DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 1 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

1.0

PURPOSE

1.1. To inform applicants how to apply for Mine Safety and Health Administration

(MSHA) Field Modifications.

1.2. To specify the documentation and processing steps necessary to evaluate a field

modification application compliant with MSHA requirements.

1.3. To identify the Applicant’s responsibilities during the investigation process.

2.0

SCOPE

This procedure applies to all approved (permissible) equipment owners who wish to

apply for a field modification under Title 30 Code of Federal Regulations, Section

18.81.

3.0

REFERENCES

3.1. APOL2153 – “Policy on Motor Overload Protection”

3.2. APOL1009 – “Application Cancellation Policy”

4.0

DEFINITIONS

4.1. A&CC – the Approval and Certification Center.

4.2. Applicant – A mine owner or their designate. The designate may be a mine

superintendent, master mechanic, shop foreman, mine engineer, or other

responsible mine official.

5.0

PROCEDURE

5.1. Application

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 2 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

5.1.1. An applicant who desires to modify equipment approved under 30 CFR, Part

18 must submit a written Field Modification Request to the A&CC. A

separate request must be submitted for each different approval number of

equipment modified, even though identical modifications are proposed.

Different extensions of the same approval numbers may be covered under the

same field modification request if the proposed modifications are relevant to

each extension. Alternate or optional components cannot be added under the

Field Modification Program.

5.1.2. All applications for Field Modification must include the following:

5.1.2.1. Two copies of the Field Modification Request. (See Appendix 1, Enclosure

A for blank request forms, Enclosure B for a completed sample of the

request form for Part 18 approved machines.)

5.1.2.2. Two copies of each drawing, bill of material, specification, etc., necessary

for documenting the proposed modification(s).

5.1.2.3. Field Modification Requests should be mailed to:

Approval and Certification Center

Mine Safety and Health Administration

RR #1, Box 251

Industrial Park Road

Triadelphia, West Virginia 26059

5.1.2.3.1.

Applications may be submitted in electronic format. The procedure is

available on the MSHA web page

http://www.msha.gov/techsupp/acc/application/online.htm.

5.1.3. Fee Authorization

5.1.3.1. Upon receipt of the Field Modification Request by A&CC, a letter will be

written to the applicant and will include an estimate of the maximum

anticipated fee to complete the investigation. An authorization response

form will also be included in which the applicant agrees to pay expenses up

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 3 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

to the maximum estimated fee for the investigation or requests cancellation

of the application. This form must be returned before any further action is

taken on the application. If the form letter is not returned within 30 days

from the date of the letter, the application will be canceled.

5.1.3.2. The applicant can pre-authorize the application by authorizing up to a

certain dollar amount of investigation time in the application letter. This

will permit MSHA to initiate the investigation while the fee estimation

process is taking place.

5.1.3.3. If unforeseen circumstances are encountered during the investigation that

results in exceeding the estimated fee, the applicant will be contacted and

given the option of canceling the action or accepting the new estimated fee.

When the fee authorization is returned to the A&CC, the technical

investigation of the request will resume.

5.2. Application Requirements

5.2.1. A&CC requires detailed information concerning proposed modifications to

approved (permissible) equipment. Properly presented information will

contribute to the expeditious processing of each Field Modification Request.

5.2.2. The following information must be included on the application:

5.2.2.1. Company name

5.2.2.2. Mine name or number

5.2.2.3. MSHA Portal ID number

5.2.2.4. Mailing address to be used for the fee authorization, discrepancy letter, and

field modification acceptance letter.

5.2.2.5. Date of application

5.2.2.6. Application Code Number. The application code number is a unique six (6)

digit number assigned by the applicant used for application identification.

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 4 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

5.2.2.7. Type of equipment (continuous miner, shuttle car, etc.).

5.2.2.8. Manufacturer. The manufacturer is the original equipment manufacturer

of the approved machine.

5.2.2.9. MSHA approval number, extension number, model number, and the serial

number(s)

5.2.2.10. Voltage rating and current. The voltage rating of machine(s) and current

(AC or DC) must be specified.

5.2.2.11. Number of machines changed

5.2.2.12. Machine location and date available for inspection. The machine inspection

can be done at the mine site or at a rebuild shop. If necessary, this

determination will be made through communications with the MSHA

district office or the A&CC’s Quality Assurance and Materials Testing

Division.

5.2.2.13. Name and telephone number of a person to contact for additional

information must be indicated. If available, a fax number or e-mail address

may be added to aid communications. The contact person may be the

rebuild shop who did the modifications or mine personnel.

5.2.2.14. Signature of responsible mine company official

5.3. Application Guidelines

5.3.1. The basic function of the equipment type cannot be changed by the field

modification request (e.g., a continuous miner cannot be converted into a

loading machine). Also, a machine built prior to Schedule 2G may be

modified, but that part of the machine being modified must comply with

current 30 CFR, Part 18 requirements.

