Evaluation of Low-volume Sprayers Used in

Asian Citrus Psyllid Control Applications

Clint Hoffmann1,8, Brad Fritz1, Dan Martin1, Ryan Atwood2,

Tim Hurner3, Mark Ledebuhr4, Matt Tandy5, John L. Jackson6,

and Gail Wisler7

ADDITIONAL INDEX WORDS. technology, Diaphorina citri, greening

SUMMARY. The asian citrus psyllid [Diaphorina citri (Sternorrhyncha: Psyllidae)] is

a detrimental pest to citrus (Citrus spp.) crops when it serves as a vector of the

pathogen that causes greening (huanglongbing). Transmission of this disease causes

mottling, chlorosis, dieback, and reductions in fruit size and quality. Citrus

producers have found that many pesticides, when applied properly, are very

effective at suppressing or eliminating asian citrus psyllids in groves. Due to the

threat of greening, several pesticides have been granted Special Local Needs

registration for use in the state of Florida if the product is sprayed with a volume median

diameter of 90 mm or greater. A number of studies involving numerous citrus sprayers

and a.i. were conducted to determine the droplet sizes generated by different

sprayers operating under user-established settings and the adjustments required

to those settings for the sprayers to meet the 90-mm requirement. In the sprayer

tests, it was found that reductions in engine speed or increases in flow rate were

required to increase droplet sizes to meet the product label-required droplet size.

As the equipment tested here represent the most typical application equipment

used in Florida for asian citrus psyllid control, these results will provide applicators,

growers, and extension agents with general guidelines to ensure that spray

systems are operated in a manner that complies with label restrictions.

T

he asian citrus psyllid is a detrimental pest to citrus crops

when it serves as a vector of

the pathogen that causes greening

[huanglongbing (HLB)]. Transmission of this disease causes mottling,

chlorosis, dieback, and reductions in

Mention of a trademark, vendor, or proprietary

product does not constitute a guarantee or warranty

of the product by the U.S. Department of Agriculture

or U.S. Navy and does not imply its approval to the

exclusion of other products that may also be suitable.

This study was supported in part by a grant from the

Deployed War-Fighter Protection (DWFP) Research

Program, funded by the U.S. Department of Defense

through the Armed Forces Pest Management Board

(AFPMB).

1

U.S. Department of Agriculture-Agricultural Research Service-Areawide Pest Management Research

Unit-Aerial Application Group, 2771 F&B Road,

College Station, TX 77845

2

University of Florida, IFAS Extension, 1951 Woodlea Road, Tavares, FL 32778

fruit size and quality (Halbert and

Manjunath, 2004). Once a tree is

infected, there is no cure, and trees

may only live for another 5 to 8 years,

potentially never bearing usable fruit.

It is well established that the presence

of asian citrus psyllids and the vectored pathogen necessitate chemical

control in the form of pesticide applications (Tolley, 1990). Given the

seriousness of the disease, it is important to protect even apparently

disease-free trees (Aubert, 1990),

especially with new growth flush

(Aubert 1987). Recommended treatment intervals range from 10 to

13 treatments per year (Roistacher,

1996) to every 7 to 20 d (Gonzales

and Viñas, 1981), with area-wide

treatments being preferred (Aubert

1990). Supriyanto and Whittle (1991)

recommend high-efficacy pesticides

as essential to provide sufficient control to significantly delay a greening

epidemic. It can be further conjectured that optimal application techniques also are critical to obtaining

maximum biological control of asian

citrus psyllids.

Stover et al. (2002), in a survey

to indentify current spray application

practices on citrus crops in Florida,

identified three predominate sprayer

types, including two airblast sprayers

at mid- and high-volume application

rates and a low-volume application

rate air-assisted sprayer, with spray

rates ranging from 25 to 750 gal/

acre. Sprayer type is generally selected

by the operator based on experience

and/or perceived coverage and deposition of spray material within the

citrus canopy. The selected sprayers

can typically be modified to generate

spray plumes that fit tree contours

through changes in nozzle numbers,

and orientation of and/or oscillation

of airflow (Stover et al., 2003). With

the need for numerous spray treatments for asian citrus psyllid control,

applicators are looking to and adapting for use a number of spray application machines initially targeted for

the mosquito vector control industry.

Machines that apply agrochemical

products at these low-volume rates

allow applicators to respond to the

need to treat large numbers of acres

repeatedly in a timely manner. These

machines can produce droplets with

volume median diameters that range

from 5 to 210 mm, depending on

spray solution and equipment setup

(Hoffmann et al., 2007a).

