Sign PDF for Sales Teams Safe

Make the most out of your eSignature workflows with airSlate SignNow

Extensive suite of eSignature tools

Robust integration and API capabilities

Advanced security and compliance

Various collaboration tools

Enjoyable and stress-free signing experience

Extensive support

Keep your eSignature workflows on track

Our user reviews speak for themselves

Grasping the advantages of utilizing safe for teams pdf

Employing airSlate SignNow not only enhances document signing but also guarantees that your operations are secure for teams. This robust tool offers a protected platform for overseeing electronic signatures and document workflows, making it perfect for enterprises of all sizes. Whether you are dispatching contracts, agreements, or any other critical documents, airSlate SignNow simplifies the procedure while safeguarding your data and making it accessible.

How to utilize airSlate SignNow for safe for teams pdf

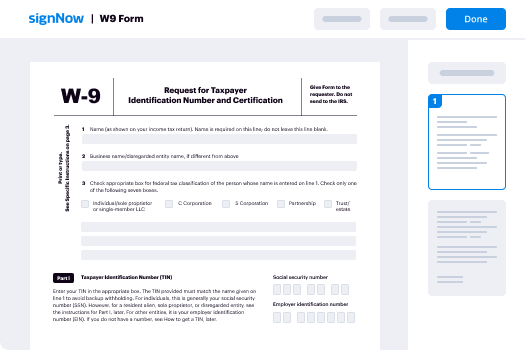

- Launch your browser and go to the airSlate SignNow website.

- Establish a free trial account or log into your current account.

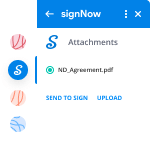

- Choose the document you want to sign or send for signatures, and upload it to the platform.

- If you intend to use this document regularly, consider saving it as a template for future reference.

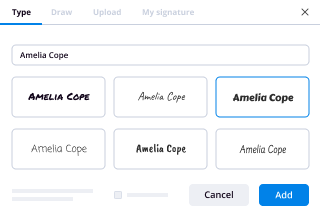

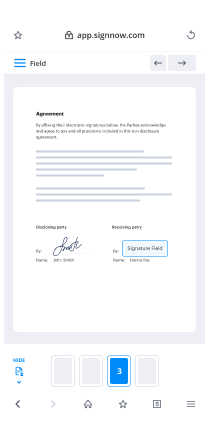

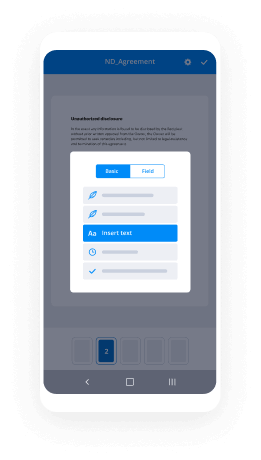

- Open the uploaded file to modify: add fillable fields or insert required information.

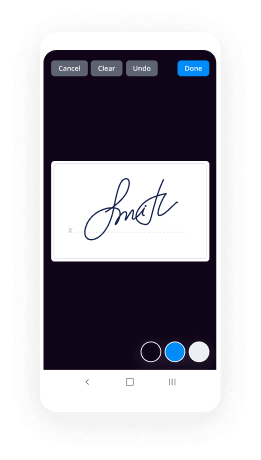

- Sign the document and include signature fields for your recipients.

- Click Continue to set up and send an eSignature invitation.

In summary, airSlate SignNow presents several advantages for businesses aiming to improve their document management processes. By offering a secure, efficient, and user-friendly platform, it enables teams to collaborate effectively while ensuring compliance and protection.

Prepared to experience the benefits of airSlate SignNow for your business? Start your free trial today and discover how it can revolutionize your document management workflow!

How it works

Rate your experience

-

Best ROI. Our customers achieve an average 7x ROI within the first six months.

-

Scales with your use cases. From SMBs to mid-market, airSlate SignNow delivers results for businesses of all sizes.

-

Intuitive UI and API. Sign and send documents from your apps in minutes.

A smarter way to work: —how to industry sign banking integrate

FAQs

-

What makes airSlate SignNow a safe solution for teams using PDF documents?

airSlate SignNow is designed with security as a top priority, ensuring that all PDF documents are encrypted both in transit and at rest. With features like user authentication and audit trails, it guarantees that your team's sensitive information remains safe. This makes it a reliable choice for teams looking for a 'safe for teams pdf' solution.

-

How can airSlate SignNow improve team collaboration on PDF documents?

With airSlate SignNow, teams can easily collaborate on PDF documents by sending them for eSignature and receiving real-time updates on their status. The platform allows multiple users to access and sign documents simultaneously, streamlining the workflow. This collaborative approach enhances productivity, making it a 'safe for teams pdf' option.

