Fordbid Validated Field with airSlate SignNow

Do more online with a globally-trusted eSignature platform

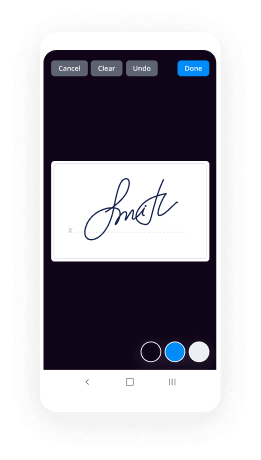

Outstanding signing experience

Trusted reports and analytics

Mobile eSigning in person and remotely

Industry polices and conformity

Fordbid validated field, faster than ever

Helpful eSignature add-ons

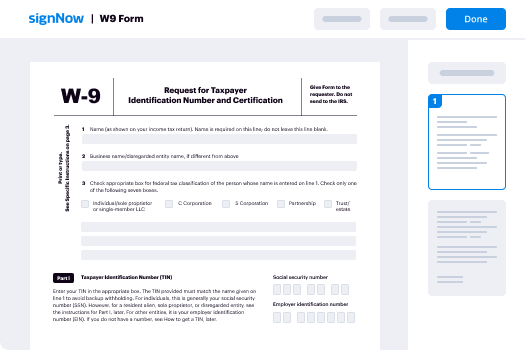

See airSlate SignNow eSignatures in action

airSlate SignNow solutions for better efficiency

Our user reviews speak for themselves

Why choose airSlate SignNow

-

Free 7-day trial. Choose the plan you need and try it risk-free.

-

Honest pricing for full-featured plans. airSlate SignNow offers subscription plans with no overages or hidden fees at renewal.

-

Enterprise-grade security. airSlate SignNow helps you comply with global security standards.

Your step-by-step guide — fordbid validated field

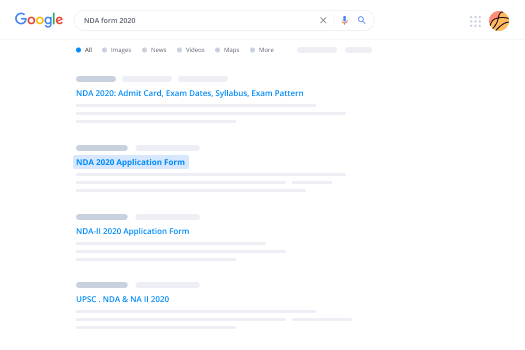

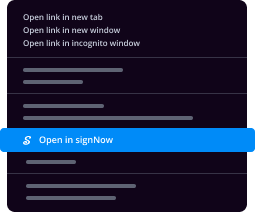

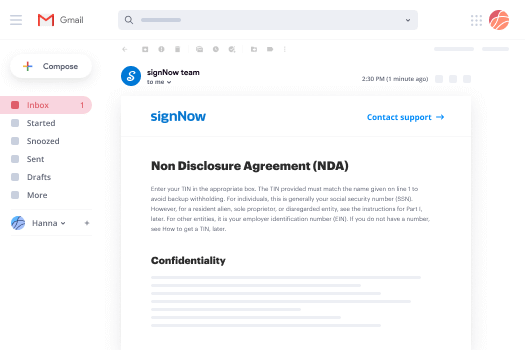

Leveraging airSlate SignNow’s electronic signature any business can increase signature workflows and sign online in real-time, providing an improved experience to customers and workers. fordbid validated field in a few simple actions. Our mobile apps make work on the move achievable, even while off the internet! Sign signNows from anywhere in the world and close up deals faster.

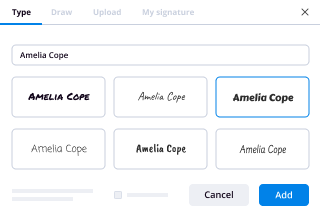

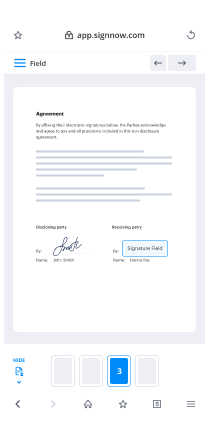

Take a stepwise guideline to fordbid validated field:

- Log in to your airSlate SignNow account.

- Find your record in your folders or upload a new one.

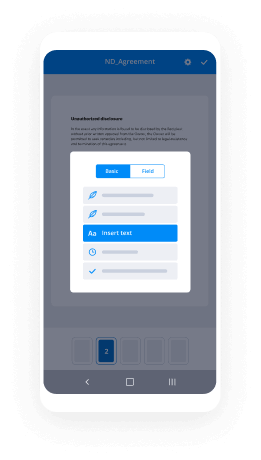

- Access the record and edit content using the Tools list.

