Fill and Sign the Marine Cargo Insurance Application Form Blocktonb Basiabbcomb

Valuable advice on preparing your ‘Marine Cargo Insurance Application Form Blocktonb Basiabbcomb’ online

Are you fed up with the complications of handling paperwork? Look no further than airSlate SignNow, the premier eSignature platform for individuals and small to medium-sized businesses. Wave goodbye to the monotonous tasks of printing and scanning documents. With airSlate SignNow, you can effortlessly complete and sign documents online. Leverage the robust features embedded within this intuitive and cost-effective platform and transform your method of document management. Whether you need to sign forms or gather eSignatures, airSlate SignNow manages it all seamlessly, with just a few clicks.

Follow this comprehensive guide:

- Access your account or sign up for a free trial with our service.

- Click +Create to upload a document from your device, cloud storage, or our template repository.

- Open your ‘Marine Cargo Insurance Application Form Blocktonb Basiabbcomb’ in the editor.

- Click Me (Fill Out Now) to prepare the document on your end.

- Add and assign fillable fields for other parties (if necessary).

- Proceed with the Send Invite settings to seek eSignatures from others.

- Download, print your copy, or convert it into a reusable template.

Don't worry if you need to collaborate with your colleagues on your Marine Cargo Insurance Application Form Blocktonb Basiabbcomb or send it for notarization—our platform provides everything you require to accomplish such tasks. Create an account with airSlate SignNow today and take your document management to the next level!

FAQs

-

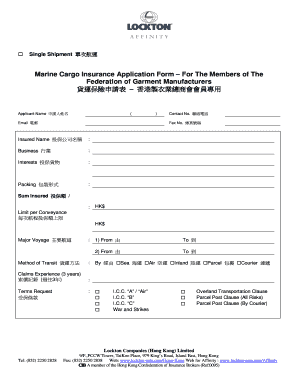

What is the Marine Cargo Insurance Application Form Blocktonb basiabbcomb?

The Marine Cargo Insurance Application Form Blocktonb basiabbcomb is a specialized document designed for businesses looking to secure cargo insurance. It simplifies the process of applying for coverage, ensuring that all necessary information is collected efficiently. By using this form, you can expedite your insurance application and protect your goods during transport.

-

How can I access the Marine Cargo Insurance Application Form Blocktonb basiabbcomb?

You can easily access the Marine Cargo Insurance Application Form Blocktonb basiabbcomb through the airSlate SignNow platform. Simply sign up for an account, and you will find the form available for download and electronic signing. This user-friendly interface makes it convenient to manage your insurance applications.

-

What are the benefits of using the Marine Cargo Insurance Application Form Blocktonb basiabbcomb?

Using the Marine Cargo Insurance Application Form Blocktonb basiabbcomb provides numerous benefits, including streamlined processing and reduced paperwork. This form helps ensure that you include all necessary details for your insurance application, minimizing delays. Additionally, the ability to eSign the document facilitates quick submissions and approvals.

-

Is there a cost associated with the Marine Cargo Insurance Application Form Blocktonb basiabbcomb?

The Marine Cargo Insurance Application Form Blocktonb basiabbcomb is part of the airSlate SignNow service, which offers various pricing plans. Depending on your chosen plan, you may have access to this form at no additional cost or for a nominal fee. It's best to review the pricing options to find the plan that suits your business needs.

-

Can I integrate the Marine Cargo Insurance Application Form Blocktonb basiabbcomb with other software?

Yes, the Marine Cargo Insurance Application Form Blocktonb basiabbcomb can be integrated with various software solutions, enhancing your workflow. airSlate SignNow supports integrations with popular business tools, enabling seamless data transfer and document management. This capability allows you to streamline your operations further and improve efficiency.

-

What features does the Marine Cargo Insurance Application Form Blocktonb basiabbcomb offer?

The Marine Cargo Insurance Application Form Blocktonb basiabbcomb includes essential features such as customizable fields, electronic signatures, and automated reminders. These features not only simplify the application process but also ensure compliance with industry standards. With airSlate SignNow, you can manage your insurance documents with ease.

-

How secure is the Marine Cargo Insurance Application Form Blocktonb basiabbcomb?

The Marine Cargo Insurance Application Form Blocktonb basiabbcomb is protected by airSlate SignNow's robust security measures. Your data is encrypted and stored securely, ensuring that sensitive information remains confidential. This commitment to security allows you to complete your insurance applications with peace of mind.

Find out other marine cargo insurance application form blocktonb basiabbcomb

- Close deals faster

- Improve productivity

- Delight customers

- Increase revenue

- Save time & money

- Reduce payment cycles