Urge Validated Field with airSlate SignNow

Do more online with a globally-trusted eSignature platform

Remarkable signing experience

Reliable reporting and analytics

Mobile eSigning in person and remotely

Industry polices and compliance

Urge validated field, quicker than ever

Useful eSignature extensions

See airSlate SignNow eSignatures in action

airSlate SignNow solutions for better efficiency

Our user reviews speak for themselves

Why choose airSlate SignNow

-

Free 7-day trial. Choose the plan you need and try it risk-free.

-

Honest pricing for full-featured plans. airSlate SignNow offers subscription plans with no overages or hidden fees at renewal.

-

Enterprise-grade security. airSlate SignNow helps you comply with global security standards.

Your step-by-step guide — urge validated field

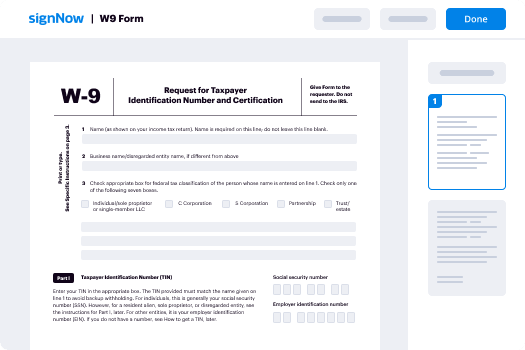

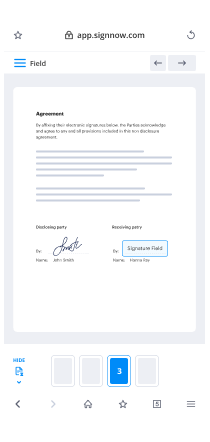

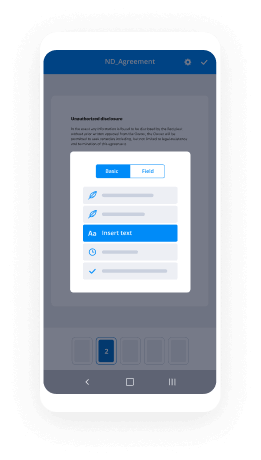

Adopting airSlate SignNow’s eSignature any organization can increase signature workflows and eSign in real-time, supplying an improved experience to customers and staff members. urge validated field in a couple of simple steps. Our handheld mobile apps make operating on the run achievable, even while off-line! eSign documents from any place in the world and close up deals in less time.

Take a step-by-step guide to urge validated field:

- Log on to your airSlate SignNow profile.

- Locate your document within your folders or import a new one.

- Open the record and make edits using the Tools menu.

- Drag & drop fillable boxes, add text and eSign it.

- Include numerous signers using their emails and set the signing order.

- Specify which recipients will get an executed doc.

- Use Advanced Options to reduce access to the document and set up an expiry date.

- Tap Save and Close when completed.

In addition, there are more advanced functions available to urge validated field. Include users to your common digital workplace, browse teams, and monitor teamwork. Millions of people all over the US and Europe recognize that a solution that brings everything together in a single holistic digital location, is what companies need to keep workflows performing effortlessly. The airSlate SignNow REST API allows you to embed eSignatures into your application, website, CRM or cloud. Try out airSlate SignNow and enjoy quicker, smoother and overall more productive eSignature workflows!

How it works

airSlate SignNow features that users love

See exceptional results urge validated field with airSlate SignNow

Get legally-binding signatures now!

FAQs

-

How do you know if a survey is valid?

Step 1: Establish Face Validity. This two-step process involves having your survey reviewed by two different parties. ... Step 2: Run a Pilot Test. ... Step 3: Clean Collected Data. ... Step 4: Use Principal Components Analysis (PCA) ... Step 5: Check Internal Consistency. ... Step 6: Revise Your Survey. -

How do you validate research?

Step 1: Establish Face Validity. This two-step process involves having your survey reviewed by two different parties. ... Step 2: Run a Pilot Test. ... Step 3: Clean Collected Data. ... Step 4: Use Principal Components Analysis (PCA) ... Step 5: Check Internal Consistency. ... Step 6: Revise Your Survey. -

How can researchers check on the reliability of their survey Why is this important?

The answer is that they conduct research using the measure to confirm that the scores make sense based on their understanding of the construct being measured. This is an extremely important point. Psychologists do not simply assume that their measures work. Instead, they collect data to demonstrate that they work. -

What is validation research?

core definition. Validation is a process of confirming that an existing programme of study or a newly designed one can continue or commence operation. -

How do you assess a survey?

Collect Data Correctly. ... Input Your Results. ... Run Raw Numbers. ... Cross-Reference Your Results. -

How do you validate data?

Select one or more cells to validate. On the Data tab, in the Data Tools group, click Data Validation. On the Settings tab, in the Allow box, select List. In the Source box, type your list values, separated by commas. ... Make sure that the In-cell dropdown check box is selected. -

How do you know if a test is valid?

The criterion-related validity of a test is measured by the validity coefficient. It is reported as a number between 0 and 1.00 that indicates the magnitude of the relationship, "r," between the test and a measure of job performance (criterion). -

What is a validated survey?

When a survey is "validated" it means that the researcher has come to the opinion that the survey is measuring what it was designed to measure, or the researcher has received a statement from another researcher indicating that they believe the instrument is measuring what it was designed to measure. -

Why does an instrument need to be validated?

Validating instruments of measure : Is it really necessary? All instruments assessing patient reported outcomes have to be evaluated for its reliability and validity in the country prior to its use. The purpose of this is to ensure that the instrument used is measuring what it is supposed to measure. -

How do you test the validity and reliability of a questionnaire?

Establish face validity. Conduct a pilot test. Enter the pilot test in a spreadsheet. Use principal component analysis (PCA) Check the internal consistency of questions loading onto the same factors. Revise the questionnaire based on information from your PCA and CA. -

What is a validated measurement tool?

