Scale Mark with airSlate SignNow

Improve your document workflow with airSlate SignNow

Flexible eSignature workflows

Instant visibility into document status

Simple and fast integration set up

Scale mark on any device

Advanced Audit Trail

Strict protection standards

See airSlate SignNow eSignatures in action

airSlate SignNow solutions for better efficiency

Our user reviews speak for themselves

Why choose airSlate SignNow

-

Free 7-day trial. Choose the plan you need and try it risk-free.

-

Honest pricing for full-featured plans. airSlate SignNow offers subscription plans with no overages or hidden fees at renewal.

-

Enterprise-grade security. airSlate SignNow helps you comply with global security standards.

Your step-by-step guide — scale mark

Adopting airSlate SignNow’s electronic signature any business can accelerate signature workflows and sign online in real-time, providing a greater experience to clients and workers. scale mark in a few easy steps. Our handheld mobile apps make operating on the go feasible, even while off-line! eSign signNows from any place in the world and complete trades faster.

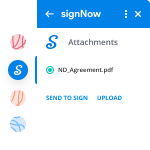

Follow the walk-through guideline to scale mark:

- Log in to your airSlate SignNow profile.

- Find your document within your folders or upload a new one.

- Access the template adjust using the Tools menu.

- Drop fillable areas, add textual content and sign it.

- Include numerous signers by emails and set the signing order.

- Choose which recipients can get an signed version.

- Use Advanced Options to reduce access to the record and set up an expiry date.

- Click on Save and Close when done.

In addition, there are more advanced functions available to scale mark. Add users to your common digital workplace, view teams, and keep track of collaboration. Millions of customers all over the US and Europe agree that a solution that brings people together in a single holistic enviroment, is the thing that businesses need to keep workflows functioning smoothly. The airSlate SignNow REST API enables you to embed eSignatures into your application, website, CRM or cloud. Try out airSlate SignNow and get quicker, smoother and overall more effective eSignature workflows!

How it works

airSlate SignNow features that users love

See exceptional results scale mark with airSlate SignNow

Get legally-binding signatures now!

FAQs

-

How do you scale marks?

To curve grades, start by finding the highest grade earned in the whole class. Then, subtract that grade from 100. Finally, add that number to every student's grade. For example, if the highest score in the class was 90 percent, you would subtract 90 from 100 and get 10. -

What does it mean to scale an exam?

Curving or Scaling grades is a way of standardizing the measure of performance from test to test and class to class. Its two purposes are to make the grades meaningful in a larger sense, and to be fair to students. -

Do uni exams get scaled?

Depending on the faculty there doesn't have to be an official scaling system. It can be simply re-weighting assessments at the end of the year or marking the final exam easier to get the required mean. With all of that explained it should be straight forward to realise that high marks can be brought down ('scaled'). -

How do you scale a test?

To curve grades, start by finding the highest grade earned in the whole class. Then, subtract that grade from 100. Finally, add that number to every student's grade. For example, if the highest score in the class was 90 percent, you would subtract 90 from 100 and get 10. -

What does a Stanine score of 4 mean?

Because they are expressed in single-digit whole numbers, stanines carry with them a meaning that can be learned in about 30 seconds. As indicated earlier, a stanine score of 4 indicates that someone performed "about average," while a stanine score of 8 indicates that someone performed well above average. -

What is a grading scale range?

Grading Scale Percentage Letter Grade 93 \u2013 100 A 90 \u2013 92 A- 87 \u2013 89 B+ 83 \u2013 86 B 80 \u2013 82 B- 77 \u2013 79 C+ 73 \u2013 76 C 7. -

What is A+ grade in percentage?

Grades and grade points that are included in the computation of the Grade Point Average (GPA) are assigned as follows: A+ = 4.30. A = 4.00. A- = 3.70. -

How do you calculate relative grade?

