Understanding Electronic Signature Lawfulness for Shipping in Mexico

- Quick to start

- Easy-to-use

- 24/7 support

Simplified document journeys for small teams and individuals

We spread the word about digital transformation

Why choose airSlate SignNow

-

Free 7-day trial. Choose the plan you need and try it risk-free.

-

Honest pricing for full-featured plans. airSlate SignNow offers subscription plans with no overages or hidden fees at renewal.

-

Enterprise-grade security. airSlate SignNow helps you comply with global security standards.

Your complete how-to guide - electronic signature lawfulness for shipping in mexico

Electronic Signature Lawfulness for Shipping in Mexico

In Mexico, electronic signatures are legally recognized under the Federal Law of Electronic Signatures. To ensure compliance with the law when shipping goods within the country, businesses must use electronic signatures that meet the specified requirements.

airSlate SignNow Benefits:

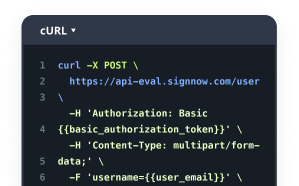

- Launch the airSlate SignNow web page in your browser.

- Sign up for a free trial or log in.

- Upload a document you want to sign or send for signing.

- Convert your document into a template for future use.

- Edit your file by adding fillable fields or inserting information.

- Sign the document and add signature fields for recipients.

- Click Continue to set up and send an eSignature invitation.

airSlate SignNow enables businesses to streamline their document signing processes with an intuitive and cost-effective solution. It offers a great return on investment, is easy to use and scale for businesses of all sizes, has transparent pricing with no hidden fees, and provides superior 24/7 support for all paid plans.

Experience the benefits of airSlate SignNow today and simplify your document signing workflow!

How it works

Rate your experience

What is the electronic signature lawfulness for shipping in Mexico

The electronic signature lawfulness for shipping in Mexico refers to the legal framework that governs the validity and enforceability of electronic signatures in shipping documents. Under Mexican law, electronic signatures are recognized as equivalent to handwritten signatures, provided they meet certain criteria established by the Federal Civil Code and the eSignature Law. This framework ensures that electronic signatures can be used for various shipping-related documents, including contracts, bills of lading, and customs declarations, facilitating smoother and faster transactions.

How to use the electronic signature lawfulness for shipping in Mexico

To effectively use the electronic signature lawfulness for shipping in Mexico, businesses should ensure that their electronic signatures comply with legal requirements. This involves using a reliable eSignature solution, like airSlate SignNow, which provides secure and legally compliant electronic signatures. Users can fill out shipping documents online, apply their eSignature, and send them for signature to other parties. This process not only enhances efficiency but also maintains the legal standing of the documents involved in shipping transactions.

Steps to complete the electronic signature lawfulness for shipping in Mexico

Completing the electronic signature lawfulness for shipping in Mexico involves several straightforward steps:

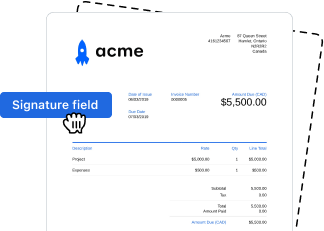

- Access the shipping document through airSlate SignNow.

- Fill in the required information, ensuring accuracy.

- Apply your electronic signature using the platform's eSigning feature.

- Send the document for signature to relevant parties, if necessary.

- Once all signatures are obtained, securely store the completed document for future reference.

Legal use of the electronic signature lawfulness for shipping in Mexico

The legal use of electronic signatures in shipping documents in Mexico is supported by various laws that affirm their validity. The Federal Civil Code and the Law on Electronic Signatures outline the conditions under which electronic signatures are considered legally binding. For electronic signatures to be legally recognized, they must be created using a secure method that ensures the identity of the signer and the integrity of the document. This legal framework allows businesses to confidently use electronic signatures in their shipping processes.

Key elements of the electronic signature lawfulness for shipping in Mexico

Key elements that contribute to the lawfulness of electronic signatures for shipping in Mexico include:

- Authentication: The signer’s identity must be verified through secure methods.

- Integrity: The document must remain unchanged after signing.

- Consent: All parties must agree to use electronic signatures.

- Record-keeping: Businesses must maintain records of signed documents for legal compliance.

Security & Compliance Guidelines

Ensuring security and compliance when using electronic signatures for shipping in Mexico is crucial. Businesses should implement robust security measures, such as encryption and secure access controls, to protect sensitive information. Compliance with local laws and regulations is also essential. Utilizing a trusted eSignature platform like airSlate SignNow helps in adhering to these guidelines by providing features that enhance document security and ensure legal compliance throughout the signing process.

Examples of using the electronic signature lawfulness for shipping in Mexico

Examples of using electronic signatures in shipping documents include:

- Signing contracts for freight services electronically.

- Approving bills of lading and shipping manifests.

- Submitting customs declarations with electronic signatures.

- Finalizing agreements with suppliers and distributors through eSigning.

-

Best ROI. Our customers achieve an average 7x ROI within the first six months.

-

Scales with your use cases. From SMBs to mid-market, airSlate SignNow delivers results for businesses of all sizes.

-

Intuitive UI and API. Sign and send documents from your apps in minutes.

FAQs

-

What is the electronic signature lawfulness for shipping in Mexico?

The electronic signature lawfulness for shipping in Mexico is governed by the Federal Law on Electronic Signatures, which recognizes electronic signatures as legally binding. This means that businesses can use electronic signatures for shipping documents without legal concerns. airSlate SignNow ensures compliance with these laws, making it a reliable choice for your shipping needs.

-

How does airSlate SignNow ensure compliance with electronic signature lawfulness for shipping in Mexico?

airSlate SignNow adheres to the legal standards set by Mexican law regarding electronic signatures. Our platform uses advanced encryption and authentication methods to ensure that all signed documents are secure and legally valid. This guarantees that your shipping documents meet the electronic signature lawfulness for shipping in Mexico.

-

What features does airSlate SignNow offer for electronic signatures?

airSlate SignNow offers a range of features including customizable templates, real-time tracking, and multi-party signing. These features enhance the efficiency of document signing processes while ensuring compliance with electronic signature lawfulness for shipping in Mexico. Our user-friendly interface makes it easy for businesses to manage their shipping documents.

-

Is airSlate SignNow cost-effective for businesses shipping to Mexico?

Yes, airSlate SignNow provides a cost-effective solution for businesses looking to streamline their shipping processes. With flexible pricing plans, you can choose the option that best fits your needs while ensuring compliance with electronic signature lawfulness for shipping in Mexico. This allows you to save time and resources while maintaining legal integrity.

-

Can airSlate SignNow integrate with other shipping platforms?

Absolutely! airSlate SignNow offers seamless integrations with various shipping platforms and software. This allows you to manage your shipping documents efficiently while ensuring that all electronic signatures comply with the electronic signature lawfulness for shipping in Mexico. Integration enhances your workflow and simplifies the signing process.

-

What are the benefits of using electronic signatures for shipping documents?

Using electronic signatures for shipping documents offers numerous benefits, including faster turnaround times, reduced paper usage, and enhanced security. By utilizing airSlate SignNow, you can ensure that your electronic signatures are compliant with the electronic signature lawfulness for shipping in Mexico, providing peace of mind for your business transactions.

-

How secure is airSlate SignNow for electronic signatures?

airSlate SignNow prioritizes security by employing advanced encryption and secure authentication methods. This ensures that all electronic signatures are protected and comply with the electronic signature lawfulness for shipping in Mexico. You can trust that your sensitive shipping documents are safe and legally binding.