How To Sign Kansas Banking Work Order

Contact Sales

Make the most out of your eSignature workflows with airSlate SignNow

Extensive suite of eSignature tools

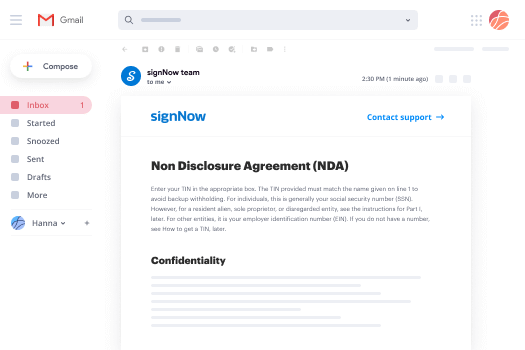

Discover the easiest way to Sign Kansas Banking Work Order with our powerful tools that go beyond eSignature. Sign documents and collect data, signatures, and payments from other parties from a single solution.

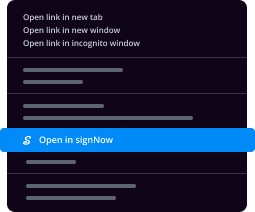

Robust integration and API capabilities

Enable the airSlate SignNow API and supercharge your workspace systems with eSignature tools. Streamline data routing and record updates with out-of-the-box integrations.

Advanced security and compliance

Set up your eSignature workflows while staying compliant with major eSignature, data protection, and eCommerce laws. Use airSlate SignNow to make every interaction with a document secure and compliant.

Various collaboration tools

Make communication and interaction within your team more transparent and effective. Accomplish more with minimal efforts on your side and add value to the business.

Enjoyable and stress-free signing experience

Delight your partners and employees with a straightforward way of signing documents. Make document approval flexible and precise.

Extensive support

Explore a range of video tutorials and guides on how to Sign Kansas Banking Work Order. Get all the help you need from our dedicated support team.

Document type sign work order ohio mobile

Keep your eSignature workflows on track

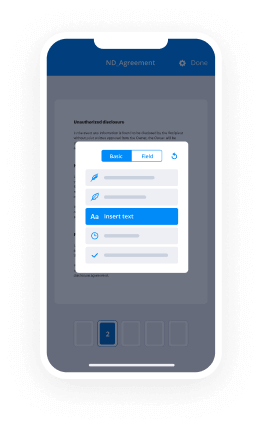

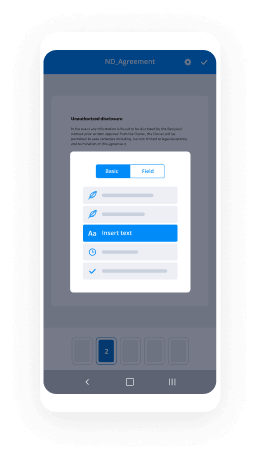

Make the signing process more streamlined and uniform

Take control of every aspect of the document execution process. eSign, send out for signature, manage, route, and save your documents in a single secure solution.

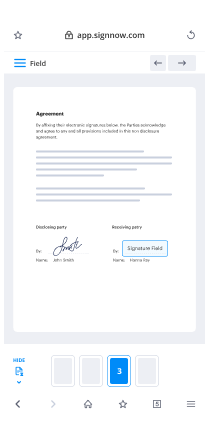

Add and collect signatures from anywhere

Let your customers and your team stay connected even when offline. Access airSlate SignNow to Sign Kansas Banking Work Order from any platform or device: your laptop, mobile phone, or tablet.

Ensure error-free results with reusable templates

Templatize frequently used documents to save time and reduce the risk of common errors when sending out copies for signing.

Stay compliant and secure when eSigning

Use airSlate SignNow to Sign Kansas Banking Work Order and ensure the integrity and security of your data at every step of the document execution cycle.

Enjoy the ease of setup and onboarding process

Have your eSignature workflow up and running in minutes. Take advantage of numerous detailed guides and tutorials, or contact our dedicated support team to make the most out of the airSlate SignNow functionality.

Benefit from integrations and API for maximum efficiency

Integrate with a rich selection of productivity and data storage tools. Create a more encrypted and seamless signing experience with the airSlate SignNow API.

Collect signatures

24x

faster

Reduce costs by

$30

per document

Save up to

40h

per employee / month

Our user reviews speak for themselves

-

Best ROI. Our customers achieve an average 7x ROI within the first six months.

-

Scales with your use cases. From SMBs to mid-market, airSlate SignNow delivers results for businesses of all sizes.

-

Intuitive UI and API. Sign and send documents from your apps in minutes.

A smarter way to work: —how to industry sign banking integrate

Trusted esignature solution— what our customers are saying

be ready to get more

Get legally-binding signatures now!

