Fill and Sign the Illinois Contractor Premium Adjustment Form

Useful suggestions for finalizing your ‘Illinois Contractor Premium Adjustment Form’ online

Fed up with the inconvenience of handling documents? Your solution lies in airSlate SignNow, the leading eSignature platform for both individuals and businesses. Bid farewell to the labor-intensive task of printing and scanning files. With airSlate SignNow, you can effortlessly fill out and approve documents online. Utilize the robust functions available within this intuitive and cost-effective platform, and transform your document handling practices. Whether you need to validate forms or gather electronic signatures, airSlate SignNow manages everything seamlessly, with just a few clicks.

Adhere to this detailed guide:

- Access your account or initiate a free trial with our service.

- Select +Create to upload a file from your device, cloud storage, or our template library.

- Open your ‘Illinois Contractor Premium Adjustment Form’ in the editor.

- Click Me (Fill Out Now) to finalize the form on your end.

- Add and designate fillable fields for others (if required).

- Proceed with the Send Invite settings to solicit eSignatures from others.

- Download, print your version, or convert it into a reusable template.

No need to worry if you need to collaborate with others on your Illinois Contractor Premium Adjustment Form or send it for notarization—our platform provides all the tools you require to accomplish those tasks. Register with airSlate SignNow today and elevate your document management to new levels!

FAQs

-

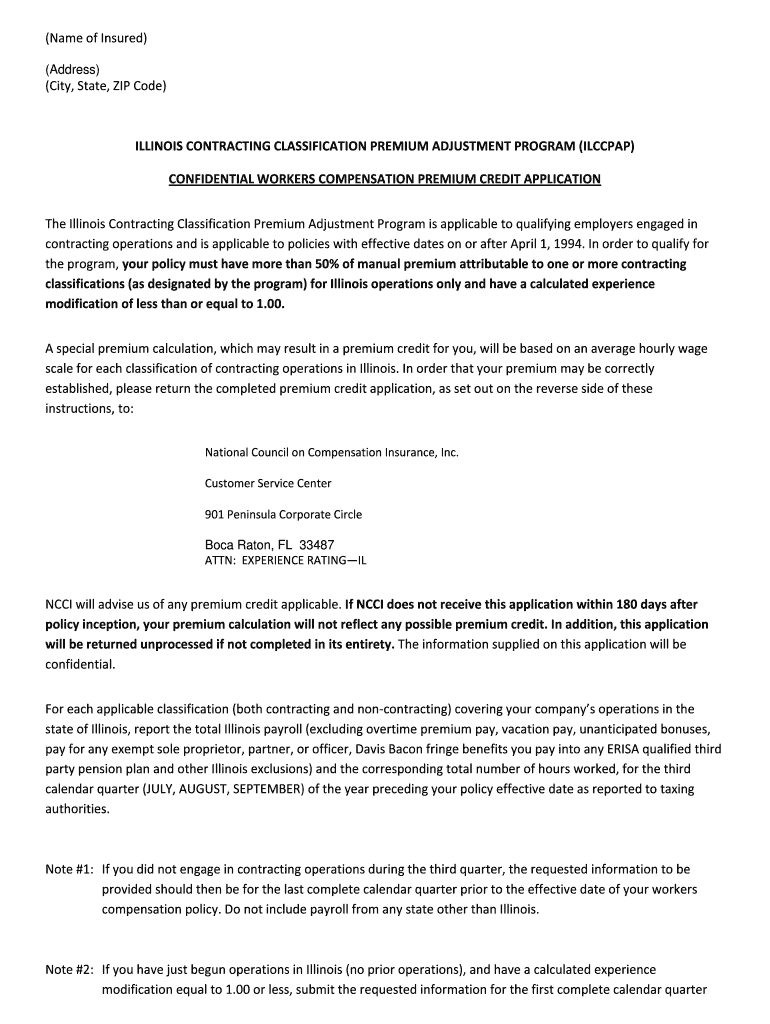

What is the Illinois Contractors Premium Adjustment Form?

The Illinois Contractors Premium Adjustment Form is a document used by contractors in Illinois to request adjustments to their insurance premiums based on their actual payroll and work classification. This form helps ensure that contractors pay the correct premium amounts, reflecting their actual business operations and risk factors.

-

How do I fill out the Illinois Contractors Premium Adjustment Form?

To fill out the Illinois Contractors Premium Adjustment Form, begin by gathering all relevant payroll information and work classification details. Accurate data is crucial to ensure your premium adjustments are calculated correctly. Once your information is ready, you can easily complete the form using airSlate SignNow for a streamlined eSigning experience.

-

What are the benefits of using airSlate SignNow for the Illinois Contractors Premium Adjustment Form?

Using airSlate SignNow for the Illinois Contractors Premium Adjustment Form offers several benefits, including a user-friendly interface, secure document storage, and efficient eSigning capabilities. Our platform allows you to complete and send your forms quickly, reducing the time spent on paperwork and improving your overall workflow.

-

Is there a cost associated with submitting the Illinois Contractors Premium Adjustment Form through airSlate SignNow?

While there is no direct fee for submitting the Illinois Contractors Premium Adjustment Form itself, using airSlate SignNow does involve a subscription cost based on the features you choose. However, the benefits of increased efficiency and reduced administrative burdens often outweigh the costs for businesses looking to streamline their document processes.

-

Can I track the status of my Illinois Contractors Premium Adjustment Form submission?

Yes, airSlate SignNow provides tracking features that allow you to monitor the status of your Illinois Contractors Premium Adjustment Form submission. You will receive notifications when your form is viewed and signed, ensuring you stay updated on the progress of your document.

-

What integrations does airSlate SignNow offer for managing the Illinois Contractors Premium Adjustment Form?

airSlate SignNow integrates seamlessly with various third-party applications such as Google Drive, Salesforce, and Dropbox. These integrations enhance your ability to manage the Illinois Contractors Premium Adjustment Form and other documents, making it easier to access, share, and store your forms securely.

-

Is it safe to use airSlate SignNow for the Illinois Contractors Premium Adjustment Form?

Absolutely! AirSlate SignNow prioritizes your data security with advanced encryption and compliance with industry standards. When you use the platform for the Illinois Contractors Premium Adjustment Form, you can trust that your sensitive information is protected throughout the signing and submission process.

Find out other illinois contractor premium adjustment form

- Close deals faster

- Improve productivity

- Delight customers

- Increase revenue

- Save time & money

- Reduce payment cycles