-

What are the pricing options for airSlate SignNow for teams?

airSlate SignNow offers flexible pricing plans tailored to meet the needs of teams of all sizes. You can choose from monthly or annual subscriptions, with discounts available for larger teams. This cost-effective solution ensures that you get a 'safe for teams pdf' service without breaking the bank.

-

Does airSlate SignNow integrate with other software tools?

Yes, airSlate SignNow seamlessly integrates with various software tools, including CRM systems, cloud storage services, and project management platforms. This integration capability enhances your team's workflow and document management processes, ensuring a 'safe for teams pdf' environment as you work across multiple applications.

-

What features of airSlate SignNow enhance document security for teams?

Key features that enhance document security in airSlate SignNow include advanced encryption, customizable access controls, and detailed audit logs. These features work together to provide a 'safe for teams pdf' experience, protecting your documents from unauthorized access and ensuring compliance with industry standards.

-

Is it easy to use airSlate SignNow for teams?

Absolutely! airSlate SignNow boasts an intuitive user interface that makes it easy for teams to navigate and manage their PDF documents. With user-friendly tools for sending, signing, and tracking documents, it ensures that even non-technical users can enjoy a 'safe for teams pdf' experience.

-

Can airSlate SignNow be used for legally binding signatures on PDF documents?

Yes, signatures collected through airSlate SignNow are legally binding and compliant with eSignature laws, such as the ESIGN Act and UETA. This means your team can confidently use airSlate SignNow to sign important PDF documents, ensuring a 'safe for teams pdf' solution that meets legal requirements.

-

What is the best Mobile App for small businesses?

ScanBizCards: We randomly meet many signNow contacts on the go, whether while networking or during travel, and we cannot afford to lost their details to search for them later. ScanBizCards convert your business cards to contacts and actionable leads within seconds with many additional features like manual card transcript and export to CRM.Download for iOS & AndroidAccompany: Multiple meetings, business associates, partners, and clients- there is a long list of people you need to remember. Accompany conducts the requisite research and maintains an updated database of over 250 million people while also managing rich profiles of contacts and companies you are interested in, making your business life easy.Download for iOSAsana: With this, manage your team projects and tasks on the go. Use the timeline to create a plan. Quickly update and add your work, map out each step and organize all your work details, and track your entire work from beginning till end. With over 100 integrations, it allows you to see everything in one place.Download for iOS & AndroidTeam Viewer: A popular choice for remote support and access. So, if you are accessing your PC from the park, video conferencing or sharing your screen from the other part of the world, you can still communicate with your team effectively. You can also take control of a team member’s desktop if they are having issues.Download for iOS & AndroidWeekdone: This makes you employee feedback and progress tracking tasks easy, and integrates with Asana, Basecamp, and JIRA. It also provides reports on the alignment between employee objectives and the company goals. The crux is you can track weekly progress, offer feedback and let everyone move in the same direction.Download for iOS & Android

-

What's the difference between the right-wing and the alt right?

The alt right is the US equivalent of the European identitarian far right. Both of those groups have radical differences with the traditional American/European right (whether it is libertarian, conservative or center-right):The alt right/identitarian right are skeptical of free market capitalism. In the US, Richard Spencer and other alt-righters support single-payer healthcare system and guaranteed basic income. In Europe, Golden Dawn supports socialist economics, opposing privatizations, wanting more spending and generally having a left-wing discourse. On the other hand, the traditional ri...

-

What are the best practices for construction safety inspections?