The list of pesticides approved

for application to control asian citrus

psyllids in Florida is limited. As a result

of the urgent need for control, applicators in Florida have been granted

Special Local Needs provisions on

a number of insecticides, including

spinetoram (DelegateÒ WG; Dow

3

University of Florida, IFAS Extension, 4509 George

Boulevard, Sebring, FL 33872

4

Ledebuhr Industries, 795 Progress Court, Williamston, MI 48895

5

Curtis DynaFog, 17335 U.S. Highway 31 North,

Westfield, IN 46074

6

Florida Citrus Industry Research Coordinating

Council, 30205 SR 19, Tavares, FL 32778

7

U.S. Department of Agriculture-Agricultural Research Service, National Programs, 5601 Sunnyside

Avenue, Beltsville, MD 20705

8

Corresponding author. E-mail: clint.hoffmann@ars.

usda.gov.

632

Units

To convert U.S. to SI,

multiply by

U.S. unit

SI unit

To convert SI to U.S.,

multiply by

0.3048

3.7854

9.3540

2.54

1

0.4470

70.0532

6.8948

ft

gal

gal/acre

inch(es)

micron

mph

oz/acre

psi

m

L

L�ha–1

cm

mm

m�s–1

g�ha–1

kPa

3.2808

0.2642

0.1069

0.3937

1

2.2369

0.0143

0.1450

•

June 2010 20(3)

�AgroSciences, Indianapolis), diflubenzuron (MicromiteÒ 80WGS; Chemtura, Middlebury, CT), fenpropathrin

(Danitol 2.4 EC; Valent, Walnut

Creek, CA), and zeta-cypermethrin

(Mustang; FMC, Philadelphia). All

of these Special Local Needs labels

require air-blast or air-assisted sprayers

with application rates of no less than

2 gal/acre and with volume median

droplet diameters of 90 mm or larger.

Most labels allow the addition of

adjuvants or other tank-mix partners

as long as the other restrictions are

maintained; however, fenpropathrin

does not allow use of additional adjuvants. No information is given regarding the reasoning behind the

90-mm lower limit, though it is likely

based on risk assessment analysis for

spray drift. The Special Local Needs

labels also do not specify an upper

limit on the droplet size. Given that

spray droplet size is dependent on and

changes with varying combinations

of spray equipment, equipment setup,

and spray product (Hoffmann et al.,

2007b), the objectives of this work

were: 1) evaluate three sprayers, under laboratory conditions, for droplet

size produced from a.i. formulations

and the necessary equipment adjustments needed to meet the Special

Local Needs label; 2) conduct ‘‘onsite’’ evaluations of production application equipment for droplet size

when operating under normal conditions; 3) adjust the individual sprayer’s

operating parameters to produce a volume median diameter of 90 mm or

greater to ensure compliance with the

Special Local Needs labels; and 4)

document the general operational

modifications required for machine

type to provide guidance for future

spray calibrations.

field-based evaluations were conducted at two locations in central

Florida. Both sets of trials followed

the same testing protocols with the

exception of the field-based trials not

using a.i. formulations. These procedures, along with greater details on the

site-specific testing, are discussed further in the following sections.

GENERAL TESTING PROCEDURES.

To evaluate the droplet size produced

by a particular sprayer and spray formulation combination, the sprayer

was first operated under its normal

factory or user-established settings.

Basically, the sprayer was initially operated as-is. A droplet measurement

system (Sympatec, Clausthal, Germany) mounted on a custom-made

forklift mount was used to measure

droplet size at the sprayer nozzle

outlet. The unit was positioned such

that the location of measurement was

�1 to 2 m from the outlet of the

sprayer (Fig. 1). This distance varied

somewhat from sprayer to sprayer

depending on the droplet density of

the resulting spray cloud and the

width of the spray plume. Wider spray

plumes required a closer distance to

avoid depositing spray material on the

lenses of the droplet measurement

unit. Denser sprays required further

distance to insure that the spray cloud

density did not prevent the diffracted

laser light from reaching the measurement sensor. The spray cloud from

the sprayer was directed through the

laser beam for 10 to 20 s during

which time droplet size measurements of the spray cloud were made.

The time that the spray cloud was

directed through the optical path of

the laser varied between sprayers

depending on the width of the spray

plume generated by the sprayer. The

entire spray plume for each sprayer

was measured by traversing the laser

through the plume using the forklift

(ASTM International, 2009). Three

replicated measures were made for

each unique piece of equipment and

specific set of operational conditions.

DROPLET SIZING SYSTEM. The

Helos laser diffraction droplet sizing

system (Sympatec), which uses a 623nm helium-neon laser, was fitted with

an R5 lens, resulting in a dynamic size

range from 0.5 to 875 mm in 32 sizing

bins. The authors found that when

using the laser system under adverse

conditions (outdoors and mounted

to a forklift), the last channel (i.e.,

sizing bins) of the Helos system

should be turned off such that it is

not factored into the droplet size

measurement results. This channel

represents the largest droplet size

and tends to pick up some ‘‘noise’’

or random signals that typically result

from equipment vibration or scattered ambient light. With this channel

turned off, the dynamic range of the

instrument was from 0.5 to 735 mm.

These channels were not turned off if

any droplets were measured within

two sizing bins of the nearest deactivated channel.

