Parallel Mark Routing Made Easy

Do more on the web with a globally-trusted eSignature platform

Outstanding signing experience

Reliable reports and analytics

Mobile eSigning in person and remotely

Industry regulations and conformity

Parallel mark routing, quicker than ever before

Helpful eSignature add-ons

See airSlate SignNow eSignatures in action

airSlate SignNow solutions for better efficiency

Our user reviews speak for themselves

Why choose airSlate SignNow

-

Free 7-day trial. Choose the plan you need and try it risk-free.

-

Honest pricing for full-featured plans. airSlate SignNow offers subscription plans with no overages or hidden fees at renewal.

-

Enterprise-grade security. airSlate SignNow helps you comply with global security standards.

Your step-by-step guide — parallel mark routing

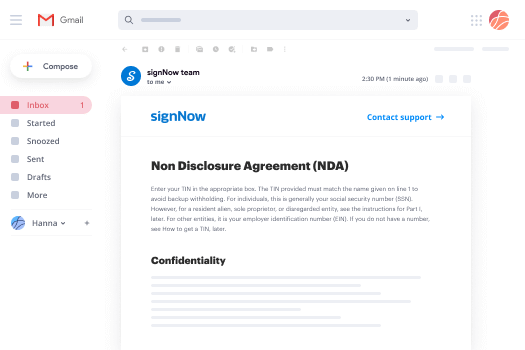

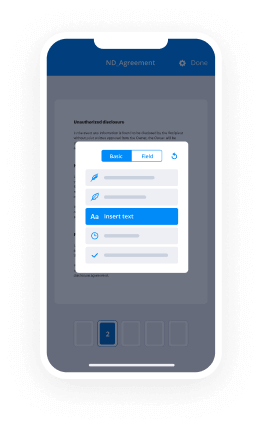

Using airSlate SignNow’s electronic signature any company can enhance signature workflows and eSign in real-time, supplying an improved experience to clients and staff members. Use parallel mark Routing in a few simple actions. Our handheld mobile apps make work on the run possible, even while off the internet! Sign signNows from anywhere in the world and close up deals in less time.

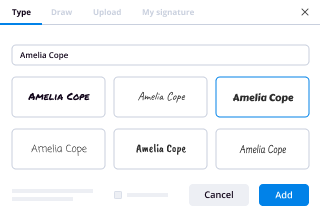

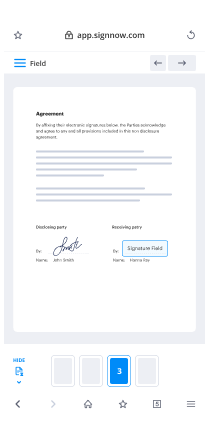

Follow the stepwise instruction for using parallel mark Routing:

- Sign in to your airSlate SignNow account.

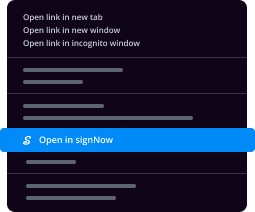

- Locate your document in your folders or upload a new one.

- Open up the document and edit content using the Tools menu.

- Drag & drop fillable areas, type textual content and eSign it.

- Include several signers via emails configure the signing sequence.

- Indicate which recipients can get an executed copy.

- Use Advanced Options to restrict access to the document add an expiry date.

- Click on Save and Close when finished.

Furthermore, there are more enhanced functions open for parallel mark Routing. Include users to your collaborative digital workplace, view teams, and track teamwork. Numerous consumers all over the US and Europe concur that a solution that brings everything together in one holistic workspace, is the thing that businesses need to keep workflows functioning easily. The airSlate SignNow REST API enables you to integrate eSignatures into your application, website, CRM or cloud. Check out airSlate SignNow and enjoy faster, easier and overall more effective eSignature workflows!

How it works

airSlate SignNow features that users love

See exceptional results parallel mark Routing made easy

Get legally-binding signatures now!