5.3.2. The description of modification should be a narrative describing the

modification(s) made to the equipment, including specific references to the

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 5 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

electrical components modified or added, in addition to providing details of

the modification(s). (See Appendix No. 1, enclosures A and B)

5.3.3. The “Components Removed” section is a bill of materials for components

removed. List and identify certified components removed from the modified

machine. List and identify all other essential components that were removed

(e.g., overload relays, packing glands, gland plugs, etc.). Cable and conduit

information is not required in this section. All cable and gland parts should

be listed on the packing gland and cable data sheets.

5.3.4. The “Components Added” section is a bill of materials for added

components. Cable, conduit, and packing gland information is not required

to be listed under the components added section.

5.3.5. If explosion-proof (certified) enclosures are removed or added, the type of

enclosure must be specified including: the electrical rating (if applicable), the

manufacturer, part number, and the MSHA Certification Number. Headlight

enclosures must also include the voltage and wattage of the light bulb.

Motors must be identified by the frame number, voltage, horsepower, and

full load rating in amperes.

5.3.5.1. If an explosion-proof enclosure is added that was accepted under an

approval investigation, it must be identified by the model/part number

and Approval Number of the machine under which it was evaluated.

5.3.5.2. Except for special applications, all cable runs on a permissible machine

must originate and terminate within a certified enclosure. A packing gland

and cable data sheet must be completed for each cable run that was

modified or added to the machine.

5.3.5.3. In special applications, such as MSHA accepted intrinsically safe circuits,

the cable run originates within a certified enclosure and terminates in most

cases in a non explosion-proof enclosure. In this case the MSHA evaluation

(IA) number must be specified for the intrinsically safe circuit.

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 6 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

5.3.5.4. The routing of a circuit extending from the permissible machine to a nonpermissible area may be considered a special application. In this scenario,

both ends of all ungrounded conductors must be fused at less than the

ampacity rating of the cable, but cannot exceed 5 amperes. The fuse voltage

ratings must be greater than the maximum voltage in either the permissible

or non-permissible enclosure.

5.3.5.5. Motor overload information must be in accordance with APOL2153 – Policy

on Motor Overload Protection (contact A&CC for copy).

5.3.5.6. Electrical cable conductor size, number of conductors, cable type (SO, GGC, etc.), length, outside diameter (O.D.), and short-circuit protection must

be documented. Cables between machine components are required to be

MSHA approved as flame-resistant, unless they are totally enclosed in

MSHA approved flame-resistant hose conduit.

5.3.5.7. The inside diameter (I.D.) and length must be provided for all hose conduit

specified.

5.3.5.8. “From/To” is used to identify the certified enclosure where the cable run

originates and where the cable run terminates, respectively. The enclosures

should be identified by type, manufacturer, and certification number.

Examples:

From: Control Station, Galis, X/P-1126-3

To: Emergency Stop Sw., Ensign, X/P-1818-0

From: Starter (original), Joy, 18-XPA030039-0

To: Control Station, P/N 500186-5, 2G-2005-6

5.3.5.9. Information concerning the "Packing Gland and Cable Data Sheet" must be

provided when any cable or packing gland parts are added or modified.

However, when a packing gland and the cable are not modified by the

proposed change, even though they are described on the data sheet, write

“As Approved” across the packing gland component box.

5.3.5.10. The packing gland component manufacturer and part number is normally

reported. In some cases an on file at A&CC drawing may be referenced

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 7 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

which specifies the part number. In the case where a vendor assigns a part

number to the manufacturer part, the original part number must be

specified. If a part is machined by the applicant or repair shop, a drawing

must be submitted depicting the component with the machining

dimensions, tolerances, and type of material.

5.3.5.11. Packing material: The cable’s outer jacket must be in contact with the

packing material for no less then 1/2” when the gland assembly is fully

assembled. The packing material must be accepted by MSHA as flame

resistant.

