TP104-08

June 26, 1996

U.S. DEPARTMENT OF TRANSPORTATION

NATIONAL HIGHWAY TRAFFIC SAFETY ADMINISTRATION

LABORATORY TEST PROCEDURE

FOR

FMVSS 104

Windshield Wiping and Washing Systems

SAFETY ASSURANCE

Office of Vehicle Safety Compliance

Room 6115, NSA-30

400 Seventh Street, SW

Washington, DC 20590

OVSC LABORATORY TEST PROCEDURE NO. 104

�TABLE OF CONTENTS

PAGE

1.

PURPOSE AND APPLICATION ........................................................................

1

2.

GENERAL REQUIREMENTS ............................................................................

2

3.

SECURITY.........................................................................................................

3

4.

GOOD HOUSEKEEPING ..................................................................................

3

5.

TEST SCHEDULING AND MONITORING.........................................................

3

6.

TEST DATA DISPOSITION ...............................................................................

3

7.

GOVERNMENT FURNISHED PROPERTY (GFP) ............................................

4

8.

CALIBRATION OF TEST INSTRUMENTS ........................................................

5

9.

SUGGESTED TEST EQUIPMENT ....................................................................

6

10.

PHOTOGRAPHIC DOCUMENTATION .............................................................

7

11.

DEFINITIONS ....................................................................................................

8

12.

PRETEST REQUIREMENTS.............................................................................

10

13.

COMPLIANCE TEST EXECUTION ...................................................................

11

14.

POST TEST REQUIREMENTS .........................................................................

16

15.

REPORTS..........................................................................................................

17

15.1. MONTHLY STATUS REPORTS .............................................................

17

15.2. APPARENT TEST FAILURE...................................................................

17

15.3

FINAL TEST REPORTS..........................................................................

17

15.3.1 COPIES ........................................................................................

15.3.2 REQUIREMENTS.........................................................................

15.3.3 FIRST THREE PAGES.................................................................

15.3.4 TABLE OF CONTENTS ...............................................................

17

18

18

24

16.

DATA SHEETS ..................................................................................................

25

17.

FORMS ..............................................................................................................

29

�1

1.

PURPOSE AND APPLICATION

The Office of Vehicle Safety Compliance (OVSC) provides contracted laboratories with

Laboratory Test Procedures (TPs) which serve as guidelines for obtaining compliance

test data. The data are used to determine if a specific vehicle or item of motor vehicle

equipment meets the minimum performance requirements of the subject Federal Motor

Vehicle Safety Standard (FMVSS). The purpose of the OVSC Laboratory Test

Procedures is to present a uniform testing and data recording format, and provide

suggestions for the use of specific equipment and procedures. Any contractor

interpreting any part of an OVSC Laboratory Test Procedure to be in conflict with a

Federal Motor Vehicle Safety Standard or observing any deficiencies in a Laboratory Test

Procedure is required to advise the Contracting Officer's Technical Representative

(COTR) and resolve the discrepancy prior to the start of compliance testing.

Contractors are required to submit a detailed test procedure to the COTR before initiating

the compliance test program. The procedure must include a step-by-step description of

the methodology to be used.

The OVSC Laboratory Test Procedures are not intended to limit or restrain a contractor

from developing or utilizing any testing techniques or equipment, which will assist in

procuring the required compliance test data.

NOTE: The OVSC Laboratory Test Procedures, prepared for use by independent

laboratories under contract to conduct compliance tests for the OVSC, are not intended

to limit the requirements of the applicable FMVSS(s). In some cases, the OVSC

Laboratory Test Procedures do not include all of the various FMVSS minimum

performance requirements. Sometimes, recognizing applicable test tolerances, the Test

Procedures specify test conditions which are less severe than the minimum requirements

of the standards themselves. Therefore, compliance of a vehicle or item of motor vehicle

equipment is not necessarily guaranteed if the manufacturer limits certification tests to

those described in the OVSC Laboratory Test Procedures.

�2

2.

GENERAL REQUIREMENTS

FMVSS 104, Windshield Wiping and Washing Systems — Passenger Cars, Multipurpose

Passenger Vehicles, Trucks, and Buses, specifies that each vehicle shall have a powerdriven windshield wiping system with at least two speeds that meets the standard when

tested in accordance with SAE Recommended Practice J903a, and a windshield washing

system that meets the requirements of SAE Recommended Practice J942, Passenger

Car Windshield Washer Systems, except that the reference to "the effective wipe pattern

defined in SAE J903, paragraph 3.1.2" shall be deleted. The areas established in

accordance with S4.1.2.1 of FMVSS 104 shall be used instead. A different exception

applies to multipurpose passenger vehicles (MPVs), trucks and buses.

�3

3.

SECURITY

The contractor shall provide appropriate security measures to protect the OVSC test

vehicles from unauthorized personnel during the entire compliance testing program. The

contractor is financially responsible for any acts of theft and/or vandalism which occur

during the storage of test vehicles. Any security problems which arise shall be reported

by telephone to the Industrial Property Manager (IPM), Office of Contracts and

Procurement, within two working days after the incident. A letter containing specific

details of the security problem will be sent to the IPM (with copy to the COTR) within 48

hours.