The spray droplet size data were

determined and reported as a mean

and standard deviation corresponding to the data measured during the

three replications for each combination of sprayer and pesticide. Means

and standard deviations of the volume

median diameter [VMD or DV0.5

(ASTM International E1620-97,

2004)], DV0.1, and DV0.9 were determined. The DV0.5 is the droplet

diameter in micrometers where 50%

of the spray volume is contained in

droplets smaller than this value (ASTM

Materials and methods

Sprayer droplet size testing was

completed in two stages: one looking

at three sprayers and five a.i. under

laboratory conditions and the second,

a field-based evaluation of production

sprayers brought to a central location

by local applicators. The first laboratory-based work was conducted at

the U.S. Department of AgricultureAgricultural Research Service (USDAARS) Areawide Pest Management

Research Unit’s Riverside campus facilities in College Station, TX. The three

sprayers to be evaluated were provided

by the equipment manufacturers. The

•

June 2010 20(3)

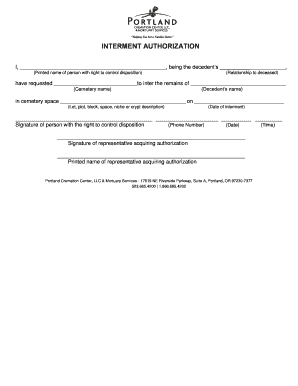

Fig. 1. Testing setup showing the droplet measurement system with the spray

plume from the citrus sprayer directed through the laser beam of the droplet

measurement system.

633

�TECHNOLOGY AND PRODUCT REPORTS

Standard E1620, 2004). Similarly,

the DV0.1 and DV0.9 values are the

diameters at which 10% and 90%,

respectively, of the spray volume is

contained in droplets of these sizes.

ACTIVE INGREDIENT TESTS. For

the laboratory studies, five a.i. along

with water plus a nonionic surfactant

(NIS) were used. The use of a specially

designed scrubbing system allowed

for the use of these a.i. without adverse environmental impacts. Three

liquid-based products were used:

malathion (Malathion 5EC; Drexel

Chemical, Memphis, TN), dimethoate (Dimethoate 4E; Arysta LifeScience North America, Cary, NC),

and fenpropathrin. Two of the products were wettable powders: diflubenzuron and spinetoram. The rates at

which these products were tested are

shown in Table 1. For all a.i. tests,

spray rates were maintained at 3 gal/

acre. For each of the three sprayers

tested, the first step was to run the

sprayer at the factory settings using

water to determine a benchmark for

further modifications. Depending on

the measured DV0.5, engine speed was

modified such that the 90-mm lower

size requirement was met. The goal

for each a.i. formulation tested was to

determine the appropriate engine

speed settings that resulted in compliance with the Special Local Needs

permit.

C ITRUS SPRAYER CALIBRATION

RODEOS. The field evaluations were

organized by the Florida Extension

Service in Lake Placid, FL, and Haines

City, FL. Growers and applicators in

the region were invited to bring their

equipment to these locations for droplet size measurements. Thirty-three

machines were evaluated representing

Table 1. Five a.i. (three liquid and

two wettable powders) and the rates

at which they were used in the

sprayer calibration trials.

Liquid

formulation

Malathion

Dimethoate

Fenpropathrin

Wettable

powders

Diflubenzuron

Spinetoram

z

1 oz/acre = 70.0532 g�ha–1.

634

Application rate

(oz/acre a.i.)z

9.0

13.9

6.2

Application rate

(oz/acre a.i.)

5.0

1.0

16 different models of sprayers. Water

with 0.25% volume/volume addition

of a NIS (R-11; Wilbur-Ellis, Walnut

Creek, CA) was used during these

tests as there were a large number of

spray trials conducted and a large

number of people involved. This prevented any environmental contamination or adverse health effects. The

water plus NIS solution simulates

most water-based insecticide sprays

well (Hoffmann et al., 2007a,

2007b). Each sprayer tested was initially run at the user settings. Based

on the measured DV0.5, engine

speed and, in a few cases, sprayer

pressure were adjusted until the 90mm size requirement was met. Typically, engine speed was first reduced

to its minimum level and if the

resulting measured DV0.5 was still

less than 90 mm, spray pressure was

increased.

An example of the data reports

that were provided to each of the

applicators is shown in the Appendix

(Fig. 2).

Results

ACTIVE

INGREDIENT TESTS WITH

THREE SPRAYERS. Final equipment set-

tings required to meet the DV0.5 90mm size requirement for each a.i. are

shown in Tables 2 through 4 for the

three sprayers tested. Droplet size at

the factory settings for water and

water plus NIS are also included for

reference. For the London Fog model

18–20 sprayer (London Fog, Long

Lake, MN) (Table 2), initial testing

with water and water plus NIS with

the machine operating at 2810 and

1850 rpm, respectively, and a rate of

1.9 L�min–1 produced DV0.5 of 57.8 ±

13.2 and 85.9 ± 1.2 mm (mean ± SD of

three replications), respectively. Two

of the a.i. formulations, diflubenzuron and spinetoram, produced

DV0.5 values that were at or near the

90-mm requirement while operating

the sprayer at 1500 rpm while two,

fenpropathrin and malathion, required reducing the engine speed to

1350 rpm. The dimethoate formulation was such that even at the lowest

engine speed setting (1350 rpm), the

90-mm size requirement could not

be met.

