Sign Ohio Electrical Services Contract Safe

Make the most out of your eSignature workflows with airSlate SignNow

Extensive suite of eSignature tools

Robust integration and API capabilities

Advanced security and compliance

Various collaboration tools

Enjoyable and stress-free signing experience

Extensive support

Document type sign electrical services contract ohio safe

Keep your eSignature workflows on track

Our user reviews speak for themselves

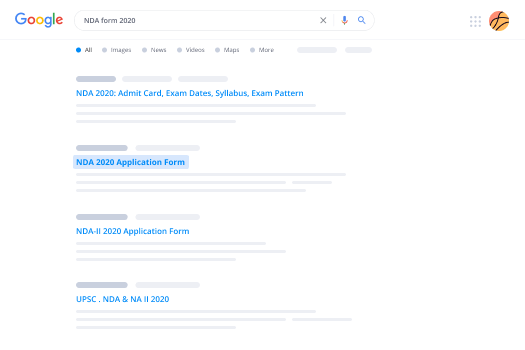

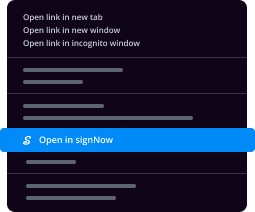

Wondering about Sign Electrical Services Contract Ohio Safe? Nothing can be more comfortable with airSlate SignNow. Its an award-winning platform for your company that is easy to embed to your existing business infrastructure. It plays perfectly with preferable modern software and requires a short set up time. You can check the powerful solution to create complex eSignature workflows with no coding.

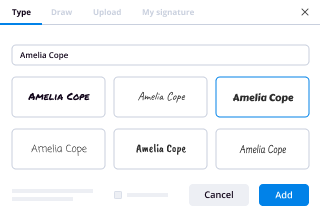

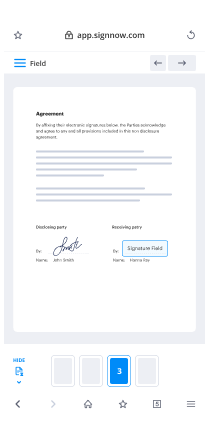

Sign Electrical Services Contract Ohio Safe - step-by-step guidance:

- Sign up if you have no account yet. You can also log in with your social account - Google or Facebook.

- Get started with a 30-day free trial for newcomers or check airSlate SignNow pricing plans.

- Create your customized forms or use ready-to-use templates. The feature-rich PDF editor is always at your fingertips.

- Invite your teammates and create an unlimited number of teams. Collaborate in a single shared workspace.

- Easily understand Sign Electrical Services Contract Ohio Safe feature by self serve on our website or use the customer support.

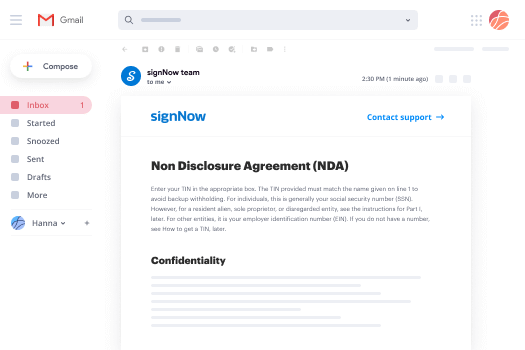

- Create document signing links and share them with your clients. Now you can collect signatures ten times faster.

- Get instant email notifications about any user action.

- Try out the free mobile application to be in touch on the go.

Improve your experience with airSlate SignNow. Creating your account, you get everything needed to close deals faster, enhance business performance, make your teammates and partners happier. Try out the advanced feature - Sign Electrical Services Contract Ohio Safe. Make sure it's the best solution for the company, customers, and each individual.

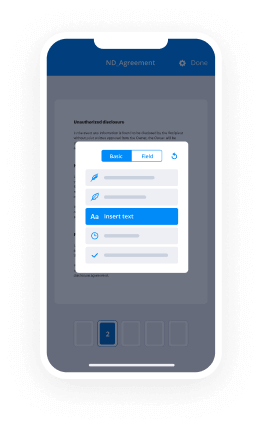

How it works

Rate your experience

-

Best ROI. Our customers achieve an average 7x ROI within the first six months.

-

Scales with your use cases. From SMBs to mid-market, airSlate SignNow delivers results for businesses of all sizes.

-

Intuitive UI and API. Sign and send documents from your apps in minutes.

A smarter way to work: —how to industry sign banking integrate

Trusted esignature solution— what our customers are saying

Get legally-binding signatures now!

Related searches to Sign Ohio Electrical Services Contract Safe

Frequently asked questions

How do you make a document that has an electronic signature?

How to eSign a docx?

How to sign the pdf document?

Get more for Sign Ohio Electrical Services Contract Safe

- Sign Massachusetts Bank Loan Proposal Template Fast

- How To Sign Virginia Guaranty Agreement

- Sign Massachusetts Bank Loan Proposal Template Simple

- Sign Massachusetts Bank Loan Proposal Template Easy

- Sign Massachusetts Bank Loan Proposal Template Safe

- How Do I Sign Virginia Guaranty Agreement

- How To Sign Connecticut Investor Proposal Template

- Help Me With Sign Virginia Guaranty Agreement

Find out other Sign Ohio Electrical Services Contract Safe

- Forms librarywisconsin department of health servicesmedicaiddhcf washington d cforms librarywisconsin department of health

- Medicaid for the elderly blind or disabled application form

- Wi dpi ohi checklist form

- Fact sheet wisconsins ampquotunborn child protection act form

- Ordering information child care licensing inquiry packets dcf f cfs2022 child care licensing

- Authorization to administer medication child care centers dcf f cfs0059 form

- California board of psychology verification of experience form instructions california board of psychology verification of

- Internship program overview form

- Family medical leave flma application columbia county form

- Job hazard analysis checklist fill online printable form

- Hipaa data backup and contingency plan form

- Medicalsurgical skills checklist form

- Red star backgrounds form

- M usic recording contract form

- Standard joining agreement for integrated project delivery for use with the form

- Surrey trekkers volkssport club members shaw form

- Domiciliary care allowance form download

- Ontario tax on taxable income form on428

- Form 682849831

- Franchise application2 doc fishaways co form