- Drag & drop fillable fields, add textual content and eSign it.

- Add numerous signers by emails and set up the signing order.

- Specify which individuals will get an signed doc.

- Use Advanced Options to limit access to the template and set an expiration date.

- Click on Save and Close when done.

Moreover, there are more extended features available to fordbid validated field. Include users to your shared work enviroment, view teams, and track cooperation. Millions of people all over the US and Europe concur that a system that brings everything together in one cohesive enviroment, is exactly what enterprises need to keep workflows performing effortlessly. The airSlate SignNow REST API allows you to embed eSignatures into your app, website, CRM or cloud storage. Check out airSlate SignNow and get faster, smoother and overall more efficient eSignature workflows!

How it works

airSlate SignNow features that users love

See exceptional results fordbid validated field with airSlate SignNow

Get legally-binding signatures now!

FAQs

-

How do I bypass field validation?

If you're looking to improve your document workflows, impress your customers, and save money while maximizing ROI, airSlate SignNow is the electronic signature solution for you. With high-volume features like bulk sending and in-person signing, airSlate SignNow is the perfect choice for small and medium businesses looking to streamline their operations. With airSlate SignNow, you'll be able to move fast and stay ahead of the competition while ensuring a smooth and efficient workflow for all your employees. -

What is a validation rule?

A validation rule is a feature in software systems that checks if input data meets specific criteria or standards before it is accepted or saved. It ensures that any data entered into a system is accurate, consistent, and valid. With airSlate SignNow, SMBs and mid-market companies can save time, increase productivity, and impress customers by streamlining document workflows with high-volume eSignature features. Users can easily send and eSign documents on the go, from any device, anywhere in the world. By eliminating paper-based processes, airSlate SignNow helps businesses save money while maximizing ROI. Whether you’re a business owner, manager, or employee responsible for documents, airSlate SignNow empowers you to take control of your workflow and get more done in less time. With customizable templates, bulk sending capabilities, and advanced security features, airSlate SignNow is the preferred eSignature solution for today’s fast-paced, data-driven business environment. So why wait? Try airSlate SignNow today and start taking your business to the next level! -

What are data validation rules?

Data validation rules are a set of criteria or regulations implemented on data to guarantee its accuracy, completeness, and consistency. These rules are usually used in computer systems where data is entered into the system to ensure that the input data is valid. airSlate SignNow is an excellent electronic signature solution that offers users several high-volume eSignature features to increase productivity in document workflows. By using airSlate SignNow, companies can impress their customers by providing fast and secure document workflows while saving money. airSlate SignNow is the perfect choice for businesses looking to maximize ROI while ensuring that all document workflows are legally compliant. With airSlate SignNow, users can streamline their workflows, automate document generation, and easily track documents. This streamlines business operations, freeing up time for more essential tasks and ultimately driving faster growth. airSlate SignNow provides advanced customization features, making it easy to tailor the platform to meet the specific needs of any business or industry. By using airSlate SignNow, SMBs, managers, and employees alike can take control of their document workflows and move their businesses forward with confidence. -

What are Salesforce validation rules?

airSlate SignNow is an electronic signature solution that enables companies to streamline document workflows. With high-volume eSignature features, users can increase productivity and impress customers while saving money and maximizing ROI. Whether you're a small business owner, manager, or employee accountable for documents, airSlate SignNow's customizable workflows can help you move fast and get things done with ease. -

When can a validation rule be used?

A validation rule can be used when you want to ensure that a certain condition is met before data is saved to a database or displayed to the user. airSlate SignNow is an all-in-one eSignature solution that accelerates document workflows while impressing customers. With high-volume features like templates, bulk send, and smart tags, airSlate SignNow offers an easy, secure, and compliant way to eSign and manage documents. By streamlining workflows, businesses can save time, money, and impress customers with user-friendly eSigning. With airSlate SignNow, users can increase productivity while maximizing ROI. -

What is a validation rule in Salesforce?

A validation rule in Salesforce is a powerful feature that enables businesses to input pre-defined conditions and restrictions on their data to ensure data accuracy and quality. With validation rules, Salesforce helps companies maintain clean data and avoid errors, redundancies, and inaccuracies. Overall, validation rules create a more productive and efficient environment for businesses that use Salesforce. airSlate SignNow is an electronic signature solution that empowers businesses to accelerate their workflows and streamline their document management processes. With airSlate SignNow, companies can use high-volume eSignature features to improve productivity, impress customers, and save money while optimizing their ROI. By maximizing efficiency and reducing manual processes, airSlate SignNow allows users to focus on what matters most - growing their business. Whether you're a small business owner, a manager, or an employee, airSlate SignNow can help you achieve your goals, improve your workflows, and become a leader in your industry.