This means that businesses in the logistics sector can use e signatures for contracts and documents, ensuring compliance with legal standards. Understanding the e signature legality for logistics in Mexico is crucial for streamlining operations and enhancing efficiency.

-

How does airSlate SignNow ensure compliance with e signature legality for logistics in Mexico?

airSlate SignNow adheres to the legal requirements set forth by Mexican law regarding e signatures. Our platform provides secure and verifiable e signatures that meet the necessary compliance standards. This ensures that your logistics documents are legally binding and recognized in Mexico.

-

What features does airSlate SignNow offer for logistics companies?

airSlate SignNow offers a range of features tailored for logistics companies, including customizable templates, bulk sending, and real-time tracking of document status. These features enhance the efficiency of document management while ensuring e signature legality for logistics in Mexico. Our user-friendly interface makes it easy for teams to collaborate and finalize agreements quickly.

-

Is airSlate SignNow cost-effective for logistics businesses?

Yes, airSlate SignNow provides a cost-effective solution for logistics businesses looking to implement e signatures. With flexible pricing plans, companies can choose the option that best fits their needs without compromising on features. This affordability, combined with the assurance of e signature legality for logistics in Mexico, makes it an ideal choice.

-

Can airSlate SignNow integrate with other logistics software?

Absolutely! airSlate SignNow offers seamless integrations with various logistics and business management software. This allows for a smooth workflow and ensures that all documents signed electronically comply with e signature legality for logistics in Mexico. Integrating our solution enhances productivity and reduces manual errors.

-

What are the benefits of using e signatures in the logistics industry?

Using e signatures in the logistics industry streamlines the signing process, reduces paperwork, and accelerates transaction times. It also enhances security and provides a clear audit trail, which is essential for compliance. Understanding the e signature legality for logistics in Mexico further reinforces the benefits of adopting this technology.

-

How secure is airSlate SignNow for handling sensitive logistics documents?

airSlate SignNow prioritizes security by employing advanced encryption and authentication measures to protect sensitive logistics documents. Our platform ensures that all e signatures are secure and compliant with e signature legality for logistics in Mexico. This commitment to security helps businesses maintain trust and confidentiality.

Related searches to e signature legality for logistics in mexico

Join over 28 million airSlate SignNow users

Get more for e signature legality for logistics in mexico

- Transform your paperwork with digital signature in ...

- Experience gratis document signing online with airSlate ...

- Easily and securely electronically sign the document ...

- Experience the power of our document signing ...

- Experience online document signing free with airSlate ...

- Simplify your workflow with digital signing PDF ...

- Quickly insert your signature into a PDF with airSlate ...