eSigning Manufacturing and Supply Agreement Made Easy

Get the robust eSignature capabilities you need from the company you trust

Choose the pro service designed for professionals

Set up eSignature API with ease

Work better together

Esigning manufacturing and supply agreement, within minutes

Reduce your closing time

Keep sensitive data safe

See airSlate SignNow eSignatures in action

airSlate SignNow solutions for better efficiency

Our user reviews speak for themselves

Why choose airSlate SignNow

-

Free 7-day trial. Choose the plan you need and try it risk-free.

-

Honest pricing for full-featured plans. airSlate SignNow offers subscription plans with no overages or hidden fees at renewal.

-

Enterprise-grade security. airSlate SignNow helps you comply with global security standards.

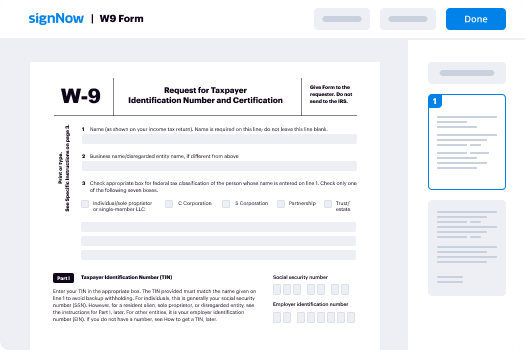

Your step-by-step guide — esigning manufacturing and supply agreement

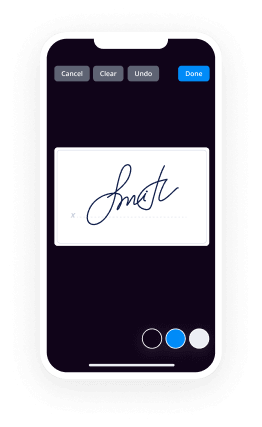

Using airSlate SignNow’s electronic signature any business can enhance signature workflows and sign online in real-time, providing an improved experience to customers and staff members. Use esigning Manufacturing and Supply Agreement in a couple of easy steps. Our mobile-first apps make work on the run feasible, even while offline! Sign signNows from any place worldwide and close up tasks in less time.

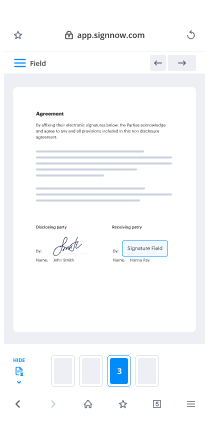

Follow the step-by-step guide for using esigning Manufacturing and Supply Agreement:

- Sign in to your airSlate SignNow account.

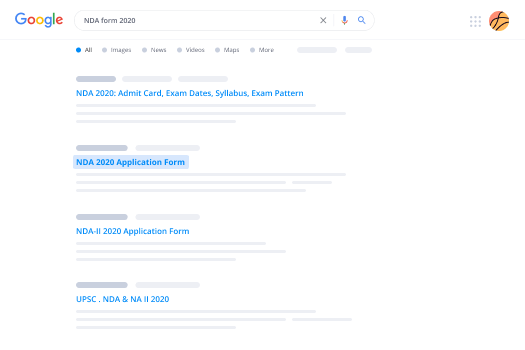

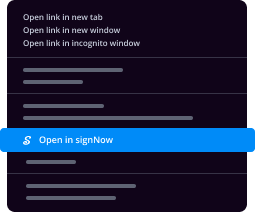

- Find your needed form within your folders or import a new one.

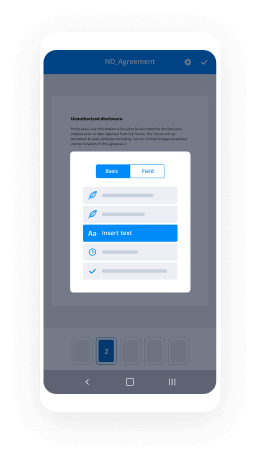

- Open up the template adjust using the Tools list.

- Drag & drop fillable boxes, type text and sign it.

- Include several signers by emails configure the signing sequence.

