Fill and Sign the California Notary Resignation Letter Sample Form

Valuable advice on preparing your ‘California Notary Resignation Letter Sample’ online

Are you fed up with the inconvenience of handling paperwork? Look no further than airSlate SignNow, the premier eSignature solution for both individuals and businesses. Say farewell to the lengthy process of printing and scanning documents. With airSlate SignNow, you can easily complete and sign paperwork online. Take advantage of the robust tools integrated into this simple and cost-effective platform and transform your document management practices. Whether you need to authorize forms or gather eSignatures, airSlate SignNow manages it all seamlessly, requiring just a few clicks.

Follow this step-by-step plan:

- Log in to your account or initiate a free trial with our service.

- Click +Create to upload a file from your device, cloud, or our template repository.

- Open your ‘California Notary Resignation Letter Sample’ in the editor.

- Click Me (Fill Out Now) to set up the form on your end.

- Add and designate fillable fields for other individuals (if necessary).

- Proceed with the Send Invite settings to solicit eSignatures from others.

- Download, print your version, or convert it into a reusable template.

No need to worry if you need to collaborate with others on your California Notary Resignation Letter Sample or send it for notarization—our solution provides you with all the necessary tools to accomplish such tasks. Create an account with airSlate SignNow today and elevate your document management to new levels!

FAQs

-

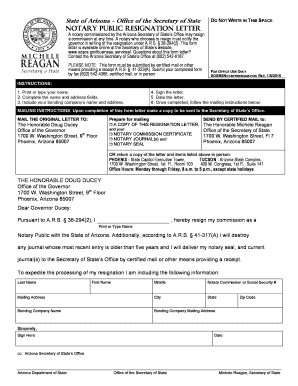

What is a California Notary Resignation Letter Sample?

A California Notary Resignation Letter Sample is a template used by notaries in California to formally resign from their position. This letter outlines the notary's intent to resign and includes essential details like their name, notary commission number, and the effective date of resignation. Using a California Notary Resignation Letter Sample ensures that all necessary information is included and presented professionally.

-

How can I create a California Notary Resignation Letter using airSlate SignNow?

Creating a California Notary Resignation Letter using airSlate SignNow is simple. You can start by accessing our template library to find a California Notary Resignation Letter Sample. Once you select the template, you can customize it to include your information and easily eSign it or send it to others for signatures.

-

Is there a cost associated with downloading a California Notary Resignation Letter Sample?

Downloading a California Notary Resignation Letter Sample from airSlate SignNow is free of charge. Our platform offers various templates at no cost, allowing you to create professional documents without any hidden fees. Additionally, our subscription plans are competitively priced for users who need advanced features.

-

What are the benefits of using airSlate SignNow for my California Notary Resignation Letter?

Using airSlate SignNow for your California Notary Resignation Letter provides numerous benefits, including a user-friendly interface, quick document preparation, and secure eSigning capabilities. This ensures that your resignation letter is not only crafted professionally but also delivered efficiently, saving you time and hassle.

-

Can I integrate airSlate SignNow with other applications when preparing my California Notary Resignation Letter?

Yes, airSlate SignNow offers seamless integration with various applications, including Google Drive, Dropbox, and CRM systems. This allows you to easily import and export your California Notary Resignation Letter Sample and streamline your workflow. Integrating these applications enhances your document management process.

-

What features does airSlate SignNow offer for handling resignation letters?

airSlate SignNow provides features such as customizable templates, eSigning, and document tracking, making it ideal for handling resignation letters like a California Notary Resignation Letter Sample. These tools enable users to create, sign, and manage documents efficiently, ensuring compliance and reducing paperwork.

-

How secure is my information when using airSlate SignNow for my California Notary Resignation Letter?

Your information is highly secure when using airSlate SignNow. We utilize advanced encryption technology and comply with industry standards to protect your data. This ensures that your California Notary Resignation Letter and any associated documents are safe from unauthorized access.

Find out other california notary resignation letter sample form

- Close deals faster

- Improve productivity

- Delight customers

- Increase revenue

- Save time & money

- Reduce payment cycles