What active users are saying — parallel mark routing

Parallel mark routing

Voiceover:The Wood Whisperer is sponsored by Powermatic, the gold standard since 1921 and by Rockler Woodworking and Hardware, create with confidence. (lively music) The following video is part of the recent Split-Top Roubo guild build. For more information about this project or to join the guild, go to woodwhispererguild.com. Marc:The power tool method for flattening a workbench is really pretty cool. It's a lot like a C&C machine. Your router is going to go into a sled. That sled is going to ride along two rails. These rails will be attached to the outside of the bench. The idea is your bit is set at a fixed depth. Anything that's higher than that depth gets chewed away by the router bit and when it's all set and done you have a nice flat workbench. The reason why I like this so much is because this isn't just a single use jig, you can use this apparatus to flatten all kinds of unwieldy large boards. If you have a real big slob that just is not going to fit through your plainer, you don't feel like taking the time to try to flatten it by hand, you can use this system to flatten it perfectly using the router. This is something you can just kind of put the jig in the corner of the shop and there will be a time, I guarantee you where you're going to want to use this again. There's a few parts that we need to make but it's all made with cheap materials and construction grade lumber. Let's jump right into it. The router sled is going to be comprised of three pieces, of three quarter inch plywood. You've got a base piece and then two fence pieces on either side. These fence pieces serve to guide the router back and forth but they also stiffen up this structure. Without these, you're going to get a sag. These prevent that from happening. The dimensions of the fences are four inches wide by 32 inches long. The 32 inches accounts for the fact that we need to bring the router all the way out to the edge. If we terminate exactly at 24, we're never going to get there. We're going to have a part of the router unsupported. We want to make sure we add a few inches per side. I added four per side for a total of 32. Now the base piece is a bit of a different story. We're going to go to 32 inches. It should match the length of your fences pieces but the width is going to be variable. It's going to depend on the width of your base. I really want the fences to sort of guide the base as it goes through. What you need to do is measure the diameter. Obviously this festal base is kind of wacky looking. I just took this dimension from the longest flat to the other end. If you have a circular base, it's a little bit easier and here's the formula. You take the width of the base and add an inch and a half and that accounts for your two fences. The reason we add an inch and a half because I'm sure some of you are saying, "But Marc plywood is not exactly three quarters of an inch." That's actually going to work in our favor because these pieces are slightly undersized, that gives us just a little bit of breathing room for that router. If it was perfectly tight, you would probably have trouble sliding the router back and forth. That little bit was just basically about a 30 second of an inch under for each of these pieces is perfect for the router. Take the width of your base, add an inch and a half and that should be the width of your base piece. Before we attach our fence pieces to our base, it's a good idea to remove a channel of material for that router bit because we're going to plunge down and move across the bench. It's a good idea if that material is already gone so we don't have to plow through it with the router bit. Where this channel goes is really dependent on the shape of your base. You may notice that mine is slightly offset. This is just a product of the way my base is shaped. The router bit just happens to land right there. If you have a perfectly round base, you're going to be pretty much dead center. That's one thing that you need to know. The other thing is the width of this channel really just depends on the bit that you're going to use. If you decide to use something like our half inch router bit that we've been using in this project. All you really need is a channel that's just a little bit wider than a half inch. Now, you can use this but think about it. The size of this bench, it's going to take forever to go over this with a half inch bit. If you have the means, I do recommend going with something wider. This is a Amana bit that's an inch and three quarters in diameter. This monster is going to chew away some material pretty quickly and it's going to allow me to get through the entire bench in much less time. There's also a comparable one made by Freud which you can check out that's a little bit cheaper. I need to make sure that my bit is going to safely fit into this channel. My channel here is a little bit wider than the bit itself. To cut this, I'm just going to drill a couple of holes and use my jigsaw. I'm just going to put one hole at each corner and before I go any further, I should mention that this line here stops about four inches from the edge. I don't really need this slot to be any wider than the work piece that the bit is going to have to cover. Let