Construction safety inspections are the most effective means of catching and countering bad habits and hazards.(Next to inspections, the two most important components of a good safety program are planning and training.)Here is a detailed guide on construction safety inspections.Overall, construction companies—large and small—are reporting positive financial impacts from safety programs. And the size of those benefits increases as the depth of the program increases. In an industry that operates on low margins, this is a powerful finding.Let’s take a look at the benefits of safety1) Worker safety and retentionFirst of all, you want your workers to be safe. You want them going home in the same condition they came to work in.Companies that fail to provide safe work environments are unable to retain their workforce, at least in the long term.On the contrary, when companies comply with regulations, provide all necessary PPE, eliminate jobsite hazards and risks, and listen to their workers when concerns are raised, they enjoy the benefits of safe worksites—which translates into both a high retention rate of current workers and an increased flow of new ones.In times of construction worker shortage, this alone can give you a big competitive advantage. But there’s more.2) ReputationA well-performing safety program will give you a big advantage in the marketplace. Developers are becoming more interested in safety programs as well. They recognize that a safety-conscious general contractor reduces their potential liability for lawsuits and bad publicity. A safety program is a legitimate marketing advantage that allows you to separate your firm from your competition.3) OperationsA safety program is a benefit from an operational standpoint as well, as it will prevent you from suffering incidents and project disruptions that create delays and waste time. Obviously, this leads to improved performance and more on-time project deliveries.Also, workers will come to your job sites trusting that they operate within a safe work environment, which improves both morale and productivity.Let’s also not forget that injuries lead to higher insurance premiums and potential fines.4) RegulationsIf OSHA or another outside person/agency inspects the work site, you will have clear documentation about the inspections that have been performed. For example, if a crane on your jobsite malfunctions but you have documentation showing it was recently inspected, you can demonstrate you followed proper safety procedures.=> Let’s sum up the benefits of construction safety once more:Your workers will be safeIt will be easier for you to find and retain workersIt will give you a reputation advantage and help you win dealsIt will reduce delays (due to incidents) and insurance premiums while increasing worker morale and productivityIt will help you comply with regulations (and avoid fines)Applying the best practices listed in this article will increase the success of your safety program and your safety inspections. So keep on reading.In this guide you’ll learn the following:What are construction safety inspections?Construction safety inspections: How often and by whom?Best practices for safety inspection site visitsSafety inspections and checklistsWhat goes into a safety inspection report?Best practices for safety inspection reportsHow to draft safety inspection reports without spending an hour at the end of the dayHow to select the right safety inspection appBest practices for getting the most out of your safety inspectionsConstruction safety inspections: How often and by whom?How often should you we do safety inspections?As in all things, it depends—but here’s a useful guideline:Informal inspections should be done by all supervisors whenever they are out on site. Such inspections identify hazardous conditions and either correct them immediately or report them for corrective action. The frequency of these inspections varies with the frequency and conditions of equipment use.Formal documented inspections are ideally done weekly by supervisors and monthly by health and safety representatives.It’s also a good idea to get project managers or even company leadership involved with inspections to emphasize their importance.Best practices for safety inspection site visitsHere are a couple of useful tips for executing safety inspection site visits:Draw attention to the presence of any immediate danger. Other items can await the final report.Shut down any hazardous items that cannot be brought to a safe operating standard until repaired.Do not operate equipment. Ask the operator for a demonstration. If the operator of any piece of equipment does not know what dangers may be present, this is cause for concern. Never ignore any item because you do not have knowledge to make an accurate judgment of safety.Look up, down, around and inside. Be methodical and thorough. Do not spoil the inspection with a “once-over-lightly” approach.Make “on-the-spot” recordings of all findings before they are forgotten.Ask questions, but do not unnecessarily disrupt work activities.Consider operational factors, such as how the work is organized or the pace of the work, and how these factors impact safety.Discuss as a group whether any problem, hazard or accident might generate from a given work situation. Determine what corrections or controls are appropriate.Take a lot of photos.Safety inspections and checklistsThe goal of safety inspections is to identify hazards—and the best way to do that is with a checklist. With everything written down, it’s easy to make sure you’ve covered all your bases, reducing the chance of missing a potential hazard.For his must-read book The Checklist Manifesto, Atul Awnada interviewed experts from many disciplines (pilots, doctors, contractors).His conclusion? People need checklists to execute projects efficiently. Checklists reduce the risk of mistakes and increase the likelihood everything will get done as specified.When it comes to safety inspections, a checklist is a powerful way to ensure you don’t overlook important details. They free up your mental RAM.The checklist should be comprehensive, covering the following topics at a minimum:Personal Protective Equipment (PPE): Has the correct gear been distributed to all workers? Is each piece of equipment in good repair?Tools and equipment: Are they in proper working order? Are people using the right tool for the job?Fall protection methods: Is fall protection in use? Is it properly set up?Protective devices and signs: Are welders surrounded by a curtain to protect others? Are signs easy to read and warnings clear?Electrical concerns: Are electrical cords safe, and kept off the floor? Is there proper lighting? Is temporary electricity safely installed?Scaffolding: Are all connections secure? Is scaffolding tied to the structure? Are all connections secure?Now, let’s move on to the safety inspection reports that result from the inspections.What goes into a safety inspection report?Obviously, not all safety inspection reports will look the same. Depending on your business and the type of projects you perform, you’ll need to include different items.Here are the most common elements of a safety inspection report:Project information: add the project name, project number, address, name of the person who created the report, etc.Report date: If you want to record what happened or what didn’t happen on particular day or week, you need to put the date on your report.Safety hazards and incidents:Copy all unfinished items from the previous report on the new report.Document all safety risks and observations with enough photos to illustrate the issue. Add recommended methods of control.in - This website is for sale! - Control Resources and Information. the case of accidents or incidents, record who they impacted, who was involved, when and where they occurred, the impact on work, and any photos of the event.Number each item consecutively.Classify hazards. A hazard rating establishes priorities for corrective action and also highlights the level of severity or seriousness of the hazards.Add a due date to the items.Assign the items so responsibilities are clear. This will facilitate accountability and prevent problems from slipping through the cracks. It’s not enough for workers to note they found problems; those problems also need to be resolved quickly.Make sure the location of the item is clear, e.g. by adding annotations to a floor planSignatures: Optionally, you can ask people present to sign off the report.Best practices for safety inspection reportsYour inspections and reports are the basis for corrective actions and follow-up, which will prevent incidents from happening in the first place. So it’s worthwhile to make your safety reports are effective by following these best practices:Provide sufficient detail: State exactly what has been detected and accurately identify its location, together with pictures.Document items and file reports as early as possible: Memories can fade quickly. The shorter the time frame between events and notation, the more accurate the reports will be. Using an app, you can document observations immediately. Copies of inspection reports should also be sent to managementReadability: Keep it simple, use common language, and include enough pictures. Don’t use specialist terms, but don’t be too prosaic, either. Just