For the Curtec sprayer (Curtec

of Florida, Vero Beach, FL), water

and water plus NIS resulted in DV0.5

that were greater than 90 mm at

factory settings. Dimethoate and

diflubenzuron formulation also achieve

the 90-mm requirement at the factory

settings, while the malathion, spinetoram, and fenpropathrin formulation required engine speeds to be

reduced to 4800, 4000, and 4000

rpm, respectively.

For the Proptec sprayer (Ledebuhr

Industries, Williamston, MI), water

and water plus NIS resulted in DV0.5

values that met the 90-mm requirement. Spinetoram and diflubenzuron

formulations also met the 90-mm

requirement at the 5100-rpm factory setting, while malathion and

fenpropathrin formulations required

the engine speed to be reduced to

3500 rpm.

C ITRUS SPRAYER CALIBRATION

RODEOS: SINGLE MACHINE

EVALUATIONS. During the calibration

rodeos, there were 17 unique models

of machines evaluated. Fourteen of

the models only had one machine of

that type that was tested. Two, the

Dyna-Fog Ag-Mister LV-8 (Curtis

Dyna-Fog, Westfield, IN) and the

London Fog model 18–20, had multiple machines of that type tested.

Of the individual machines

tested, eight had a DV0.5 of 90 um

or greater (Table 5). Three of the

remaining sprayers were able to be

adjusted via spray pressure or engine

speed to achieve a DV0.5 near or

greater than 90 mm. One of the

sprayers, MaxCharge ES100 (Electrostatic Spraying Systems, Watkinsville, GA), was designed to generate

droplets with a DV0.5 of between 30

and 40 mm to optimize the electrostatic charge that it imparts to the

spray droplets.

There were 14 Dyna-Fog AgMister LV-8 (LV-8) and six London

Fog model 18–20 citrus sprayers evaluated in the calibration rodeos (Table 6). Each row of data presented

in Table 6 represents a unique machine. These machines were all of

different age, levels of maintenance,

degree of user modification, and standard operating settings thus variation

in spray droplet size among the machine was expected. Of the 14 LV-8

sprayers, four were version 1 (LV-8V1), one was version 2 (LV-8-V2),

and nine sprayers contained some

modifications of pumps and spray

lines that made it difficult to distinguish a specific version. Therefore, all

data are presented by individual machine, with no attempt to characterize

•

June 2010 20(3)

�Table 2. Effects of a.i. and engine speed on spray atomization for the London Fog model 18–20 sprayer (London Fog, Long

Lake, MN).

Formulation

Water

Water + 0.25% NISx

Diflubenzuron

Spinetoram

Fenpropathrin

Malathion

Dimethoate

Engine speed

(rpm)

Rate per

atomizer

(gal/min)z

DV0.1 y

(mm ± SD)

Droplet sizey

DV0.5

(mm ± SD)

2810

1850

1500

1500

1350

1350

1350

0.6

0.6

0.6

0.6

0.6

0.6

0.6

22.3 ± 5.1

30.2 ± 2.3

38.1 ± 0.4

35.1 ± 0.5

38.1 ± 0.7

37.1 ± 1.0

30.0 ± 2.7

57.8 ± 13.2

85.9 ± 1.2

94.0 ± 2.7

86.4 ± 0.6

91.4 ± 0.4

92.0 ± 0.9

79.6 ± 2.8

DV0.9

(mm ± SD)

110.6 ± 22.3

214.7 ± 14.8

305.5 ± 6.5

260.7 ± 12.9

322.2 ± 10.5

279.2 ± 9.9

205.1 ± 52.7

z

1 gal = 3.7854 L.

DV.01, DV.05, and DV.09 = the droplet diameter where 10%, 50%, and 90%, respectively, of the spray volume is contained in droplets smaller than this value. Values represent the

mean of three replications; 1 mm = 1 micron.

x

NIS = nonionic surfactant (R-11; Wilbur-Ellis, Walnut Creek, CA).

y

Table 3. Effects of a.i. and engine speed on spray atomization for the Curtec sprayer (Curtec of Florida, Vero Beach, FL).