Just to recap, absolute grading refers to grading based on fixed percentage scales (e.g., 97%+ = A+, 93%-96% = A... Below 70 = F, etc.). By contrast, relative grading refers to grading based on score distributions within class (e.g., top 16% = A...the middle 10% = B+... Bottom 5% = F, etc.). -

Is relative grading good?

The reason: relative grading. What each student scores, is only good if it is good in comparison to the grades of the rest of the class. ... However, this does not mean there are always A-grades or failures in a class, the system decides an average and assigns grades above and below the average accordingly. -

What is absolute grading system?

Absolute grading is a mode of grading where grades are given based on predetermined cutoff levels. Here, each point value is assigned a letter grade. ... In the U.S., an absolute grading system assigns an A for points 90-100, a B for points 80-89, a C for 70-79, a D for points 60-69 and an F for points 59 and below. -

How do you figure out what I need to get on my final?

Divide the percentage of your grade your final is worth by 100. For example, if your final is 40 percent of your grade, divide 40 by 100 to get 0.4. Subtract the Step 1 result from 1 to find the portion of your grade comprised of your other assignments. In this example, subtract 0.4 from 1 to get 0.6. -

How do I figure out what I need to pass?

Suggested clip Calculating Your Mark and What you Need to Pass a Course ...YouTubeStart of suggested clipEnd of suggested clip Calculating Your Mark and What you Need to Pass a Course ... -

How do you calculate what you need on a final weighted grade?

All you have to do is convert the percentage the assignment is worth into a decimal and multiply that by your grade. To convert, just divide the percentage of your final grade the assignment represents by 100. So your 10 percent assignments turn into a weighted factor of 10 / 100 = 0.1, and your exam is 50 / 100 = 0.5. -

How do I calculate my final grade percentage?

Suggested clip Ex: Find a Course Percentage and Grade Using a Weighted ...YouTubeStart of suggested clipEnd of suggested clip Ex: Find a Course Percentage and Grade Using a Weighted ... -

How do I calculate a percentage?

To calculate the percentage of a specific number, you first convert the percentage number to a decimal. This process is the reverse of what you did earlier. You divide your percentage by 100. So, 40% would be 40 divided by 100 or .