When a test or measurement is "validated," it simply means that the researcher has come to the opinion that the instrument measures what it was designed to measure. ... Repeated use of the instrument is a strong indication that the instrument was designed to measure what it set out to measure. -

How do you check for the validity and reliability of a questionnaire?

Establish face validity. Conduct a pilot test. Enter the pilot test in a spreadsheet. Use principal component analysis (PCA) Check the internal consistency of questions loading onto the same factors. Revise the questionnaire based on information from your PCA and CA. -

How do you validate a research instrument?

Step 1: Establish Face Validity. ... Step 2: Run a Pilot Test. ... Step 3: Clean Collected Data. ... Step 4: Use Principal Components Analysis (PCA) ... Step 5: Check Internal Consistency. ... Step 6: Revise Your Survey. -

Can surveys be trusted?

This doesn't mean that all survey questions cannot be trusted. ... In fact, the answers to these types of questions can be verified objectively. However, questions that require value judgments or reporting beliefs are susceptible to bias because these are inherently subjective. -

What does validation mean in research?

Validation. core definition. Validation is a process of confirming that an existing programme of study or a newly designed one can continue or commence operation.

What active users are saying — urge validated field

Related searches to urge validated field with airSlate airSlate SignNow

Urge validated field

today's presenters are herb Schuneman Norah Bello and Kevin Fernandez you may remember herb from our last webinar on package integrity testing nor is the vice president of San Jose and has been with Westpac for 12 years Kevin is our Quality Manager has been with us for 8 Nora take it away good afternoon everyone we're so grateful that you join us this afternoon for our webinar on writing package validations with ISO 11600 and speed to market in mind Kevin and herba myself will be commentating for about the next hour so join along feel free to ask any questions as we go Kevin no way to you as a test lab we do a lot of package validation testing we see and execute a lot of these package validation protocols for our clients so that means that we do the climatic conditioning we do that package performance testing the accelerated aging the bubble the peel testing the processing pretty much all testing that you need to do in order to properly validate your medical device package system so we do have a bit of experience reading and executing these protocols and sometimes we run into issues in the way that these protocols are written not that they're bad or wrong but there are some things in the protocol where a little more clarification in detail would make the whole testing process go a little smoother and minimize any potential delays and ultimately minimizing your time to the market with most companies at time to market is important and the package validation can be critical with this since packaging is often one of the last steps in this whole process so the point of this webinar is to offer some tips and suggestions when it comes in developing your package validation protocol there are some things to be aware of when you're writing your protocol in order to make it go as smooth as possible with testing with your test lab and with the FDA which again ultimately reduces your time to market so here is our agenda for this webinar we're gonna now briefly go over a description of a packaging system the FDA requirements ISO 11 607 common sections in a validation protocol common issues when developing your protocol what to look for when choosing a test lab tool or to execute your protocol and how to work closely with your test lab to minimize time to market so we're on the same page I'm gonna briefly go over a definition of a packaging system for medical devices a packaging system comprises of a sterile barrier system and the protective packaging the sterile barrier system is typically your primary package this is your package that is an intimate contact with your product and provides the sterile barrier this is the package that allows for sterilization and provides a microbial barrier so these are usually your breathable pouches and trays which is most commonly a spun polyolefin material also known by its trade name as Tyvek then we have the protective packaging this is your secondary and tertiary packaging this is a packaging that actually contains and protects your primary packaging so these are your cartons your shippers or whatever your package configuration may be herb do you want to comment on this and thanks Kevin this is herb shinonono and welcome to ruin two-hour webinar the Kevin's the points are exactly right these are the primary areas of concern we're looking at packaging systems for medical devices and similar I want to emphasize that they're not the only package functions so there are many many more tradition there were four of them taught to us and in the dark ages when I went through the curriculum at school and they're added and subtracted by various authors since that point but these are the primary ones that that does seem to be very important for medical device and similar product and package validations and that's why we're focusing on them I just want to make sure everyone's were that we're not trying to state these are the only package functions they're simply the ones we're focusing on right now coming back to you thanks herb so that's what we're gonna be focused on the entire packaging system and it's that entire package system that must be validated for clearance by the FDA so I'm gonna briefly go over what the FDA is looking for when we're validating this so obviously obviously validation is one of your critical steps when it comes to getting your product to the market and this is gonna be based on FDA requirements for 510 K submission so what are they looking for exactly and what they're looking for is pretty straightforward but it's also a little vague at the same time since they don't actually provide too much guidance on it the FDA pretty much says that the package system must provide adequate protection against damage during shipping and must maintain sterility of the device for the duration of the shelf-life and they say that prove this with a package validation or to prove the spec about package of validation with testing prove that your package can withstand the shipping and distribution environment and maintain sterility so this should comprise of your distribution simulation testing your sterile barrier system integrity testing and them an aging shelf-life testing but again they they say to do this to prove this but they don't provide too much guidance on exactly what needs to be done specifically but they do suggest following iso:1162 the standard for validating sterilized medical device packaging and being compliant with this should provide enough proof that your packaging satisfies what the FDA is looking for it'll show that your package allows for sterilization it provides effective protection and it can maintain sterility up to the point of use it's also an FDA recognized consensus standard and it's required for European regulation in order to get a see e mark so it's no wonder most companies use eleven six oh seven just for this but even then I so love in six oh seven is still just I get a guidance document when you actually read through it you'll see that it gives you all the requirements that need to be satisfied but it still gives you a lot of different options and suggestions of how to satisfy all of the requirements it still doesn't tell you exactly what type of testing you need to run so this is gonna be up to you to decide and to document in your internal validation protocol it's your protocol that's gonna have the specific test plan on exactly how you're going to prove that your packet systems satisfies the FDA's requirements so this is what we're going to be talking about today you're a validation protocol I'm gonna briefly go over some of the common packaging validation protocol sections it's not to say that these are all of the sections that are mandatory for a protocol or that these are the only sections you need but these are just some common sections adds it applies the package validation I'm gonna go over some of these sections briefly and then dive into a little more detail on certain sections where we may have some helpful insight for you so real briefly a purpose section of your protocol this is where you state the reason for your protocol the scope this is the extent of what your protocol applies to or what it deals with the responsibilities this is where you state what parties are responsible for executing what section of the protocol the sample preparation and information section this is where you can put the details of your package configuration if it'll contain live or dummy units maybe numbering or testing designation whatever whatever else might be important to you here the sterilization section this is where you can put details of sterilizing following the packaging and prior to testing and any information here that will be important to you as it applies to sterilizing your samples so these are the sections I just wanted to mention briefly for the next sections I'll go a little deeper with us some