Formulation

Water

Water + 0.25% NISx

Dimethoate

Malathion

Spinetoram

Diflubenzuron

Fenpropathrin

Engine speed

(rpm)

Rate per

atomizer

(gal/min)z

DV0.1

(mm ± SD)

Droplet sizey

DV0.5

(mm ± SD)

DV0.9

(mm ± SD)

5100

5100

5100

4800

4000

5100

4000

0.3

0.3

0.3

0.3

0.3

0.3

0.3

41.3 ± 9.4

35.3 ± 5.2

37.9 ± 5.9

31.2 ± 1.3

66.0 ± 23.1

39.9 ± 3.7

44.3 ± 1.7

111.8 ± 12.8

94.9 ± 4.6

96.7 ± 11.0

88.9 ± 0.6

126.4 ± 11.9

105.2 ± 6.4

113.2 ± 2.9

173.6 ± 17.9

149.1 ± 4.2

167.3 ± 11.5

168.7 ± 9.0

200.5 ± 13.1

185.5 ± 11.4

218.6 ± 33.5

z

1 gal = 3.7854 L.

DV.01, DV.05, and DV.09 = the droplet diameter where 10%, 50%, and 90%, respectively, of the spray volume is contained in droplets smaller than this value. Values represent the

mean of three replications; 1 mm = 1 micron.

x

NIS = nonionic surfactant (R-11; Wilbur-Ellis, Walnut Creek, CA).

y

Table 4. Effects of a.i. and engine speed on spray atomization for the Proptec sprayer (Ledebuhr Industries, Williamston,

MI).

Formulation

Water

Water + 0.25% NISx

Malathion

Spinetoram

Diflubenzuron

Fenpropathrin

Engine speed

(rpm)

Rate per

atomizer

(gal/min)z

DV0.1

(mm ± SD)

Droplet sizey

DV0.5

(mm ± SD)

5100

5100

3500

5100

5100

3500

0.36

0.36

0.36

0.36

0.36

0.36

29.4 ± 0.8

33.0 ± 4.2

33.7 ± 1.6

32.6 ± 2.0

31.6 ± 1.1

34.5 ± 0.4

98.4 ± 5.7

94.9 ± 15.8

91.6 ± 4.0

97.6 ± 5.9

93.8 ± 3.8

96.4 ± 2.1

DV0.9

(mm ± SD)

161.2 ± 13.6

193.0 ± 21.6

173.6 ± 3.8

165.8 ± 7.0

172.9 ± 4.1

209.5 ± 11.1

z

1 gal = 3.7854 L.

DV.01, DV.05, and DV.09= the droplet diameter where 10%, 50%, and 90%, respectively, of the spray volume is contained in droplets smaller than this value. Values represent the

mean of three replications; 1 mm = 1 micron.

x

NIS = nonionic surfactant (R-11; Wilbur-Ellis, Walnut Creek, CA).

y

general sprayer model performance.

For each machine tested, the droplet

size under the initial operational settings is presented followed by the

droplet size at the adjusted settings.

Typically, for the LV-8 and LV-8-V2,

decreasing the engine rpm resulted in

increased droplet size such the 90-mm

size requirement was met. There were

•

June 2010 20(3)

several of the LV-8 machines that,

even with maximum reduction of

the engine speed, the 90-mm level

was not met. Each of the individual

machines tested had unique lower

engine speed, again due to variability in machine age, maintenance,

and level of modification. For the

LV-8-V1 machines tested, similar

adjustments in engine speed did not

result in sufficient increase in droplet

size. The LV-8-V1 has a smaller

pump and small diameter tubing leading to each of the spray nozzles,

which limits flow output and thereby

the ability to generate larger droplets.

The London Fog model 18–20

citrus sprayers followed similar trends

635

�TECHNOLOGY AND PRODUCT REPORTS

Table 5. Spray droplet size measurements from sprayers in the citrus spray calibration rodeo with the original setting results

followed by the adjusted setting results for a water plus nonionic surfactant solution. The sprayers were adjusted to comply

with the droplet size requirements of the Special Local Needs permits granted to some insecticides in the State of Florida.

Original settings

Liquid

Air

pressure pressure

(psi)y

(psi)

Sprayerz

Model no.

Nozzlez

Spray

rate

(gal/acre)y

Adapco

AirTec

Curtec

Curtec

Curtec

Curtec

London

Fog

ESS

190GS

CAB1000

648 D

648 D

C3000

P400D

2D MaxiPro

Standard

Albuz

Curtec coarse

Curtec fine

Curtec coarse

Proptec coarse

Standard

2

25

10

10

21

2

2

15

2

1 gal/miny

4

2800

540 - PTOw

2100

1500

540 - PTO

2100

2500

MaxCharge

ESS100

Standard

15

20

30

440 - PTO

3

7

1700

3

5

5

10

8

1700

2500

450 - PTO

1700

Proptec

Proptec

Rears

Rears

Sides

PulBlast

PulBlast

Spectrum

Proptec

coarse

Proptec fine

Rotary

Albuz ATR-80

Ogee shear

3

70

50

150

42

Adjusted settings

Air

Liquid

pressure pressure

(psi)

(psi)

Engine

speed

(rpm)

Engine

speed

(rpm)

Sprayer

Model no.