What active users are saying — scale mark

Related searches to scale mark with airSlate airSlate SignNow

Scale mark

welcome my name is william messicar i'm a master model railroader in the fourth division of the pacific northwest region of the national model railroad association and i want to welcome all of you to the virtual layout tour we'll have presented today by members of the nmra we would encourage you to find out about the nmra and join in order to participate in these virtual tours we have other virtual clinics and other activities for the national model railroad association that we think you'll find a big help to your modeling and you'll get to meet model railroaders just like you so welcome to our tour and i hope you enjoy it um first off thank you very much for inviting me i do appreciate it not for your division to the division to the north of you although i think the number of people who are on the attendee list may have operated up here during van rail i know burr has for sure i think greg writes on the on the video as well uh my son isaac is finally helping with the technology and the video so uh you know it's shaky it's not me it's him but i'm shaking a little bit too um so first welcome to the columbian western uh my name is mark kent i've been a model rarity since i was about 10. although i took a big jump out of there that was in the 70s so i took a big jump out of there when i went to work um it was out of the hobby until about 2005 which is when i started constructing this layout uh it was fully operational in about 2008 and we had a fresh operating system done and we've had about 70 operating sessions since then but of course we have an operation there by the year which is unfortunate because it was designed for operations it follows the community specific boundary subdivision so we'll do a few slides about the prototype and then we'll do a walk around so you can see how that was constructed and then we're gonna run the train uh so the prototype is in british columbia southeastern british columbia an area called the kootenai uh named computing river so the railroads in this area were built in the 1890s when silver and copper were discovered and the canadian james hills decided to try and suck all the ore out of british columbia and feed his smelters which were just for the boundary subdivision this story just flows the boundary between the u.s and canada and because the canadian pacific main line was several hundred miles north there was nothing to take in from doing that spending for doing that so the canadian pacific was the uh with the help of the canadian government of the british columbia government built a series of rail lines just north of the border of the southern mainland which included the kettle valley division to help try and cut off james hill from getting access to all that oil so very interesting political history so the boundary subdivision was built around 1898 and completed around 1910 and started in nelson and went westward along the kenya river to conjunction with the the columbia river at castle guard there on the roslin subdivision down to the head padme smells where they can make the smoker the trail but the boundary subdivision continued across the mangashi pass at barron and down into the cascade terminated initiated grand forks where there was a lumber milan smelter that was then continued on to midway where it met up with the kettle valley division so that's the boundary subdivision which is the primary area that i model in my layout columbia and western there's also a major branch up to spokane valley so kansas city where there's a major male a rail barge that took the train to boost locomotive and hall up the silicon lake to roysbury or connected with the cathode subdivision which initially was a narrow gauge line running from castle to sanding but in 1970 was a incentive to be drawn to ran up too much on the columbia river on the upper lake so i had imagined that this isolated branch line would be very interesting for me to operate by myself in between operating sessions because it's really a once a week kind of job uh very slow paced switching intensive and that forms effectively the second layout model is in the middle of my layout room which you'll see so of course for any kind of mountain railway has to follow the water lines as much as they can and to get between the valleys you have to cross passes and the boundary subdivision had two mountain passes one in fairness and the one that i modeled with pusher jobs is that the fan 500 foot climb from both castles are and cascade up to the some of their bearings baron was interesting because there was a pusher station at the summit as opposed to at the base and uh this was something that kind of really spiked my imagination you're always talking about what like his imagination with the rds but for me was the idea of families of pushers and their crews resident up at fair and summit which get we get 30 to 40 foot of snow per year waiting to be called to their jobs from apparently we dispatched either the cascade of the capsule and then pushed the job at that point so i modeled that summit i don't want to be able to my effectively stops the cascade so it's a four deck layout although during operations you nearly directed one or two decks the lowest accuracy i use is actually the storage deck it includes a and you'll see this when i pull it out it includes an eight-track indexing table capable of holding eight complete trains and i use that as a fill yard between sessions to feel the trains make change the makeup and make sure everything's going in the right direction that feeds the layout through two helixes which which connect to staging controllers which are just out of sight from the visible portion of the line so there's very little hidden running during operations so this is the lowest deck two and a half feet off the floor the next step which is the main deck is the uh level two which is 42 inches above the floor it includes all the intensive switching areas so that the yard trackage the soaking branch and then with the pulp packaging castlevan the contour frame on both sides is the next deck that includes some pretty deep seams so we maintained the section in the middle is actually a single deck scene which you'll see and then the snow scenes are fairing and heading down back to cascade the fourth deck is actually accessed only by the the car barge that's how i say the casual branch which is about it's actually what i call a double mushroom for the single middle middle deck facing outwards and the two inner decks facing inwards there's a picture of the mushroom with me looking much younger there you know a