stick to a concise and clear description of the facts so anyone can read and understand the reports. Also remember that often people don’t read long texts, but they will look at pictures. As the old adage goes, a picture says more than a 1000 words, so make sure to include enough pictures.Layout and branding: Clean, structured, professional reports that include the company’s logo, header, footer, and other branding will radiate a professional attitude regarding safety towards all parties involved (client, workers, subcontractors, etc). If you demonstrate that you are being serious about safety, others will be more inclined to be serious as well.Include positive elements, too: When certain safety risks are managed well, or when a hazard that had been registered during a previous inspection has been addressed, don’t forget to compliment the workers on site and to mention this on your inspection report as well. People will be more receptive to your advice — and like you better, too. Safety officers that only include problems and non-conformities in the report rarely achieve good results. Including compliments and positive items are great for worker motivation. With positive reinforcement, you add a reward for workers exhibiting desired behavior. Rewarding good conduct, rather than punishing negative actions, is a proven method to help promote positive behavior in both children and adults. By doing so you reinforce the desired action, which has a much stronger effect than punishment.Here is a preview of a safety report generated with ArchiSnapper:How to draft safety inspection reports without spending an hour at the end of the dayIf you’re still reading, you probably have no doubt that safety management and safety inspections are fundamental. Nevertheless, there has to be a better way to draft your safety report than having to spend at least an hour to manually put it together: writing out the text, inserting photos, managing the layout of the report, etc.It’s no secret that construction safety reports are a big struggle for safety officers and supervisors.With today’s technology, safety inspection reports do not require that much effort. With tools like ArchiSnapper, you can easily fill in a checklist, take photos and write text (or use voice to text), and the inspection reports will immediately be made available for everyone. Your logo, header, footer and other branding and layout settings will be applied automatically.With such an app you can use your tablet or phone on site. Just open the app, tap “new report,” and provide the required data:Fill in the project statusReview a checklistWrite texts or use the voice-to-text functionalityTake photos and annotate themHave the report signed off (if needed)Find the report archived to your cloud automatically, together with the signed versions and distribution historyThis way, you won’t have to spend an hour or so typing out scribbled notes, transferring pictures from your phone to your PC and then importing them into the report, or struggling with the layout in Word.Curious to see how this works with ArchiSnapper? Check out this video.How to select the right safety inspection appWhen you’re selecting a safety inspection app, make sure to take into account the following:SimplicityLess is more. At first, it might be tempting to choose an app with a lot of features, fields, forms, and configurations.But keep in mind that 90% of the time, you’ll only need 10% of your app’s core functionalities. What you need is a quick and easy way to review your safety checklist from your phone or tablet, with the ability to include photos and notes.Fewer buttons and functionalities means less risk for bugs, issues, and misunderstandings—and more adoption by your team, more standardization, and less frustration.Offline functionalitySooner or later, you’ll be without a reliable internet connection. (Think: broken wifi, no 4G network, unpaid telecommunications invoices…)So make sure your app works offline—and that you can at least capture notes and photos without a connection.Cloud storageYou don’t want to lose all your daily reports if your phone gets stolen or breaks. So your software should have a web backend where your data is synced, and which allows multiple colleagues to access all the inspection reports for viewing, editing, or distribution.CompatibilityThough it probably goes without saying, your app should work on both your mobile device and computer.I hear from a lot of safety professionals who prefer to use their phone on-site (to take photos and add quick notes) and then finish the report online from their desktop.Just a suggestion: I’d avoid buying a Windows device, since the software giant is no longer developing new features or hardware for Windows 10 mobile.Ample featuresThough your app should be simple, it should also include these essential capabilities and functions:Checklist functionalityThe ability to capture notes by typing on your phone/tablet/desktop OR using voice-to-textThe ability to capture photos with annotationsThe ability to draw and sketch on photosThe ability to generate safety reports in PDF format with brandingSignature capture functionalityThe ability to email the PDF construction reports to all parties involvedAutomatic data archiving and backupsThe ability to export/import data from other systemsAuto-numbering of items and reportsBest practices for getting the most out of your safety inspectionsDoing safety inspection visits and generating safety reports takes a lot of time and energy. So don’t forget to apply the following practices in order to get the best results from this process.Planning aheadPrior to doing inspections you need to make sure to have a checklist, an inspection schedule, that inspection members are trained, etc.You also must develop a plan for using your data, not just collecting it. How will the findings be communicated and shared? Will they be corrected in a timely manner and tracked to completion? As trends develop, how will action plans be developed and implemented to prevent reoccurrence?For most construction companies, each jobsite has its own unique risks. Devote time before construction starts to identify those risks and establish a plan to address them. Communicate this safety analysis regularly to workers so they know what hazards to expect and how to work around them.Follow upObservations are the beginning, not the end, of the inspection process.Any health and safety deficiencies identified during the inspection should be noted and corrective action should be taken. Follow up to see that the corrective action has been taken and that the hazard has been effectively dealt with. That’s why it makes sense to always start from your previous inspection report and keep unfinished items in the report—and mark solved items as “OK.” (Positive reinforcement, remember!)Where inspections are being done by the company’s health and safety coordinator or the site health and safety representative, the site supervisor should accompany them so that any corrective action needed can be implemented as soon as possible.AnalyzeMost companies stop once the inspection is completed and the initial hazards are discovered, shared, and fixed (i.e., once the moles are whacked). This is a major error that will prevent meaningful improvements in the safety process.If you are not conducting trend analysis on the observations you collect, these incidents could be happening quite often. Ideally, you should be looking at trends and leading metrics on a number of fronts, for instance:What are the top hazards identified by hazard category?Who are the most at-risk contractors?What are the most at-risk projects?What recurring trends are developing?By tracking and trending this information, you can turn collected data into actionable information.Don’t shoot the messengerIt is essential that the observation reporting, especially signNow hazards, be non-punitive and protected. In other words, don’t shoot the messenger! This often occurs from a misperception that finding unsafe observations is a reflection of how well one does the job, which will then reflect poorly on the observer or project team. It also can occur if a senior manager reacts poorly to the discoveries, such as reprimanding the observer or failing to act on the data collected.Management involvementKey to the success of any safety program is strong commitment, support, and backing from management. Frontline supervisors and safety officers do the majority of planned general inspections, but middle and upper management must also conduct safety tours.Whatever the project manager and leadership focuses on will be viewed by the team as important. The old saying, “Actions speak louder than words,” is true. Project managers who place a premium on integrating safety into their projects will ensure better overall project performance. They set the tone, agree to and enforce standards, and establish the concept that focusing on safety is the only way to do business.Furthermore, workers and their representatives should also be involved in all aspects of your safety program—including setting goals, identifying and reporting hazards, investigating incidents, and tracking progress.Workers should be encouraged and have the means to communicate openly with management, to report safety and health concerns without fear of retaliation.