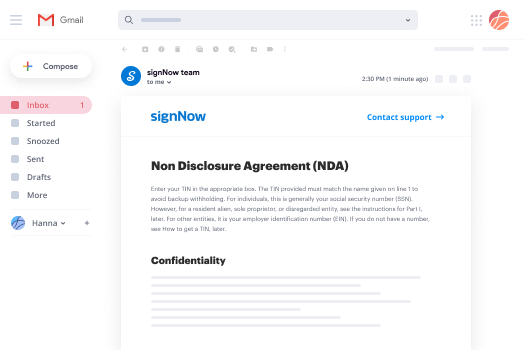

- Indicate which recipients will receive an executed doc.

- Use Advanced Options to restrict access to the document add an expiry date.

- Tap Save and Close when done.

Moreover, there are more extended capabilities available for esigning Manufacturing and Supply Agreement. List users to your common workspace, view teams, and monitor teamwork. Millions of customers across the US and Europe concur that a solution that brings people together in one cohesive workspace, is exactly what companies need to keep workflows functioning easily. The airSlate SignNow REST API allows you to embed eSignatures into your application, internet site, CRM or cloud storage. Try out airSlate SignNow and get quicker, smoother and overall more efficient eSignature workflows!

How it works

airSlate SignNow features that users love

See exceptional results esigning Manufacturing and Supply Agreement made easy

Get legally-binding signatures now!

FAQs

-

What is a manufacturing and supply agreement?

Free Manufacturing and Supply Agreement. Use our attorney-drafted Manufacturing and Supply Agreement form to outline the business relationship between a distributor and the manufacturer or supplier of their products. -

What is an example of contract manufacturing?

Production of complete goods entirely by one firm for another, under the brand or label of the latter. ... For example, large companies that manufacture computer hardware use contract manufacturing for the smaller computer parts and components that are, in turn, manufactured by other firms. -

What should be included in a supplier agreement?

Written agreements document all the specific details, such as what you want, what you'll get, how much you'll pay and when. Supplier agreements cover such issues as: supply conditions, including volume, price, discounts, ordering periods, take or pay and delivery times. payment terms. -

What is a product supply agreement?

Product Supply Agreement Law and Legal Definition. A product supply agreement is an agreement between a supplier and a buyer for supply and purchase of products. The agreement specifies the terms upon which the parties agree to supply and purchase products from each other. -

What is supply contract?

Supply contract. An agreement by which a seller promises to supply all of the specified goods or services that a buyer needs over a certain time and at a fixed price, and the buyer agrees to purchase such goods or services exclusively from the seller during that time. -

What is a supply chain agreement?

Supply Chain Contracts are agreement between buyer and. supplier on issues like. Pricing and volume discounts. Minimum and maximum purchase quantities. -

What is the meaning of contract manufacturing?

Contract Manufacturing Defined Contract manufacturing is the outsourcing of part of the manufacturing process of a product to a third-party. More specifically, contract manufacturing is an outsourcing of certain production activities that were previously performed by the manufacturer to a third-party.