5.3.5.12. Packing gland grommets must be made of MSHA approved flame resistant

material. The radial clearance between the cable jacket and the nominal

inside diameter of the grommet shall not exceed 1/32”, based on the

nominal specified cable diameter. The radial clearance between the

nominal outside diameter of the grommet and the inside wall of the

stuffing box shall not exceed 1/32”. The grommet must be in contact with

the cable jacket for no less then 1/2” when the packing gland is fully

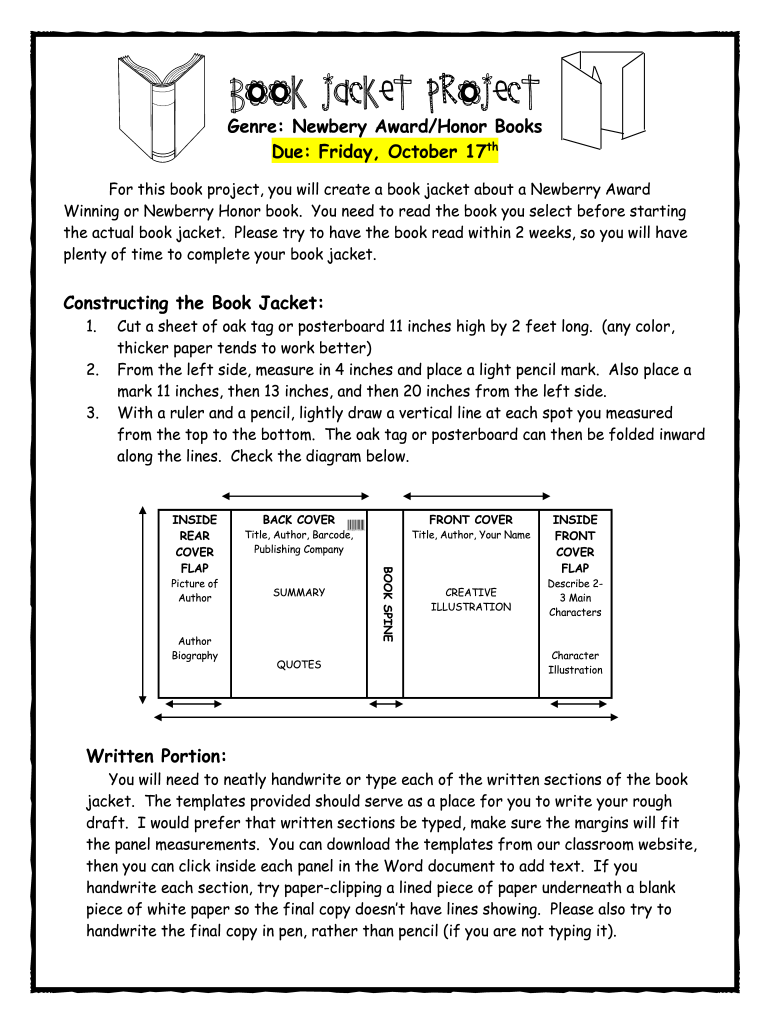

assembled. (See Figure 1.)

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 8 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

Stuffing Box

Gland Nut

Grommet

Washer

1/2" Minimum

Cable

Radial clearance not to

exceed 1/32"

Radial clearance not to

exceed 1/32"

Figure 1

5.3.5.13. Remarks: Enter any remark that would clarify the reported information on

the cable run data sheet.

5.3.5.14. For gland component measurement see Figures 2 and 3.

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 9 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

Cable

Gland Nut ID

O uter Bushing ID

Packing

Stuffing Box ID

Inner Bushing ID

Stuffing Box

Through Hole ID

Figure 2. Typical Motor Gland Assembly

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 10 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

Cable

Gland Nut ID

Packing

Stuffing Area ID

Stuffing Box

Through Hole ID

Figure 3. Typical Slip-In Gland Assembly

5.3.5.15. As an alternate to the Packing Gland and Cable Data Sheets, the applicant

can submit a Component Layout/Bill of Materials drawing depicting all of

the components and cable runs. Neither the component layout nor bill of

materials can have optional or alternate components or cable listed.

5.3.5.16. Drawings of the packing gland assembly may be submitted, or drawings on

file at A&CC may be referenced. Documentation of gland parts/assemblies

not previously accepted must include the following dimensions:

5.3.5.16.1. Through holes of packing glands and nuts,

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 11 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

5.3.5.16.2. Packing areas,

5.3.5.16.3. Packing material and size,

5.3.5.16.4. Bushings (outside and inside diameters, and thickness),

5.3.5.16.5. Threading, and

5.3.5.16.6. Machining tolerances

5.3.5.16.7. When assembled, the gland nut must have at least 3 threads engaged and

have 1/8” or more to travel before meeting interference by parts other

than the packing material.

5.3.5.17. Schematic diagram (indicating the changes)

5.3.5.17.1. A schematic diagram may have highlighted areas, inked-in notations, or

blacked-out areas shown on the drawing, but it cannot depict optional or

alternate settings or components. All information depicted on drawings

submitted must be legible.

5.3.5.18. Photographs or other supporting documentation may be submitted.

5.3.5.18.1. Any device not previously accepted at A&CC must be evaluated, and all

requested information must be provided by the applicant or vendor

before the application can be processed.

5.3.5.19. A checklist has been developed as an aid to the applicant. The checklist

applies only to those components/parts being modified. The checklist does

not need to be submitted with the application. (See Appendix No. 2.)