suggestions so the first section that I like to talk about is reference documents in this section this is where you're referencing where you're referencing industry standards or SOPs these are the documents and the methods that will need to be followed in order to execute the testing in your protocol and an issue we often see here is referencing old versions of industry standards so if you're going to put revision dates here we recommend making sure that you call out the correct and the latest revision for these standards usually industry standards don't get revved up very often and when they do get revved it's not at a regular interval so you really need to do your homework and see what the latest revision is if you're actually unsure of the differences between different revisions of certain standards I would suggest asking your packaging test lab a good test lab will know the newest revision and they should know that changes compared to previous ones so um another thing to add is if you're gonna reference internal SOPs be sure that your test lab has these SOPs as well these standard operating procedures for your company may have very specific test parameters that the packaging test lab needs in order to conduct your testing properly and not providing this SOPs can cause delays or even a deviation so make sure you provide this to your M test lab as well as the protocol herb did you want to add something in on this thanks Kevin at the risk of sounding like a broken record uh I do want to make sure there are seminar attendees to realize that this is one of the most common pitfalls that we see in specifications not calling out the correct revision number and any auditor is going to catch this and not be happy and we all know that happy auditors make our lives much easier so make sure that you keep a really close eye on this one of the techniques that we've seen that we highly recommend is to not even reference revision numbers when you call out other documents within your protocol but simply say latest revision and then you don't have to worry too much about it and it's not going to get caught or flagged by an auditor so just a suggestion again that's that's one of the things that we've seen the most as far as pitfalls and we'll be talking about this more later kept them back to you thanks for the next section I'm going to talk about is a sample size and this is a question we get asked a lot and as we know this topic can be a webinar on its own workshop or even a semester class so I'm not going to go too deep into this topic in the interest of time a lot of companies usually have a specific sample planning documentation or standard operating procedures that provide the sample size and rationale so if you have that and you're able to reference it and it's applicable to what you need then I suggest using that but often times uh clients don't have this information and they ask us for guidance if you ask a statistician about this the answer they usually give you is it depends it depends on the confidence the severity of what you're looking for how conservative you want to be what your process is whatever it just depends and usually that isn't too helpful so when people ask us this question for a package for this type of package validation testing I'm sorry our recommendation would be fifty nine samples for ninety five percent confidence and ninety-five percent reliability in the absence of other data this is based on attribute sampling so that is a total of fifty nine sterilized units or primary package if you want more detailed information on this we can assist you with a rationale offline if requested herb is there anything else that you wanted to speak on to Memphis yeah thanks Kevin know that as Kevin pointed out it's one of the most common questions that we get a lot of we did touch on this briefly during a previous webinar so if you want some brief information without you know talking to a real live person you can go to our website ww-why cm and look for the the webinars and the the one held in September of this year does briefly talk about the 95 95 you know sample size attribute quality level all that kind of stuff and what are the sample sizes for like a 90 90 or 85 85 and it's straight from Statistics and a lot of the background information is given there so it's a little bit of help there thanks Kevin back to you thanks sir the next section I'd like to touch briefly on is the equipment section this is the section that addresses the equipment that will be used for testing you can be as detailed as you want to be here but since you really don't know exactly what equipment and associated instrumentation that your tests lab will be using I would recommend just keeping this section general just state that the equipment used will be in current calibration and will be traceable and that the tests lab will provide identification of the equipment and calibration dates in their final report so I would just leave the edit that so under the actual testing portion of the protocol package integrity testing also known as package performance testing distribution simulation and transit testing or even shake rattle and roll testing this is where you're going to outline your test sequence for the test that's gonna challenge your packaging to the shipping and distribution environment this is where you bring the worst case scenario real world into the test lab and subject your packaging to it industry standards are usually referenced for this testing and common procedures are ASTM D for 169 ASTM D 73 86 different ista procedures such as 2a or 3a or even a custom test sequence that your company may have come up with these shipping simulations usually consist of climatic conditioning drop testing compression testing vibration concentrated impacts and low pressure testing and herb did you want to comment on this we're often asked this question about this this kind of protocol and Kevin's advices is good here the two ASTM standards reference are probably the most common that we see ASTM is an alcohol ASTM International used to be American Society for testing of materials it is a consensus organization here in the United States since is over 100 years old as when publishing these standards and their world recognized so there's nothing wrong with them is ta the international safe transit Association is also a well-established organization but until recently has not really published standards that were recognized as consensus they had a committee that put them together and they were every bit as good but the FDA kind of had a qualms about it we understand that that is changing rapidly and so very shortly we anticipate that is T procedures will also not wrinkle the nose if you will of the FDA so a lot of changes going on in this area one of the things that that you can rely on with with a good testing laboratory and we kind of put ourselves in that that category obviously is that we keep track of that when we keep our nose to their to the to the ground if you will our ear to the ground those to the grindstone whatever that is so we we try to try to take that burden off of our clients keep track of what's going on in the standards which ones say which so that's why we make these recommendations they simply seem to work best for our clients Kevin back to you um so a lot of clients will actually ask us what T what test sequence they should use further product for their packaging which standard is best and for the purpose of medical medical device package validation testing our recommendation would be sticking with what's on the FDA approved list and right now for package testing the FDA recognizes ASTM D for 169 and D 73 86 so we would recommend going with either of those two test sequences for the time being these are like herp said these are consensus standards these are based on empirical data to back up the test sequences they're FDA recognized so if there's gonna be less questions from the FDA if you go with either of these so they're a pretty safe bet that's not to say that these standards are better or worse than its those test procedures but the ASTM ones are recognized by the S by the FDA so it's our recommendation in either case a D for 169 or D 73 86 the procedures actually have many options that choose from depending on your packaging and your expected distribution environment but there are standard sequences that are commonly used if you actually need assistance with what test sequence to choose I would again consult your packaging test lab a good test lab should be able to give you a good recommendation based on your package configuration and purpose of testing so that's our recommendation for now just thiquid whatever is on FDA's approved list and like herb said we may have some changes in the future with this then we may have more options but for now we would just say stick with these four one six nine orgy's 73 86 so the next topic I'm going to go into is a shelf-life testing or aging the FDA and ISO 11600 seven say says that you must prove that your packaging will maintain sterility throughout tribution and throughout its intended shelf-life so real-time aging is required but it says you could run an accelerated aging in parallel in order to get your product out to the market without having the weight that one two or three years of real-time aging so accelerated aging this is accelerating that adverse effects of