What active users are saying — esigning manufacturing and supply agreement

Esigning manufacturing and supply agreement

hi this professor Cummings and this is your class number one our lecture number one for DFM a a know the slides this class would say it's lecture number one and this one we're going to go through an introduction of design for manufacturing assembly beyond that first intro video that I hope you guys all watch now this is going to have your first homework assignment and it's going to also give you some understanding of what design for manufacturing assembly is and what the benefit of taking this course is so let's see here we have these are the topics we're going to cover we're going to go over how design influences costs I'm also going to go over some of the design manufacturing paradigms and if I'm going to go through concurrent engineering then we're going to start to explain design for assembly design for manufacturing and design for manufacturing assembly you know that's because there are three separate things that follow one another and then how do you manage design for manufacturing assembly within an organization and then some of the basic critique of a design that I would like for you to to use in your project as well as you as you leave this class and finally there's going to be some review questions or just a short list of questions that I want you to look at and consider as you after you finish this just to make sure you know and if you have any trouble with those questions you know go ahead and rewatch the lecture and try to get a better grip on them because you know they just basic question from the lecture and then finally I'm going to go over your first homework assignment now when I was an engineer at Delphi an engineer an older engineer said this to me is it it's possible to manufacture most things that people can design you know that's not the problem the problem is you either don't have enough time enough money or otherwise enough resources which makes a lot of sense and that's a pretty important concept a pretty important rhythm to keep in mind you know you can design and manufacture all sorts of elaborate and fancy things but you know depending on the design you're either going to take a lot more time to manufacture it this would be a pretty expensive thing to manufacture are you going to need a lot of resources that may or may not be at your disposal you know they keep that in mind when you consider your design so it's more cost-effective to design quality and efficient manufacturing practices into the product now this is a concept that you see in lean seeing a lot of Toyota manufacturing processes our philosophies you know it's the whole idea of designing you know these things actually into the process designing quality in particular into the process that's something that has always been a very important thing that that has been part of the Japanese manufacturing culture and in this case of our class efficient manufacturing falls under that as well you know it's just easier to design an efficient manufacturing process into the product itself don't make something that has to take a lot of elaborate and very meticulous manufacturing or very specialized manufacturing that you're going to have difficulty achieving those resources now this picture here is just a triangle that I put together that we're going to see popping up in lectures quite a bit now you see down here at the bottom you have the design parameters production volume so things that you need to know when designing a product as you move up you have things like material selection up primary processes secondary and tertiary and then finally assembly you know so what this is just the entire design process laid out of a pyramid and the reason I have them as a pyramid or a triangle is because as you go through your design process you know as you go through this sequence each subsequent step not only is dependent upon the previous step but it becomes more restricted by what the previous step said so as you come up with the as you got a problem presented to you and you come up with the design parameters and how much you're going to need the production volume you know now you are a little are restricted in your material selection for a variety of reasons that we'll go into once you've decided the material selection as well as your design parameters your primary processes you know the type of raw stock that you're going to be able to use in the first place starts to go down you start to get restricted once you've decided what the primary process is any secondary processes and tertiary process has become even more restricted until finally you've got a very limited number of options in how you assemble the process so if we were to break this triangle up you could think of as the upper portion is your manufacturing processes and the lower portion is your design process or are your design processes and what we're going to look at now is we're going to specifically design a define what exactly is designing a product as well as what it means to actually manufacture a product and keep in mind that you know in manufacture you've got different types of products there are steps here of primary secondary and tertiary and finally assembly and you know and in design we're only covering things such as design parameters and production volume and material such and I know that that's a very simplistic triangle but you know it will help you as far as our discussion you know we just think of it know that I know there's more involved in design and then coming up parameters in a material selection but for our purposes in and for reason such as cost and actual implications to the rest of the processes we can break them down this way and be pretty safe in doing so so what exactly is design how would you define that I mean we use that word a lot we say you know we're going to design this product we're going to design a process we're going to design a solution what exactly is design design is the process of creating a solution to a specific problem okay and that's all it really is if you're coming up with a solution to a specific problem I give you a problem you know how are you going to get to work today and you come up with you design a solution to that I'm going to take the bus I'm taking the train I'm right bicycle I'm going to walk so a problem you know how do you work after daylight hours you know without any other type of source of light you know you would be restricted to working just during daylight hours at one point in time you know we didn't have any ability to work past sunset so how did we solve this problem well depending on what point in time in history and how far you want to take this the solution was delightful now when we think of design design would be the one thousand attempts that Thomas Edison and his team used in order to create that final product in order to be able to create this product and all this in the middle was the design this was all over all the things that he was taking into account that needs to go into creating that solution so when you're designing the designer has to understand all the parameters required features and end-user desires that's part of the design process so you know parameters meaning things like there are there certain material restrictions or there certain safety standards you've got a you're limited to does it have to have certain functional requirements such as things as you're working within a certain temperature a range has to endure a certain type of pressure you know this is going to be in an environment where pressure as a factor does it need a certain cleanliness