Sign New Jersey Banking Notice To Quit Easy

Contact Sales

Make the most out of your eSignature workflows with airSlate SignNow

Extensive suite of eSignature tools

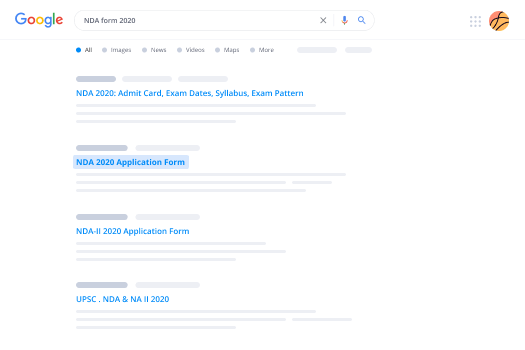

Discover the easiest way to Sign New Jersey Banking Notice To Quit Easy with our powerful tools that go beyond eSignature. Sign documents and collect data, signatures, and payments from other parties from a single solution.

Robust integration and API capabilities

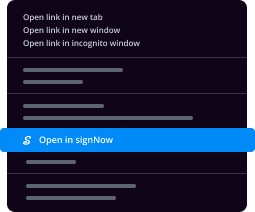

Enable the airSlate SignNow API and supercharge your workspace systems with eSignature tools. Streamline data routing and record updates with out-of-the-box integrations.

Advanced security and compliance

Set up your eSignature workflows while staying compliant with major eSignature, data protection, and eCommerce laws. Use airSlate SignNow to make every interaction with a document secure and compliant.

Various collaboration tools

Make communication and interaction within your team more transparent and effective. Accomplish more with minimal efforts on your side and add value to the business.

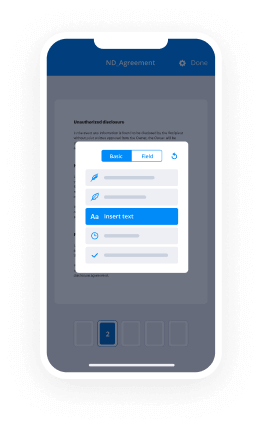

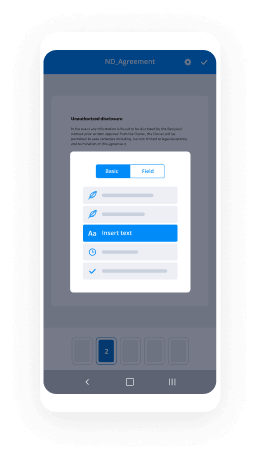

Enjoyable and stress-free signing experience

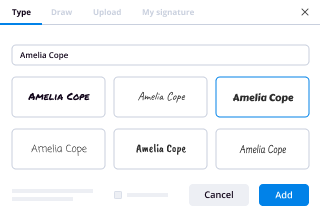

Delight your partners and employees with a straightforward way of signing documents. Make document approval flexible and precise.

Extensive support

Explore a range of video tutorials and guides on how to Sign New Jersey Banking Notice To Quit Easy. Get all the help you need from our dedicated support team.

Industry sign banking new jersey notice to quit easy

Keep your eSignature workflows on track

Make the signing process more streamlined and uniform

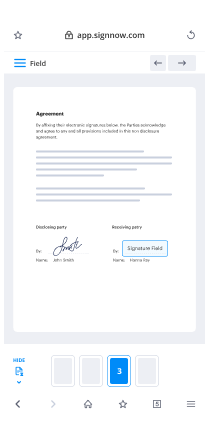

Take control of every aspect of the document execution process. eSign, send out for signature, manage, route, and save your documents in a single secure solution.

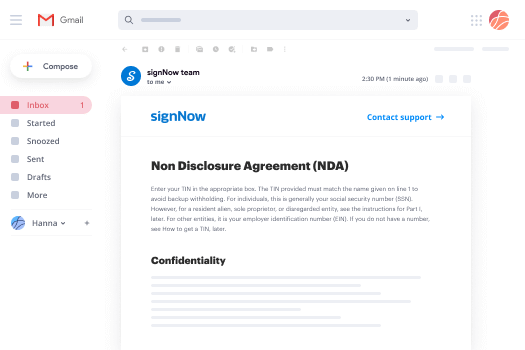

Add and collect signatures from anywhere

Let your customers and your team stay connected even when offline. Access airSlate SignNow to Sign New Jersey Banking Notice To Quit Easy from any platform or device: your laptop, mobile phone, or tablet.

Ensure error-free results with reusable templates

Templatize frequently used documents to save time and reduce the risk of common errors when sending out copies for signing.

Stay compliant and secure when eSigning

Use airSlate SignNow to Sign New Jersey Banking Notice To Quit Easy and ensure the integrity and security of your data at every step of the document execution cycle.

Enjoy the ease of setup and onboarding process

Have your eSignature workflow up and running in minutes. Take advantage of numerous detailed guides and tutorials, or contact our dedicated support team to make the most out of the airSlate SignNow functionality.

Benefit from integrations and API for maximum efficiency

Integrate with a rich selection of productivity and data storage tools. Create a more encrypted and seamless signing experience with the airSlate SignNow API.