aging by storing the samples at an elevated temperature for a certain amount of time and this will be equivalent to a certain shelf life at normal temperature so what usually happens is the samples will go through a distribution system installation testing then aging men a sterile barrier testing to evaluates this for any sterility breaches and this should prove that your sample can maintain sterility throughout its intended shelf-life a question we get asked often is what accelerated aging tempered temperature to use and accelerated aging follows ASTM after 1980 this is based on the Arrhenius equation which shows that an increase in temperature increases molecular activity in a material which in turn speeds up the adverse effects of aging so time and temperature the the time and temperature to use is going to be based on different variables these variables are aging shelf life real time temperature aging temperature the Q factor which are all defined in ASTM F 1980 in a few slides Nora is actually gonna go into a little more detail on manipulating these factors but the bottom line is the higher the temperature you use the faster the aging however the caution is that you don't want to go too hot because you may actually damage your product so our recommendation is go ahead and speed up this test with a higher temperature but you only want to go you only want to go with the temperature that your packaging can safely withstand and usually 60 to 65 C is usually a safe upper limit but the bottom line is you should know your product and your packaging characteristics and avoid any temperatures that would damage them or you want to edit us thanks Kevin a question that arose during our earlier webinar on the same topic involved the use of humidity with the temperature in an accelerated aging process and at that time we simply explained that the Arrhenius equation which this whole accelerated aging is based simply states that molecular activity particularly in organic molecules is a function directly related to temperature if you double the basic increase of temperature by 10 degrees C you double the molecular activity of organic molecules there's no mention of humidities effect and and we've seen that as well we do offer accelerated aging conditions with humidity but the trend is vastly away from that it's a difficult thing to do it's an unknown variable quite honestly in the equation and there's a bunch of other issues that can it can negatively affect and kind of cloud what you're really trying to do if anyone's interested in that effect we'd certainly like to you know talk to you so email us your your comments concerns or questions but for this the purpose of this webinar we want to emphasize that humidity does not have a validated effect or a noted effect in aging and it is not referenced in any of those standard documents people do question it but that's that's our standard answer Kevin back to you thanks for so following the package performance testing and following the aging you want to evaluate your sterile barrier to make sure that it didn't develop any breaches during all of that testing typically bubble testing dye penetration and/or visual inspections are used to do this I so 11 607 also says that you need to demonstrate an adequate seal strength of your pouches and trays so typically peel testing or burst testing is done for this we've seen many protocols in the industry and a lot of times companies will call out either visual inspections bubble testing or dye penetration testing or some combination of the three and our recommendation wouldn't or we wouldn't solely suggest that relying on visual inspections for your integrity evaluation visual inspections are based on f 1886 really are just for evaluating the seals on the package and it only has a defect rate um detection rate as low as 60% the human eye can only see so much we would we also wouldn't suggest just going with dye penetration and testing because that really is for just evaluating the seals of your pouch or tray it doesn't test the surface of your package and it really is only appropriate first seal validations gross leak detection or bubble testing would be more appropriate I say it's a test it tests the entire package it tests the seals and it tests the surface our internal validation with ASTM F 20 96 here at West spec showed greater than 90% detection rate so this is the testing that we suggest for this as far as a demonstrating adequate seal strength for your pouch or tray a question sometimes we get asked is it spheal testing and burst testing interchangeable and in my opinion I would say not really pure I'd say peel testing is more appropriate here because you're actually measuring the strength of your seals you're measuring the actual force it takes to pull the seals apart which is important for keeping your package sealed and it gives you quantitative data on what it's like to open your package at the point of use in a few slides nor is actually going to talk a little more about the detail regarding acceptance criteria for peel testing but that's also I'll say with that for now for burst testing this is more for identifying weak spots or evaluating how well the seals hold up to pressure differentials this is a good test to ensure your process is in control or a good test if your pouches aren't breathing and may have a potential to burst at high altitude so it's not a bad test but I'd say for this package validation testing that peel testing would give you more usable and relevant data all right thank you Kevin this is Nora chiming in so we've just discussed the various components that comprise a protocol written to satisfy the ISO 11 and 607 guideline now let's discuss some elements that can help us get through the validation process with as few snags as possible seemingly minor details in your protocol have the ability to turn mole hills into mountains and want to help you avoid that some of the most significant issues that we've seen here at Westpac can be lumped into one category of flexibility as Kevin mentioned stating your acceptance criteria and then meeting that criteria is the structure behind conducting a package validation test however there are situations where the inability to meet specific criteria doesn't necessarily jeopardize the validity of testing results and we will go through a few of those examples now so it's come and discussed one of the packet validation inputs is the compression test in this example the target load I'm sorry and the target load is based on several factors including the dimension of a shipper you're going to be testing to ASTM D for 169 the compression formula will change based on whether your shipper is under or over two cubic feet and the example that you see here we have two shippers and one our left is two cubic feet while the one on the right is slightly under two cubic feet just based on that half inch dimension less this difference of a half an inch has an impact on the compression top load of close to 900 pounds which is very significant now you have the ability to write in to your protocol what you want the h or the the height factor to be if you know your distribution environment and if you know that packages will not be sacked over 54 inches or 60 inches or 72 whatever that may be you can use that specific number for H in place of 108 now in this example we have two identical shippers that again and our two cubic feet at assurance of a one which is the most conservative and most difficult level the safety factor which is F is 10 and the target --top' load is therefore 1600 pounds however you can write into your protocol use of assurance level 3 or 2 for compression only and that reduces the safety factor down to 5 or 7 based on its assurance level 3 or 2 and that would decrease the top load down to about 800 pounds or half the amount now prior to doing this you really should understand your distribution environment and what inputs the shipper will be subjected to do you want to go ahead and jump in here thanks Nora we've been asked what in the world was going through the standard writers mind when such variables can be written into a standard and those variables are specifically what nor did it said either changing a assurance level or you know changing the dimensions of a container a very small amount half an inch in this particular case well remember that these are consensus standards what does that mean it means that a bunch of people knowledgeable in either the process the equipment or of general interest in the area sit around the table twice a year in this particular case and they talk about that MKS in fact they even argue about it in fact most of the time they argue about it the net result is a compromise that everyone can agree to or the least number of people disagree with which is more often the case so they're not perfect they do have some glitches in them and this is one of the ones that we've noticed and it's it's simply a a result of the fact that these are consensus standards and we're not don't get me wrong I'm not trying to do to a Democrat or degrade the process standard or on anything like that all I'm saying is they exist this this kind of thing exist what we're trying to do is tell you about these pitfalls and I'll how to avoid them because some of our clients have kind of fallen into this trap before and the compression testing is probably not