Sign Delaware Banking Notice To Quit Fast

Contact Sales

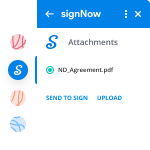

Make the most out of your eSignature workflows with airSlate SignNow

Extensive suite of eSignature tools

Discover the easiest way to Sign Delaware Banking Notice To Quit Fast with our powerful tools that go beyond eSignature. Sign documents and collect data, signatures, and payments from other parties from a single solution.

Robust integration and API capabilities

Enable the airSlate SignNow API and supercharge your workspace systems with eSignature tools. Streamline data routing and record updates with out-of-the-box integrations.

Advanced security and compliance

Set up your eSignature workflows while staying compliant with major eSignature, data protection, and eCommerce laws. Use airSlate SignNow to make every interaction with a document secure and compliant.

Various collaboration tools

Make communication and interaction within your team more transparent and effective. Accomplish more with minimal efforts on your side and add value to the business.

Enjoyable and stress-free signing experience

Delight your partners and employees with a straightforward way of signing documents. Make document approval flexible and precise.

Extensive support

Explore a range of video tutorials and guides on how to Sign Delaware Banking Notice To Quit Fast. Get all the help you need from our dedicated support team.

Industry sign banking delaware notice to quit fast

Keep your eSignature workflows on track

Make the signing process more streamlined and uniform

Take control of every aspect of the document execution process. eSign, send out for signature, manage, route, and save your documents in a single secure solution.

Add and collect signatures from anywhere

Let your customers and your team stay connected even when offline. Access airSlate SignNow to Sign Delaware Banking Notice To Quit Fast from any platform or device: your laptop, mobile phone, or tablet.

Ensure error-free results with reusable templates

Templatize frequently used documents to save time and reduce the risk of common errors when sending out copies for signing.

Stay compliant and secure when eSigning

Use airSlate SignNow to Sign Delaware Banking Notice To Quit Fast and ensure the integrity and security of your data at every step of the document execution cycle.

Enjoy the ease of setup and onboarding process

Have your eSignature workflow up and running in minutes. Take advantage of numerous detailed guides and tutorials, or contact our dedicated support team to make the most out of the airSlate SignNow functionality.

Benefit from integrations and API for maximum efficiency

Integrate with a rich selection of productivity and data storage tools. Create a more encrypted and seamless signing experience with the airSlate SignNow API.

Collect signatures

24x

faster

Reduce costs by

$30

per document

Save up to

40h

per employee / month

Our user reviews speak for themselves

-

Best ROI. Our customers achieve an average 7x ROI within the first six months.

-

Scales with your use cases. From SMBs to mid-market, airSlate SignNow delivers results for businesses of all sizes.

-

Intuitive UI and API. Sign and send documents from your apps in minutes.

A smarter way to work: —how to industry sign banking integrate

Trusted esignature solution— what our customers are saying

be ready to get more

Get legally-binding signatures now!

Related searches to Sign Delaware Banking Notice To Quit Fast

Frequently asked questions

How do you make a document that has an electronic signature?

How do you make this information that was not in a digital format a computer-readable document for the user? "

"So the question is not only how can you get to an individual from an individual, but how can you get to an individual with a group of individuals. How do you get from one location and say let's go to this location and say let's go to that location. How do you get from, you know, some of the more traditional forms of information that you are used to seeing in a document or other forms. The ability to do that in a digital medium has been a huge challenge. I think we've done it, but there's some work that we have to do on the security side of that. And of course, there's the question of how do you protect it from being read by people that you're not intending to be able to actually read it? "

When asked to describe what he means by a "user-centric" approach to security, Bensley responds that "you're still in a situation where you are still talking about a lot of the security that is done by individuals, but we've done a very good job of making it a user-centric process. You're not going to be able to create a document or something on your own that you can give to an individual. You can't just open and copy over and then give it to somebody else. You still have to do the work of the document being created in the first place and the work of the document being delivered in a secure manner."

How do i put my sign on a pdf file?

How do I get your permission?

How to electronically sign and certify a pdf?

I'm in California and don't want to deal in bitcoins. Do the signatures have any value in California at the moment? Also, can I take out an insurance policy just in case things go bad?

Thanks,

Jeff

Hi Jeff,The best way to handle this issue is to use a service like: or If you are in California and you don't want bitcoins or don't want a bitcoin address, then use a service to provide you with a copy of the original and your signature. If you don't have the signature that you signed you cannot take out an insurance policy for damage. You can also use a service to get the original if it doesn't already signatures from the bitcoin address are the ones that must be verified. They can be obtained and verified in a number of ways. The most basic is to have them signed by a notary public at the issuing office. It is easy to do but you have to be there. The same applies if you obtain the original from the issuing company. For a fee you can have a notary verify them but it is not that can have a notary check them online. If it is not that simple then you can get the signed document from the issuing office. They have all these documents at every office. They will have the original, the original and the verified or signed version. This is the version you have to be able to show if you do insurance fraud is easy to get a signature that you have signed. I'm in California and don't know anything about bitcoins and don't trust the company so I use BitSign which is free and relia...

Get more for Sign Delaware Banking Notice To Quit Fast

- Electronic signature Hawaii Real Estate RFP Later

- Can I Electronic signature Georgia Real Estate Contract

- How Do I Electronic signature Minnesota Plumbing Work Order

- Electronic signature Hawaii Real Estate RFP Myself

- Help Me With Electronic signature Minnesota Plumbing Work Order

- How To Electronic signature Hawaii Real Estate RFP

- How Do I Electronic signature Hawaii Real Estate RFP

- Electronic signature Hawaii Real Estate RFP Free

Find out other Sign Delaware Banking Notice To Quit Fast

- Massachusetts mutual form fr1202

- Hardship withdrawal application form

- 93432 cm life insurance company printbooks internal use only quarter 3 print books 3 form

- Massmutual withdrawal form

- Washington massmutual form

- Osha first report of injury fillable 2002 form

- Twcc 1 form

- Transferring the family business i introduction pinnacle financial form

- Metlife 403 b plan termination authorization form

- 403b withdrawal form

- What is naic number for enumclaw insurance form

- Mutual of omaha prior auth form

- Mutual of omaha form

- Mutual of omaha claim status death benefit form

- How to fill eye test form

- Fast trac form

- Online builders pdf form

- Ny life loan 2009 form

- New york life annuity form

- New york life fixed annuity forms