me try and locate this so I don't go over my lines but this does not have to be absolutely perfect. Using my jigsaw and a very fine tooth blade, I'm just going to drop the blade into the whole and essentially connect the dots and try to follow my line as best as I can. (lively music) Even using a really fine blade, you're still going to get some tear out in plywood so just go ahead and sand that away. I've got my two fence pieces in place and I've got my base upside down and we could do the assembly this way. We can kind of just position everything where it needs to be and then pre-drill and drive some screws into the fence material. What I want to do is make sure that I clamp these down because sometimes when you drive those screws, they have a tendency to push the material one way or the other. If there's a clamp there, it's going to be much less likely that that's going to happen. We use a little bit of glue, I guess you don't really have to use glue but I kind of like to, just a nice thin bit. Drop the base on top and all I really need to do is make sure that it's nice and flush on the ends and flush along the length. The other thing I want to point out is if your fence pieces are cut nice and straight, those are what establish the flatness of the base. If this had a big curve in it, the base would then conform to that. As long as you cut your pieces straight, you shouldn't have any problems with this base being nice and flat along its length. That feels pretty good. Let me go ahead and add a clamp here. Now I'm just going to pre-drill and counter sink for screws. An inch and a quarter screw should do the trick. Now if I just flip the piece around, we can attach the other fence in the same exact way. Just like that, a router slide is born. Probably not a bad idea to make sure your router fits. Here we go. This is exactly what we're looking for. As I mentioned before, the router sled is going to ride on two rails and those rails will be attached to the front and the back of the bench. Those rails really can be made out of just about anything that you can get a nice straight edge on. For me I don't really have anything that's this long, a full eight feet long that would work for this so I just went out and got a two by six, a construction grade two by six's. These are kiln dried, I would recommend you go with the kiln dried stock if you can get it because it would be more stable after you mill them. Even with that, these tend to hold a lot more moisture than we're used to. When you mill them, do this process on the very same day. If you mill this ahead of time and leave it for a couple of days and come back, I guarantee you these edges will no longer be nice and straight. Mine are freshly milled, I basically just skip plain them. I had to make sure when I was at the store to get the straightest ones possible so that I could very easily skip plain and just put one jointed edge. You don't necessarily need the other edge to be jointed because we're only referencing from one side. Once you have them at this stage, the edge is nice and straight. We can attach them to the bench with a couple of clamps. If you got a helper, attaching this rails should be fairly easy. If you're by yourself, it's a lot more difficult. What I'm going to do is attach a couple of clamps to the bench. One on each side and I keep them fairly low, then I could bring my rail in like so. Put it on top of that clamp and that should hold it in place temporarily. Put one on the other side. With the two rails in position I could just take another clamp and clamp the rails to the bench, and one on this side too. Now we can remove that first set of clamps, we don't need them anymore. They were just acting as another set of hands basically. With the rails held in place we can now make some adjustments to get these rails in the right position. Now, first of all they're really high right now. I want them down lower because if you think about it, when the sled is moving back and forth, we've got to plunge that bit down far enough to make contact with the bench. The higher these rails are, the further that bit has to travel. I'd rather not have to extend it too far. Realistically, the rails don't need to be very much higher than the benchtop surface itself. I'm going to aim for I don't know, maybe a half inch, sounds good to me. I'm going to take my dead blow. I'm going to start making slight adjustments. If the rails are moving obviously you might want to loosen the clamp a little bit but not too much because you don't want it to fall. I got my adjustable square, set to a half inch and I could just sight from the side here make little adjustments to try to get this rail just about a half inch above the bench. Do the same thing at this corner, and the same thing on the front left. I have a half inch on this side, a half on this side and a half inch over there. That corner is the one that's unknown. Really my goal at this point is to get the two rails to be parallel with one another and I really rather not touch this one because it's even on this side, even on this side and I'm pretty confident that my front sled is fairly flat to begin with. I can clamp this front one in place and not really count on moving it at all. How do we make sure that that back rail is perfectly