the best fit their nodes of a package validation and it's probably one of the least important functions of the secondary or tertiary package for this so it's an easy thing to avoid and this exactly what the Moores trying to tell us here more back to you thank you so another snag that we see on many medical device customers run into is the inflexibility with in peel testing now that's testing often referred to as attribute testing measures the strength of a seal typically Tyvek and poly pouches when they're pulled apart Kevin talked about this earlier an issue standard is typically a minimum seal strength of one pound force per one inch seal now I'd queered a lot of customers over the years about why they have them in unsocial to one pound in their protocols and I have yet here anyone with a basis for this number even 11 607 which is a guidance document for the testing of sterile packages doesn't reference the one-pound factor it's typically just a historical number that's been built into a company's history and we've seen validations failed because one seal measured point nine eight pounds force and you're talking after a product build after sterilization after transit testing accelerated aging once it finally gets through all that one inch heel hits 0.98 pounds instead of one pound in the hole valuation fails - bummer there's a little non document out there called Ian eight 68.5 that states that the minimum value for ceilings that have been sterilized is 1.5 Newtons per 15 millimeter seal this translates to a minimum she'll strength of 0.5 seven pounds for a one inch steel just typically what we use here in the Americas and again flexibility within your protocol is key do you have the ability to write into your protocol that the average seal strength for all samples is greater than one pound force and an individual seal can dip below that as long as it stays above a minimum threshold a point seven or point eight pounds herbs you want to add anything here those are really good points in our we also find that that not only a minimum strength in the seal area is important but also a consistent strength is a very important I mean if you just look at minimums you could have a 15 or 20 pounds per inch but the simple fact is that you couldn't get the everything open in a in a area let's call it a sterile field or this product is being dispensed so those who use this type of packaging consistently tell us in very clear terms they really like and if they could they would insist on consistent seal strength so that they can tell exactly what force it's going to take to dispense this product correctly into sterile field so again not only do you need minimum strengths but I think you need consistent strength and that's what you should really be surprising for if you really want to sell your product consistently to a happy set of clients Novak do thanks herb and then again the whole point of this recommendation is to try to avoid a pitfall that may stall your products getting to market now if you find yourself and your projects timeline in jeopardy of meeting your deadlines manipulation of the accelerated aging variables may be one way to gain back some of your time to market as Kevin eluded accelerated aging testing allows for a package and a product to be subjected to an elevated temperature to simulate the effects of the aging process ageing temperatures typically range from 45 to 65 C with 55 C being the most common and based on the Iranian the duration of the test decreases in half for every 10 degree input or increase in each chamber temperature now we've all experienced the time crunch that can come when a product launch which is the package validation stage behind schedules a high-pressure situation at this point a process many projects are behind schedule and lucky to make up that time in one area you were able to do so to make up that time is to work some flexibility into the aging portion of your protocol if your protocol states in aging duration of 50 degrees C and one year shelf-life would take around 56 days however increasing that ageing temperature to 60 degrees C would decrease your aging duration by 28 days and that's 28 days that you can add back on to getting your product out to market now please note well this is a tool to speed your package and process and speed to market it should only be undertaken if the research has been done to ensure that the elevated temperature does not affect the glass transition rate of the products the last thing you want to do a high pressure and time-sensitive situation as soon as this unexplained or unanticipated failure into the process if you've done research and doing this to be an acceptable Avenue to take then you should write into your protocol the ability to adjust the aging temperature and therefore the duration without compromising the testing input back to the flexibility within the protocol now if you're curious about how different variables may affect the aging duration please feel free to visit our microsite medical device testing calm and play right around with our accelerated aging calculator that's on there now many of our customers have internal tensile or in strong test machines to do internal peel testing and while this is perfectly acceptable to use these machines and save a little bit of money it does require an extra layer of scheduling calibrating report writing and reviewing auditing and communication and etc consider having all the package validation testing done by your testing laboratory this will consolidate the package validation test data into one place it will reduce the level of communication that you have to work with it's going to reduce the amount of documentation and paperwork that you have to organize and in a long run it will save you time and money to do this and that's the point of will speed your product to market excellent point Nora this does sound somewhat self-serving when a test lab says let us do your work the simple fact is that several instances have occurred order and clients had a kind of a snafu in this whole process and and really were in a world of hurt and it all happened because they they were doing part of the process in-house and part of it here and part of there and so what we urge clients to do is to consolidate that into one place put put the pressure on one source so you only have one button to push and and have that testing done and including the accelerated aging real-time aging whatever at one source because that they'll then then you have one place to go to make sure it's not now obviously that place has to have their act together because you don't wanna put all your eggs in one basket that's bad basket however if it's done correctly it will in fact a speed your process to market and we've seen the results of not doing this correctly so that's why we put this this hint in here of you know do what you know best in other words stand your own wheelhouse so it's excellent point thanks Nora back to you thanks sir alright Omar a key point here during the testing process often questions arise on a project that the test lab needs answered by the medical device manufacturer these questions include but are not limited to do you know the corrugated strength of the shipper or what surface do you consider to be the base now the answers to these questions will have an impact on the testing inputs and results however many times the answers to those questions are not ready to be readily available in the right person it needs to be tracked down to answer them be knowledgeable about your protocol about your packaging and the purpose of testing and being able to decisively and clearly communicate those answers with your testing lab as quickly as possible will help to reduce any downtime in the validation process in the final way that we wanted to touch on to help speed your product launch date to market is to write your protocol with the ability to adapt unforeseen circumstances now while we try to minimize the occurrence human air equipment air and power outages occasionally occur during the testing process does your protocol allow you the flexibility in the risk assessment process to move forward or to start over based on a specific situation does it require a blanket do-over regardless of the risk to the project the flexibility within a protocol to make a go or no-go decision may help keep your testing timeline on schedule and of course to market now this of course is provided that that interaction and that nonconformist did not have ADD first effect on the texting inputs or messaging results a testing laboratory of high quality standards will work with you to talk through the situation and help determine the risk assessment to your project don't jump in here yes or thank you one of the things that we really encourage our clients to do is to witness the testing and whenever possible and and this has a normally a very positive effect on answering the nuanced questions that that whatever thinks of and and it's not that we're not diligent or anyone else is intelligent there's always things that occur that see exactly what's going on you can ask questions so you can also talk about them to your instrument to the FDA to whatever questions I'm much more authoritative ly stuff whatever possible we encourage clients to view that the actual testing not that you have to you know sit outside the accelerated aging door for 