The contractor shall protect and segregate the data that evolves from compliance testing

before and after each vehicle test. No information concerning the vehicle safety

compliance testing program shall be released to anyone except the COTR, unless

specifically authorized by the COTR or the COTR's Branch Chief or Division Chief.

NO INDIVIDUALS, OTHER THAN CONTRACTOR PERSONNEL DIRECTLY

INVOLVED IN THE COMPLIANCE TEST, SHALL BE ALLOWED TO WITNESS ANY

COMPLIANCE TEST UNLESS SPECIFICALLY AUTHORIZED BY THE COTR.

4.

GOOD HOUSEKEEPING

Contractors shall maintain the entire vehicle compliance testing area, test fixtures and

instrumentation in a neat, clean and painted condition with test instruments arranged in

an orderly manner consistent with good test laboratory housekeeping practices.

5.

TEST SCHEDULING AND MONITORING

The contractor shall submit a vehicle test schedule to the COTR prior to conducting the

first compliance test. Tests shall be completed as required in the contract. Scheduling of

vehicle tests shall be adjusted to permit vehicles to be tested to other FMVSSs as may

be required by the OVSC. All vehicle compliance testing shall be coordinated with the

COTR in order to allow monitoring by the COTR and/or other OVSC personnel if desired.

6.

TEST DATA DISPOSITION

The contractor shall make all vehicle preliminary compliance test data available to the

COTR at the test site within four hours after the test. Final test data shall be furnished to

the COTR within five working days. Additionally, the contractor shall analyze the

preliminary test results as directed by the COTR.

All backup data sheets, strip charts, recordings, plots, technician's notes, etc., shall be

either sent to the COTR or destroyed at the conclusion of each delivery order, purchase

order, etc..

7.

GOVERNMENT FURNISHED PROPERTY (GFP)

ACCEPTANCE OF VEHICLE

The Contractor has the responsibility of accepting the test vehicle from either a new car

dealer or a vehicle transporter. In both instances, the contractor acts in the OVSC's

�4

behalf when signing an acceptance of the test vehicle. If the vehicle is delivered by a

dealer, the contractor must check to verify the following:

A.

All options listed on the "window sticker" are present on the test vehicle.

B.

Tires and wheel rims are new and the same as listed.

C.

There are no dents or other interior or exterior flaws.

D.

The vehicle has been properly prepared and is in running condition.

E.

The glove box contains an owner's manual, warranty document, consumer

information, and extra set of keys.

F.

Proper fuel filler cap is supplied on the test vehicle.

If the test vehicle is delivered by a government contracted transporter, the contractor

should check for damage which may have occurred during transit.

A "Vehicle Condition" form will be supplied to the contractor by the COTR when the test

vehicle is transferred from the new car dealer or between test contracts. The upper half

of the form describes the vehicle in detail, and the lower half provides space for a

detailed description of the post-test condition. Vehicle Condition forms must be returned

to the COTR with the copies of the Final Test Report or the reports will NOT be accepted.

NOTIFICATION OF COTR

The COTR must be notified within 24 hours after a test vehicle has been delivered.

�5

8.

CALIBRATION OF TEST INSTRUMENTS

Before the contractor initiates the safety compliance test program, a test instrumentation

calibration system will be implemented and maintained in accordance with established

calibration practices. Guidelines for setting up and maintaining such calibration systems

are described in MIL-C-45662A, "Calibration System Requirements". The calibration

system shall be set up and maintained as follows:

A.

Standards for calibrating the measuring and test equipment will be stored and

used under appropriate environmental conditions to assure their accuracy and

stability.

B.

All measuring instruments and standards shall be calibrated by the contractor, or a

commercial facility, against a higher order standard at periodic intervals NOT TO

EXCEED TWELVE (12) MONTHS! Records, showing the calibration traceability

to the National Institute of Standards and Technology (NIST), shall be maintained

for all measuring and test equipment.

C.

All measuring and test equipment and measuring standards will be labeled with

the following information:

(1)

(2)

(3)

D.

A written calibration procedure shall be provided by the contractor which includes

as a minimum the following information for all measurement and test equipment:

(1)

(2)

(3)

(4)

(5)

E.

9.

Date of calibration

Date of next scheduled calibration

Name of the technician who calibrated the equipment

Type of equipment, manufacturer, model number, etc.

Measurement range

Accuracy

Calibration interval

Type of standard used to calibrate the equipment (calibration traceability of

the standard must be evident)

Records of calibration for all test instrumentation shall be kept by the contractor in

a manner which assures the maintenance of established calibration schedules. All

such records shall be readily available for inspection when requested by the

COTR. The calibration procedure must be approved by the COTR before the test

program commences.

SUGGESTED TEST EQUIPMENT

A

Stop watch or equivalent timing device, 0 to 60 minutes, with accuracy of ± 2

seconds in 60 minutes

B.

Engine tachometer, 0 to 8,000 rpm, with accuracy of ± 15 rpm

C.

Soft water, hardness 12 grains/gallon

�6

D.

Water spray system with 2 nozzles, with 50 to 100 cubic inches/minute flow, and

accuracy of ± 2.5 cubic inches/minute. System shall maintain temperature below

100 F.

E.

Nonabrasive windshield washing compound

F.

Wiper cycle counting device, 0 to 1,000 cycles

G.