to it also in user desires such as you know does it have to be a certain speed a certain type of height requirements certain type of weight requirements so all these things go into building the restrictions the limitations that you as a designer need to take into account and for most designers you know they're pretty good understanding this portion of design being able to say ok I've got a product what does my end customer need what environment am i putting it in and what are the requirements and for it to be in terms of like regulations and standards now you also have manufacturing and you got a manufacturing engineer what his role is to understand the manufacturing methods you know the limitations of methods and abilities and the application so when to do something we're not to do it in Linden when you choose one manufacturing process over another based on what you're trying to design so you establish the manufacturer in the assembly process you know your goal is also to try and reduce cycle time which is a big thing when you're a manufacturing engineer reducing cycle time you're selecting tooling you're ensuring the process capability making sure that you're making the product right and within certain quality standards and you're also having to justify the expenses that you're doing as you make that process no good to making a product that is going to not be able to pay for itself with the process that you bet you made and that is also why I started the manufacturing section at this point of the triangle you know these are all the things that manufacturing engineer has control over but as you can remember from the triangle it's also restricted based on things such as what type of materials he would have had to search he or she would have had to select as well as any other design parameters that the design engineer had to operate under you know so if the design engineer decided to make something that out of a special material that needed a certain type of tool and requirement well he's restricted in terms of what type of tooling you can use you know if the you know the reduction cost if the designer designed something that you know required tons and tons of machining time or some sort of odd geometry that meant that they had to cast apart or had to do some other process then well he had to yeah that's going to impact how much cycle time and other types of cost labor rate setting up time that's going to come on and establish a manufacturing assembly process again if you make something you require something to be 3d printed well guess what there's only one way to make that and that's through 3d printing so all these things are things that the manufacturing engineers responsible for and he is complete he or she is completely restricted by what went on in the design process now going to you know exactly what is manufacturing and assembly you know I know that's kind a basic question but let's wait and establish it so when we say manufacturer what do we actually mean we're actually talking about producing components from raw materials and your raw materials could be anywhere from you know raw plastic you know off-the-shelf bar stock from a metal supplier to castings or any other you know product that hasn't been processed by you yet assembly for our discussion is going to be the joining of components to make the actual product so now you let completed and finished components that you're actually going to put together and we're calling that the assembly process our assembly manufacturing can be things such as milling you know casting or even you know woodworking carpentry all those things are are forms of manufacturing and again manufacturing is very vast it could be several other things beyond that but you know those are just some manufacturing processes things such as assembly you know you've seen an auto car plant where they literally are putting the car together with nuts and bolts and welding and you know threads and screws and other types of assembly processes adhesives and what you know what so you know you got completed components you know each one of those components in and of itself represents some manufacturing process whether this is a stamping process or some sort of injection molded process it came in as a completed part and it was bolted stamped welded glued together in the assembly process now oftentimes what happens is that the manufacturing and design processor treated as completely separate entities and what that has led to in the past traditionally has been called over the wall design or over the wall manufacturing but over the wall you know so basically what you're looking at this as is the design team oops design team is different from the manufacturing team the manufacturing team and somebody comes up with the design you know they know what a customer wants some salesmen you know comes up with the idea and you know the product engineer says okay we will are the sales guy relays number two the product engineering team and they come up with some solution to what that customer was requesting they draw it out put it on a 3d model or whatnot and send it over to a manufacturing team this may or may not be in the same company but oftentimes it can be in the same company this could be some small design company and goes to a manufacturer and the manufacturer just has to deal with it you know they have a product they have a blueprint they have a 3d model and they've got to manufacture to that 3d model now part of the problem is that can be a very expensive process it may restrict the try the hands of a particular manufacturer and you don't get a whole lot of feedback to your design that may have actually helped you out there is some communication you know there's sometimes the manufacturing team will say hey this is unreasonable or this is unusual but you as the manufacturer might still expect that just makes that product as you have received it over the wall barring any any real issues with it now some of the other problems with that you know so we've got this pie chart here and it's broken up into design material labor and overhead so some of the costs and expenses of manufacturing now as you can see here the design when it comes to actually making a product whether it be a car or a pair of gym shoes the majority of the costs 60 to 80 percent or in this case 70% of the cost is determine during the design process remember the pyramid remember the triangle you know so the biggest part of the triangle was the depth the bottom has the designers guys designer portion of it and that's seventy percent 70 percent of the product costs so 70 percent of the cost of your shoes seventy percent of the cost of your computer seventy percent of the cost of your stove your Peter was established based on the decide designed decisions that were made early on in the product product lifecycle the next most expensive is the type of material that was used and then there's the labor and the overhead which you are fairly small when you think of all the other expenses that are taken into account so you know just to put that into perspective you know that's a lot of your your costs are being decided at the bottom into that pyramid ninety percent if we take the pyramid as I'd truly Eunos but seventy percent is just you know what they call just the traditional design product design portion now how does that happen why why does that get so much of the cost of a product well it breaks out a little bit like this again there's the bottom of that that triangle so it comes out of what the design engineer is actually responsible for you know versus what we just looked at what the manufacturing engineer was responsible