long time ago so that would have been about 2000 and 2010. i didn't set out to design a double mushroom it just kind of happened uh you penetrate the mushroom with a swing gate and then at 42 inches and the branch line train goes into the mushroom operates from the lower level which you continue operating and there's a pull out except for operating the apple deck you'll see that but the actual contest to the fairing is actually a single deck visible for me with a single visible that visible to the outside of the mushroom so a few important specs i think probably most important was it was the timeline so i was fortunate enough to be able to take time off work for a couple years from 2005 through 2008 and i was able to focus nearly full-time in construction where i was a single-person construction and we had it inside our first operating session in 2008 and we've had about 70 cents we operated with tom tape on trainwreck where i enjoy operations a great deal i enjoyed the social aspect of it from the science point of view though it feels the majority of a two-car garage is about 350 square feet 17 miles longer than two model and branch lines and complexity-wise there's about 200 switches about one-third of which are power using tortoises the trainwater stations through six of them they're controlled by the dispatcher panel we sit in the crew lounge there's about 40 locomotives and 300 to 400 cars that are used in your operating and i try to have all the guests trained sound equipped in some ways okay so we're gonna do do a walk-around tour so um okay so i'll give you a quick overview i'm wearing a headset so that we have a good connection about take this off just from the top running a train so you can hear the sound of the community so around i chose um a configuration for the track time which tried to optimize the amount of space i had available and mathematically that's a double deck or multi-deck around the wall configuration in order to get into the room you have to use gates and i'll show you the swing gates as well but here's an example of the construction so this is fairing summit it's at 54 inches height so it's 64 inches height which is a good height for me i'm about six foot tall these heights are ideal for a six foot tall person kind of pumps his head on the ceiling and two forces and we have a 42 inch deck here which is nelson yard so nelson was a division point yard is a division point yard in my lab it was a division point yard in the prototype and uh to the east so actually configuration orientation wise the canadian pacific right along the southern edge of the water features the rivers and lakes in most cases so we're actually standing in yahweh looking south so we actually have west to all right and east to our left which is a little encounter in two videos fairly quickly the most most events and purposes the layout starts in nelson but i at the the homeless crew will actually operate trains from east staging which is crown broken and uh and preston i'll operate those under yard limits into the yard and only keep the yard fluid the layout supports about seven or eight operators during an operating session two of them will be dedicated to nelson yard nelson's main features are a diesel shop in the middle of the yard which is scratch built actually although all the buildings here are scratch filled after uh there's a prototype it's very fortunate to have a very well documented prototype in the process of building this down now so i've been building structures now for four or five years not my favorite part of the hobby but it's gonna work out the nelson yard is the division point we have nelson subdivision running from yellowstone to cranbrook to the east as i mentioned i bring in trains from didn't see where the kitchen's fluid and they're under yellow limits [Music] river so we see the kootenai river here this is the bridge at tayden which is where the bikuni river narrows down so it could be lake norris down to the river this was compressed about fifty percent uh the prototype actually has a crossing of two islands where i have a single island here we have the the line falling down from from uh down to down to cascade and on my left which is your right we have uh corkin dollar luxia media broken that was a very long sighting which was effective for meeting the trains here we have the junction of castle guard this is a train coming off the resident subdivision from cadmax from the smelter uh one of the interesting features of the prototype was the heavy use of fairbanks morse designed and that were constructed by canadian locomotives company in london ontario clc so there's a large mix that was primarily fm and 1970 but it was also ge and alco designs as well you see all of those in a variety of paint schemes so the color schemes in the mix of locomotives and cars are appropriate for 1970. in castlegar which occupies a person in a full operating session there's also a sawmill and a large pulp mill which is the cell bar mill so initially the the boundary subdivision was was developed by the prototype for extraction of mineral resources copper and lead and zinc and uh and silver but as it was played out they became more and more forest products we see a lot of lumber mills coal minerals and apartments the pot melon cell variety was to use great pulp that went to edmonton for creation of ringworm we're using in their clothing and above above castle we have the kettle river bridge this is a full-size bridge model full-size fish crossing the kettle and we have the foot of the grated cascade and then we have hidden staging representing grand forks in midway this scene here my my hope was actually i was very inspired by the new england berkshire and western as i was growing up there's a polytechnic popularity and if any of you remember the scene of the champlain lake champlain um the red rock scene maybe this was my intention there was a time while the red rock scene without a lot of experience designing layouts i decided i want a very long uh deep scene of true feeling areas but i didn't realize how many trees i was going to consume my estimate was probably about two or three thousand trees in this one scene here so that's the boundary subdivision and as i mentioned there's also the sophen and the castle subdivisions they're inside the mushroom in order to get to the uh in order to get to that subdivision there's a swing gate that swings out from underneath corcondale and meets up with the main line here this is silicon junction it's actually based on the bicycle neck it runs nice and level so you can actually park local park the cars and at the industries on the on the swing gate this is going out twice