5.3.5.20. The above information is considered the minimum necessary for processing

field modification applications. Except for drawings and other related

specifications, the required information should be provided on "Field

Modification Application" forms and data sheets. (See Appendix No. 1.)

5.4. Technical Investigation

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 12 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

5.4.1. The assigned A&CC investigator will evaluate the change(s) to determine if

they meet the applicable requirements of 30 CFR, Part 18. The applicant will

be notified of any discrepancies, or if additional information is needed to

process the application. All requests for additional information must be

addressed in a timely manner or the application will be subject to

cancellation. (Ref. APOL1009 – “Application Cancellation Policy” – contact

A&CC for copy.)

5.4.2. When the technical evaluation is completed and all discrepancies are

corrected, a copy of the field modification request will be forwarded to the

appropriate MSHA district office. The MSHA district office will assign an

inspector to verify the information documented in the application. The

A&CC may also inspect the application at the repair facility. In this case, the

application will not be forwarded to the MSHA district office until the Field

Modification acceptance letter is sent.

5.4.3. A&CC investigators can only verify approval documentation. They cannot

provide approval drawings or proprietary information about the approved

machine or its components. If the applicant needs this type of information, it

must be obtained from the MSHA approval holder.

5.5. Equipment Inspection Preparation

5.5.1. The machine(s) must be made available for inspection within six (6) months

after notification that the application has been evaluated or the application

will be cancelled.

5.5.2. The equipment must be prepared by the applicant for examination by MSHA

personnel in the following manner:

5.5.2.1. The equipment must be located where it will be free from obstruction and

unsafe conditions.

5.5.2.2. Personnel must be provided to assist in the examination.

5.5.2.3. The flanges and interior of each enclosure affected by the change, including

the cover, must be cleaned thoroughly.

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 13 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

5.5.2.4. All modified or added hoses, cables, and cords must be cleaned to expose

surface markings.

5.5.2.5. All electrical components must be cleaned to reveal all stampings,

identification plates, and certification plates.

5.6. Inspection

5.6.1. The physical inspection of the machine(s) will include, but may not be limited

to, the following:

5.6.1.1. A general inspection of the machine to determine if it is being maintained

in permissible condition,

5.6.1.2. An inspection of all components affected by the modification,

5.6.1.3. Adequacy of mechanical protection of cables, adequacy of cable strain

clamps, and positioning of cables, particularly the proximity to hydraulic

lines and pinch points,

5.6.1.4. Adequacy of guarding against physical damage to headlights, pushbuttons,

switch operators or any other vulnerable electrical components, and

5.6.1.5. The ratings and settings of overload and short-circuit protective devices.

5.6.2. After completing the field inspection, the MSHA district office will send a

Field Modification Inspection Report to A&CC. If no discrepancies are found,

a short memorandum to that effect will be sufficient (See Appendix 1,

Enclosure C for sample.) If minor discrepancies are found, the inspector may

require the applicant to correct the application documentation and submit

corrections to the A&CC or include the corrections in the report (See

Appendix 1, Enclosure D for sample.) If the discrepancies are extensive, the

inspector will forward a list of the discrepancies to the A&CC for

reevaluation (See Appendix 1, Enclosure E for sample), and if necessary,

require the applicant to correct the application documentation. A copy of any

revised documents submitted must be retained by the applicant in order to

ensure that the documentation matches the records on file at A&CC.

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 14 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

5.6.3. If the MSHA district office determines that the modification constitutes a

hazard due to the particular mine environment in which the machine(s) will

operate, or the Field Modification Request is not in compliance with the

applicable provisions of 30 CFR, Parts 57 or 75, the district office will notify

A&CC that the request should not be accepted. (See Appendix 1, Enclosure F

for sample.)

5.7. Acceptance

5.7.1. If the application is determined by A&CC to meet all applicable

requirements, a letter of Field Modification Acceptance will be sent to the

applicant. An invoice for the total cost of the investigation will then follow.

Copies of the notification will also be sent to the district office.

5.8. Additional Modifications

5.8.1. An applicant is not required to submit a Field Modification Request to A&CC

for certain modifications. In these cases, the applicant must notify the MSHA

district office in writing of the changes. Inspection of the modification may

be made at the discretion of the district manager. A copy of all notifications

should be maintained in the appropriate mine file. Field modification

requests that don’t require a request to the A&CC include:

5.8.1.1. Addition of methane monitors (excluding methane monitors that tie into

the shutdown systems of diesel equipment)

5.8.1.2. Field modifications duplicating the original equipment manufacturer's

approved design of an essentially identical machine. For example, a shuttle

car with approval number 2G-2000-0 may have been originally approved

without an emergency stop switch. Subsequently, the manufacturer filed

an application and received approval from A&CC to install a specific

switch, X/P-1000-0 on all new shuttle cars. These shuttle cars would bear

Approval Number 2G-2000-1, or the first extension of the original approval.

