Understanding eSignature Legality for Lodger Agreement in European Union

- Quick to start

- Easy-to-use

- 24/7 support

Simplified document journeys for small teams and individuals

We spread the word about digital transformation

Why choose airSlate SignNow

-

Free 7-day trial. Choose the plan you need and try it risk-free.

-

Honest pricing for full-featured plans. airSlate SignNow offers subscription plans with no overages or hidden fees at renewal.

-

Enterprise-grade security. airSlate SignNow helps you comply with global security standards.

Your complete how-to guide - esignature legality for lodger agreement in european union

eSignature legality for Lodger Agreement in European Union

When it comes to ensuring the legality of eSignatures for Lodger Agreements in the European Union, it is important to follow the proper procedures to comply with regulations. Utilizing airSlate SignNow can streamline this process and provide a secure solution for signing important documents.

Steps to utilize airSlate SignNow for eSigning Lodger Agreements:

- Launch the airSlate SignNow web page in your browser.

- Sign up for a free trial or log in.

- Upload a document you want to sign or send for signing.

- If you're going to reuse your document later, turn it into a template.

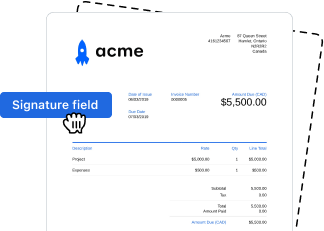

- Open your file and make edits: add fillable fields or insert information.

- Sign your document and add signature fields for the recipients.

- Click Continue to set up and send an eSignature invite.

airSlate SignNow empowers businesses to send and eSign documents with an easy-to-use, cost-effective solution. Its great ROI makes it an excellent choice for businesses of all sizes, offering transparent pricing and superior 24/7 support for all paid plans.

Experience the benefits of airSlate SignNow today and streamline your eSigning process for Lodger Agreements in the European Union.

How it works

Rate your experience

What is the esignature legality for lodger agreement in european union

The legality of electronic signatures for lodger agreements in the European Union is established under the eIDAS Regulation, which provides a comprehensive legal framework for electronic signatures. This regulation ensures that electronic signatures have the same legal standing as handwritten signatures across EU member states. For a lodger agreement to be valid, it must meet specific criteria, including the signer's consent and the ability to identify the signatory. It is essential to ensure that the eSignature solution used complies with these legal requirements to avoid any disputes or issues in the future.

How to use the esignature legality for lodger agreement in european union

Utilizing the eSignature legality for a lodger agreement involves several straightforward steps. First, create the lodger agreement document using a reliable electronic signature platform like airSlate SignNow. Next, fill out the necessary details, such as the names of the parties involved, the rental terms, and any additional clauses. Once completed, you can send the document for signature electronically. The signers will receive a notification to review and eSign the document, ensuring a smooth and efficient process. After all parties have signed, the completed agreement is securely stored, providing easy access for future reference.

Steps to complete the esignature legality for lodger agreement in european union

To complete the eSignature process for a lodger agreement, follow these steps:

- Prepare the lodger agreement document, ensuring all necessary information is included.

- Upload the document to airSlate SignNow or your chosen eSignature platform.

- Fill in any required fields, such as names, dates, and rental terms.

- Send the document for signature to all parties involved.

- Each signer will receive an email notification to review and eSign the document.

- Once all signatures are collected, the completed agreement will be stored securely.

Security & Compliance Guidelines

When using eSignatures for lodger agreements, adhering to security and compliance guidelines is crucial. Ensure that the eSignature platform complies with the eIDAS Regulation and offers robust security features, such as encryption and secure storage. Additionally, implement identity verification methods to confirm the signers' identities. Regularly review and update your security practices to protect sensitive information and maintain compliance with applicable laws. This approach not only safeguards your documents but also instills confidence in all parties involved in the agreement.