for so the design engineer can determine what kind of material you're going to make which means that you're going to know what whether you're going to be machining whether you're going to be casting whether you're going to be you know how the machining process is going to work it also can describe any preparatory processes are post processing post processes that come because of the material they're just certain materials that go through the manufacturing processes that need a lot more care a lot more hand-holding when they're being used in manufacturing when did a lot of people I found when I was in industry don't really take into account is something like tolerances tolerances can have a major impact on the cost of a product a lot of times engineers will design something and give it a tolerance just based on the previous design without considering the fact that by picking a very restrictive tolerance they have just dictated a certain type of manufacturing process not all manufacturing processes have the same level of capability to them some of them just aren't you're not going to get the same tolerance of trying to saw something as you would laser cutting it okay you know art using a EDM machine electro discharge machine so the tolerance starts to go is your counters goes up you start to restrict manufacturing processes and you you know machining operations inspection methods also start to become restricted as you start increasing or tightening tolerances another one is geometry you know so things like radiuses fill its whole sizes you know making things that are non-standard you know non-standard sizes if you go to Home Depot and look at drills they come in a range of sizes a set of drills are going to have a very predictable range of sizes so if you pick them from this slightly in between two sides of drills and others a non sand sized hole you're going to have to move away from standard size tool and you've gone from a a $2.00 drill to a twelve dollar drill now because you're going to have to get special grinding and special manufacturing done on the tool before you can do the actual manufacturing of your part also it can affect the size of stock that you select and even the type of material handling use in order to pick the part up you know just because it might have an awkward shape and now you're worried about a safety issue and then you know it comes down to things such as the components themselves like when we think about the car example the paneling or any of the other components in the car you know how you design them how you have them work together and fit together affect the assembly process as well as the number of parts which means this cycle time are the extent of your assembly process so the design engineer has a lot of responsibilities or maybe the responsibility is not quite the right or maybe we could call that implications of the design engineer you know and here's just a list of processes you know these are our decisions that could be made based on a design that can actually impact how you manufacture you know putting a hole with a certain type of tolerance could be the difference between a boring process which can be done on any type of turning machine or even a milling machine to a honing process which is a much more specialized process as you see the saliva manual automotive industries so they'll typically have a machine and all they can do is do honing it actually hasn't requires a certain type of honing fluid and a very specific type of tooling that comes in here versus a more generic tooling that you get into a boring process deciding something has a Adar unique shape to it you know so a net shape you know which means now you've got to go into a casting process before you go into a manufacturing process and then finally maybe grinding and other things that you can do versus say off-the-shelf Vashta which is typically one of the cheapest ways you can manufacture something on the other hand there is a drawback to this as well you know when you've got net shape there's a lot less post processing secondary and tertiary processes you know since you've already removed a lot of material you're not having to worry about doing quite as much machining so you know you got a way out whether or not it's worth it to go to net shape because the extra cost of casting the cost you are saved in the machining processes versus bar stock where your keep looking after machine a lot of material away but it's a cheaper starting material another thing is when you come up with really unique and odd shapes now you're going to have to come up with very complex fixturing you know the workholding that it's going to take to actually hold your component during the manufacturing and assembly process you know these are some automotive parts to select some sort of a crank guitar gearcase housing you know this is an engine block of course you know these odd shapes you know have to have a fixture of the design specifically to hold that shape which means there are thousands and sometimes tens of thousands of dollars they just go into a fixture you know when you come up with these weird and unique shape not a big deal when you're making parts by the thousands you know when you're making parts at like the automotive industry does you know you're going to buy this and this fixtures in the last for years and years so it'll pay for itself you know and over here you've got more generic shapes and you can go to any Home Depot or Harbor Freight and buy a vase of ice and actually hold onto a square component and drill holes in it all day you know a couple hundred bucks versus you know eight or nine thousand dollars for for the other fixture so those are all decisions are implications of a design decision that can add cost to a product or a manufacturing process that may have been unforeseen to the design engineer so again no cost implications you know there's implications through the materials the amount of cycle time direct labor you know people who actually have to hold and handle apart indirect labor you know anybody supporting it although the water spider the person is to run your materials special tooling perishables things like drills Mills of grinding wheels invested capital you know so if you come up with a design that requires a really specific manufacturing process well they may have to buy a machine or they're going to have to outsource that process in order to make your design and then non-value-added activities you know things such as the part sitting in storage part going through shipment but you know even inspections considered a non-value-added activity so some of the design and manufacturing paradigms you know just if we consider design and manufacturing as you know kind of two separate entities you've got we already went over over the wall which is the most distance between the two then we've got the sign-off which is you know manufacturing actually looks at everything after it's done and says okay we know what we're in for let's go ahead and then do this this this would be almost the equivalent of of what happens when you outsource a product they're essentially just doing a sign-off saying they understand what they're expected to make then there's the limited collaboration this is a little bit better than the sign off in terms of your Interop interacting with the the manufacturer designers interact with the manufacturer and what this is doing the design process let's say you're you're the design engineers you come up with a feature and you're wondering is that a reasonable feature so you go talk to your your manufacturing engineer say what would it take to make this this Riveter so you make