An operator owning a shuttle car with the original approval 2G-2000-0 and

wishing to add an emergency stop switch can contact the manufacturer. If

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 15 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

the switch X/P-1000-0 is installed as approved under the first extension, it

is not necessary to notify A&CC.

5.8.1.3. Field modifications duplicating previously accepted field changes for

machines of the same type and with the same approval number at the same

mine or under the direction of the same maintenance supervisor(s).

5.8.1.4. Installation of silicon diode grounding equipment in existing explosionproof enclosures on machines, provided no cable gland openings are made

in the machine and provided the installation meets the requirements of 30

CFR 75.703-3(d) which refers to voltage and current ratings, and over

current protection for such devices.

5.8.1.5. Removal of non-safety-related electrical components from a machine. For

example, relocation of the headlight resistors to the machine control box

would eliminate the headlight resistor enclosures. All unused cable

entrances must be plugged, and plugs must be secured in place in

accordance with Part 18 requirements.

5.8.1.6. Changes that are made within explosion-proof enclosures and do not

conflict with permissibility requirements. Circuit breakers, overload relays,

and fuse protection must be maintained as originally approved.

5.8.1.7. Change of trailing cables on machines with cable reels having external

trailing cable connections from flat to round or vice versa, from a G to GGC or vice versa, and changes to a larger cable size, provided the insulated

trailing cable strain clamp still grips the cable properly and provided no

changes are made to the cable entrance glands.

5.8.1.8. Change of trailing cable from G to G-GC or vice versa on machines with

direct cable entry into an enclosure. Changes in the physical cable size

(outside diameter) require cable entry modification and a field change

application and report. Cables that are the same size electrically may not

have the same outside diameters due to insulation differences.

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�DOCUMENT NO: ASAP 2006

VERSION: 2008-01-10

Page 16 of 16

TITLE: Field Modification Application Procedures

MSHA Mine Safety and Health Administration, Approval & Certification Center

5.8.1.9. Change in the length of the trailing cable to maximum allowable as shown

in Table 9 of 30 CFR, Part 18.

5.8.1.10. Modification involving installation of illumination systems that are covered

under a Statement of Test and Evaluation (STE) or the interchanging of

alternate lighting fixtures of STE lighting systems that have been found by

A&CC to have similar photometric patterns.

5.8.1.11. Installation of any electrical components of a braking system required by 30

CFR, Section 18.20(f).

5.8.1.12. Insulation of cable reels or battery box lids with material that has been

accepted by MSHA.

5.8.1.13. Interchanging of certified headlights that meet Part 18 requirements and are

designed to accept the same size cable. Replacement lamps in these

headlights must be in conformance with the headlight certification.

5.8.1.14. Substitution of a certified or approved battery and tray assembly for an

assembly on an existing machine.

5.8.1.15. Relocation of electrical components on a machine, provided the

interconnecting cables meet the requirements of 30 CFR, Section 18.36(b).

ASAP2006 2008-01-10.doc

Print Date: 1/14/2008

PRINTED AND ELECTRONIC COPIES OF THIS DOCUMENT ARE

UNCONTROLLED. VERIFY CORRECT VERSION PRIOR TO USE.

TCRI0001, Rev 01

�APPENDIX NO. 1

TITLE 30 CFR, PART 18

FIELD MODIFICATION FORMS

�FIELD MODIFICATION APPLICATION

Chief

Approval and Certification Center

RR #1, Box 251

Industrial Park Road

Triadelphia, West Virginia 26059

Company: _____________________

Mine: ________________________

Portal I.D. No.:______________

Address: _____________________

Application Code No.:

Gentlemen:

Date: ____________

We are requesting acceptance of a field modification, pursuant to Title 30 CFR Part 18.81, of the

following equipment:

Equipment type: __________________________________________

Manufacturer: ______________________________

Approval No.:

Model No.:

Number of machines changed:

Voltage

AC or DC

Serial No.(s): ______________________

____________________________________________________________________________

The machine(s) will be available for inspection on ______________

(date)

At ______________________________________________________________

(location)

Enclosed are two (2) copies of all drawings and specifications related to the modification.

If there are any questions, please contact (Mr./Ms.) ______________________

at __________________________________________________

(Telephone, FAX, E-mail)

Sincerely yours,

(Signature of Mining Company Representative)

(Print or Type Mining Company Representative Name and Title)

Enclosure A,

(Sht. 1)

�2.

Concise Description of Modification:

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

(If additional space is needed, attach additional sheets)

Enclosure A,

(Sht. 2)

�3.