-

What are examples of the best practices for construction safety?

Construction safety inspections are the most effective means of catching and countering bad habits and hazards.(Next to inspections, the two most important components of a good safety program are planning and training.)Here is a detailed guide on construction safety inspections.Overall, construction companies—large and small—are reporting positive financial impacts from safety programs. And the size of those benefits increases as the depth of the program increases. In an industry that operates on low margins, this is a powerful finding.Let’s take a look at the benefits of safety1) Worker safety and retentionFirst of all, you want your workers to be safe. You want them going home in the same condition they came to work in.Companies that fail to provide safe work environments are unable to retain their workforce, at least in the long term.On the contrary, when companies comply with regulations, provide all necessary PPE, eliminate jobsite hazards and risks, and listen to their workers when concerns are raised, they enjoy the benefits of safe worksites—which translates into both a high retention rate of current workers and an increased flow of new ones.In times of construction worker shortage, this alone can give you a big competitive advantage. But there’s more.2) ReputationA well-performing safety program will give you a big advantage in the marketplace. Developers are becoming more interested in safety programs as well. They recognize that a safety-conscious general contractor reduces their potential liability for lawsuits and bad publicity. A safety program is a legitimate marketing advantage that allows you to separate your firm from your competition.3) OperationsA safety program is a benefit from an operational standpoint as well, as it will prevent you from suffering incidents and project disruptions that create delays and waste time. Obviously, this leads to improved performance and more on-time project deliveries.Also, workers will come to your job sites trusting that they operate within a safe work environment, which improves both morale and productivity.Let’s also not forget that injuries lead to higher insurance premiums and potential fines.4) RegulationsIf OSHA or another outside person/agency inspects the work site, you will have clear documentation about the inspections that have been performed. For example, if a crane on your jobsite malfunctions but you have documentation showing it was recently inspected, you can demonstrate you followed proper safety procedures.=> Let’s sum up the benefits of construction safety once more:Your workers will be safeIt will be easier for you to find and retain workersIt will give you a reputation advantage and help you win dealsIt will reduce delays (due to incidents) and insurance premiums while increasing worker morale and productivityIt will help you comply with regulations (and avoid fines)Applying the best practices listed in this article will increase the success of your safety program and your safety inspections. So keep on reading.In this guide you’ll learn the following:What are construction safety inspections?Construction safety inspections: How often and by whom?Best practices for safety inspection site visitsSafety inspections and checklistsWhat goes into a safety inspection report?Best practices for safety inspection reportsHow to draft safety inspection reports without spending an hour at the end of the dayHow to select the right safety inspection appBest practices for getting the most out of your safety inspectionsConstruction safety inspections: How often and by whom?How often should you we do safety inspections?As in all things, it depends—but here’s a useful guideline:Informal inspections should be done by all supervisors whenever they are out on site. Such inspections identify hazardous conditions and either correct them immediately or report them for corrective action. The frequency of these inspections varies with the frequency and conditions of equipment use.Formal documented inspections are ideally done weekly by supervisors and monthly by health and safety representatives.It’s also a good idea to get project managers or even company leadership involved with inspections to emphasize their importance.Best practices for safety inspection site visitsHere are a couple of useful tips for executing safety inspection site visits:Draw attention to the presence of any immediate danger. Other items can await the final report.Shut down any hazardous items that cannot be brought to a safe operating standard until repaired.Do not operate equipment. Ask the operator for a demonstration. If the operator of any piece of equipment does not know what dangers may be present, this is cause for concern. Never ignore any item because you do not have knowledge to make an accurate judgment of safety.Look up, down, around and inside. Be methodical and thorough. Do not spoil the inspection with a “once-over-lightly” approach.Make “on-the-spot” recordings of all findings before they are forgotten.Ask questions, but do not unnecessarily disrupt work activities.Consider operational factors, such as how the work is organized or the pace of the work, and how these factors impact safety.Discuss as a group whether any problem, hazard or accident might generate from a given work situation. Determine what corrections or controls are appropriate.Take a lot of photos.Safety inspections and checklistsThe goal of safety inspections is to identify hazards—and the best way to do that is with a checklist. With everything written down, it’s easy to make sure you’ve covered all your bases, reducing the chance of missing a potential hazard.For his must-read book The Checklist Manifesto, Atul Awnada interviewed experts from many disciplines (pilots, doctors, contractors).His conclusion? People need checklists to execute projects efficiently. Checklists reduce the risk of mistakes and increase the likelihood everything will get done as specified.When it comes to safety inspections, a checklist is a powerful way to ensure you don’t overlook important details. They free up your mental RAM.The checklist should be comprehensive, covering the following topics at a minimum:Personal Protective