Collect signatures

24x

faster

Reduce costs by

$30

per document

Save up to

40h

per employee / month

Our user reviews speak for themselves

-

Best ROI. Our customers achieve an average 7x ROI within the first six months.

-

Scales with your use cases. From SMBs to mid-market, airSlate SignNow delivers results for businesses of all sizes.

-

Intuitive UI and API. Sign and send documents from your apps in minutes.

A smarter way to work: —how to industry sign banking integrate

Trusted esignature solution— what our customers are saying

be ready to get more

Get legally-binding signatures now!

Related searches to Sign New Jersey Banking Notice To Quit Easy

new jersey notice to quit for nonpayment of rent

how to evict a family member in new jersey

Frequently asked questions

How do you make a document that has an electronic signature?

How do you make this information that was not in a digital format a computer-readable document for the user? "

"So the question is not only how can you get to an individual from an individual, but how can you get to an individual with a group of individuals. How do you get from one location and say let's go to this location and say let's go to that location. How do you get from, you know, some of the more traditional forms of information that you are used to seeing in a document or other forms. The ability to do that in a digital medium has been a huge challenge. I think we've done it, but there's some work that we have to do on the security side of that. And of course, there's the question of how do you protect it from being read by people that you're not intending to be able to actually read it? "

When asked to describe what he means by a "user-centric" approach to security, Bensley responds that "you're still in a situation where you are still talking about a lot of the security that is done by individuals, but we've done a very good job of making it a user-centric process. You're not going to be able to create a document or something on your own that you can give to an individual. You can't just open and copy over and then give it to somebody else. You still have to do the work of the document being created in the first place and the work of the document being delivered in a secure manner."

How to sign a document on a pdf?

A: You can use a PDF as long as no copyright, license, or attribution is specified.

Q: What is the difference between the two types of licenses?

A: Open licenses allow you and other people to use the work in many ways. By giving others permission to remix, translate, and redistribute the work, you give them the legal right to copy, modify, use, display, and distribute your work.

Q: Why does Creative Commons want me to get a Creative Commons license?

A: The main benefit of the Creative Commons licenses is giving you control over how your work is used. When using the Creative Commons licenses, you can be as specific or as vague as you like about who the recipients of your work are. This can have a big impact on the kinds of uses you can put your work to.

Q: Is there a deadline when I will want to use a Creative Commons license?

A: The best way to figure out when you and your friends will get a Creative Commons license is to sign up for the monthly updates. In the Updates you'll find information about when to get your license, and how to get the license if you decide to use it yourself.

Q: How does Creative Commons help my community?

A: In addition to making licenses easy to understand and understand, the CC licenses also encourage others to join together and support each other. When you make a public work, you give everyone else the same opportunity to use and adapt it. You can help your community's work survive by using Creative Commons licenses, and encouraging...

How do i verify an electronic signature?

1. Go to the website of the electronic signature authority that issued your electronic signature and follow the instructions there. 2. Check the Electronic Signature section of the site. 3. In the "Verify Signature" section, verify the digital signature of the official that issued it by entering the e-mail address and name, preferably the name of the official, and check the signature and date.

For more about the electronic signature system, and how it works, visit our Web pages on the Electronic Signatures Act.

For more about eSignatures on paper please click on the Electronic Signatures Act on Paper.

For more about eSignatures on other electronic formats please contact your state's office of statutory declaration or the Department of Justice at:

To verify an Electronic Signature, please contact the Electronic Signature Association.

You may also contact the Department of State's Office of Electronic Records.

Please call 1-800-842-2233 to verify your eSignature.

If you are the legal guardian of a minor, please verify your eSignature for him/her.

Get more for Sign New Jersey Banking Notice To Quit Easy

- Electronic signature Indiana Courts Profit And Loss Statement Mobile

- Help Me With Electronic signature New Hampshire Sports Emergency Contact Form

- Electronic signature Hawaii Courts Credit Memo Online

- Electronic signature Hawaii Courts Credit Memo Computer

- How Can I Electronic signature New Hampshire Sports Emergency Contact Form

- Electronic signature Indiana Courts Profit And Loss Statement Now

- Electronic signature Hawaii Courts Credit Memo Mobile

- Can I Electronic signature New Hampshire Sports Emergency Contact Form

Find out other Sign New Jersey Banking Notice To Quit Easy

- Backflow form fayette county

- Instructions for preparing request for form

- Fayette county water system backflow prevention fill online form

- Instructions for preparing request for drawdown of cdbg funds dca state ga form

- Hiaasen carl flush the dinoff school form

- S adlro form

- Hawaii license electricians form

- Licenses tags and permits idfgidahogov idfg idaho form

- Rs121 form

- Instructions for form ic 211 iic idaho

- The total unpaid liability on all open claims on which compensation form

- Illinois history geography and government quiz illinois secretary form

- Il sworn form

- Illinois pioneer certificate form

- Illinois military records form

- Illinois form statement exemption get

- Project next generation brochure illinois secretary of state form

- June 2010 spectre footnotes form

- Illinois patriot information form illinois secretary of state

- Illinois your history form