during an operating session for the for the entrance and edge of the train so you swing this out here and then the y junction connects to the slogan subdivisions actually while we're here i mentioned that in order to get inside the layout there are a couple of swing gates yeah they're here this is the one that the operators will use you need to for example leave to go to get a drink or use the bathroom whatever during an operating session and above it is a gate is actually locked in place during the session this opens up and includes the light panel and everything so this whole section actually swings the other direction i won't touch it now because it's all set up for operations so here's the double mushroom you might be able to get a view inside here to get an idea of how it looks so to your right on the lower lower level is the so-can subdivision which winds its way up the silicon river very plastic very calm very nice little place kind of a lost backwoods area we have bellicon and then we have a couple of small bridges and the tracks when it swings into silicon city which is at the south end of silicon lake where there was a major sawmill this song originates at least a dozen cards per operating session of chip hoppers and cut lumber and interestingly enough is one of the main features is actually the car barge the car barge actually was used to take the trains all the way up to the castle subdivision and it would actually they would actually load the um the locomotives and the cables at the same time and take the whole train up um and this is a picture this is a double wingfield picture of the operation and this is one of the things that kind of inspired me just to model the whole area a beautiful paint job on the rsg tug this is operational up until the i think the late 70s early 80s so it's my time frame and it's because of that operation i was actually able to create a fourth deck i don't think i would have had the imagination that she had imagined using a barge to take a train up to another level so what i'm just going to step outside i'm going to pull out this pull out this is the uh the step that we used to operate because the subdivision this runs on the rail the box and then we can get on top of it and i do this once per session so after the operators are finished switching out the uh silicon subdivision i will take the train take the barge and lift the barge up and put it up here on the raspberry and pull out the step power is transferred to these copper wipers brass wipers in the back of the barge and they contact metal pilings which provide also mechanical mechanical indexing and then the uh the slips are actually made out of soldered brass so they're nice and strong so we don't have a touchwiz and having anything damaged during operating sessions so the train is unloaded from the barge backs up into the yard there's actually a hidden staging for the new denver that goes to penetrates the backdrop and then the train runs over the summit summit lake then down into the test and the configuration of the cusp is actually a combination of the track before and after the lower lake was flooded with a huge keynesian side down so we have new the configuration of newton across in the back and the configuration of old necros which is before the lake was flooded so we have pole mills and sawmills and shake mills and some oil dealerships here so this job running from nelson into the silicon nothing up to and so wrapped in the casper would take at least a full three maybe four hours during an operating session so we have at least half of the jobs that we render in our first operating session from the full length of the operating session it was one of the objectives that i had i wanted to have very long jobs as a short jobs okay so we're gonna run a train now and then we'll take questions i'm gonna take the headphones off so you guys can hear the sound here's where we get to see whether the train held together in the tunnel or whether we're just going to locomotives coming out with no train behind it so this is train 81 it's the only numbered train that's running westbound on the decision of the land during operating sessions so it has superior variables we'll probably meet a couple of trains that have flags on them designated as extras running westbound i i actually imagine that the uh the copper fields to the west of nelson are still active and actually in connection to the mainline super fennel valley vacuum as well so actually run through trains which wouldn't been run in 1970 would also run pushers which would have been stopped if it wasn't for that prototype visualized but you know my railroad i just do what i want so we're running two shields and we're going to run across it's a big curved vessel so all the major bridges on the on the uh division has been moderate after until about 2005 when they went dead on me turned out that they actually shut down they weren't the gentleman retired i had no access to finding any man at that time i was actually working at a company where one of our major investors was also a business investor in the pacific he put me in contact with the industrial relationship manager so it was kind of useful to have that kind of connection i asked first influencer uh from the investigative industrial relations market and about three weeks later i had two long just get to know these people this is far too good it's a contacted graduated class of two-handed lyrics and you can see that there's a channel that goes down to the eastbound nothing for us so what we're going to do is we pass between the stations we're actually going to protect our team so i'm actually going to press the button so she's going to wait until the train passes and then it's going to drop the board behind the loose and keep it down for 27 minutes to make sure that anything that's following this is going to be properly set up swing away from the lower left mountain through the bulldog tunnel it's about one kilometer so about two thirds of a mile in the end i actually bite through it a couple of times i'd be very worried about that running the berries in that tunnel and when we come out of bulldog we're actually uh crossing porcupine phil in the cell scene quite important to me to actually model the celestine because as i mentioned the image in my head with his family's literacy things like cell the smell is actually a hydra panel it uses my my i use my garments techniques for myself as i mentioned at the united buildings and layout i've been really trying to add as many lights than all the lighting is led if i had to do it over again i would actually make sure that i got a low voltage line three volt line when i and the power