Oscillograph recorder or equivalent continuous recorder, 10 ipm minimum chart

speed, with an accuracy of ± 1%

H.

Thermocouple or equivalent temperature sensing device, 0 to 250 F, with an

accuracy of ± 1 F

I.

Anemometer, 0 to 20 mph, with accuracy of ± 0.1 mph

J.

Grease pencil

K.

Camera

L.

Nonabrasive windshield washing equipment

M.

Test dust, fine grade, as described in SAE J726 or equivalent

N.

Measuring device for volume of test dust and water, 0 to 32 fluid ounces, with an

accuracy of ± 0.5 fluid ounces

O.

Hand type atomizer or equivalent

P.

Windshield washer fluid, as specified by vehicle manufacturer

�7

10.

PHOTOGRAPHIC DOCUMENTATION

Photographs shall be black and white, 8 x 10 inches, and properly focused for clear

images. A tag, label or placard identifying the test vehicle model, NHTSA number and

date or item of equipment part number and date shall appear in each photograph and

must be legible. Each photograph shall be labeled as to the subject matter.

As a minimum the following photographs shall be included in each vehicle final test

report:

A.

Left side view of vehicle

B.

Right side view of vehicle

C.

3/4 frontal view from left side of vehicle

D.

3/4 rear view from right side of vehicle

E.

Vehicle's certification label

F.

Vehicle's tire information label

G.

Wiped Area Test Equipment setup

H.

Wiped Windshield Area Test Pattern on vellum showing AREAS A, B and C

I.

Washer Capability Test - Pretest Coated Windshield

J.

Washer Capability Test - Post Test Cleared Windshield

K.

Washer Capability Test, 1st Run - Cleared Windshield Area Test Pattern on vellum

showing AREAS A, B and C

L.

Washer Capability Test, 2nd Run - Cleared Windshield Area Test Pattern on vellum

showing AREAS A, B and C

M.

Any damage or apparent test failure that cannot be seen in the above photographs

�8

11.

D

EFINITIONS

BALLOONING

Unwiped areas within the wiper pattern varying is size and usually round.

CHATTER

Irregular movement of the wiper blade usually accompanied by temporary visible radial

lines and/or noise.

COMMERCIAL ADDITIVES

Materials which are compatible with the system and which may be added to depress the

fluid freezing point, assist in cleansing, and/or increase the wetting capacity of the fluid.

HAZING

An aerated film spread by the blade and resulting in a transient trailing band on the

windshield glazing surface.

LACE CURTAIN

A maze of fine individual water droplets which are formed after the wiper blade passes

over the windshield glazing surface.

SCALLOPING

Uneven wipe at the outer periphery of pattern.

STREAKING

Fine arcuate lines of unwiped moisture within the wipe pattern.

TANDEM PATTERN

The pattern produced by the wiper blades operating in the same direction across the

windshield glazing surface simultaneously.

WASHER SOLUTION

The fluid in the system consisting of water or water with appropriate commercial

additives.

�9

11.

EFINITIONS....Continued

D

WINDSHIELD WASHER SYSTEM

An apparatus for storing, filtering and applying fluid to the exterior of the windshield

glazing surface together with the necessary controls to actuate and arrest operations.

WINDSHIELD WASHER SYSTEM CONTROL

A means for actuating and arresting the windshield washer system. The actuation may

be coordinated or semicoordinated with components of the windshield wiper system or

may be fully independent.

WINDSHIELD WIPER SYSTEM

An apparatus for clearing the exterior surface of windshield glazing together with the

necessary devices and controls to actuate and arrest the operations.

WIPER CYCLE

The wiper blade movement during system operation from one extreme of the windshield

wipe pattern to the other extreme and return.

�10

12.

PRETEST REQUIREMENTS

Prior to conducting any compliance tests, contractors are required to submit a detailed

in-house compliance test procedure to the COTR which includes a step-by-step

description of the methodology to be used. Written approval must be obtained from the

COTR before initiating the compliance test program so that all parties are in agreement.

The contractor's test procedure shall contain a complete listing of test equipment and a

detailed check-off list. There shall be no contradiction between the OVSC Laboratory

Test Procedure and the contractor's in-house test procedure. The list of test equipment

shall include instrument accuracy and calibration dates.

TEST DATA LOSS

A compliance test is not to be conducted unless all of the various test conditions specified

in the applicable OVSC Laboratory Test Procedure have been met. Failure of a

contractor to obtain the required test data and to maintain acceptable limits on test

parameters (such as impact velocity) in the manner outlined in the applicable OVSC

Laboratory Test Procedure may require a retest at the expense of the contractor. The

retest costs may include the cost of the replacement vehicle (with the same equipment as

the original vehicle) or item of motor vehicle equipment and all costs associated with

conducting the retest. The original test specimen (vehicle or equipment item) used for

the invalid test shall remain the property of OVSC, and the retest specimen shall remain

the property of the contractor.

The Contracting Officer of NHTSA is the only NHTSA official authorized to notify the

contractor that a retest is required. The retest shall be completed within two (2) weeks

after receipt of notification by the Contracting Officer that a retest is required. If a retest is

conducted, no test report is required for the original test.

�11

13.