parallel with this front rail? Here's the old trick. Basically you're going to take a string or some sort of a chord. In this case I have some plastic coated metal wires. This is just sold by the foot at Home Depot. It's got good visibility, it's thick, and it's going to help us see what we're trying to do here. I've already got one strung across from corner to corner. Let's install the second one from that corner to this corner. This is just temporary. I'm just going to use a screw with a little washer here and drive it into the rail. Once I'm pretty close, I will take the string or your chord or whatever you purchased for this. Wrap it around the screw. It's a little hard to bend, and drill in. Nice grip there. Another screw at the diagonal corner and I could take my chord here and wrap it around the screw. This one, you want to pull tight because you want this to be a fairly tight connection. I'm going to wrap it around, give it a good thug. Tighten it up. Let's take a look at where the two chords intersect and put your thinking cap on because sometimes this can be a little bit confusing to envision but essentially if our two rails are perfectly parallel with one another, these two strings where they meet in the middle will want to go right through each other. Now of course they can't do that because they're made of actual solid material. What we need to do is take this top string and we can take some cutoff material. We need to raise this top chord, basically the thickness of one piece of string. Then when we come back and look here, when these two pieces just kiss one another, when they first made contact we know that they're exactly parallel but it's only because we raised this top string by the thickness of one piece of chord. Let's install those. I'm going to slide it over here and put the other one on the opposite corner. Just a recap, the string that's on top now has a little cutoff underneath it to raise it up on this corner and this corner. The other two are left exactly as they were. Now when these two strings touch one another, we could be pretty sure that these rails are nice and parallel. Let's take a close look of what we've got right now. We basically have a gap between the two strings here. It's about a quarter of an inch. The way we're going to resolve this is to tap one of the corners down until these two strings touch one another. Before locking everything in, I want to go back and make sure that the three corners that I had set at a half inch are still there and it's a very good possibility that things have moved because we're hammering on one of the rails. You just want to make sure that they're all on alignment, make any adjustments and keep going back and looking in the middle to make sure that those two strings are just kissing one another. Just as a bit of reality check, I'm going to measure this by corner. This is the one that we know slopes up, we don't know how much it slopes up but I double checked and we're at a half inch everywhere else. If this slopes up and this rail is parallel to the rail in the front then we know that this distance should be less than a half inch. In fact when I measure it, I've got about a quarter inch which tells me that this is a little bit more of a slope up than I really thought it was if we have to remove a quarter inch extra material here. One more thing we can check in the dead center, I'll show you a neat little trick for making sure that those two chords really are just touching one another. When you push down with just a little bit of pressure on the lower chord, you should not see the top chord move at all. If it does move, it means that they're actually making a little bit too much contact. You would want to lift the top chord up a little bit to remedy that. When I push down, that top chord does not move at all but when I push down on the top chord, I can't even touch the top chord without the bottom chord moving, do you see that? No movement at the top chord when I'm pushing down on the bottom an immediate movement when I push down on the top. That tells me that these surfaces are just touching one another. At this point I'm going to tighten up my clamps and I'm even going to add another one in the middle just for some extra support. Of course we don't need the screws or the chords anymore. The goal now is to put our sled on top of the rails, drop a router in place and then we're just going to make one pass and move the router forward. Make another pass, move the router forward. That's a lot of movement on this carriage here. It's probably a good idea to use a little bit of wax and that should make it a little bit easier to slide this router back and forth. Now your goal is to plunge the router down to what would essentially be the lowest spot of the workbench. I don't know absolutely for sure but based on my measurements, my observations with the surface, I'm guessing that right about here at the end cap is going to be the lowest spot. Now, it could very well be consistent all the way across. We won't really know until we start cutting into it but this should be pretty close so that's where I'm going to start. I'm going to plunge this big old bit down until it makes contact with the wood and then I'm going to tighten it up. I'm going to hold that setting for