Description of Components Removed:

MANUFACTURER___

__Part No.______

MSHA

Cert. No. (X/P)

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

COMPONENT

(If additional space is needed, attach additional sheets)

Enclosure A, (Sht. 3)

�4.

Description of Components Added:

MANUFACTURER___

__Part No.______

MSHA

Cert. No. (X/P)

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

COMPONENT

(If additional space is needed, attach additional sheets)

Enclosure A,

(Sht. 4)

�PACKING GLAND AND CABLE DATA SHEET

Sheet No.:

of ____

Complete Description of Modified and/or Additional Packing Glands and Cable Runs

CABLE - Type:

Conductors:

Size:

O.D.:______

Is cable flame-resistant? _____

Cable Length:

Short-Circuit Protection:_______________________________________________

Overcurrent Protection: ________________________________________________

Hose Conduit - I.D.:

Length: ___________________

To: ____________________________

Item--Mfg.--Cert. No. (X/P)

From:

Item--Mfg.--Cert. No. (X/P)

Packing Gland

Components

Stuffing Box Thru

Hole

Inner Bushing

Outer Bushing

Gland or Gland

Nut

Hose Tube

Packing Size

Stuffing Area

I.D.

Component Mfg. and

Part No.

I.D.

Component Mfg. and Part

No.

Is the stuffing box welded inside and outside? __________________________

Is cable enclosed in flame-resistant hose conduit? ______________________

Are the hose conduits securely clamped? _________________________________

Is the packing material asbestos or MSHA accepted substitute? ___________

Remarks:_________________________________________________________________

�FIELD MODIFICATION APPLICATION

Chief

Approval and Certification Center

RR #1, Box 251

Industrial Park Road

Triadelphia, West Virginia 26059

Company: Northwest Chemical Corp.

Mine: Trestle Mine

Portal I.D. No.: 48-90347

Address: R.D. 5, Box 72

Green River, Utah 75849

Application Code No.: 000025

Date: November 11, 2004

Gentlemen:

We are requesting acceptance of a field modification, pursuant to Title 30 CFR Part 18.81, of the following

equipment:

Equipment type: Roof Drill

Manufacturer: Jay Goode Co.

Voltage: 480 AC or DC

Approval No.: 2G-9751A-1 Model No.: DD0-15

Number of machines changed: 3

Serial No(s).: 70475, 70476, and 70482

The machine(s) will be available for inspection on May 11, 1997

(date)

at Northwest Chemical Corp. Central Shop, Durham Road, Price, Utah

(location)

Enclosed are two (2) copies of all drawings and specifications related to the modification.

If there are any questions, please contact (Mr./Ms.) William Palmer

at (411) 291-1380

Fax: Unavailable_____E-mail:_Unavailable

(Telephone, FAX, or E-mail)

Sincerely yours,

Bill Palmer

Mine Mechanic

Enclosure B, (Sht. 1)

�2.

Concise Description of Modification:

The 75 hp electric pump motor, X/P-4476-2, was replaced by a similar 75 hp, 68 FLA motor, X/P-4476-7.

No changes were made in the cable or packing glands. A Warren Electric stop button (remote) was added.

This necessitated a nipple (1221-A) to be installed in the right end plate of the starter box (X/P-4407-0) and

an appropriate packing gland assembly was added to accept the added #14-3/c Type SO cable.

The stop button is protected by a Warren Electric Intrinsic Safe Relay, Model 123-W, IA-925-1, installed in

the starter box.

(If additional space is needed, attach additional sheets)

Enclosure B,

(Sht. 2)

�3.

Description of Components Removed:

MANUFACTURER___

__Part No.______

MSHA

Cert. No. (X/P)

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

COMPONENT

�3.

Description of Components Added:

MANUFACTURER___

__Part No.______

MSHA

Cert. No. (X/P)

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

____________

_______________

________________

________________

COMPONENT

�PACKING GLAND AND CABLE DATA SHEET

Sheet No.: 1 of 2

Complete Description of Modified and/or Additional Packing Glands and Cable Runs

CABLE - Type: SHD-GC Conductors: 3

Size: 2/0 AWG O.D.: 2.00 inch

Is cable flame-resistant? Yes

Cable Length: 10 feet

Short-Circuit Protection: Circuit breaker set at 1500 amp max

OL's Wesley Electric, Code CA, Range 68-75 amp,

Overcurrent Protection: trip amps 81

Hose Conduit - I.D.: 2-1/2 inch

Starter Box

From: Jay Goode, X/P-4407-0

Item--Mfg.--Cert. No. (X/P)

Packing Gland

Components

Stuffing Box Thru

Hole

Inner Bushing

Outer Bushing

Gland or Gland

Nut

Hose Tube

Packing Size

Stuffing Area

I.D.