28 days to know and that's not I'm talking about but the dynamic portion of it yes that there's lots to be learned in that process stuff but you can never really anticipate but it's a really good exercise and we highly encourage it Laura back to you okay thanks sir so we've just covered six tips to consider when writing your test protocol that should minimize downtime in the validation process and speed your products to market now as a medical device manufacturer speed to market is one of your highest priorities and as a testing laboratory integrity and data is our top priority now my spec always appreciates the ability to partner with our customers to ensure that those of these priorities are accomplished for a mutually beneficial partnership now speaking of the process of validating a package this is typically considered a critical process parameter for medical device companies and therefore the laboratory that you choose should be on your critical vendor list now there are several levels of certification that a testing laboratory may obtain and these escalating levels increase the labs adherence to testing practices quality procedures and calibration standards now as a medical device manufacturer it's your job to determine what level of quality control your project requires and to align those needs with the appropriate testing laboratory typical certifications that you can expect to find at a testing laboratory include what you see here I stay a lab certification demonstrates that the laboratory is properly equipped to conduct ist a package performance testing iso 9001 certification that I'm sure we are all mostly familiar with is focused on the quality management system of an organization it tends to focus on documentation auditing training non conformance 'iz and management's responsibility certification then 9001 is conducted typically through annual audits from a third-party certification body now iso 17025 accreditation process takes the 9001 certification as its foundation and then it adds technical competence of testing and calibration accreditation to 17025 looks not only at the quality management system including documentation control documents internal audits all those fun things but also the technical competence of the testing engineers and the calibration engineers calibration standards are held to a higher level than this traceability and uncertainty of measurement budgets must accompany all the calibration methodologies additionally accredited labs must comply with proficiency testing whereby blind studies are conducted similar to round robin studies and those labs are ranked amongst each other it is the highest certification that a testing or calibration lab can hold and therefore it holds the most esteem now there are a few other certification that a laboratory may hold that you may be interested in ISO 14001 is a standard dedicated to the reduction of waste and pollution and so 18001 as a standard out of britain and it focuses on occupational health and safety performance and finally ISO 1345 which I'm sure most of you are wonderfully familiar with is typically not applicable to third-party testing laboratories as it covers the manufacturing process of devices that we do not conduct now before we close we will discuss a few tips on how to partner with your Destin laboratory in order to make the best use of both of your time and energy and get the product to market as fast as possible now first and foremost the customer and the testing laboratory are partners in this process each to take time to understand each other processes fears expectations a quick phone call would serve to set these expectations for example at Westpac the process of receiving the product into our shipping and receiving area through our staging area and onto the production floor is pretty fluid and relatively quick process assuming those shippers arrive with the proper documentation however if the product arrives without any traceability valuable time and manpower is used trying to track down where the shippers came from and what they're there for and we're supposed to do with them this creates unnecessary delays and just adds time onto the end of the validation process knowing the process and the best practices of your lab will help speed your project through the pipeline now at the same time your laboratory of choice should be proactively discussing with you there urgency of your project any challenges that we may be able to assist with that's kind of what this slide also states if you have specific urgencies or challenges or blind spots with your validation process make sure you communicate communicate those to your laboratory and the lab may have a queue or a lead time and if you have a very specific urgent request na be able to work with those and get you in faster now speaking of these conversations and setting expectations it is a wildly important that all the critical information be related to your testing laboratory simple factors may be overlooked which may have an impact on the test these include if the products are over packed upon arrival if specifics ramp rates are needed or if specific intensity levels are needed just to name a few now more importantly the purpose of the testing should be clearly communicated to your test engineer so if they have all the information that they need to process the validation through and get that get that product out to market if visual inspections are to be conducted it is important to clearly set the expectation of what you are looking for and what is important what results you want documented one last tip here contact your testing laboratory early in the validation process to gauge their lead time these early conversations may also help to identify any blind spots or potential issues in the testing schedule now in line with this recommendation ensure that your internal protocol is approved and signed off with the ample time to deliver a copy to the testing laboratory in that vein if your protocol references other applicable company SOPs ensure that you've also delivered those to your testing laboratory her did you want to chime in before we conclude here surprisingly I don't have any comments on that of it I want you to think both Kevin and Nora for an excellent presentation for putting this all together and and in a flow and of in a fashion that really made a lot of sense so no comments here why don't you guys close it up and we'll see if there's any questions from our audience oh we've rendered her speechless the first to conclude our webinar today again here's a few of the things that we discussed Kevin went over empty requirements for package validation and a few of the ISO 11600 meant requirements he went through the different sections that you typically would find in a validation protocol briefly through those and then I discussed some common issues to avoid when developing your protocol remember we talked a lot about the flexibility and building flexibility into your protocol what to look for when choosing your third-party testing laboratory and then how to best work with your laboratory to speed your project through and get it out to market quickly so that's about it for a presentation today Greg do we have any questions from the audience we got a few here is the first one is ASTM D 7 386 more or less stringent in the Depot 169 which one is the more severe of the two or is there an apples-to-apples comparison or is it completely different you guys got a comment on that one so surely I always have comments good even though I don't have any comment that's a comment did the two are very different standards they were set up for primarily the same reason but by different different groups within ASTM it would be very difficult to hang a more or less severe a handle on either one of them because they both have some flexibility in terms of their what we refer to as assurance levels 41 69 first introduced the concept of assurance levels as a way of saying you know if we take the distribution environment and use amplitude levels that are max they're 3 Sigma 99.4% of those measured in the environment for all of them we over test so they allowed for some levels of reducing either amplitude levels or durations or both in order to make the test more suitable for the application and to a lesser extent 47:43 86 does the same thing so it's it's a difficult question I don't think there's there's any way to to really say yes or no remember that both of these standards are what we refer to as qualitative test and Westpac has kind of used the terminology of calling them a package integrity test as a because they are qualitative there are no numbers generated during the test as opposed to a qualitative test wherein you actually generate numbers you put transducers in the products and and you measure responses so these are our qualitative tests and therefore the results are going to be different and there there's going to be no numerical method of saying this one's more severe or response than that one because we're again we're judging the results qualitatively did it pass or not so the answer to the question is I don't know and I don't know anyone who does know so it's there there really isn't a good answer for that one in my opinion Greg thank you thanks herb looking at stmd porn 69 can it be applied for electronic devices so if you have an electronic medical device or a