line for the to the main line i actually packed into the pcc power power bus to power the leds using dropping resistance keep things in the power that you lost and dropping i'm lucky enough that my pcc system members were added to january afterwards this this search was actually visible from higher through a for a long time i'm running quite a bit faster than the rendering operating system [Music] velocity [Music] um so no operating session would take quite a bit longer to get down the hill first off it would be a 30-minute break check at the summit and then there'll passing an old limestone triple the uh scenery on this side of your fangirl is much much dryer more barren a lot of plunderers securities funners fine freaked out more than you can decide if you weather more logical times crossing the kettlebell so so we're going into cascade and here we're meeting our eastbound counterpart actually 87.52 this 1015 is bringing loaded wood chip hoppers from the males from midway and from the grand forks which will go to the fault and casserole as well as some fruit free and this is where i'll tie up so hopefully that gives you a bit of a sense of what it's like to operate across the current summit um normally this as i mentioned this could be this job would either be pushed from the basic shields or would have been doubled probably from parents of shields so this one job could easily take you an hour and an hour and a half to get across the summer you have any questions because that's the end of our demo mark we had one question what is the little yellow thing at the end of the barges oh that's a winch that's a very good question so the train only ran up to the to uh rosary once per week however through the week there would have been a train that ran from nelson to silicon city and if there was additional cars that wouldn't fit on a single barge they would actually barge up separately so the cars would be winched on would be dropped so it would be placed on the the barge by the locomotive then the orange would be taken up without locomotive to rosemary and the winds would be used to winch on or off um um so uh does anyone else want to ask a question mark this russ signer it's incredibly impressive layout uh what's the grade you use on the your main lines it's the same as the prototype 2.2 percent max it was very long and i was very fortunate i'm very fortunate with the prototype i chose because the fm the units in 1970 were pretty much on the end of their life so they used to put four locomotives on a train of five or six cars in some cases because they'd be picking up a lot of loaded cars on the other side they'd they'd be guaranteed to lose one locomotive on the way there and one locomotive on the way back so uh so you have these you know very impressive concepts of locomotives pulling very short trains over cpels so it's a great very model modelable prototype now one of the problems with that was that when i came to design a lab i couldn't think of any i didn't want to model i wanted to keep everything so that is resulting i'm trying to cram everything in which forced me to have to go vertical which ended up with a more complicated layout than i really intended to build so how long has it taken you to build the layout to where you are now well i started in 2005 but the majority of the construction occurred between 2005 and 2008 so it was physically 100 complete and operable every piece of track by 2008 uh since then there's been scenery and about probably two years just building bridges and instructors and then i made a major mistake about six years ago we got a dog that cut the modeling time in half so i got more exercise but i had much less time so you designed the layout and actually completed it from start to finish in that times frame correct did you have to make any modifications to your original plan very very few very very few i mean i followed the prototype so you know most things i wanted to do and i became more of a prototype modeler that went along um because i followed the prototype from a track planning point of view most of the things i wanted to do were accommodated we did find some stuff fairly quickly into the first operating sessions we needed some additional locomotive capacity um i added a couple more industries you know because there wasn't enough reason away i had a lot more trains actually i spent a lot of time building the second deck but the prototype only ran two trains today one in each direction and that wasn't satisfying to me so i had a very good friend brian pate some of you may know a very very excellent hom3 modeler and he advised me that i could basically do whatever i wanted and if i wanted to add more trains i should do it uh so we actually came up with some justification for running the pusher trains and also for the pusher helpers and also running the orange rings and eventually i added a waveframe as well so we actually run 10 trains per day across the uh the summit whereas the prototype only ran two so that's one change so we had to have a few changes attracted for very low so how often do you have operating sessions assuming you could operate with groups now probably once every two months you know we ran 70 70 operating sessions over 11 years okay uh would you have the ability to demonstrate the transfer table to us right now oh sure sir i'd like to do that so that's located down here so there's the flip down plexiglas panel i use a lot of small country glass panels to hide what i don't want people to see so inside here you can actually see there's eight staging tracks this is also my uh programming table for dcc and then you can just simply pull out transfer click on it the index is out you can hear the data clicking so the dayton's locking the ends but most importantly there's actually a winch configuration a pulley configuration silvery the cable that causes the both ends can be parallel at the same time if i pull on one end it doesn't camber over it actually pulls both both ends of the tape at the same time that keeps it running parallel and what's the height above the ground of that table this is about two and a half feet yeah but this isn't used during operating session as i mentioned this is just simply used to as a failure between staging between sessions so this this storage yard the fiddle yard actually feeds the um the staging tracks in several different directions so it goes out to the left it goes out through a helix a wedding cake which is over there against the wall and that has two charts on the top and that's some staging that represents padma in the other direction there's a major helix inside here that has a four-track staging garden at this east staging