this this fill it what would it take to get this surface finish where I think I need it to be and that's when the manufacturing just says well if you do this you're going if you that's your requirement you're going to need a grinding process but if you loosen that up a little bit we can do that on the machine tool in the machine shop you know so is that limited collaboration can help you make some decisions but ultimately the designer is still the one in charge and completely in charge and has the last say and then you've got concurrent engineering and this is the one that we're going to look at this is a bit more of a general term that we're going to start to cover it's the manufacturing and design actually work together from conception to product launch so this isn't just going to a limited collaboration where you've already decided what the solution is and you are actually going through the process of designing it and you're getting some some input here and there concurrent engineering means that manufacturing and designer are looking at this product up front you know together and you're actually trying to do the design together to make it more manufacturable which in turn will reduce costs so what is concurrent engineering that's the design philosophy that requires the stakeholders we have the stakeholders and the design engineers engage in the design process so it's an important word your stakeholders will define what that means in a little bit design engineers typically you know they have their expertise and it's typically not manufacturing or assembly you know I mean I know I understand it a lot of times everybody has an Emmy or an m-80 degree so we all know a little bit about both sides to the wall but this is speaking of typically if you're a design engineer you generally aren't going to have a whole lot of manufacturing experience and if you remain faction you generally have moved away and you're doing a lot more manufacturing than design again let's we sit before 60 or 80 percent or 70 percent to the pie chart the product cost is desert determined by design decisions so concurrent engineering addresses the manufacturing process measure effective issues early again that is very important that is one of the beauties of concurrent engineering you address the stakeholders concern when you're still in the conception phase are well before you've nailed down the design so more concurrent engineering now there are several types of concurrent engineering it's not just this is not just a synonym for design for manufacturing engineering so concurrent using that word stakeholder comes in again so procuring engages the stakeholders of each level of the product and that can be designed for assembly design for quality design for service designed for the environment and even design for disassembly you know our design for maintenance and oftentimes this is referred to as dfx design for X where X is that stakeholder so that's all concurrent engineering is it's just an umbrella term for all the types of engineering where you're considering designing your product around a certain stakeholders concerns in this case we are going to be looked at design for assembly where that's the primaries are one of the primary stakeholders and design for manufacturing where that's also a major stakeholder so this is would be a format of or a small diagram of concurrent engineering where everybody from the design side you know the customer the product engineer sales is interacting with the manufacturing side so a manufacturing quality and product manager we could even put in other people such as you know the little ills of blind workers and other people who might actually have to interface with your products but the point of this concurrent engineering model is here everybody's got some sort of an input to how this product is going to be built and how it's going to impact them so design for manufacturing you know it reduces the cost reduces the number of steps number of operations it selects the more economical process so manufacturing you can tell the person upfront the designer upfront you know what are some of the processes that will probably be best suited that he could design for helps to understand you to limit scrap can immediately eliminate process variation or minimize the effects of prostration you know again that's establishing Collins's understanding how parts might be supported being able to detect where something might have some vibrations at least to our manufacturing you know certain things you're going to have an issue with your manufacturing certain geometries increase your throughput you know make something one of the things you could do is mix up two it actually it's held in a fixture without having to be released and taken out right of it you know so it gets handled a lot less and reducing the amount of cycle time so all these are things that that design for manufacturing actually does design for assembly get a very simple reduces the number of assembly operations makes easier to assemble and to perform assembly to perform so it's got this little diagram of a part with multiple little components and then making sure part where they eventually built some of these components pre assembled or made as a unit so we've eliminated all these little nuts and bolts and dials that probably aren't going to move relative to one another and may actually just be as simple to Nate rigid and turn them into one component in other words part time combining so we reduce all those parts down to this limited number of ours easier to assemble faster assemble less parts to keep track of so the goal is to address the costly manufacturing and assembly issues and to design prototype stages of a project so again back in that early part lies the most expensive part of the project you know that 70% is when you're trying to understand where the manufacturing issues are going to come from so if you can reduce the amount of costs established early that means you do solve a cost of the manufacturing process for the life of the product manufacturing and assembly supplements the skill set of product design so you're not taking over the manufacturing it isn't taken over the design process they're just giving you enough information to know that the product you know it's going what's going to make it easier are not so easy to manufacture so some of the things to think about in terms of how this affects costs well obviously I've bolded some of these in madam red simplicity you know creating liberal tolerances as a direct impact on cost easily processable materials avoid process restrictiveness in other words of the manufacture is enough flexibility to put something on various machines that could actually cause a little more nimbleness in the process and there's several other standard materials and components standardize the design of a product one part number doesn't have a bunch of unnecessary changes from the next when they do change overs and you know in a few others some of the advantages again you can see your 39 percent of it is actually the time to market one of the biggest advantages because you're reducing a whole lot of the issues from the design as well as reducing a lot of the manufacturing are simply a cost it's being taken out the design design or the manufacturing process is a lot faster a lot more efficient another one is the quality benefits the manufacturing time itself and then you know to others it's assembly time and you know the part cost and count our other advantages but you need the biggest one is actually getting things to market and making those decisions a lot faster so what the process looks like you know