2.390”

± .01

2.188”

± .01

2.188”

± .01

2.196”

± .01

3/8”

2.650”

+.01/-.03

Length: 10 feet

To: Motor, Smithfield, X/P-4478-94

Item--Mfg.--Cert. No. (X/P)

Component Mfg. and

Part No.

Steel

2.75

Brass

2.66”

Brass

2.66”

Steel

2.76”

N/A

N/A

Steel

I.D.

½”

2.96”

Is the stuffing box welded inside and outside? Yes

Is cable enclosed in flame-resistant hose conduit? No

Are the hose conduits securely clamped? Yes

Is the packing material asbestos or MSHA accepted substitute? Yes

Remarks:

PACKING GLAND AND CABLE DATA SHEET

Component Mfg. and

Part No.

Smithfield

609029-3A

Smithfield

609030-5B

Smithfield

609030-5B

Smithfield

609031-1X

N/A

N/A

Smithfield

609029-3A

�Sheet No.: 2 of 2

Complete Description of Modified and/or Additional Packing Glands and Cable Runs

Conductors: 3

CABLE - Type: SO

Cable Length: 12 feet

Size: 14 AWG O.D.: .67"

Is cable flame-resistant? No

Short-Circuit Protection: Protected by IA-925-1

Overcurrent Protection: N/A

Length: 10 feet

Hose Conduit - I.D.: 3/4"

Starter Box

Stop Button

From: Jay Goode Co., X/P-4407-0

To: Warren Elec.,Model R4321

Item--Mfg.--Cert. No. (X/P)

Item--Mfg.--Cert. No. (X/P)

Packing Gland

Components

Stuffing Box Thru

Hole

Inner Bushing

Outer Bushing

Gland or Gland

Nut

Hose Tube

Packing Size

Stuffing Area

I.D.

.75”

± .01

N/A

N/A

.75”

± .01

3/8”

1.00”

+.01/-.03

Component Mfg. and

Part No.

Steel

Brass

N/A

N/A

Steel

Is the stuffing box welded inside and outside? Yes

Is cable enclosed in flame-resistant hose conduit? Yes

Are the hose conduits securely clamped? Yes

Is the packing material asbestos or MSHA accepted substitute? Yes

Remarks:

I.D.

N/A

Component Mfg. and

Part No.

IS Circuit

�MEMORANDUM FOR JOHN P. FAINI

Chief, Approval and Certification Center

THROUGH:

JOHN J. JONES

District Manager

Coal Mine Safety and Health

District 5

FROM:

SAMUEL S. SMITH

Mine Inspector (Electrical)

SUBJECT:

Field Modification Inspection Report

A&CC Par No. 82356

The modifications have been examined and compared to the described changes on the

application. There were no discrepancies found and the modifications were judged not to

increase the fire and explosive hazards involved in the operation of this machine in gassy or

dusty mines.

Enclosure D

�MEMORANDUM FOR JOHN P. FAINI

Chief, Approval and Certification Center

THROUGH:

JOHN J. JONES

District Manager

Coal Mine Safety and Health

District 5

FROM:

SAMUEL S. SMITH

Mine Inspector (Electrical)

SUBJECT:

Field Modification Inspection Report

A&CC Par No. 82356

The modifications have been examined and compared to the described changes on the

application. The following discrepancies were found:

1)

The connection box listed on the Description of Components Added sheet and the

Packing Gland and Cable Data Sheet No. 1 of 2 was identified as serial number 37148L,

but the manufacturer's plate listed it as 3714BL. The manufacturer was contacted and the

serial number 3714BL is correct.

2)

The fuses providing protection for the headlight circuit were specified as 10 amperes, but

one of the fuses installed was rated at 20 amperes. It was replaced with a properly rated

fuse.

All discrepancies were corrected and the modifications were judged not to increase the fire and

explosive hazards involved in the operation of this machine in gassy or dusty mines.

Enclosure E

�MEMORANDUM FOR JOHN P. FAINI

Chief, Approval and Certification Center

THROUGH:

JOHN J. JONES

District Manager

Coal Mine Safety and Health

District 5

FROM:

SAMUEL S. SMITH

Mine Inspector (Electrical)

SUBJECT:

Field Modification Inspection Report

A&CC Par No. 82356

The modifications have been examined and compared to the described changes on the

application. The connection box listed on the Description of Components Added sheet and the

Packing Gland and Cable Data Sheet No. 1 of 2 was identified as a Smith Manufacturing

Company enclosure accepted under Approval No. 2G-8000-1, but the box installed was a

Johnson Machine Company enclosure certified as X/P-8254-6. The two sheets affected by this

change were corrected to show this information. Please verify that the enclosure and gland parts

listed on the Data Sheet were accepted under the certification records.