and on the top here this is stage and there's two tracks up here so you have the total of eight staging tracks that are fed from the storage area between the sessions so can you go directly from the top level there down to the transfer table yes i can so this is useful for turning trains between sessions as well and there's also a turning loop on the storage level so i can take trains down here and they can turn them into that's your y in here i can turn the trains into y if necessary take it out feed nelson yard or bend them down so this this whole storage yard acts as a connector between all the different ends of the layout do you have a youtube channel where you have some of your videos about operations i do i have a youtube channel and videos it's not not as well updated i'd like it to be though yes you can provide that link and there's actually a flickr page the flickr page is kept current for new projects as well when you did this you used basically a shadow box effect to do all your scenes of course to get so many levels do you have any secrets to how you got all the scenery and details to the back versus the front young at the time i was young yeah we all were once at one point yeah uh you know i'll never build a lane like this again ever i mean there's too much energy that went into it i was incredibly fortunate at the time of the resources to dedicate it it's a one-man job the with the exception of the installation of the dcc system the code here story i've been on everything else myself um definitely because i just find it's more efficient and i enjoy all the different aspects of the hobby and it's actually a manageable size it's it's the limit of what i'd be able to do but i can't never be able to find the energy you do it again um and then the scenery and the backdrops just kind of evolved i've always liked painted backdrops i'm experimenting with photo backdrops now you may have seen the experimental photo backdrop behind the silicon forest product mail that maybe may work my ability to actually paint buildings is very very limited and i like steve stark he's very good at it their artistry is fantastic thank you very much i appreciate it definitely been a labor of love as all our layouts are i've been fortunate enough to operate in many of your layouts when i go down the samuel as well uh mark did you build the entire layout yourself yes i did wow yeah uh we have pretty small building lots in vancouver so this is a 33 foot lot with a 400 square foot garage on it i don't have any other route building so i actually had to build figure out a way to build it and that i was able to actually have room to actually build the different modules and install them and then when i finally finished building nelson yard i installed it and then i disassembled the saws and put them away i've been fortunate enough not to have to bring those out again uh would you be willing to film the walking out of the room so we can see your computer where you do the dispatching and and see the process of leaving the room yeah of course that room of course hasn't been tidied up so thank you for that bro so i use uh hardwood railings these are cut on a tremolo for very shallow angle and they're lubricated with lithium grease uh this has run very well so these gates have been in existence now for about 12 years and then i'm fine so this skate would normally be open by checking open right now if we finish so this will be opened and closed once per session so that's what you want to do all the time this is the crew lounge dispatcher's office this is a dispatcher panel um it's a jmri uh panel pro panel it's just used to activate and clear the the six trainer signals but it's clear this was the corkendal signal it was that was down when we were passed but that's now clear that the december signal crooked off very nice and how about the call board can you show us that sure it's pretty straightforward so all the jobs that are available are listed and we have some we use cards for people to pick randomly or for randomly assigning the order which people pick their jobs and one thing i do differently slightly differently it's personally when i go and operate on someone's own i'm scared to death but screwing up so i'd like to understand what the level of complexity of each of the jobs are so we have to use a ski hill analogy to actually rate the difficulty of each of the jobs from easy to challenging so a double black diamond would be very very challenging we don't actually have any double black diamonds we have a single black diamond job there's some of you guys would have done which was the craft job it's running from nelson to tassel bar switching out the pump mill and back and that's that's a three-hour job something like that but it can be very complicated any other questions so for an operator of a particular run what's a typical time duration at least an hour the yard jobs are full session jump so they're four hours the silicon and castle branch is a four hour job the um craft job which which is a craft mill would be three hours at least maybe four and then the three freights are probably an hour and a half something like that two hours so you can when you actually have the uh all the transit upper money after you adhere to the slow orders and your train orders it can easily take you an hour and a half to two hours to get across the summit the push of jobs would be about an hour so if you were operating on the layout you operate at least two jobs maybe three uh if you're not offering one of the dedicated jobs so during a session there's not necessarily a whole bunch of social social interaction going on guys are busy working their trains it could be but i mean this is the kootenai so things are pretty slow we always have entertainment where people forget their orders run over flag and stuff incredibly impressive yes indeed hey mark i just wanted to mention uh thank you very much for the tour i really enjoyed my visit you've got an incredible layout there it's just incredible when the covert restrictions are you guys are all welcome all right thank you very much mark thank you bear thank you for watching guys hello again uh this is another reminder that this virtual layout tour has been brought to you by members of the fourth division of the pacific northwest region of the national model railroad association and we hope you've enjoyed it and we want to encourage you to again find out about the nmra online both pnr and nmra have an excellent website where you get information about joining and participating this and other activities like our clinics that are held all over the region so thank you for joining us today and wish you great modeling