Equipment (PPE): Has the correct gear been distributed to all workers? Is each piece of equipment in good repair?Tools and equipment: Are they in proper working order? Are people using the right tool for the job?Fall protection methods: Is fall protection in use? Is it properly set up?Protective devices and signs: Are welders surrounded by a curtain to protect others? Are signs easy to read and warnings clear?Electrical concerns: Are electrical cords safe, and kept off the floor? Is there proper lighting? Is temporary electricity safely installed?Scaffolding: Are all connections secure? Is scaffolding tied to the structure? Are all connections secure?Now, let’s move on to the safety inspection reports that result from the inspections.What goes into a safety inspection report?Obviously, not all safety inspection reports will look the same. Depending on your business and the type of projects you perform, you’ll need to include different items.Here are the most common elements of a safety inspection report:Project information: add the project name, project number, address, name of the person who created the report, etc.Report date: If you want to record what happened or what didn’t happen on particular day or week, you need to put the date on your report.Safety hazards and incidents:Copy all unfinished items from the previous report on the new report.Document all safety risks and observations with enough photos to illustrate the issue. Add recommended methods of control.in - This website is for sale! - Control Resources and Information. the case of accidents or incidents, record who they impacted, who was involved, when and where they occurred, the impact on work, and any photos of the event.Number each item consecutively.Classify hazards. A hazard rating establishes priorities for corrective action and also highlights the level of severity or seriousness of the hazards.Add a due date to the items.Assign the items so responsibilities are clear. This will facilitate accountability and prevent problems from slipping through the cracks. It’s not enough for workers to note they found problems; those problems also need to be resolved quickly.Make sure the location of the item is clear, e.g. by adding annotations to a floor planSignatures: Optionally, you can ask people present to sign off the report.Best practices for safety inspection reportsYour inspections and reports are the basis for corrective actions and follow-up, which will prevent incidents from happening in the first place. So it’s worthwhile to make your safety reports are effective by following these best practices:Provide sufficient detail: State exactly what has been detected and accurately identify its location, together with pictures.Document items and file reports as early as possible: Memories can fade quickly. The shorter the time frame between events and notation, the more accurate the reports will be. Using an app, you can document observations immediately. Copies of inspection reports should also be sent to managementReadability: Keep it simple, use common language, and include enough pictures. Don’t use specialist terms, but don’t be too prosaic, either. Just stick to a concise and clear description of the facts so anyone can read and understand the reports. Also remember that often people don’t read long texts, but they will look at pictures. As the old adage goes, a picture says more than a 1000 words, so make sure to include enough pictures.Layout and branding: Clean, structured, professional reports that include the company’s logo, header, footer, and other branding will radiate a professional attitude regarding safety towards all parties involved (client, workers, subcontractors, etc). If you demonstrate that you are being serious about safety, others will be more inclined to be serious as well.Include positive elements, too: When certain safety risks are managed well, or when a hazard that had been registered during a previous inspection has been addressed, don’t forget to compliment the workers on site and to mention this on your inspection report as well. People will be more receptive to your advice — and like you better, too. Safety officers that only include problems and non-conformities in the report rarely achieve good results. Including compliments and positive items are great for worker motivation. With positive reinforcement, you add a reward for workers exhibiting desired behavior. Rewarding good conduct, rather than punishing negative actions, is a proven method to help promote positive behavior in both children and adults. By doing so you reinforce the desired action, which has a much stronger effect than punishment.Here is a preview of a safety report generated with ArchiSnapper:How to draft safety inspection reports without spending an hour at the end of the dayIf you’re still reading, you probably have no doubt that safety management and safety inspections are fundamental. Nevertheless, there has to be a better way to draft your safety report than having to spend at least an hour to manually put it together: writing out the text, inserting photos, managing the layout of the report, etc.It’s no secret that construction safety reports are a big struggle for safety officers and supervisors.With today’s technology, safety inspection reports do not require that much effort. With tools like ArchiSnapper, you can easily fill in a checklist, take photos and write text (or use voice to text), and the inspection reports will immediately be made available for everyone. Your logo, header, footer and other branding and layout settings will be applied automatically.With such an app you can use your tablet or phone on site. Just open the app, tap “new report,” and provide the required data:Fill in the project statusReview a checklistWrite texts or use the voice-to-text functionalityTake photos and annotate themHave the report signed off (if needed)Find the report archived to your cloud automatically, together with the signed versions and distribution historyThis way, you won’t have to spend an hour or so typing out scribbled notes, transferring pictures from your phone to your PC and then importing them into the report, or struggling with the layout in Word.Curious to see how this works with ArchiSnapper? Check