the entire process. Everything's in position. I'm just going to take my first pass and see how we do. After just a couple of passes, we could take a look at our progress. I did go back and I used the pencil to mark up the surface and this gives us a good visual reference here and you could see the dividing line from where I've remove material and where I haven't. This really is only about a 30 second of an inch. That's not too bad especially for this initial flattening process. The other thing I want to note here is that we are cutting into our rails and that's perfectly fine. These are sacrificial, they're meant to be cut into and you want to get the bit as close as you can to the edge. I'm not too worried about it if I've got a little bit of material to remove later, I could certainly do that with a scraper or a plane, that's not a problem at all. As you could see, with a bit like that, at least you're pretty much with a nice smooth surface that really isn't going to need a whole lot of work when it's all set and done. I'm just going to put the router back in place and work my way across the bench. (lively music) Before I make my last pass, I just wanted to show you what we're dealing with here and that what we see actually confirms my suspicions early on that my back slab had a bit of a twist in it. It's interesting because you think about how you get to this point and how something like this might happen and sometimes you can't even really identify what you did wrong to cause this. The bottom line is with the benchtop secured, we can now flatten this out, remove this extra stock, and be pretty confident that the benchtop is going to be nice and stable, and stay flat. As you can see, I do have a substantial. I'm out of material that's being removed at the back. At the front here, I'm still removing about a 30 second of an inch, maybe a 16th of an inch at the most right here but it does get pretty deep in the back. This is one of those cases where I'm glad I did this with a router because this would have been a heck of a lot of work to remove all that stock with a hand plane. Each method certainly has its merits but in some cases you might find the power tool method to be certainly less labor intensive. After a couple of minutes of vacuuming I can actually see the top of my workbench again which is great. It turned out really nice. Of course the router bit leaves a little bit of a sort of scalloped pattern to the top. The truth is, you can keep that in there. You don't have to flatten that out because a lot of times your bench, if it has a little bit of texture to it, it's going to grip your work pieces better. I wouldn't necessarily recommend going at this with a smoothing plane just to make it glass smooth because the more slippery your workbench top is, the harder it's going to be to work on. I'm probably just going to hit this with a sander or maybe a cabinet scraper just to do some further smoothing. I should also point out that I have little triangles here that were left because I'm using a circular bit. It only goes so far, and it winds up just leaving this little triangle, very easy to get rid of that with a block plane. Now even though the rails for this flattening process were sacrificial, the sled is not. This is something that you can hang on to and reuse again in the future. In fact, in the future it's probably going to be even easier because if you have a slab of material you could just lay that down on the workbench, take some shims, make sure it's nice and stable and sitting flat. Then all you need to do is grab two new rail pieces and rest them on the bench as long as the both sides of that rail piece are parallel with one another. Basically you joint one edge and then rip the other at the table saw. Place those down, clamp them to the workbench. You now have a perfect reference surface because the bench is flat. The reason we had to do the string thing before is because we really didn't have a perfectly flat reference. We just clamped to the outside and needed to make sure that those two rails were in the same plane. In the future, it's much easier and if you have the ability to get a hold of some sort of metal rails or something, you might even want to check out metal studs and see if those are nice and true you can have a permanent solution for flattening large projects. Think about an end grain cutting board, there's something a lot of people have trouble flattening. Wouldn't it be great to just slap it down and within a couple of minutes with the router, you have a nice flat board to work with. That's something you can do if you've got this carriage setup. Now here's the thing, this is very basic. This is as bare bones of a setup as you could possibly get but you could get pretty elaborate with it. In fact Fine Woodworking, a couple of issues ago. In fact it's December 2011, had a great article with the dude from community apparently does a lot of large natural edge slab tables and things like that. He has got a very elaborate setup and his sled is much more sophisticated than ours but it's a really nice shop made solution for flattening large surfaces. If you want to really spice it up a little bit, check out that article and e-mail me with your ideas because I'd love to see them. (mellow music)

Show more