Digital vs. Paper-Based Signing

Choosing between digital and paper-based signing for lodger agreements offers distinct advantages. Digital signing through platforms like airSlate SignNow streamlines the process, allowing for quicker execution and easier management of documents. It eliminates the need for physical storage and reduces paper waste, contributing to environmental sustainability. Furthermore, digital signatures provide enhanced security features, such as audit trails and encryption, which are often lacking in traditional paper-based methods. By opting for digital signing, you can ensure a more efficient and secure approach to managing lodger agreements.

Examples of using the esignature legality for lodger agreement in european union

Examples of utilizing eSignatures for lodger agreements in the European Union include various scenarios such as:

- A landlord and tenant finalizing a short-term rental agreement for a vacation property.

- Roommates entering into a shared living arrangement, ensuring all parties agree to the terms.

- A property management company executing agreements with multiple tenants efficiently.

In each case, the use of eSignatures simplifies the process, allowing for quick turnaround times and secure document management.

-

Best ROI. Our customers achieve an average 7x ROI within the first six months.

-

Scales with your use cases. From SMBs to mid-market, airSlate SignNow delivers results for businesses of all sizes.

-

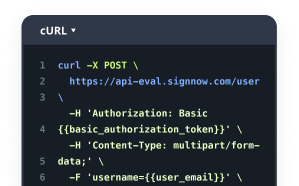

Intuitive UI and API. Sign and send documents from your apps in minutes.

FAQs

-

What is the esignature legality for lodger agreement in European Union?

The esignature legality for lodger agreement in European Union is governed by the eIDAS Regulation, which recognizes electronic signatures as legally binding. This means that as long as the esignature meets certain criteria, it can be used for lodger agreements just like traditional signatures.

-

How does airSlate SignNow ensure compliance with esignature legality for lodger agreements in the EU?

airSlate SignNow complies with the esignature legality for lodger agreements in the European Union by adhering to the eIDAS Regulation. Our platform provides secure and verifiable electronic signatures, ensuring that your lodger agreements are legally enforceable.

-

What features does airSlate SignNow offer for managing lodger agreements?

airSlate SignNow offers features such as customizable templates, real-time tracking, and secure storage, all of which enhance the management of lodger agreements. These features ensure that your documents are signed quickly and comply with esignature legality for lodger agreements in the European Union.

-

Is airSlate SignNow cost-effective for signing lodger agreements?

Yes, airSlate SignNow is a cost-effective solution for signing lodger agreements. Our pricing plans are designed to accommodate various business needs, making it easy to manage esignature legality for lodger agreements in the European Union without breaking the bank.

-

Can I integrate airSlate SignNow with other tools for my lodger agreements?

Absolutely! airSlate SignNow offers seamless integrations with various tools and platforms, enhancing your workflow for lodger agreements. This ensures that you can maintain compliance with esignature legality for lodger agreements in the European Union while using your preferred applications.

-

What are the benefits of using airSlate SignNow for lodger agreements?

Using airSlate SignNow for lodger agreements provides numerous benefits, including faster turnaround times, enhanced security, and improved document management. These advantages help ensure that you remain compliant with esignature legality for lodger agreements in the European Union.

-

How secure is airSlate SignNow for signing lodger agreements?

airSlate SignNow prioritizes security by employing advanced encryption and authentication measures. This ensures that your lodger agreements are protected and that you can confidently rely on the esignature legality for lodger agreements in the European Union.

Related searches to esignature legality for lodger agreement in european union

Join over 28 million airSlate SignNow users

Get more for esignature legality for lodger agreement in european union

- Boost Electronic Signature Legitimacy for Cease and ...

- Enhance Electronic Signature Legitimacy for Cease and ...

- Unlock Electronic Signature Legitimacy for Cease and ...

- Electronic Signature Legitimacy for Cease and Desist ...

- Unlock Electronic Signature Legitimacy for End User ...

- Enhance Electronic Signature Legitimacy for End User ...

- Unlock Electronic Signature Legitimacy for End User ...

- Ensuring Electronic Signature Legitimacy for End User ...