out this video.How to select the right safety inspection appWhen you’re selecting a safety inspection app, make sure to take into account the following:SimplicityLess is more. At first, it might be tempting to choose an app with a lot of features, fields, forms, and configurations.But keep in mind that 90% of the time, you’ll only need 10% of your app’s core functionalities. What you need is a quick and easy way to review your safety checklist from your phone or tablet, with the ability to include photos and notes.Fewer buttons and functionalities means less risk for bugs, issues, and misunderstandings—and more adoption by your team, more standardization, and less frustration.Offline functionalitySooner or later, you’ll be without a reliable internet connection. (Think: broken wifi, no 4G network, unpaid telecommunications invoices…)So make sure your app works offline—and that you can at least capture notes and photos without a connection.Cloud storageYou don’t want to lose all your daily reports if your phone gets stolen or breaks. So your software should have a web backend where your data is synced, and which allows multiple colleagues to access all the inspection reports for viewing, editing, or distribution.CompatibilityThough it probably goes without saying, your app should work on both your mobile device and computer.I hear from a lot of safety professionals who prefer to use their phone on-site (to take photos and add quick notes) and then finish the report online from their desktop.Just a suggestion: I’d avoid buying a Windows device, since the software giant is no longer developing new features or hardware for Windows 10 mobile.Ample featuresThough your app should be simple, it should also include these essential capabilities and functions:Checklist functionalityThe ability to capture notes by typing on your phone/tablet/desktop OR using voice-to-textThe ability to capture photos with annotationsThe ability to draw and sketch on photosThe ability to generate safety reports in PDF format with brandingSignature capture functionalityThe ability to email the PDF construction reports to all parties involvedAutomatic data archiving and backupsThe ability to export/import data from other systemsAuto-numbering of items and reportsBest practices for getting the most out of your safety inspectionsDoing safety inspection visits and generating safety reports takes a lot of time and energy. So don’t forget to apply the following practices in order to get the best results from this process.Planning aheadPrior to doing inspections you need to make sure to have a checklist, an inspection schedule, that inspection members are trained, etc.You also must develop a plan for using your data, not just collecting it. How will the findings be communicated and shared? Will they be corrected in a timely manner and tracked to completion? As trends develop, how will action plans be developed and implemented to prevent reoccurrence?For most construction companies, each jobsite has its own unique risks. Devote time before construction starts to identify those risks and establish a plan to address them. Communicate this safety analysis regularly to workers so they know what hazards to expect and how to work around them.Follow upObservations are the beginning, not the end, of the inspection process.Any health and safety deficiencies identified during the inspection should be noted and corrective action should be taken. Follow up to see that the corrective action has been taken and that the hazard has been effectively dealt with. That’s why it makes sense to always start from your previous inspection report and keep unfinished items in the report—and mark solved items as “OK.” (Positive reinforcement, remember!)Where inspections are being done by the company’s health and safety coordinator or the site health and safety representative, the site supervisor should accompany them so that any corrective action needed can be implemented as soon as possible.AnalyzeMost companies stop once the inspection is completed and the initial hazards are discovered, shared, and fixed (i.e., once the moles are whacked). This is a major error that will prevent meaningful improvements in the safety process.If you are not conducting trend analysis on the observations you collect, these incidents could be happening quite often. Ideally, you should be looking at trends and leading metrics on a number of fronts, for instance:What are the top hazards identified by hazard category?Who are the most at-risk contractors?What are the most at-risk projects?What recurring trends are developing?By tracking and trending this information, you can turn collected data into actionable information.Don’t shoot the messengerIt is essential that the observation reporting, especially signNow hazards, be non-punitive and protected. In other words, don’t shoot the messenger! This often occurs from a misperception that finding unsafe observations is a reflection of how well one does the job, which will then reflect poorly on the observer or project team. It also can occur if a senior manager reacts poorly to the discoveries, such as reprimanding the observer or failing to act on the data collected.Management involvementKey to the success of any safety program is strong commitment, support, and backing from management. Frontline supervisors and safety officers do the majority of planned general inspections, but middle and upper management must also conduct safety tours.Whatever the project manager and leadership focuses on will be viewed by the team as important. The old saying, “Actions speak louder than words,” is true. Project managers who place a premium on integrating safety into their projects will ensure better overall project performance. They set the tone, agree to and enforce standards, and establish the concept that focusing on safety is the only way to do business.Furthermore, workers and their representatives should also be involved in all aspects of your safety program—including setting goals, identifying and reporting hazards, investigating incidents, and tracking progress.Workers should be encouraged and have the means to communicate openly with management, to report safety and health concerns without fear of retaliation.