Show moreFrequently asked questions

What is the definition of an electronic signature according to the ESIGN Act?

How do I sign a PDF with an electronic signature?

How do I sign and scan a PDF?

Get more for scale mark with airSlate SignNow

- Carbon copy digital sign School Supply Order Invoice

- Copy autograph Truck Driver Application

- Deliver digi-sign Work Completion Record

- Stamp signature service Succession Agreement

- Champion initial Summer Camp Certificate

- Defend signatory Boarding and Daycare Contract

- Learn eSignature Settlement Term Sheet Template

- Solicit electronic signature Employee Resume

- Insist upon countersignature Summer Camp Staff Evaluation

- Order byline Free Admission Ticket

- Create Partnership Agreement Amendment digisign

- Recover Patient Satisfaction Survey electronic signature

- Authenticate Relocation Policy signed electronically

- Assure Joint Custody Agreement Template sign

- Exhibit Influencer Contract electronically signing

- Find Travel Planning Registration mark

- Fordbid ID Card Template for Parents eSignature

- Call for Coffee Shop Business Plan Template autograph

- Enforce Bachelorette Itinerary digital sign

- Back successor default

- Urge awardee conditional

- Prove uncountable cc number

- Write Home Improvement Contract Template template signature service

- Prove Freelance Web Development Request template countersign

- Endorse Editor Contract Template template sign

- Ascend Leave of Absence Agreement template initials

- Renew Secondment Agreement template eSign

- Test Volunteer Certificate template eSignature