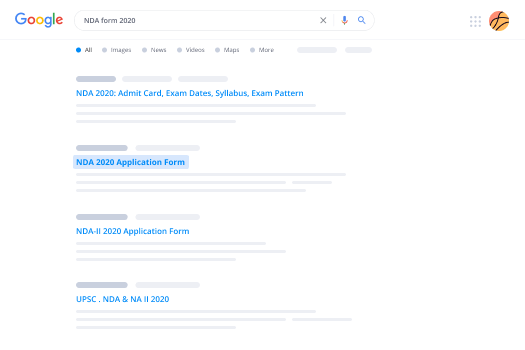

Related searches to How To Sign Kansas Banking Work Order

kansas supervised lender license search

Frequently asked questions

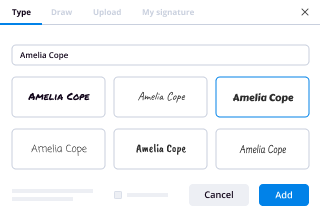

How do you make a document that has an electronic signature?

How do you make this information that was not in a digital format a computer-readable document for the user? "

"So the question is not only how can you get to an individual from an individual, but how can you get to an individual with a group of individuals. How do you get from one location and say let's go to this location and say let's go to that location. How do you get from, you know, some of the more traditional forms of information that you are used to seeing in a document or other forms. The ability to do that in a digital medium has been a huge challenge. I think we've done it, but there's some work that we have to do on the security side of that. And of course, there's the question of how do you protect it from being read by people that you're not intending to be able to actually read it? "

When asked to describe what he means by a "user-centric" approach to security, Bensley responds that "you're still in a situation where you are still talking about a lot of the security that is done by individuals, but we've done a very good job of making it a user-centric process. You're not going to be able to create a document or something on your own that you can give to an individual. You can't just open and copy over and then give it to somebody else. You still have to do the work of the document being created in the first place and the work of the document being delivered in a secure manner."

How to insert electronic signature in pdf document?

How to insert electronic signature in pdf document?

Question :

How to insert electronic signature in pdf document?

Answer :

Insert the electronic signature as shown below.

How to insert electronic signature in pdf document?

How to Insert Electronic Signature in pdf Document

In this article I will be sharing with you the steps to insert electronic signature in PDF document. I am using Windows operating system.

Step : 1

Create a new pdf document and name it as "Test PDF Document".

Step : 2

Open the new pdf document. Go to menu bar and click on View, then click on the View tab.

In the view tab, you'll find the view mode, and click on view mode.

In the view mode window, under "Text Format", click on the tab, and then click on "Text" tab.

Step : 3

Now it's time to add an electronic signature. So, from the "Text Format" tab, under "Text" tab, click on "eSignatures" as shown below.

Step : 4

Here, we are adding two eSignature. One for the first paragraph of the text and one for the second paragraph of the text.

In the text section, click on the "Save as" option and name the new pdf doc as "First Page eSignatures".

Step : 5

Now it is time to insert the electronic signature for the first paragraph of the text. In the text section, from the "First page eSignatures" tab, click on the "Insert Electronic signature" option.

In the popup that window, click on the "+eSignatures" button.

Step : 6

Now it's time to insert the electronic signature for the second paragr...

How to do a electronic signature?

This can be done with a simple Arduino.

The code for the Arduino is available on GitHub.

What is the purpose of the Arduino, you may ask? To make it as easy as possible to use the Arduino for electronics projects.

In this project, the Arduino is used to control the temperature, the light, and the LED strip.

There are several ways to achieve this, the most popular one being to use the Arduino with USB port for a computer.

But if you don't want to use USB or you don't have access to a computer you can use the Arduino as a regular microcontroller. You can use the Arduino to turn on or off lights, change colors, and even read the time. There are other ways to make use of it though.

In this project, I will show you an easier way to use the Arduino that doesn't involve any hardware, just software. It won't give you more functionality or functionality that you don't have at your disposal, but it will give you more control over it. So, you can easily use any other device that you like as the computer to program the Arduino.

There are plenty of other tutorials for controlling LEDs, sensors, motors, etc.

Let's get started.

Get more for How To Sign Kansas Banking Work Order

- Electronic signature Police Word Arizona Now

- Electronic signature Arkansas Sports Permission Slip Simple

- Electronic signature Police Word Arizona Later

- Electronic signature Police PDF Arizona Now

- Electronic signature Police Word Arizona Myself

- Electronic signature Police Word Arizona Free

- Electronic signature Police PDF Arizona Later

- Electronic signature Police Word Arizona Secure

Find out other How To Sign Kansas Banking Work Order

- Landlord notice to end tenancy province of british columbia form

- Covered by the contract form

- How to write a friendly rent increase letter with samples form

- For the purpose of improvements of real form

- The state of new hampshire department nhgov form

- Responsible for all board veterinary and transportation expenses after the date hereof form

- Shall make no claim for any breach of this contract for recission or revocation nor for any form

- Free notice to pay or quit form late rent pdfword

- Michigan 7 day notice to pay rent or lease terminates form

- 30 day notice of termination of non residential lease form

- Real property w md distinctions at pepperdine school of form

- Montana lease termination notices and formsus legal forms

- County new hampshire on form

- Notice of warning prior to termination of form

- Numerous championships there is no guarantee that you or your child will be able to reach the form

- Under new hampshire law the notice to form

- According to the lease it expires on day of 20 form

- Ohio rental laws landlordology form

- Employer member workers compensation claims manual form

- Annum or at the highest legal rate whichever is less from the date of such default until all sums form