computer or something can you apply that to validate can you apply deform section to validate your package for that yeah I don't see why not it's really a general standard for package performance testing the way the standard was written which was based on empirical data it was from sending out test samples and meant measuring what is actually happening in the distribution environment so it should be representative of them any product really so I would say yes it's applicable to electronics as well as medical devices herb did you want to say anything else you know that exactly right Kevin need to think of it this way these these test protocols are designed to simulate what happens on the truck or you know railcar aircraft whatever you think of truck knows or cares whether it's carrying electronic product or a bunch of vials of injectable solutions obviously not no no okay so the environment is the environment so whatever you have to travel through the environment electronics liquids medical devices you name it all gets tested the same way simply because the environment is the same and a truck doesn't care I'm sorry oh yeah sorry to break the news to you folks but a truck doesn't really doesn't care okay so the same procedures do apply Greg Beck you cool another question could you guys talk about the different assurance levels under deep 169 what is what can you talk about is they higher lower why would you choose one over another that's an excellent question so there's three assurance level associated with ASTM D for mine one six nine and they're aptly named assurance level one two and three assurance of a one is the most conservative and most difficult assurance of what that there is the drop heights are going to be higher the compression load is going to be heavier and the vibration input will be more intense assurance level two and three descend a little bit in their intensity assurance level three has much lower drops on half of the compression rate or after the compression load of assurance level one and a much less severe vibration input now that being said it's our recommendation to kind of stay away from assurance level three unless you really need to or unless you can justify that that is what your distribution environment is like now we do see a lot of medical device customers call out assurance level one with the exception of compression and do the compression load specifically at assurance level three because like her mentioned compression tends to be one of the difficult situations or the difficult sticking points for the validation process so that being said we do recommend that our medical device customers stick with an assurance level one or two if possible would you like to come in on that that's exactly right Nora and it's good to to reinforce what she said by by looking at the the reason for why in the world of these things develop in the first place and as we mentioned earlier a little bit earlier they are an attempt to better tune the process to the laboratory in the process strictly is bringing in the distribution environment the hazards of that distribution environment into the laboratory subjecting your product package system to those hazards and then qualitatively analyzing the result that's the process and and what we try to do is tune that as best we can in order to tune that or to bring that that environment in the lab but are you going to measure it and when you measure it you get the you know distribution curve for impacts or vibration for temperature for humidity for Kitab low compression for LP through all those things so if you want to subject it to the three sigma of each of those which you can do from any particular measurement you're going to wind up with what amounts to an over test because that never happens in the real environment so in order to kind of tune that back the people who wrote the standards came up with this this idea of different assurance levels and the the stator is kind of kind of in my opinion kind of weasel worded and says well if you want more assurance levels you do you know you want more confidence in the data things like that and what they're really doing is is what they're saying is that is that the distribution environment yes it's the same environment but what we're trying to do is to make sure that we don't over test by using the ninety-nine point four or three signal level of each of these hazards on all the packages all the time because it'll never happen okay so with the assurance levels I think are a very good way to kind of tailor that thing that did that thing the the inputs back to a more reasonable more realistic level so they're they're very well thought up and and they are exactly what Nora said their reduction as you go assurance the one two and three that reduce the amplitude or the time or the intensity or all three okay back to you Greg cool thanks her another question what type of products or materials can use for accelerated aging per ASTM in nineteen eighty as it applies to or what materials can use it for accelerated aging Prieta 1980s or something that you shouldn't age you know steel plastics those type of things what type of materials can you use for that is there anything specified in that standard did you guys know of curb let me try to tackle that it's an interesting question good the the the processes winds up being fairly limited to what our aeneas call or those people who talk about his equation called the molecular activity those are the that's the exact term that's used and and strongly geared toward I'm not sure they've actually stasis but it's trumps around the geared toward organic molecules well steel is an organic molecule so there are the the or the Arrhenius concept works in a relatively narrow range I remember trying to accelerate the the process of some stored food some time and it was a miserable failure so you have to be pretty careful about the application of it and in fact the FDA is also pretty careful about it because these standards that they use I saw eleven 607 I believe strongly recommended that you use accelerated aging in concert with real-time aging what does that mean that means that that you have to keep checking then make sure that your six month on 12 month 18 month whatever that happens to be accelerated and real-time aging results are virtually the same very very similar so good question unfortunately there's not a real good answer for it but what we do know is that the bodies that we have to to convince of our data namely FDA does accept the Irenaeus concept of accelerated aging for medical devices that once we know okay Greg back to you cool thanks syrup for is ta seven D testing they have the question is would you use those profiles for your conditioning for ASTM testing or is ta 2a 3a type testing for your validation protocols her resounding no the the the the 7b which is a brand new standard by the way dee-dawg is specifically for let's haul coal chain stuff and and and they are specific in terms of the their application as opposed to a much broader scope of shipping environment temperatures and humidity that standards such as a defense Ickx 9 and 70 386 talked about and in both cases they do reference an ASTM standard 4 3 3 2 that gives you general guidelines for testing at what are considered to be moderate and extreme temperature and humidity conditions so I would definitely recommend 4 3 3 2 which is referenced in Vaughn 69 and I believe in in 73 6 as well for your temperature and humidity conditioning I would not rely on the is ta 7 D data or process a great look back to you thanks for our last question here we're running short of time if we didn't get your question we'll get to it we'll get back to you after the webinar but regarding assurance levels have you heard of anything from the FT a peed back pushing back regarding the assurance levels used in tests has anybody heard anything fda wise on that i haven't heard anything about the fda pushing back but we did get that comment in the previous webinar that that they are I think if the STM is reevaluating the use of assurance levels so it does seem like there are some kicking out of the covers going on there with respect to those so I think time will tell and where those go to and Westpac does keep its ear to the ground we have a couple members on the different ASTM and ice-t a committee so you know aware of these things as they come out but that's a great question like all the questions were great today I mean I'm happy an impressed cool Nora Kevin herb thanks for the presentation today okay if anybody else has any other questions you can submit them to projects at Westpac comm if you missed anything or would like to listen the webinar again you can find it our website at Westpac comm under the events tab the webinars should be uploaded by next Wednesday all people who were registered for this webinar will receive an email within five days with a copy of the recording and a link to download the slides check our website for upcoming events for our under upcoming events for our next webinar if there are any other webinars you'd like to see us offer or have any other suggestions please email them to projects at Westpac comm we will be sending out a short survey following the webinar please fill it out as we are always looking to improve the process thank you all for attending i'm gregg showing hammer make it a great day