COMPLIANCE TEST EXECUTION

13.1

WINDSHIELD WIPER SYSTEM

PREPARATION

A.

Study the Owner's Manual. Visually and manually inspect the windshield wiping

and washing system controls to determine if they are accessible.

B.

Visually and manually inspect the windshield washer system fluid reservoir to

ascertain that the reservoir filler opening is readily accessible and can be filled

without the use of tools or special filling equipment.

C.

Clean the windshield glazing surface of the test vehicle with a nonabrasive type

cleaner, and position the test vehicle in a test area containing the water spray

system.

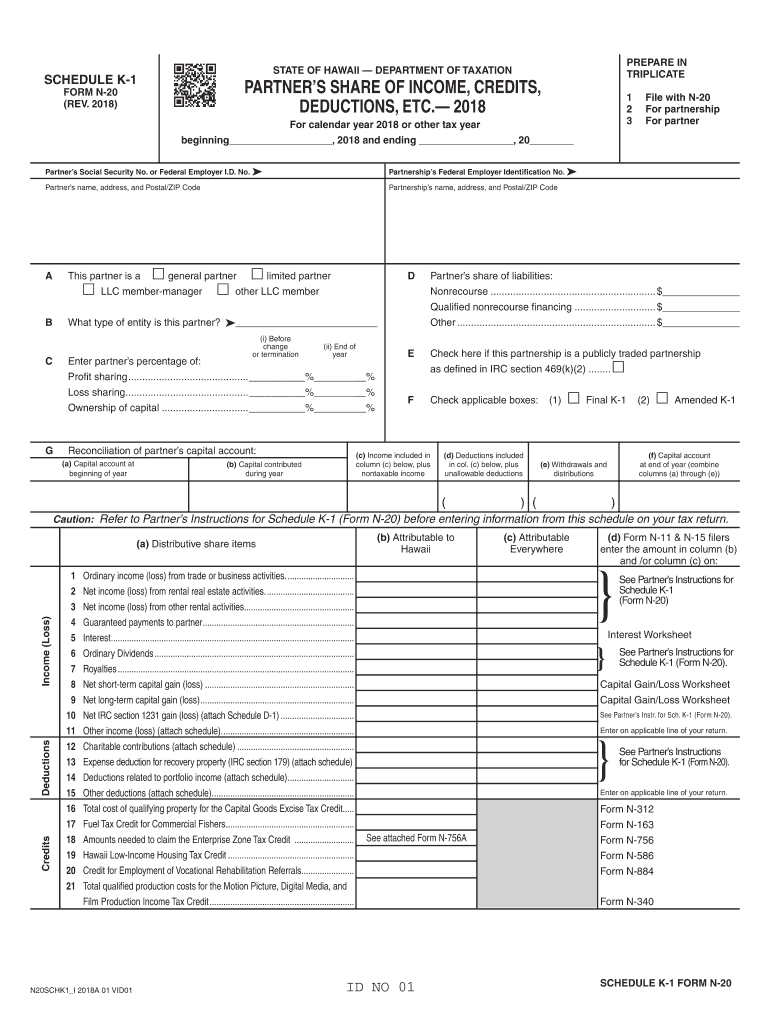

D.

Install a wiper cycle counting device on the windshield wiping system as shown

in Figure 1 below. Install a tachometer or equivalent engine r.p.m. monitoring

instrument. The tachometer shall be capable of being monitored during the test

from within the vehicle.

E.

Provide a means to vent the engine exhaust from the test area without affecting

the temperature or other conditions during the test. Verify that the test vehicle

contains sufficient gasoline to operate the vehicle engine for the duration of the

test.

TYPICAL WIPER CYCLE COUNTING DEVICE

����������������������

�������������������������

��������������������������������

����������������

��������������

��������������

�����������

FIGURE 1

������������������������

���������������������������

����������������������������������

�����������������

��������������

��������������

CYCLE COUNTER

OR RECORDING DEVICE

�12

13.

COMPLIANCE TEST EXECUTION....Continued

F.

Verify that the hardness of the water does not exceed 12 grains per gallon. The

water hardness certification may be obtained from the local water supplier.

Otherwise, contractor shall obtain an equivalent certification or conduct such test

within 60 days of beginning of compliance test run. A suitable water softener

shall be used if required.

G.

Calibrate the water flow applied to the windshield to ensure a minimum of spray

of not less than 50 and not more than 100 cubic inches of water per minute.

Adjust the spray nozzles to provide an approximately equal distribution of water

spray over the entire windshield glazing surface. The water spray shall be

applied to the windshield throughout the test. Verify that the water temperature

does not exceed 100 F.

H.

A master windshield pattern containing AREAS A, B and C will be provided by

the COTR. Make 3 working copies of the entire glass area pattern from heavy

clear vellum paper. NOTE: 2 are required for the Washer Capability test runs.

FREQUENCY TEST

A.

Maintain ambient temperature of 50 to 100 F and engine speed constant within ±

50 rpm. Transmission shall be placed in neutral.

B.

Start the test vehicle engine. Operate it at manufacturer's recommended idle

speed. Actuate the Windshield wiper control to the high speed position, and

subject the windshield wiper system to a 6 minute Frequency Test with the

external water spray applied directly to the windshield. During the first 3 minutes,

operate the wiper system at high speed with the test vehicle engine at the

manufacturer's recommended idle speed. Upon conclusion of the 3 minute

operational period, increase the engine speed to 2,000 rpm for another 3 minute

period. Calculate the average frequency of the wiper for each 3 minute test

period.