No other discrepancies were found. The physical modifications were judged not to increase the

fire and explosive hazards involved in the operation of this machine in gassy or dusty mines.

Enclosure F

�MEMORANDUM FOR JOHN P. FAINI

Chief, Approval and Certification Center

FROM:

JOHN J. JONES

District Manager

Coal Mine Safety and Health

District 5

SUBJECT:

Field Modification Inspection Report

A&CC Par No. 82356

The modifications have been examined and compared to the described changes on the

application. There were no discrepancies found regarding the requirements of 30 CFR,

Part 18. However, 30 CFR, Part 75.342(a)(2) requires an additional methane monitor sensing

device to be installed on the longwall shearing machine, which the applicant has failed to

provide.

In regard to the Field Modification Request replacing the longwall shearing machine, we are

requesting that the request be denied until or unless the provisions of 30 CFR, Part 75.342(a)(2)

are met.

Enclosure G

�APPENDIX NO. 2

TITLE 30 CFR, PART 18

FIELD MODIFICATION CHECKLIST

�FIELD MODIFICATION CHECKLIST

1.

Are all electrical components installed in locations where they are

protected from physical damage during normal operation of the machine

or is suitable guarding provided?

2.

Is a means provided by which all power conductors, including any being

added or modified, can be deenergized at the machine? NOTE: If the

machine is equipped with a methane monitor, the methane monitor must

deenergize all circuits on the machine, including any being added or

modified, except the methane monitor circuit.

3.

Are all certified enclosures being added or removed identified in the data

sheets as to manufacturer and certification number or the approval number

under which it was accepted?

4.

Are all electrical components solidly secured to the machine frame?

5.

Are intrinsically safe circuit conductors separated from power conductors?

6.

Are strain relief devices provided for trailing cable and remote

cables/cords?

7.

Is short-circuit provided for any added cables and overcurrent protection

provided for any added motors?

8.

Do cables which are not totally enclosed in hose conduit have flameresistant properties as indicated by an MSHA number?

9.

Are all cables between electrical components:

a.

Clamped in place to prevent undue movement?

b.

Protected from mechanical damage by position, flame-resistant

hose conduit, metal tubing or troughs? NOTE: Flexible or

threaded rigid metal conduit is not acceptable.

c.

Isolated from hydraulic lines and components?

(Sht. 1)

�d.

___

Protected from abrasion by removing all sharp corners or edges

which they may contact?

10.

Are electrical components inside explosion-proof enclosures insulated

where space is limited?

11.

Are lock-washers provided for all bolts, screws, or studs that secure parts

of explosion-proof enclosures?

12.

When additional holes are drilled in an enclosure, for fastenings, is at least

one-eighth inch of stock left in the bottom of the holes to ensure that the

holes do not penetrate to the interior of explosion-proof enclosures?

13.

Are the holes for fastenings threaded to a depth such that the bolts or

screws will not bottom when lockwashers are omitted?

14.

Are precautions taken to ensure that none of the fastenings used for joints

on explosion-proof enclosures are used to attach non-essential parts or for

making electrical connections?

15.

Are all threaded covers secured from loosening by a locking screw, wire,

or other means?

16.

Are the joints forming the flame-arresting paths on the explosion-proof

enclosures (flanges and covers) smooth, free from rust, corrosion, and

pitting?

17.

Are the joints securely fastened so that an appropriate size feeler gauge

cannot be inserted around the perimeter of any enclosure cover?

18.

Are all new or modified enclosures free from unnecessary through holes,

weakness in welds, or flaws in castings?

19.

Do all added or modified packing gland assemblies comply with the

following:

a.

Assembled so that the cable jacket penetrates into the interior of

the enclosure?

b.

Have a minimum of one-eighth inch clearance between the

packing nut and the stuffing box?

c.

Is the packing nut secured from loosening by a locking screw,

wire, or other means?

d.

The gland nuts have a minimum of three full threads engaged.

(Sht. 2)

�20.

NOTE:

Are accurate measurements and part numbers for the packing gland

assembly parts included in the data sheets for the following:

a.

Through hole (I.D.)

b.

Stuffing area (I.D.)

c.

Inner bushing (I.D.)

d.

Outer bushing (I.D.)

e.

Packing nut (I.D.)

f.

Hose tube (I.D.)

g.

Cable (O.D.)

h.

Diameter or size of asbestos packing

21.

Is hose conduit securely clamped to hose tube?

22.

Are all unused lead entrances closed with metal plugs which are secured in

place by spot welding, brazing, or equivalent method?

When assembled, the compressed packing must be in contact with the cable jacket for

a distance of at least one-half inch.

(Sht. 3)