Trusted esignature solution— what our customers are saying

Get legally-binding signatures now!

Frequently asked questions

How do i add an electronic signature to a word document?

How to create an electronic signature pic?

How to code an email electronic signature for business use?

Get more for Sign PDF for Sales Teams Safe

- How Do I Electronic signature New York Education Form

- How To Electronic signature North Carolina Education Form

- How Can I Electronic signature Arizona Healthcare / Medical Form

- How Can I Electronic signature Arizona Healthcare / Medical Presentation

- How To Electronic signature Oklahoma Finance & Tax Accounting PDF

- How Can I Electronic signature Oregon Finance & Tax Accounting PDF

- How To Electronic signature Indiana Healthcare / Medical PDF

- How Do I Electronic signature Maryland Healthcare / Medical Presentation

Find out other Sign PDF for Sales Teams Safe

- Letter of assignment media template form

- Nimei in ethiopia form

- Persian empire worksheet pdf form

- Medif form malaysia airlines

- Ration card form pdf download punjab

- Fahrradpass word vorlage form

- Va760cg form

- Eager beaver adventurer workbook pdf form

- Sja skjema pdf form

- Custom form p8210

- Theme worksheet 6 answer key form

- Bill of sale with lien holder form

- English chest 3 student book pdf form

- Oromia regional state constitution pdf form

- Job safety analysis example form

- Birds job application form

- Directorate of air veterans reviews form

- Mat 1 form

- Snap benefits application pdf form

- Bank guarantee renewal request letter format word