Nozzle

Targeted

rate

(gal/acre)

Adapco

Curtec

Curtec

London

Fog

ESS

190GS

648 D

C3000

2D MaxiPro

Standard

Curtec coarse

Curtec coarse

Standard

2

10

21

2

0

3

15

1 gal/min

0

4

1900

1500

440 - PTO

1640

MaxCharge

ESS100

Standard

15

30

25

540 - PTO

5

0

7

1300

5

0

7

1300

Proptec

Proptec

Proptec

coarse

Proptec fine

Droplet size in first testx

DV0.1

DV0.5

DV0.9

(mm ± SD)

(mm ± SD)

(mm ± SD)

17.2 ± 1.5 51.1 ± 5.8

37.3 ± 0.3

99 ± 1.2

30.4 ± 0.4 75.5 ± 0.8

31.6 ± 1.0 87.1 ± 3.7

27 ± 0.4 70.9 ± 0.6

63.2 ± 4.8 149.2 ± 12.2

121.4 ± 13.8

173.7 ± 4.5

133.8 ± 2.3

159.7 ± 17.6

130.6 ± 4.2

335.8 ± 79.7

17.6 ± 0.2

38.4 ± 0.1

79.4 ± 6.2

14.3 ± 0.3

41.9 ± 0.3

102.9 ± 1.1

31.5 ± 1.8 75.5 ± 6.7

31.6 ± 0.4 80.7 ± 4.2

131.6 ± 8.3 278.9 ± 16.9

56.4 ± 0.8 131.4 ± 0.4

38.6 ± 2.3 99.7 ± 8.2

147.3 ± 28.1

139.3 ± 4.5

390.7 ± 25.7

214.9 ± 1.0

184.8 ± 27.4

Droplet size after adjusting sprayerx

DV0.1

DV0.5

DV0.9

(mm ± SD)

(mm ± SD)

(mm ± SD)

39.2 ± 1.1

31.9 ± 0.8

33.3 ± 2.1

107.6 ± 4.5

79.1 ± 1.8

95.7 ± 2.7

227.2 ± 14.8

142.1 ± 4.5

180.2 ± 1.0

29.4 ± 2.1

76.7 ± 5.6

177 ± 11.5

13.3 ± 0.5

34.7 ± 1.4

83.9 ± 3.0

31.3 ± 1.8

37.4 ± 2.0

75.5 ± 6.7

88.7 ± 3.6

147.3 ± 28.1

162.9 ± 13.1

z

Adapco (Sanford, FL); AirTec (AirTec Sprayers, Winter Haven, FL); Curtec (Curtec of Florida, Vero Beach, FL); London Fog (Long Lake, MN); ESS (Electrostatic Spraying

Systems, Watkinsville, GA); Proptec (Ledebuhr Industries, Williamston, MI); Rears (Rears Manufacturing, Eugene, OR); Sides (Goldthwaite, TX); Albuz (Spirit River, AB,

Canada); Ogee (Spectrum Electrostatic Sprayers, Houston).

y

1 gal/acre = 9.3540 L�ha–1, 1 psi = 6.8948 kPa, 1 gal = 3.7854 L.

x

DV.01, DV.05, and DV.09= the droplet diameter where 10%, 50%, and 90%, respectively, of the spray volume is contained in droplets smaller than this value. Values represent the

mean of three replications; 1 mm = 1 micron.

w

Power take-off.

as the LV-8s. With a single exception,

reducing the engine speed increased

DV0.5 values such that the 90-mm size

requirement was met.

Conclusions

In response to the need for accurate droplet size assessments of

application equipment used in the

control of the asian citrus psyllid in

Florida, a variety of field application

sprayers were evaluated to determine

if the applied sprays met the Special

Local Needs labeling requirements of

volume median diameters of 90 mm

or greater. Initially, a series of studies

was conducted across three typical

636

spray systems and five a.i. to determine typical machine operating characteristics and resulting droplet sizes.

From these tests, it was found that for

typical air-blast type sprayers, reductions in engine speed were required to

reduce air-shear atomization to increase droplet sizes to the required

size. For air-assisted sprayers, this also

held true with the addition that increased flow rate also potentially increased droplet size. Following these

initial assessments, a series of droplet

sizing rodeos were held in Florida

to measure spray droplet size from

applicator- and grower-owned citrus sprayers operating in ‘‘as-is’’

conditions. Based on the resulting

spray droplet size, the sprayer settings

were adjusted such that the resulting

droplet size would comply with the

label requirements. Following the

trends seen in the initial round of

testing, the majority of the sprayers

was adjusted via the engine speed or

spray pressure such that the resulting

spray’s volume median diameter was

greater than or equal to 90 mm. As the

equipment tested here represent the

most typical application equipment

used in Florida for asian citrus psyllid control, these results will provide

applicators, growers, and extension

agents with general guidelines to

•

June 2010 20(3)

�•

June 2010 20(3)