when you actually implement design for manufacturing assembly into a process well you've got the content of your design you know then you go to design for assembly you know look for any suggestions that might impact your assembly of your process so in other words you're looking at basically how the parts put together things that need to be combined and eliminate it then finally you consider the material selection okay and this comes next because you know you're actually getting a lot more you're getting it are getting a significant boost from the assembly it's going to impact for other things further down alright so your material selection which is also you know I mean you can assemble any kind of materials you know so think of it that way you would actually have another review any tweaks to your design then you go into design for manufacture where you're actually looking and reviewing the manufacturing processes themselves okay and again you know once you've come with your materials you kind of restricted yourself but again you're trying to consider is there anything that you can change still at this point is the FDA process where you get before you commit and now you finally get to the prototype so general rules of design for those who haven't had a design class yet you know I might be seen by some people haven't had much design and good rules of thumbs you know I'll let you see these in the slides or some order to point out designed for standard tooling that's a common thing that I talk about in our manufacturing classes you know don't come up with funky shapes just for the sake of having them if you're going to have a weird shape a non-standard tool shape you'll make it be a good reason otherwise go for the standard avoid sharp corners you know again stress raisers is one reason another one is they're not always that easy to manufacture design for minimum setups avoid parting lines if you're doing castings you know so again you know there's several of these in here those are some of the most obvious the ones that jump out at me right away and again you know you have access to slides so when you're going to put the FMA into an or how do you go about this so one is managing your gift ma whoops so managing your DF MA so that means you don't have to organize the team and get everybody to engage during the entire process you know so this is going to be a pretty big cultural change for any organization you know because a lot of companies are used to the over the wall processing you also want to make sure everybody's trained in dfd MA so they know what's expected of them why they're doing it why things are going the way they're actually going and what's ultimately the goal of the SMA so first thing you want to do is get a good team together of people who all understand the product all understand or they're their relative part of the process as a stakeholder and then be able to understand that they know what that process of design for manufacturing assembly ultimately is now some of the risk of concurrent engineering as a whole including design for manufacturer design for assembly is it is a time consuming job to manage a team of people people people aren't just there to do one thing is designed for manufacturing like I said the design engineer is going to have other projects the manufacturing has to support the production so you know that you're going to have to organize these people and there is a lot of consumption there's a downside you also have to deal with personality that's that's nothing unique to this though that that's anytime you've got people working in groups you know it's expensive to bring teams together you know every time you bring a team of people together in an organization they're being paid and so when you put six people together for one hour you basically have lost six people an hour six people pay you know whatever that might be so it can be a pretty expensive endeavor you know lost time of people not performing their other tasks lost time members to perform team tasks so when you're manufacturing an engineer is in this team he's not doing a she's not doing her job on the floor and then there's the overall resistance to change you know so you've got a design engineer that may not be too keen on the until that you know they might need to change something because a guy in quality didn't did not approve so that's uh gonna be part of the the culture shock now how do you critique a design proposal you know so as you start your project you're going to critique it and you're going to have to be able to come up with some intelligent ways of attacking it you know so you have several questions that you want to ask certain ways you want to look at it before you you go into the actual start of the redesign one is can the total part count even be reduce you know can the components be standardized are the tolerance is too restrictive you know what operations are really required is it easier cheaper material processes for the same result you know are we using than some experienced expensive grade of steel when a cheaper grade would would do can the number of setups be reduced you know will special tooling be required there you go back to those standard sizes and standards and real weird geometries and what are the consequences of making certain changes another you know very important question what are the consequences of making certain changes how do you measure your success so your goal is to reduce cost as a cost and time but time typically works into into a cost so cost can be expressed as reduction of number of components the number of processes making a much simpler process is better than a complicated process less chance of error less capital investment reduction in the amount of material so not having to spend as much on material costs or reduce a lot of ways you can have a more X are less expensive process and a faster process so when you do your project or the semester this is your your goal so some few questions so here we are so what is the role of a design engineer now when you think of this process what is the role of design engineer what is the role of the manufacturing engineer and can you describe what over the wall manufacturer or over the wall engineering is and how is over the wall engineering different little different from concurrent engineering so answer some of those questions go back and review you know check out your slides and you know you're having trouble go back and review a little bit and see how how this works so your homework so for your homework I want you to read chapter 1 product design for manufacturing assembly which is just kind of an overview then on blackboard there's a few case studies I want you to go through and then write a paper no more than two to three pages that summarizes the article that's the first half of your paper our first section if a per second think of the paper is critique how they apply design for manufacturing assembly so you know they're all based on the same topic just give me your insights based on what you've read in the book and so what you've gotten from this video how are they different from one another how do you how do how do you critique what they've done with what do you think of their of their process and their application well this is Professor Cummings and this is this is a little longer than I had expected but hopefully it was uh giving you a lot of insight into why we're doing design for manufacture you can you get my office hours you know give me a call email and you know if you any questions um they enjoyed like they just submit your your solution into or your paper into blackboard alright thanks for watching