C.

Readjust the engine speed to the manufacturer's recommended idle speed.

Actuate the windshield wiper control to the lowest speed position with at least 20

cycles per minute, and subject the windshield wiper system to a 6 minute

Frequency Test with the water spray applied directly to the windshield. During

the first 3 minutes operate the wiper system at low speed and the engine at the

manufacturer's recommended idle speed. Upon conclusion of the 3 minute

operational period, increase the engine speed to 2,000 rpm for another 3 minute

period. Calculate the average wiper frequency for each 3 minute test period.

�13

13.

COMPLIANCE TEST EXECUTION....Continued

WIPED AREA TEST

A.

Clean the exterior and interior surfaces of the vehicle windshield prior to testing

with a commercial nonabrasive glass cleaning agent to provide an oil and grease

free surface for marking the dimensional area as required.

B.

Start the engine and operate it at the manufacturer's recommended idle speed ±

50 rpm with transmission in neutral.

C.

Ambient air flow should not exceed 1 mph to ensure consistent spray patterns.

Verify the velocity of the air flow using an anemometer placed 12 inches in front

of the center of the windshield. Maintain ambient air temperature at 50 to 100 F.

D.

Actuate the water spray system and adjust the windshield wiper control to the

highest speed mode. Maintain water temperature below 100 F.

E.

Using a grease pencil, outline on the internal windshield glazing surface the

areas of the windshield that are cleanly wiped by the wiper blades. The areas

shall include the wiper blade pattern plus the growth due to the high speed

operation and the 1 mph air flow.

F.

After completing the wiped area patterns on the internal windshield surface, turn

off the windshield wiper system, the water spray and air flow. Dry the windshield

and surrounding areas of the test vehicle.

G.

Place the clear vellum containing outlines of AREAS A, B and C, on the exterior

windshield glazing surface. With a grease pencil, trace onto the vellum the wiped

area patterns.

�14

13.

COMPLIANCE TEST EXECUTION....Continued

13.2

WINDSHIELD WASHER SYSTEM

PREPARATION

A.

Verify that the windshield washer reservoir contains sufficient windshield washing

fluid to perform the Windshield Washing Capability Test. The washing fluid shall

be a commercial product specified by the manufacturer. Fluid temperature shall

be 75 F ± 5 F immediately prior to the first test run.

B.

With the vehicle in position for testing, actuate the windshield washing system.

Verify that the washer nozzles are properly adjusted so the fluid spray is applied

to the windshield glazing surface target areas recommended by the vehicle

manufacturer. Air velocity at the windshield should not exceed 1 mph to ensure

consistent spray patterns.

C.

Clean the exterior and interior surfaces of the vehicle windshield.

D.

Verify that 2 vellum windshield working patterns containing AREAS A, B and C

(as made in preparation for the wiper test) are available.

E.

Mix one part test dust and two parts water by volume.

(1)

Fine grade test dust as described in SAE J726 is available from AC

Division General Motors Corporation, Flint, Michigan, or from Owns Coring

Fiberglass Co., Santa Clara, California — their 0.5" PF105, or equivalent.

CHEMICAL

SiO2

SIZE

MICRONS

0-5

PERCENT BY

WEIGHT

39 ± 2

Fe2O3

3-5%

5 - 10

18 ± 3

Al2O3

15-17%

10 - 20

16 ± 3

CaO

2-4%

20 - 40

18 ± 3

MgO

.5-1.5%

40 - 80

9±3

Total Alkalis

(2)

PERCENT BY

WEIGHT

69-76%

3-5%

Soft water temperature shall be 75 F ± 5 F and hardness shall be 12

grains/gallon.

�15

13.

COMPLIANCE TEST EXECUTION....Continued

WASHER CAPABILITY TEST

A.

Start the test vehicle engine and operate it at idle speed for the remainder of the

test.

B.

Maintain ambient temperature of 75 F ± 5 F, and wind velocity at the windshield

less than 1 mph.

C.

Using a hand-type atomizer or equivalent, wet the entire exterior windshield

glazing surface with a light film of the test dust/water mixture (freshly shaken)

without coating the wiper blades. If the dust/water mixture does not uniformly

adhere to the entire windshield, re-clean it.

D.

Within 15 seconds after the completion of the dust and water application, actuate

the window washer and wiper systems. At the completion of 10 wiper cycles

maximum, turn off the windshield wipers.

E.

Immediately mark on the interior glazing surface of the windshield the outline of

the areas of the windshield that have been cleared of the test dust using a

grease pencil.

F.

Turn off the test vehicle engine and thoroughly dry the exterior windshield

surface.

G.

Using a clear vellum containing AREAS A, B and C, trace onto the vellum pattern

the outline of the areas of the windshield cleared by the windshield washer

system with a grease pencil.

H.

Re-clean the exterior and interior surface of the windshield.

I.

Repeat the windshield washer capability test procedures for a total of 2 capability

tests at 10 wiper cycles each.

�16

14.

POST TEST REQUIREMENTS

A.