3

5

3.5

2.5

3

2.4

3

3

3

2

3

1

2

5

0.4

1

2

1.8

1.8

3

LV8

LV8

LV8

LV8

LV8

LV8

LV8

LV8

LV8

LV8-V1

LV8-V1

LV8-V1

LV8-V1

LV8-V2

18–20

18–20

18–20

18–20

18–20

18–20

Dyna-Fog

Dyna-Fog

Dyna-Fog

Dyna-Fog

Dyna-Fog

Dyna-Fog

Dyna-Fog

Dyna-Fog

Dyna-Fog

Dyna-Fog

Dyna-Fog

Dyna-Fog

Dyna-Fog

Dyna-Fog

London Fog

London Fog

London Fog

London Fog

London Fog

London Fog

4

7

6

6

10

8

7

9

9

9

6

7

6

7

7

7

2260

2500

2500

2600

2600

2600

2600

2600

2140

2600

1670

2600

2600

2500

2600

2850

2720

2600

2600

2500

Engine speed

(rpm)

23.6 ± 3.9

21.1 ± 2.7

16.1 ± 1.6

15.8 ± 0.9

20.4 ± 0.6

22.4 ± 0.1

24.8 ± 0.4

26.5 ± 2.1

24.4 ± 0.7

14.6 ± 0.8

18.3 ± 0.7

13.2 ± 1.8

14.2 ± 0.8

27.2 ± 1.6

12.4 ± 0.6

18.9 ± 0.1

22.8 ± 0.7

31.6 ± 1.6

32.2 ± 2.6

24.9 ± 5.6

64.5 ± 11.9

55.5 ± 6.4

47.1 ± 3.3

39.6 ± 2.1

53.1 ± 2.7

64.1 ± 2.1

76 ± 4.7

76.8 ± 4.4

69.8 ± 2.3

50.1 ± 12.7

44.2 ± 2.1

35.3 ± 1.7

35.4 ± 1.9

76.7 ± 1.5

25.9 ± 2.0

46.8 ± 0.1

62.0 ± 0.1

83.1 ± 3.7

89.9 ± 4.0

65.1 ± 17.7

Original settings

Droplet sizex

DV0.5

DV0.1

(mm ± SD)

(mm ± SD)

130.6 ± 23.9

112.9 ± 11.4

101.7 ± 3.5

79.8 ± 7

106.3 ± 10.3

131.5 ± 16.5

185.4 ± 0.1

176.3 ± 19.2

160.9 ± 8.3

157.9 ± 31.3

90 ± 1.4

69.2 ± 4.3

70.9 ± 5.3

166.7 ± 21.4

57.1 ± 18.4

85.0 ± 0.3

130.6 ± 3.5

177.9 ± 13.9

190.2 ± 4.4

134.7 ± 23.8

DV0.9

(mm ± SD)

2260

1800

1350

2100

1800

2040

1400

2120

2000

1600

1350

2300

2000

2020

1900

1800

1800

2400

2400

1500

29.7 ± 1.1

27.3 ± 0.3

33.5 ± 1.1

28.6 ± 0.6

34.1 ± 0.9

37.3 ± 2.3

42.2 ± 1.7

35.2 ± 0.7

31.1 ± 0.1

21.5 ± 0.4

22.1 ± 1.6

17.5 ± 0.5

17.2 ± 0.4

33.1 ± 2.6

24.1 ± 1.1

37.0 ± 0.4

48.1 ± 0.8

35.8 ± 2.3

30.2 ± 0.6

49.1 ± 1.9

87.8 ± 0.9

71.8 ± 0.4

95.5 ± 6.9

73.3 ± 2.9

98.9 ± 4.8

113.7 ± 11.9

123.8 ± 13.9

107.2 ± 4.0

98.8 ± 2.7

55.6 ± 0.5

56.1 ± 3.8

44.8 ± 0.2

45.7 ± 1.9

97.3 ± 1.8

61.1 ± 2.5

90.3 ± 1.9

117.9 ± 0.1

96.1 ± 3.1

93.2 ± 3.4

124.4 ± 6.1

Results after adjusting sprayer

Droplet sizex

DV0.1

DV0.5

Engine speed

(mm ± SD)

(mm ± SD)

(rpm)

219.5 ± 19.7

151.4 ± 1.2

240.1 ± 11.1

154.8 ± 2.8

197.3 ± 24.9

239.5 ± 33.7

277.3 ± 62.7

226.8 ± 11.0

242.3 ± 38.9

117.4 ± 2.4

112.2 ± 12.8

88.1 ± 2.5

93.5 ± 7.6

234.2 ± 16.0

104.2 ± 4.5

167.0 ± 9.6

237.8 ± 4.0

202.4 ± 15.8

221.6 ± 26.7

246.5 ± 7.6

DV0.9

(mm ± SD)

LV8 and LV8-V2 have 3/8- to 1/2-inch tubing to each nozzle, LV8-V1 has 1/8-inch tubing to each nozzle; 1 inch = 2.54 cm.