Show moreFrequently asked questions

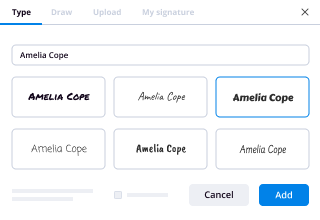

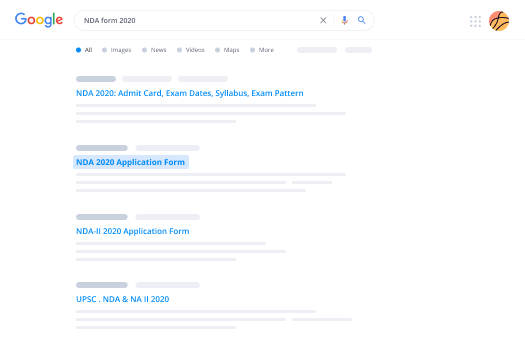

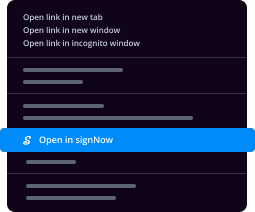

How do I add an electronic signature to a PDF in Google Chrome?

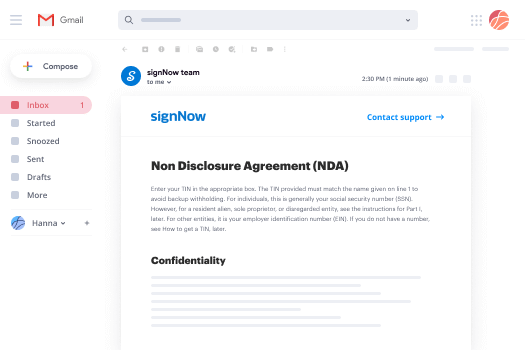

How can you have your customers eSign PDFs online?

How can I sign emailed documents?

Get more for urge validated field with airSlate SignNow

- Print electronically sign Sales Receipt

- Prove electronically signed Trip Itinerary

- Endorse digisign Moving Services Contract Template

- Authorize electronically sign Declaration of Trust Template

- Anneal mark Professional Model Release Contract

- Justify esign Christmas Gift Certificate

- Try countersign Snow Removal Contract

- Add Joint Venture Agreement eSign

- Send Wedding Photography Contract Template eSignature

- Fax Community Service Letter of Recommendation autograph

- Seal Management Report electronic signature

- Password 1040EZ Form signed electronically

- Pass Leave of Absence Agreement electronically sign

- Renew Land Contract Form electronically signing

- Test Rental Deposit Receipt mark

- Require Distribution Agreement Template signed

- Print receiver sign

- Champion visitor countersign

- Call for trustee signature service

- Void Manufacturing and Supply Agreement template esigning

- Adopt Assumption Agreement template digisign

- Vouch Fundraiser Ticket template electronic signature

- Establish Travel Gift Certificate template countersign

- Clear Grant Proposal Template template sign

- Complete Video Production Order template electronically signing

- Force Delivery Order Template template initials

- Permit Basic Employment Resume template eSign

- Customize Power of Attorney template eSignature