The contractor shall re-verify all instrumentation and check data sheets and

photographs (as required).

B.

Make photographs of the marked vellum patterns from each test run.

C.

Using the patterns traced onto the vellum windshield patterns, calculate the

percentages of AREAS A, B and C representing the following:

(1)

Wiped area test run

(2)

Washer capability test run 1

(3)

Washer capability test run 2

(4)

Washer capability test averages

D.

Copy applicable pages of Owner's Manual for inclusion in the final test report.

E.

The contractor shall retain all original records in a secure and organized file

unless otherwise directed by the COTR.

�17

15.

REPORTS

15.1. MONTHLY STATUS REPORTS

The contractor shall submit a monthly Test Status Report and a Vehicle Status Report

to the COTR. The Vehicle Status report shall be submitted until all vehicles are

transferred to another FMVSS or otherwise disposed of. Samples of the required

reports are found in the report forms section.

15.2. APPARENT TEST FAILURE

Any indication of an test failure shall be communicated by telephone or to the COTR

within 24 hours with written notification mailed within 48 hours (Saturday and Sunday

hours excluded). A Notice of Test Failure (see report forms section) with a copy of the

particular compliance test data sheet(s) and preliminary data plot(s) shall be included. If

possible, repeat that portion of the test where the failure was noted to ensure that there

is a test failure.

In the event of a test failure, a post test calibration check of some critically sensitive test

equipment and instrumentation (if applicable) may be required for verification of

accuracy. The necessity for the calibration shall be at the COTR's discretion and shall

be performed without additional costs to the OVSC.

15.3

FINAL TEST REPORTS

15.3.1 COPIES

In the case of an apparent test failure, SEVEN copies of the Final Test Report shall be

submitted to the COTR for acceptance within 3 weeks of test completion.

Where there has been no indication of an apparent noncompliance, THREE copies of

each Final Test Report shall be submitted to the COTR for acceptance within 3 weeks

of test completion. No payment of contractor's invoices for conducting compliance tests

will be made prior to the Final Test Report acceptance by the COTR. Contractors are

requested to NOT submit invoices before the COTR is provided with copies of the Final

Test Report.

Contractors are required to submit the first Final Test Report in draft form within 1 week

after the compliance test is conducted. The contractor and the COTR will then be able

to discuss the details of both test conduct and report content early in the compliance

test program. Contractors are required to PROOF READ all Final Test Reports before

submittal to the COTR. The OVSC will not act as a report quality control office for

contractors. Reports containing a significant number of errors will be returned to the

contractor for correction, and a "hold" will be placed on invoice payment for the

particular test.

�18

15.

REPORTS....Continued

15.3.2 REQUIREMENTS

The Final Test Report, associated documentation (including photographs), are relied

upon as the chronicle of the compliance test. The Final Test Report will be released to

the public domain after review and acceptance by the COTR. For these reasons, each

final report must be a complete document capable of standing by itself.

The contractor should use detailed descriptions of all compliance test events. Any

events that are not directly associated with the standard but are of technical interest

should also be included. The contractor should include as much detail as possible in

the report.

Instructions for the preparation of the first three pages of the final test report are

provided for standardization.

15.3.3 FIRST THREE PAGES

A.

FRONT COVER

A heavy paperback cover (or transparency) shall be provided for the protection of

the final report. The information required on the cover is as follows:

(1)

Final Report Number such as 104-ABC-9X-001, where —

104 is the FMVSS tested

ABC are the initials for the laboratory

9X is the Fiscal Year of the test program

001 is the Group Number (001 for the 1st test,

002 for the 2nd test, etc.)

(2)

Final Report Title And Subtitle such as

COMPLIANCE TESTING FOR FMVSS 104

Windshield Wiping and Washing Systems

****************

XYZ Motor Co.

199X Deluxe 4-door sedan

NHTSA No. CX0101

(3)

Contractor's Name and Address such as

COMPLIANCE TESTING LABORATORIES, INC.

4335 West Dearborn Street

Detroit, Michigan 48090

�19

15.

REPORTS....Continued

NOTE: DOT SYMBOL WILL BE PLACED BETWEEN ITEMS (3) AND (4)

(4)

Date of Final Report completion

(5)

The words "FINAL REPORT"

(6)

The sponsoring agency's name and address as follows

U. S. DEPARTMENT OF TRANSPORTATION

National Highway Traffic Safety Administration

Safety Assurance

Office of Vehicle Safety Compliance

400 Seventh Street, SW

Room 6115 (NSA-30)

Washington, DC 20590

�20

15.

REPORTS....Continued

B.

FIRST PAGE AFTER FRONT COVER

A disclaimer statement and an acceptance signature block for the COTR shall be

provided as follows:

This publication is distributed by the U. S. Department of

Transportation, National Highway Traffic Safety Administration, in

the interest of information exchange. The opinions, findings and

conclusions expressed in this publication are those of the author(s)

and not necessarily those of the Department of Transportation or

the National Highway Traffic Safety Administration. The United

States Government assumes no liability for its contents or use

thereof.

If trade or manufacturers' names or products are

mentioned, it is only because they are considered essential to the

object of the publication and should not be construed as an

endorsement. The United States Government does not endorse

products or manufacturers.