y

1 gal/acre = 9.3540 L�ha–1; 1 psi = 6.8948 kPa.

x

DV.01, DV.05, and DV.09= the droplet diameter where 10%, 50%, and 90%, respectively, of the spray volume is contained in droplets smaller than this value. Values represent the mean of three replications; 1 mm = 1 micron.

z

Spray rate

(gal/acre)y

Model

no.z

Sprayer

Air

pressure

(psi)y

Table 6. Spray droplet size measurements for Curtis Dyna-Fog LV8 (Curtis Dyna-Fog, Westfield, IN) and London Fog model 18–20 (London Fog, Long Lake, MN)

sprayers in the citrus spray calibration rodeo with original setting results followed by the adjusted setting results for a water plus nonionic surfactant solution. The sprayers

were adjusted to comply with the droplet size requirements of the Special Local Needs permits granted to some insecticides in the State of Florida.

insure that spray systems are operated

in a manner that complies with label

restrictions.

Literature cited

ASTM International. 2004. ASTM

E1620-97(2004) Standard terminology

relating to liquid particles and atomization. ASTM International, West Conshohocken, PA.

ASTM International. 2009. ASTM

E1260-03(2009) Standard test method

for determining liquid drop size characteristics in a spray using optical nonimaging light-scattering instruments. ASTM

International, West Conshohocken, PA.

Aubert, B. 1987. Triza erytreae del Guercio and Diaphorina citri Kuwayama

(Homoptera: Psylloidea), the two vectors

of citrus greening disease: Biological aspects and possible control strategies.

Fruits 42:149–162.

Aubert, B. 1990. High density planting

(HDP) of jiagon mandarine in the lowland area of Shantou (Guangdong China)

and implications for greening control, p.

149–157. In: B. Aubert, S. Tontyaporn,

and D. Buangsuwon (eds.). Proc. Asia

Pacific Intl. Conf. Citriculture, Chiang

Mai, Thailand, 4–10 Feb. 1990. Intl.

Soc. Citriculture, Riverside, CA.

Gonzales, C.I. and R.C. Viñas. 1981.

Field performance of citrus varieties and

cultivars grown under control measures

adopted against leaf mottling (greening)

disease in the Phillipines. Proc. Intl. Soc.

Citriculture 1:463–464.

Halbert, S.E. and K.L. Manjunath. 2004.

Asian citrus psyllids (Sternorrhyncha: Psyllidae) and greening disease of citrus: A

literature review and assessment of risk in

Florida. Fla. Entomol. 87:330–353.

Hoffmann, W.C., T.W. Walker, V.L.

Smith, D.E. Martin, and B.K. Fritz.

2007a. Droplet-size characterization of

handheld atomization equipment typically used in vector control. J. Amer.

Mosquito Control Assn. 23:315–320.

Hoffmann, W.C., T.W. Walker, D.E.

Martin, J.A.B. Barber, T. Gwinn, V.L.

Smith, D. Szumlas, Y. Lan, and B.K. Fritz.

2007b. Characterization of truckmounted atomization equipment used in

vector control. J. Amer. Mosquito Control Assn. 23:321–329.

Roistacher, C.N. 1996. The economics of

living with citrus diseases: Huanglongbing (greening) in Thailand, p. 279–285.

In: J.V. Grac

xa, P. Moreno, and R.K.

Yokomi (eds.). Proc. 13th Conf. Intl.

Org. Citrus Virologists. IOCV, Riverside,

CA.

637

�TECHNOLOGY AND PRODUCT REPORTS

Stover, E., D. Scotto, and J. Salvatore.

2002. Pesticide spraying in Indian River

grapefruit: I. Survey of current practices.

HortTechnology 12:454–460.

Stover, E., D. Scotto, C. Wilson, and M.

Salyani. 2003. Pesticide spraying in Indian

River grapefruit: II. Overview of factors

influencing spray efficacy and off-target

deposition. HortTechnology 13:166–

177.

Supriyanto, A. and A.M. Whittle. 1991.

Citrus rehabilitation in Indonesia, p. 409–

413. In: R.H. Brlansky, R.F. Lee, and

L.W. Timmer (eds.). Proc. 11th Conf.

Intl. Org. Citrus Virologists. IOCV, Riverside, CA.

Tolley, I.S. 1990. The relation of nursery

production with orchard planning and

management, p. 77–82. In: B. Aubert, S.

Tontyaporn, and D. Buangsuwon (eds.).

Proc. Asia Pacific Intl. Conf. Citriculture,

Chiang Mai, Thailand, 4–10 Feb. 1990.

Intl. Soc. Citriculture, Riverside, CA.

Appendix

Fig. 2. Handout given to applicators at the citrus sprayer calibration rodeos to explain the results of the tests;

1 mm = 1 micron, 1 gal = 3.7854 L, 1 psi = 6.8948 kPa, 1 m/s = 1 m�S21 = 2.2369 mph.

638

•

June 2010 20(3)