Show moreFrequently asked questions

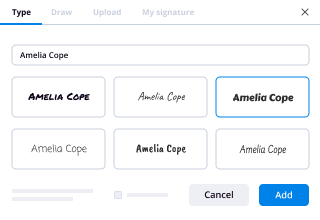

How can I eSign a contract?

How do I add an electronic signature to my PDF using a Signature Field in airSlate SignNow?

How can I type my name in the sign field in a PDF?

Get more for esigning Manufacturing and Supply Agreement made easy

- Email signature on galaxy

- Prove electronically signing Service Receipt Template

- Endorse digi-sign Limousine Service Contract Template

- Authorize signature service Catering Proposal Template

- Anneal signatory Free Admission Ticket

- Justify eSignature Brand Ambassador Contract

- Try initial Sports Event Sponsorship Proposal Template

- Add Directors Agreement electronically sign

- Send IT Project Proposal Template countersignature

- Fax Professional Birthday Party Invitation digital signature

- Seal Course Evaluation signed

- Password Commitment Letter digi-sign

- Pass Photography Order Form Template esign

- Renew DNR Form initial

- Test Summer Camp Parental Consent signature

- Require Roommate Rental Agreement Template email signature

- Comment renter esigning

- Boost trustee byline

- Compel self electronically signed

- Void Monthly Timesheet Template template electronically signing

- Adopt exhibit template mark

- Vouch Self Employed Invoice template signed

- Establish Drink Ticket template autograph

- Clear Concession Agreement Template template digital sign

- Complete School Counseling Progress Report template initial

- Force Architecture Firm Proposal Template template signed electronically

- Permit Website Design Inquiry template electronically sign

- Customize Newborn Photography Contract Template template countersignature