Prepared By: ________________________

Approved By: ________________________

Approval Date: ______________________

FINAL REPORT ACCEPTANCE BY OVSC:

Accepted By: _______________________

Acceptance Date: ___________________

�21

15.

REPORTS....Continued

C.

SECOND PAGE AFTER FRONT COVER

A completed Technical Report Documentation Page (Form DOT F1700.7) shall

be completed for those items that are applicable with the other spaces left blank.

Sample data for the applicable block numbers of the title page follows:

Block 1 — REPORT NUMBER

104-ABC-9X-001

Block 2 — GOVERNMENT ACCESSION NUMBER

Leave blank

Block 3 — RECIPIENT'S CATALOG NUMBER

Leave blank

Block 4 — TITLE AND SUBTITLE

Final Report of FMVSS 104 Compliance Testing of 199X XYZ Deluxe 4door sedan, NHTSA No. CX0101

Block 5 — REPORT DATE

March 1, 199X

Block 6 — PERFORMING ORGANIZATION CODE

ABC

Block 7 — AUTHOR(S)

John Smith, Project Manager

Bill Doe, Project Engineer

Block 8 — PERFORMING ORGANIZATION REPORT NUMBER

ABC-DOT-104-001

Block 9 — PERFORMING ORGANIZATION NAME AND ADDRESS

ABC Laboratories

405 Main Street

Detroit, MI 48070

�22

15.

EPORTS....Continued

R

Block 10 — WORK UNIT NUMBER

Leave blank

Block 11 — CONTRACT OR GRANT NUMBER

DTNH22-9X-D-12345

Block 12 — SPONSORING AGENCY NAME AND ADDRESS

US Department of Transportation

National Highway Traffic Safety Administration

Safety Assurance

Office of Vehicle Safety Compliance (NSA-30)

400 Seventh Street, SW, Room 6115

Washington, DC 20590

Block 13 — TYPE OF REPORT AND PERIOD COVERED

Final Test Report

Feb. 15 to Mar. 15, 199X

Block 14 — SPONSORING AGENCY CODE

NSA-30

Block 15 — SUPPLEMENTARY NOTES

Leave blank

Block 16 — ABSTRACT

Compliance tests were conducted on the subject 199X XYZ Deluxe 4-door

sedan in accordance with the specifications of the Office of Vehicle Safety

Compliance Test Procedure No. TP-104-XX for the determination of

FMVSS 104 compliance.

Test failures identified were as follows:

None

NOTE: Above wording must be shown with appropriate changes made for

a particular compliance test. Any questions should be resolved with the

COTR.

�23

15.

EPORTS....Continued

R

Block 17 — KEY WORDS

Compliance Testing

Safety Engineering

FMVSS 104

Block 18 — DISTRIBUTION STATEMENT

Copies of this report are available from —

NHTSA Technical Reference Division

Room 5108 (NAD-52)

400 Seventh St., SW

Washington, DC 20590

Telephone No.: 202-366-4946

Block 19 — SECURITY CLASSIFICATION OF REPORT

Unclassified

Block 20 — SECURITY CLASSIFICATION OF PAGE

Unclassified

Block 21 — NUMBER OF PAGES

Add appropriate number

Block 22 — PRICE

Leave blank

�24

15.

REPORTS....Continued

15.3.4 TABLE OF CONTENTS

Final test report Table of Contents shall include the following:

Section 1 —

Purpose of Compliance Test

Section 2 —

Test Procedure and Discussion of Results

Section 3 —

Test Data

Section 4 —

Test Equipment List and Calibration Information

Section 5 —

Photographs

Section 6 —

Vehicle Owner's Manual (applicable pages only)

Section 7 —

Notice of Test Failure (if applicable)

�25

16.

DATA SHEETS

SUMMARY OF DATA

FMVSS 104, WINDSHIELD WIPING AND WASHING SYSTEMS

VEH. MODEL YEAR/MAKE/MODEL/STYLE: _____________________________

VEH. NHTSA No.:

; VIN:

; BUILD DATE: _______

TEST LABORATORY: _______________________________________________

CONTRACT NO.: DTNH22-

; DELIVERY ORDER NO.: ______

DATES OF TEST: __________________________________________________

WIPER TYPE:

; WASHER TYPE: ____________________

WINDSHIELD AREAS: A =

in²; B =

in²; C =

MANUFACTURER'S WINDSHIELD PATTERN USED: Yes -

in²

; No - ___

ACCESSIBILITY:

(1)

Washer Control Accessible:

Yes -

; No - ___

(2)

Wiper Control Accessible:

Yes -

; No - ___

(3)

Washer Reservoir Filler Accessible:

Yes -

; No - ___

DESCRIBE UNUSUAL FEATURES OF WIPING AND WASHING SYSTEMS:

PERFORMANCE:

TEST

PASS

FAIL

WIPER FREQUENCY

WIPED AREA

WASHER CAPABILITY

RECORDED BY:

APPROVED BY: ________________

DATE: _____________

�26

16.

DATA SHEETS....Continued

FREQUENCY TEST DATA

FMVSS 104 — WINDSHIELD WIPER SYSTEM

VEH. NHTSA NO.:

: TEST DATE: __________________

VEH. MY/MAKE/MODEL/BODY STYLE: ___________________________

Water Hardness:

Water Spray Flow Rate:

Ambient Air Temp.:

grains/gallon (12 max.); Date Certified: _________

in³/min. (specified range = 50 to 100 in³/min.)

F (50-100 F); Water Temp.:

Manufacturer's Recommended Engine Idle Speed:

F (100 F max.)

rpm

RUN 1, MAXIMUM WIPER FREQUENCY TEST:

TIME

ENGINE

SPEED

TOTAL

CYCLES

AVG. CYCLES/MIN.

(45 MINIMUM)

1st 3 minutes

(idle ± 50 rpm)

2nd 3 minutes

(2000 rpm ± 50 rpm)

Frequency at least 45 cycles/minute regardless of engine speed: Yes-

; No- ___

RUN 2, LOWER WIPER FREQUENCY TEST:

TIME

ENGINE

SPEED

TOTAL

CYCLES

AVG. CYCLES/MIN.

(20 MINIMUM)

1st 3 minutes

(idle ± 50 rpm)

2nd 3 minutes

(2000 rpm ± 50 rpm)

Highest and lower frequency differ by at least 15 cycles/minute, and lower frequency is at least

20 cycles/minute regardless of engine speed: Yes; No- ___

REMARKS:

RECORDED BY:

APPROVED BY: ________________

DATE: _______________

�27

16.

DATA SHEETS....Continued

WIPED AREA TEST DATA

FMVSS 104 — WINDSHIELD WIPER SYSTEM

TEST LAB.:

; TEST DATE: ________________

VEH. MODEL YR/MAKE/MODEL/BODY STYLE: _________________________

VEH. NHTSA NO.: _________________

Air temperature in test area =

Air velocity at windshield =

Engine speed =

F (specified range of 50 to 100 F)

mph (specified range of 0 to 1 mph)

rpm (manufacturer's recommended idle ± 50 rpm)

Temperature of water spray =

Water spray flow rate =

Windshield wiper frequency =

F (100 F maximum)

in³/min. (specified range of 50 to 100 in³/min.)

cycles/min. (45 cpm minimum)

TEST RESULTS:

PERCENT WIPED

WINDSHIELD AREA

ACTUAL

A

B

C

REQUIRE

D

PASS

80%

94%

99%

REMARKS:

RECORDED BY:

APPROVED BY: ________________

DATE: _________________

FAIL

�28

16.

DATA SHEETS....Continued

CAPABILITY TEST DATA

FMVSS 104 — WINDSHIELD WASHER SYSTEM

TEST LAB.:

; TEST DATE: _____________

VEH. MODEL YR/MAKE/MODEL/BODY STYLE: _______________________

VEH. NHTSA NO.: _____________________

Air temperature in test area =

F (specified range of 70 to 80 F)

Washer reservoir fluid temperature =

Air velocity at windshield =

Engine speed =

F (specified range of 70 to 80 F)

mph (specified range of 0 to 1 mph)

rpm (manufacturer's recommended idle ± 50 rpm)

Number of windshield washer nozzles on the vehicle = ______

Windshield washer system activation coordinated with components of the wiper system: Yes __

; No - _____

TEST RESULTS:

CLEARED AREA PERCENTAGES

WINDSHIELD

AREA

TEST

1

TEST

2

A

B

C

AVG

REQD*

PASS

FAIL

75%

75%

75%

* NOTE FOR REFERENCE ONLY: SAE 942b, revised Jul72, recommends capability to clear

80% of the total wash area and 90% of the wash area included in AREA C.

REMARKS:

RECORDED BY:

APPROVED BY: ________________

DATE: ____________

�29

17.

FORMS

LABORATORY NOTICE OF TEST FAILURE TO OVSC

FMVSS NO.: 104

TEST DATE: _______________________________________

LABORATORY: _____________________________________________________

CONTRACT NO.:

; DELV. ORDER NO.: __________

LABORATORY PROJECT ENGINEER'S NAME: ___________________________

TEST VEHICLE DESCRIPTION: _______________________________________

__________________________________________________________________

VEHICLE NHTSA NO.:

; VIN: _______________________

VEHICLE MANUFACTURER: ___________________________________

TEST FAILURE DESCRIPTION:

_____________________________________

_________________________________________________________________

_________________________________________________________________

FMVSS REQUIREMENT, PARAGRAPH §

: _________________________

_________________________________________________________________

_________________________________________________________________

NOTIFICATION TO NHTSA (COTR): __________________________________

DATE:

REMARKS:

; BY: ___________________________________

�30

17.

FORMS....Continued

MONTHLY TEST STATUS REPORT

FMVSS 104

DATE OF REPORT:

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

VEHICLE NHTSA No.,

MAKE & MODEL

COMPLIANCE

TEST DATE

PASS/

FAIL

DATE

REPORT

SUBMITTED

DATE

INVOICE

SUBMITTED

INVOICE

PAYMENT

DATE

�31

17.

REPORT FORMS....Continued

MONTHLY VEHICLE STATUS REPORT

FMVSS 104

DATE OF REPORT:

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

VEHICLE NHTSA No.,

MAKE & MODEL

DATE OF

DELIVERY

TEST

COMPLETE

DATE

VEHICLE

SHIPMENT

DATE

CONDITION OF

VEHICLE

